Stickup device of support plate

A technology for sticking device and supporting plate, which is applied in the direction of laminating device, electrical components, presses, etc., to achieve the effect of improving the bonding accuracy and suppressing the generation of voids and gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

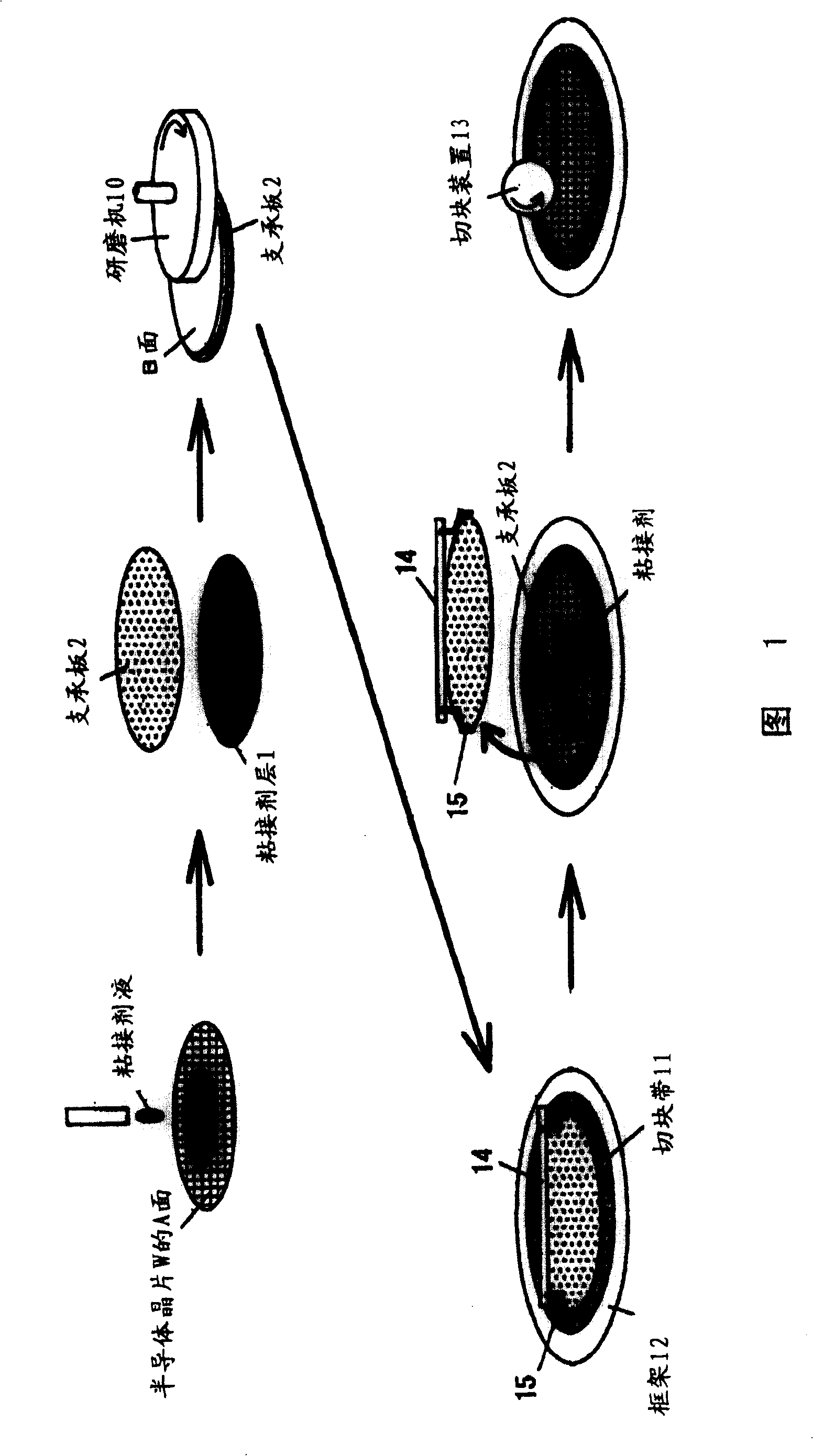

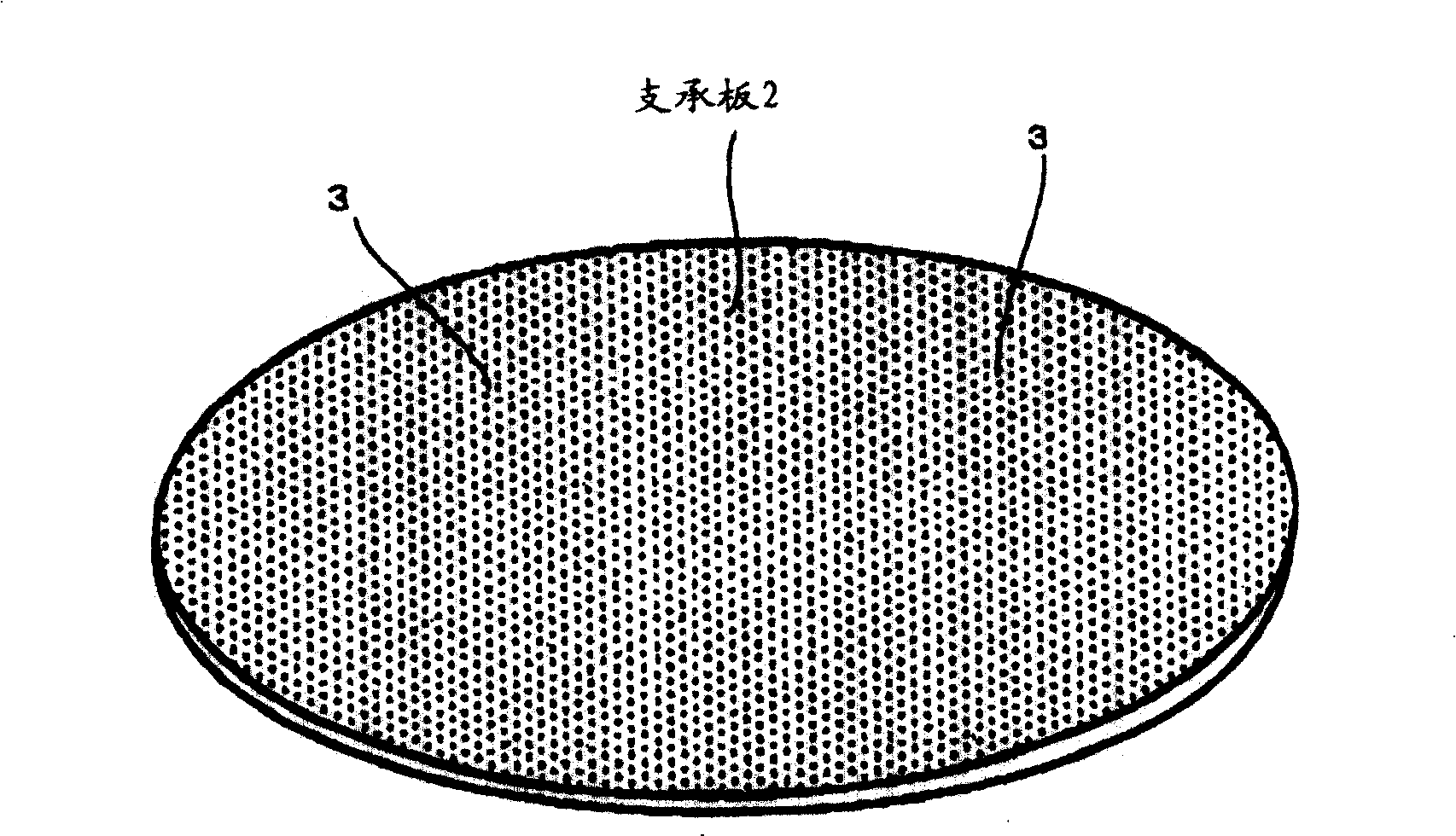

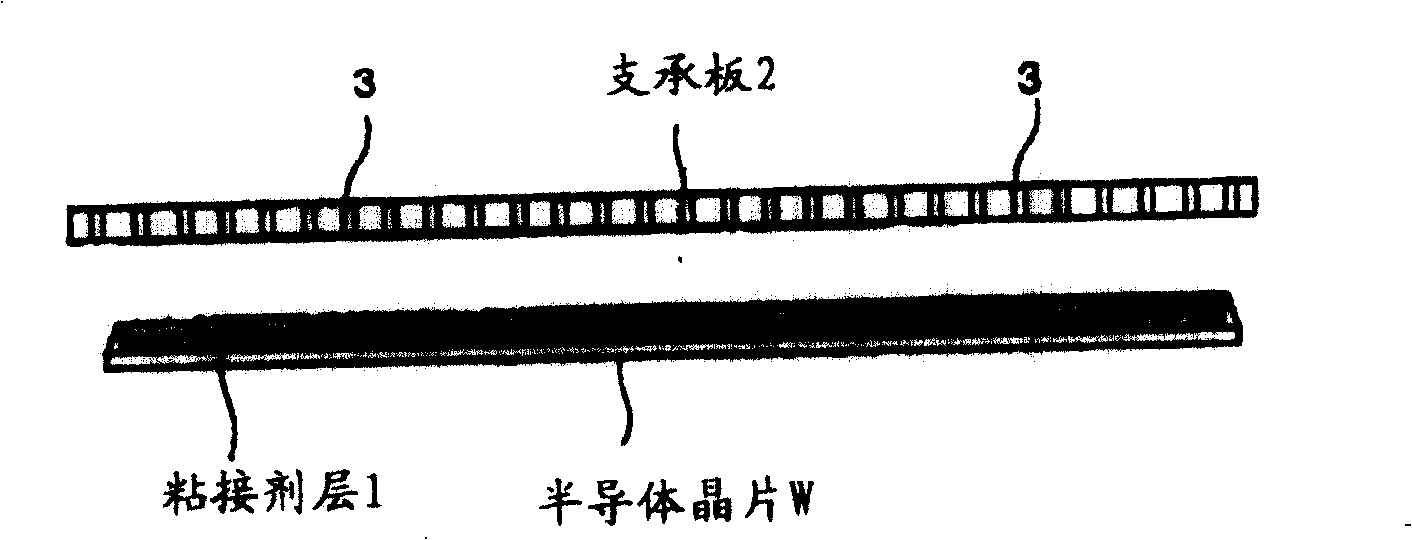

[0019] Embodiments of the present invention will be described below based on the drawings. FIG. 1 is a diagram illustrating a thinning process of a semiconductor wafer using a bonding apparatus of the present invention, figure 2 is a perspective view of the support plate, image 3 It is a side view showing the relationship between the substrate, the adhesive, and the support plate, and first, the overall thinning process will be described.

[0020] First, an adhesive liquid is applied to the circuit (element) formation surface (A surface) of the semiconductor wafer W. For coating, for example a spinner is used. Examples of the adhesive liquid include novolak-type phenolic resin-based materials, but are not limited thereto. In addition, the thickness of the adhesive is about several μm to 100 μm.

[0021] Next, if image 3 As shown, the above-mentioned adhesive is baked to cure it, and the adhesive layer 1 whose fluidity is eliminated is formed on the front surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com