A chip feeding mechanism and chip bonder

A chip and feeding technology, applied in the direction of conveyor objects, electrical components, transportation and packaging, etc., can solve the problems of affecting the speed of bonding chips, welding arm weight, and low speed, so as to improve the bonding speed and bonding accuracy, Improved consistency and product quality, low system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

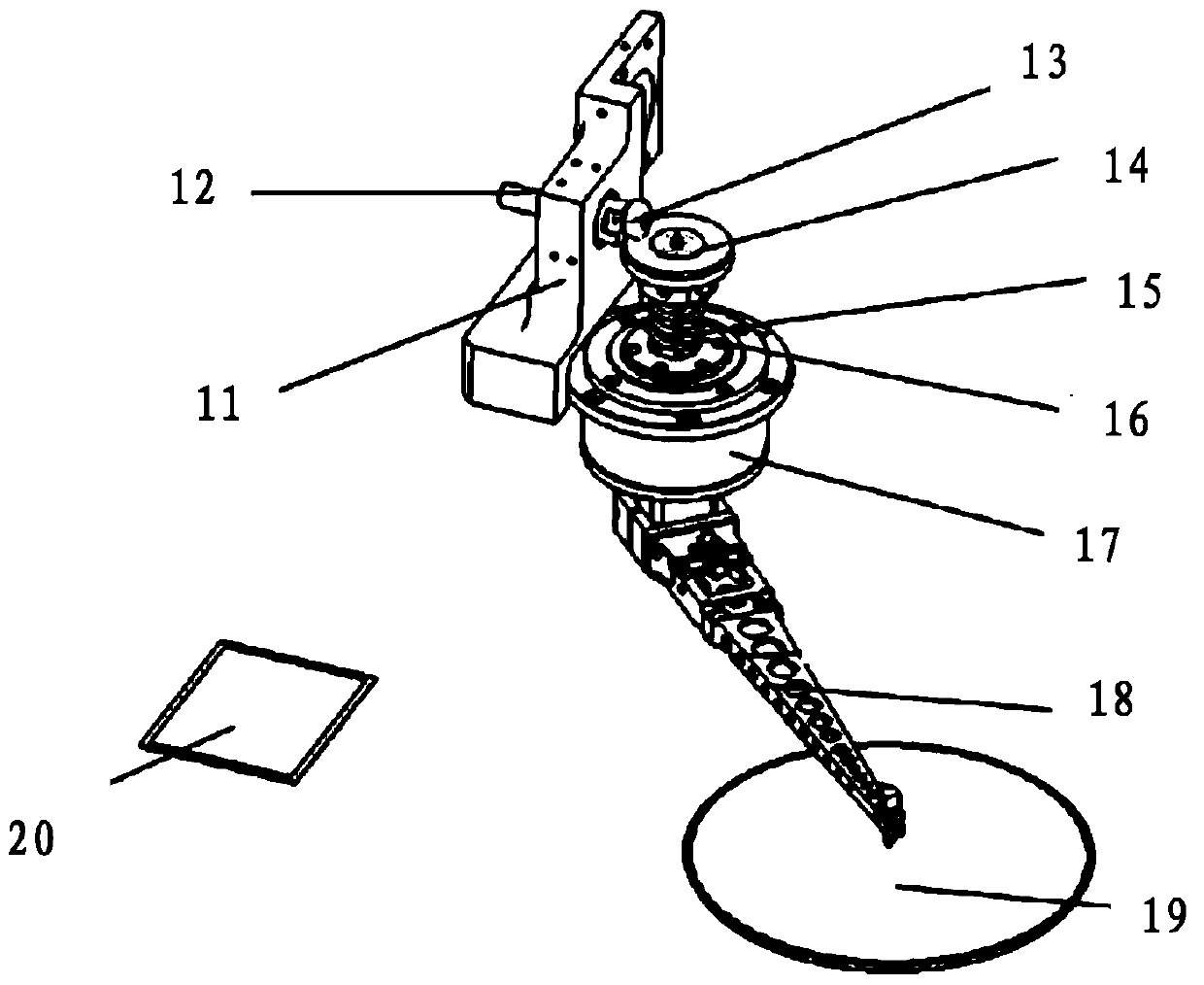

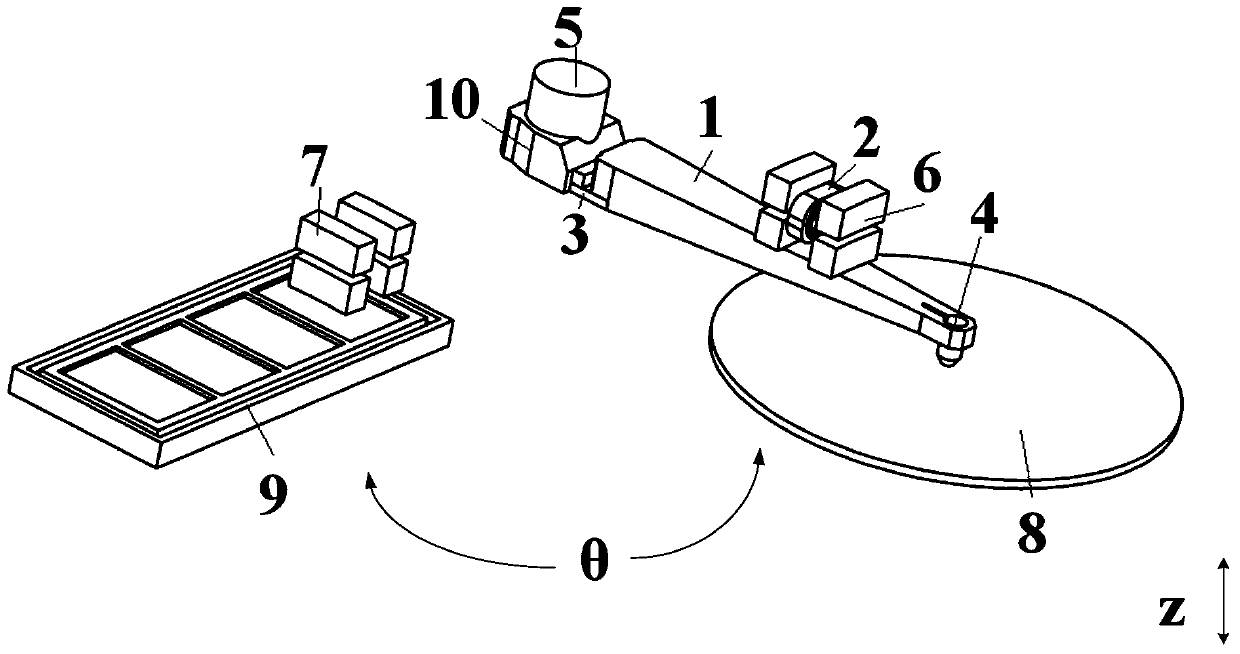

[0043] In view of the defects of the traditional chip feeding mechanism, such as image 3 As shown, the embodiment of the present invention provides a chip feeding mechanism, which includes:

[0044] Rotating device capable of rotating around the axis;

[0045] a welding arm unit distributed on the rotating device around the axis of the rotating device;

[0046] The first driving device is used to drive the welding arm unit rotating to the picking area to pick up chips from the picking area, and to drive the welding arm unit rotating to the placing area to place chips into the placing area.

[0047] Among them, the rotating device, such as image 3 or Figure 4 or Figure 5 As shown, it includes a bearing 5 that rotates around the axis and a sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com