Corrugated paper production mechanism, four-layer corrugated board production line and production process thereof

A corrugated board and production process technology, applied in the direction of mechanical processing/deformation, can solve the problems of lack of strength requirements, high cost, large paper consumption, etc., to avoid unstable transmission, improve stability, and adhesion stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

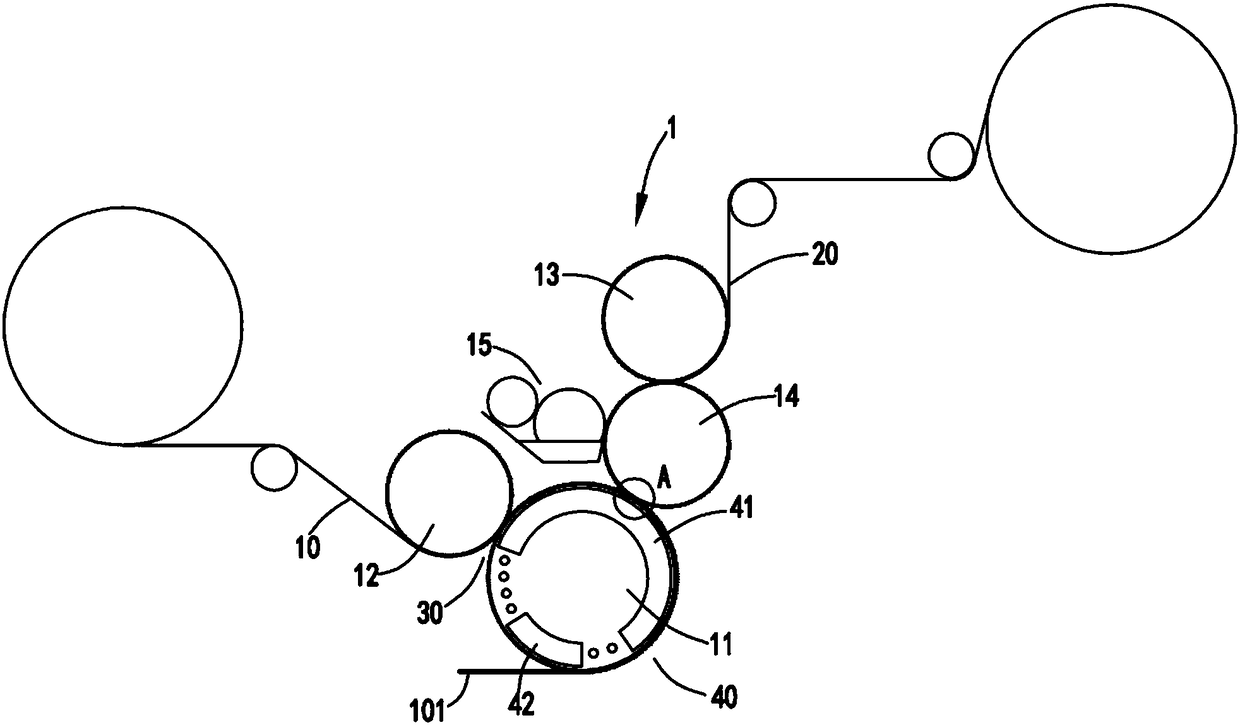

[0051] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

[0052] like image 3 , Figure 4 , Figure 5 As shown, a corrugated paper production mechanism includes a corrugated paper forming part 1, and the corrugated paper forming part 1 includes a first corrugated roll 11 and a second corrugated roll 12 for cooperating to form a first corrugated paper 10, and is used for cooperating to form a second corrugated paper The third corrugating roller 13 and the fourth corrugating roller 14 of 20 and the first gluing mechanism 15 for gluing the second corrugated paper 20; it is characterized in that: the first corrugating roller 11 is arranged on the fourth corrugating roller 14 Between the second corrugating roll 12, the first corrugating roll 11 and the fourth corrugating roll 14 cooperate to form a bonding channel 100, which is used ...

Embodiment 2

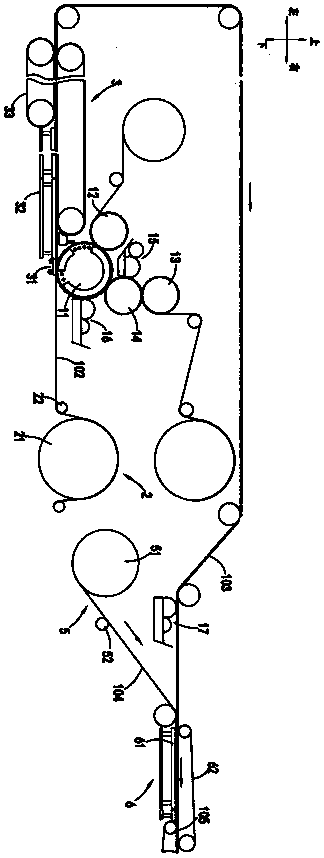

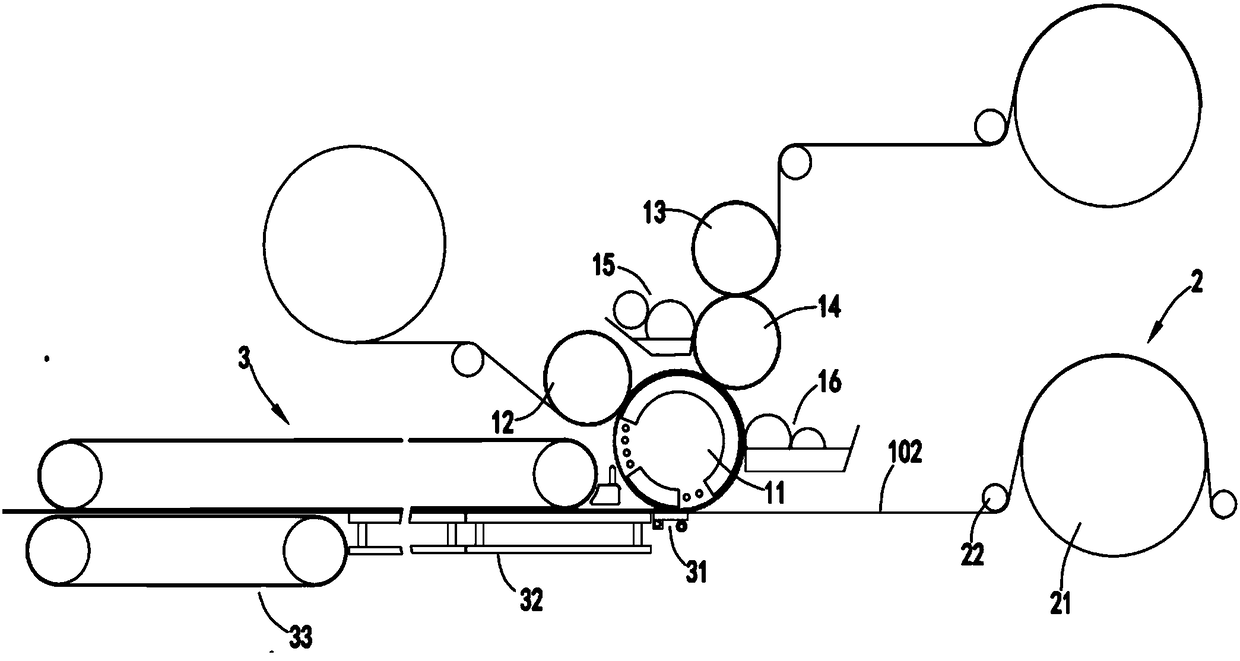

[0061] Refer to the accompanying drawings in the manual figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 A four-layer corrugated cardboard production line according to the second embodiment of the present invention is described.

[0062] like figure 1 , figure 2 , image 3 As shown, a four-layer corrugated cardboard production line also includes a second gluing mechanism 16 arranged behind the bonding channel 100, and the second gluing mechanism 16 is used for gluing the surface of the double-layer corrugated cardboard 101 .

[0063] Further, the bottom paper unwinding part 2 is also included, and the bottom paper unwinding part 2 includes a bottom paper unwinding roller 21 for unwinding the bottom paper 102 and a bottom paper guide roller 22 for guiding the bottom paper 102 .

[0064] In addition, it also includes a bottom paper bonding part 3, the bottom paper bonding part 3 includes a paper feeding assembly 31 for intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com