Preparation method of fiber surface layer immobilized multistage phase transfer catalyst

A phase-transfer catalyst and fiber technology, which is applied in the preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of not easy to break, long links, and easy control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

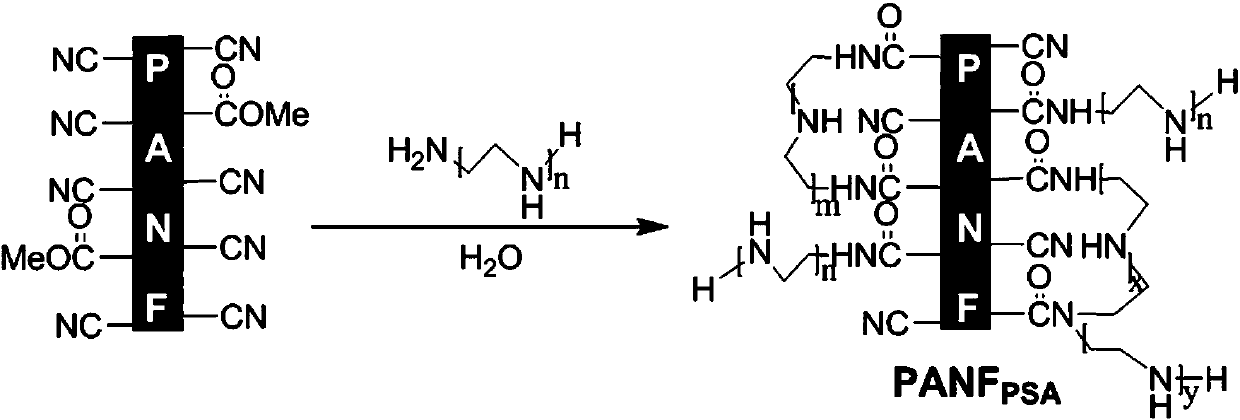

[0040] (1) Accurately weigh 30.0 g of polyethylene polyamine in a three-necked flask, add equal mass of deionized water to stir and dilute evenly, heat to 105 °C under magnetic stirring, then weigh 3.0 g of dry acrylic fibrils, add In the above solution, the reaction was carried out at 105 °C for 24 h under reflux. Then take out the fiber, wash it with 60 ℃ deionized water until the pH value of the washing liquid is 7, dry it in the air, and then put it in a 60 ℃ electric heating constant temperature blast drying oven to vacuum dry to constant weight. chemical fiber PANF PSA . The reaction process is as figure 1 shown.

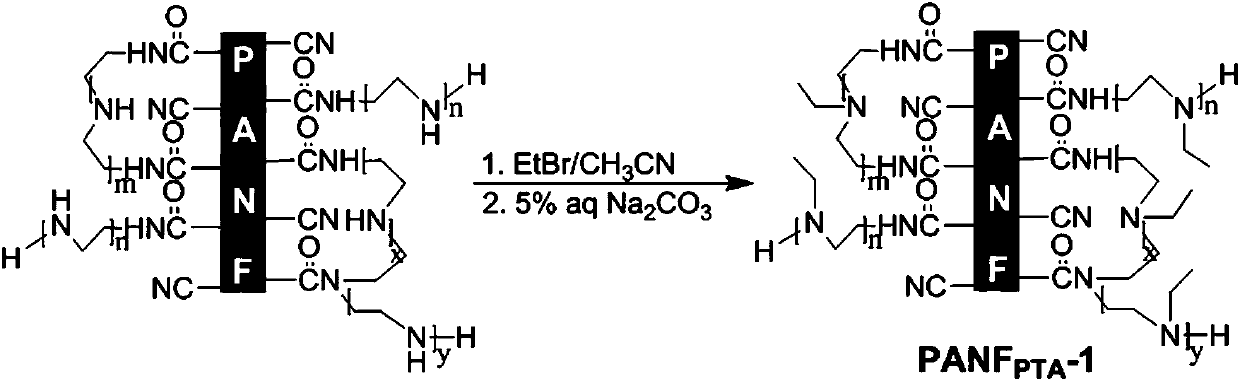

[0041] (2) Accurately weigh 10.0 g of ethyl bromide in a three-necked flask, add 100 mL of acetonitrile as a solvent, heat to reflux under stirring, and then put the dry PANF PSA Added to the above reaction solution, and kept under reflux for 8 h under magnetic stirring. Then cool to room temperature and take out the fiber, put it in 5% sodium carbonate ...

Embodiment 2

[0044] (1) The multi-level secondary amine surface functionalized fiber was prepared by the method in Example 1.

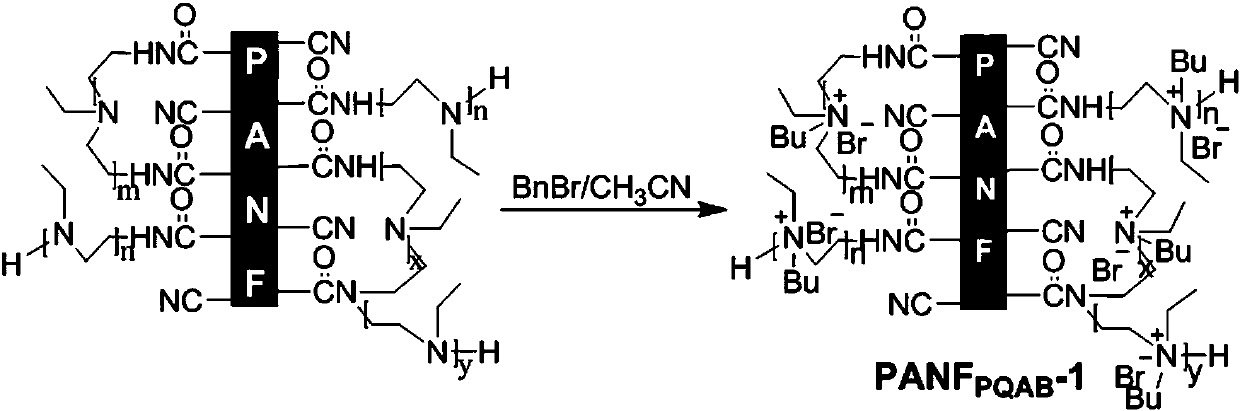

[0045] (2) Replace bromoethane with n-bromobutane of equal quality, press the method for embodiment 1, prepare the second kind of multilevel tertiary amine surface functionalized fiber PANF PTA -2. The reaction process is as Figure 4 shown.

[0046] (3) Replace benzyl bromide with n-bromobutane of equal mass, use PANF PTA -2 alternative to PANF PTA -1, by the method for embodiment 1, prepare the second kind of fiber surface immobilized multi-level quaternary ammonium salt PANF PQAB -2. The reaction process is as Figure 5 shown.

Embodiment 3

[0048] (1) The multi-level secondary amine surface functionalized fiber was prepared by the method in Example 1.

[0049] (2) By the method of Example 2, prepare the second multi-level tertiary amine surface functionalized fiber PANF PTA -2.

[0050] (3) Use PANF PTA -2 alternative to PANF PTA -1, according to the method of embodiment 1, prepare the third kind of fiber surface immobilized multi-stage quaternary ammonium salt PANF PQAB -3. The reaction process is as Image 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com