Bonding device and process for core disc air gap cushion block of shunt reactor

A kind of iron core cake and reactor technology, which is used in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problem of affecting the performance of shunt reactors, the overall height and verticality of the iron core column cannot meet the process requirements, and the bonding tolerance exceeds and other problems, to achieve the effect of satisfactory overall height and verticality, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

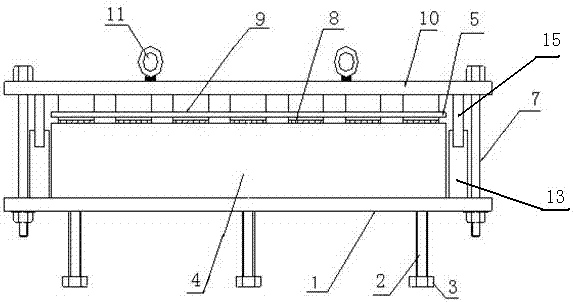

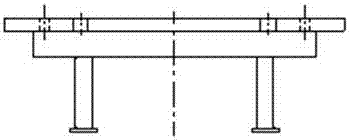

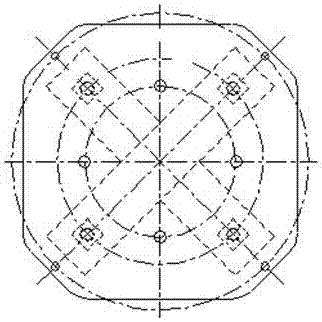

[0024] Refer to attached Figure 1-5 , a shunt reactor iron core cake air gap pad bonding device, including support platform 1, leg 2, adjustment nut 3, core cake 4, air gap pad bonding template 5, fastening bolt 7, air gap pad block 9 and pressure plate 10, a plurality of legs 2 are arranged under the supporting platform 1, adjusting nuts 3 are arranged at the bottom of the supporting legs 2, and iron core cakes 4 are arranged on the supporting platform 1; It has a circular structure, and the central part of the air gap pad bonding template 5 is provided with a positioning tube 6, and a plurality of holes 12 are arranged around the circumferential direction of the positioning tube 6 on the air gap pad bonding template 5; The bonding template 5 is pressed on the core cake 4, and the positioning tube 6 is matched with the phenolic paper tube at the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com