A device for producing paper cones for smart speakers

A technology of smart speakers and paper cones, applied in the direction of sensors, electrical components, etc., can solve the problems affecting processing efficiency, overflowing glue scene, affecting the amplitude efficiency of paper cones, etc., and achieve the effect of improving heat dissipation requirements and improving bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

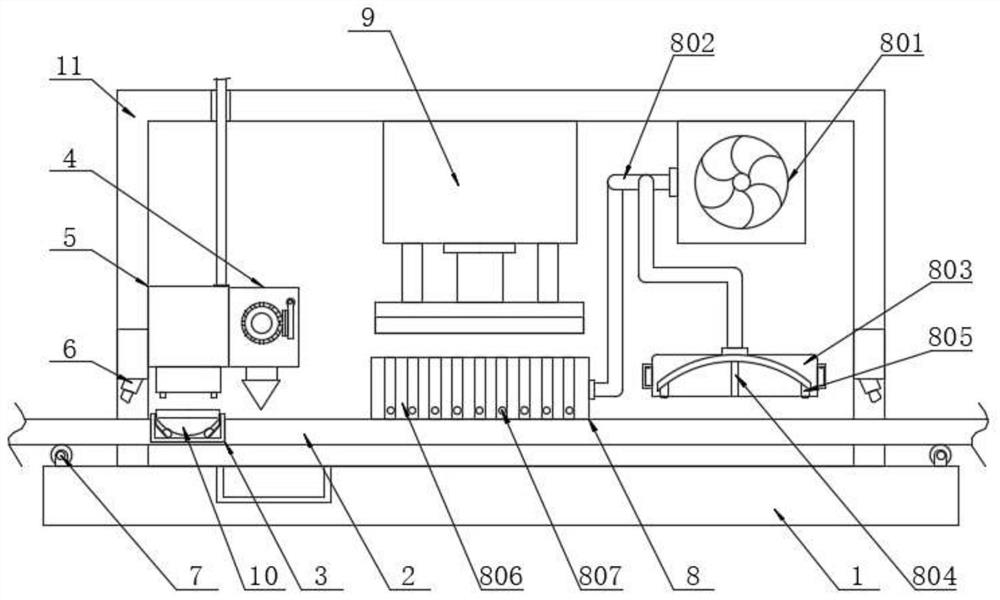

[0031] A device for producing paper cones for smart speakers, such as Figure 1-7 As shown, it includes: a base 1, and the top of the base 1 is fixedly connected with a box cover 11, and a conveyor belt 2 is slidably connected to the inside of the base 1, and the conveyor belt 2 extends outward through both sides of the box cover 11, and the box cover 11 The top of the inner cavity is provided with a pressing mechanism body;

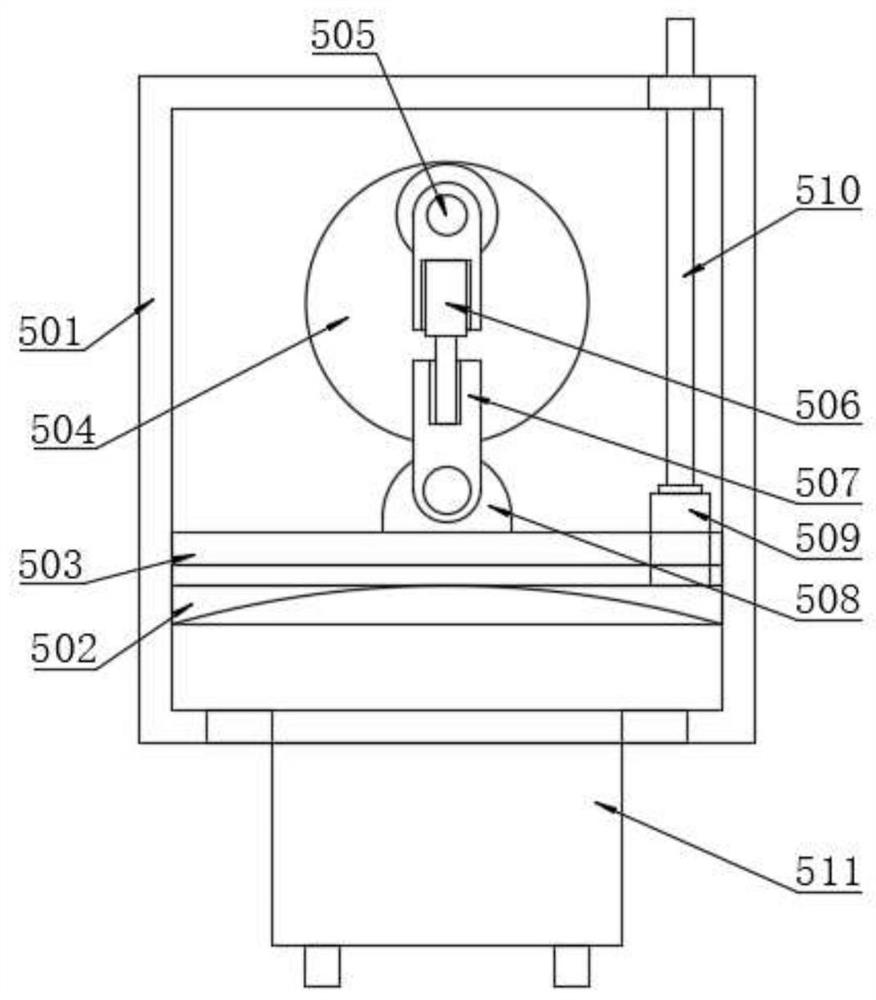

[0032] One side of the inner cavity of the case cover 11 is provided with a glue injection mechanism 5, and one side of the glue injection mechanism 5 is provided with a scraper mechanism 4, and the other side of the inner cavity of the case cover 11 is provided with a heat dissipation mechanism 8, and the case cover 11 One side is provided with a material inlet corresponding to the side of the cooling mechanism 8;

[0033] Wherein, the top of the conveyor belt 2 is embedded with a plurality of limit mechanisms 3, and the paper cone body 10 is placed in...

Embodiment 2

[0036] A kind of equipment that is used to produce intelligent sound box paper cone, differs from Embodiment 1 in that, such as figure 1 with 4 As shown in -5, the heat dissipation mechanism 8 includes a heat dissipation fan 801, and one side of the heat dissipation fan 801 is connected with an air outlet pipe 802, and the outlets on both sides of the air outlet pipe 802 are connected with a blowing seat 806 and a heat dissipation seat 803, and the blowing seat 806 is fixedly connected to the bottom of the pressing machine body 9, the heat dissipation seat 803 is fixedly connected to the bottom of the heat dissipation fan 801, and the heat dissipation seat 803 is located on the side of the blower seat 806, the cross-sectional shape of the blower seat 806 is arc-shaped, and the blower A plurality of second nozzles 807 are embedded in the inner cavity of the seat 806. The cross-sectional shape of the inner cavity of the heat dissipation seat 803 is arc-shaped, and the inner cavi...

Embodiment 3

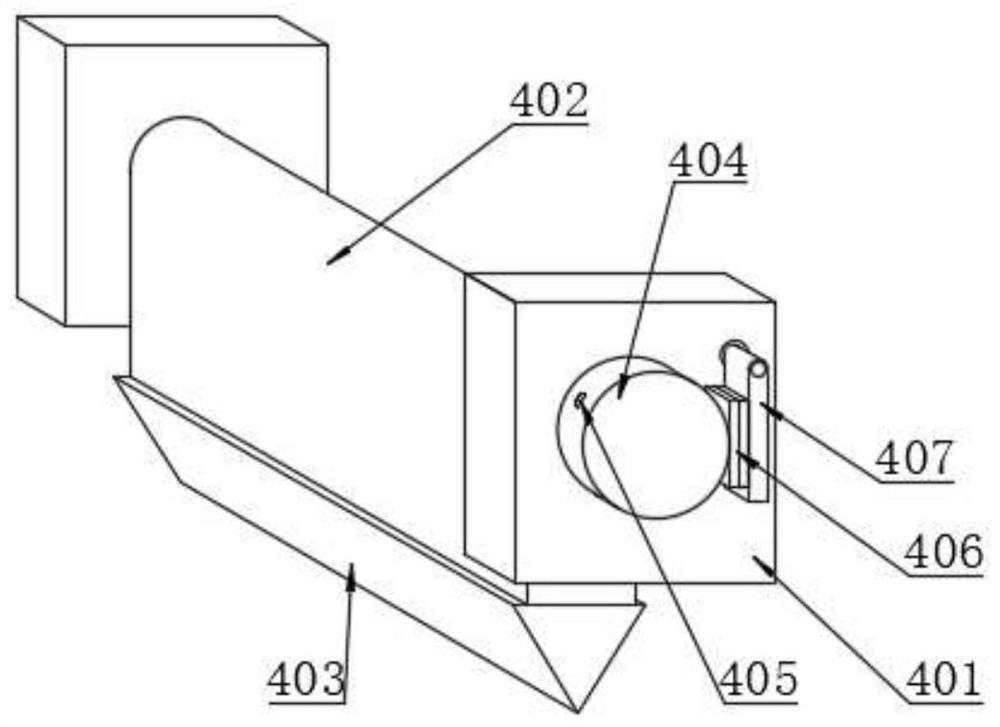

[0039] A kind of equipment that is used to produce intelligent sound box paper cone, differs from Embodiment 1 in that, such as figure 1 with 3 As shown, the limiting mechanism 3 includes a limiting seat 301, which is embedded on the top of the conveyor belt 2, and elastic plates 302 are fixedly connected to both sides of the inner cavity of the limiting seat 301, and the elastic plates One side of 302 is fixedly connected with a fitting pad 303, and both sides of the elastic plate 302 and the two sides of the fitting pad 303 are extruded and bonded to one side of the paper cone body 10, the elastic plate 302 is an elastic plastic plate, and the scraping material The mechanism 4 includes two fixing plates 401, and the fixing plates 401 on both sides are fixedly connected to one side of the glue injection mechanism 5, bearings are embedded between the fixing plates 401, and a rotating shaft is sleeved in the bearings, and the outer wall of the rotating shaft is clamped. A defl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com