Heating bonding clamp

A bonding and fixture technology, which is applied in the direction of connecting components, manufacturing tools, workpiece clamping devices, etc., can solve the problems of increased processing costs, low bonding efficiency, and inaccurate bonding positions, and solves the problem of uneven bonding gaps , high bonding efficiency and precision, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

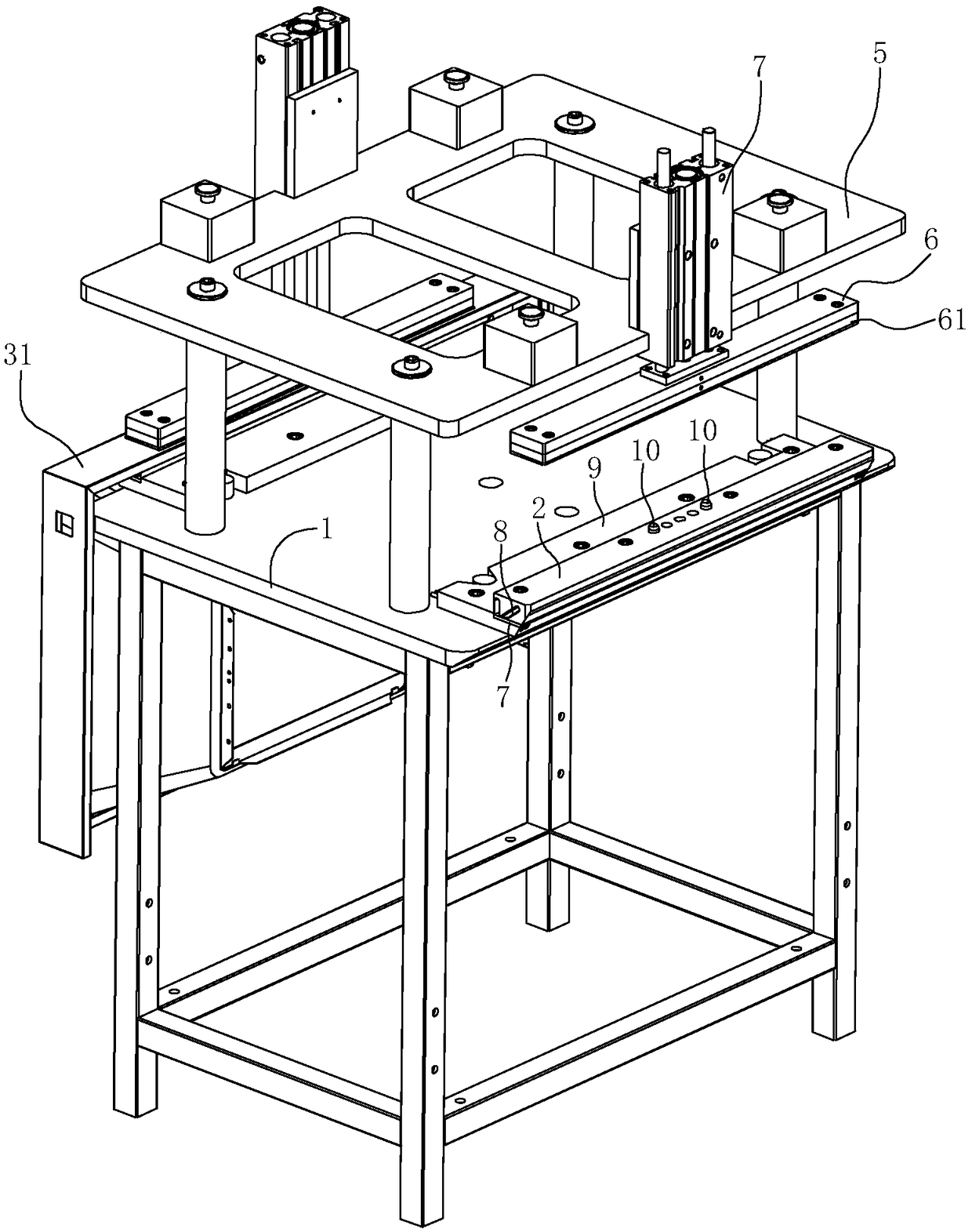

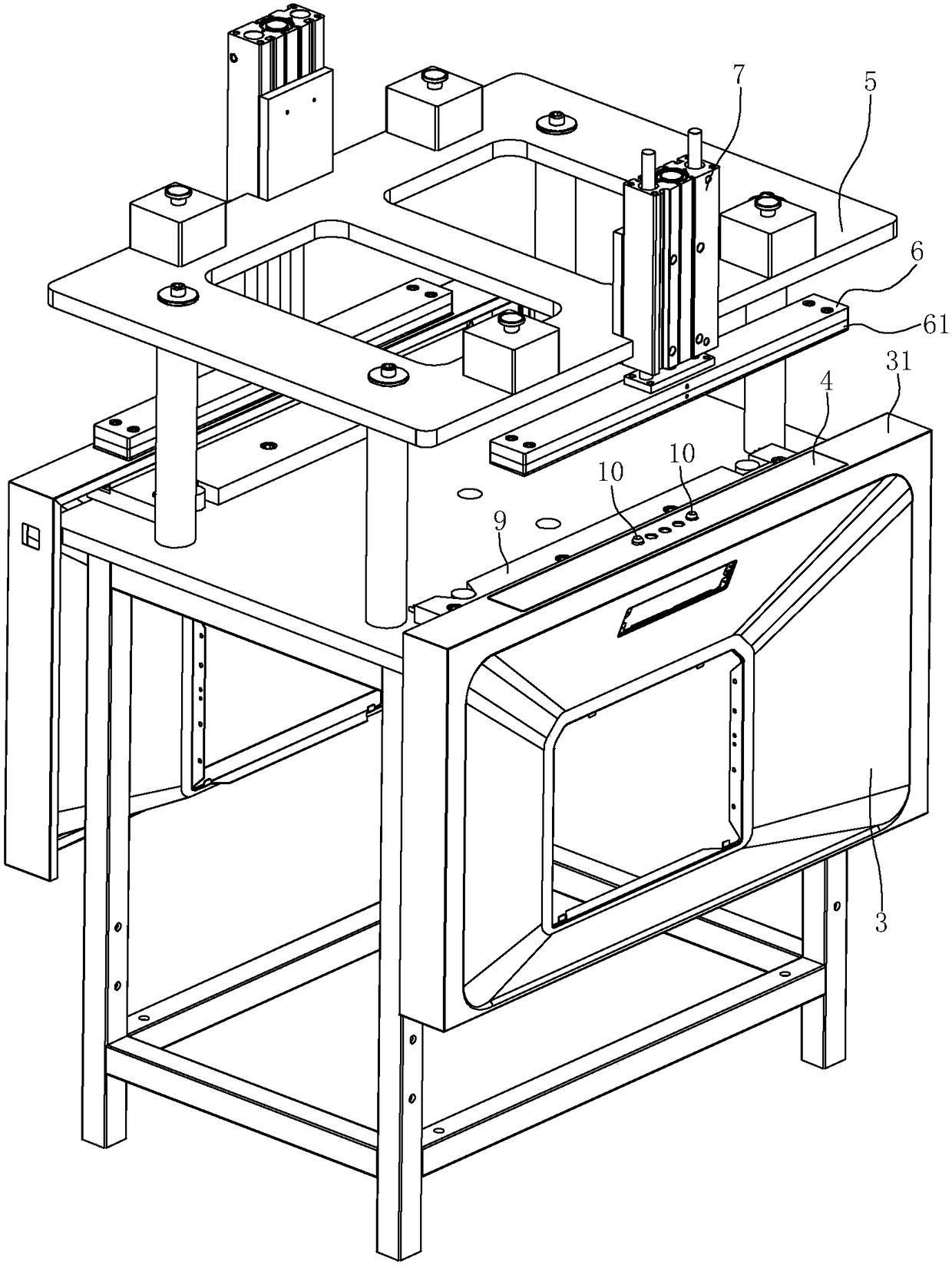

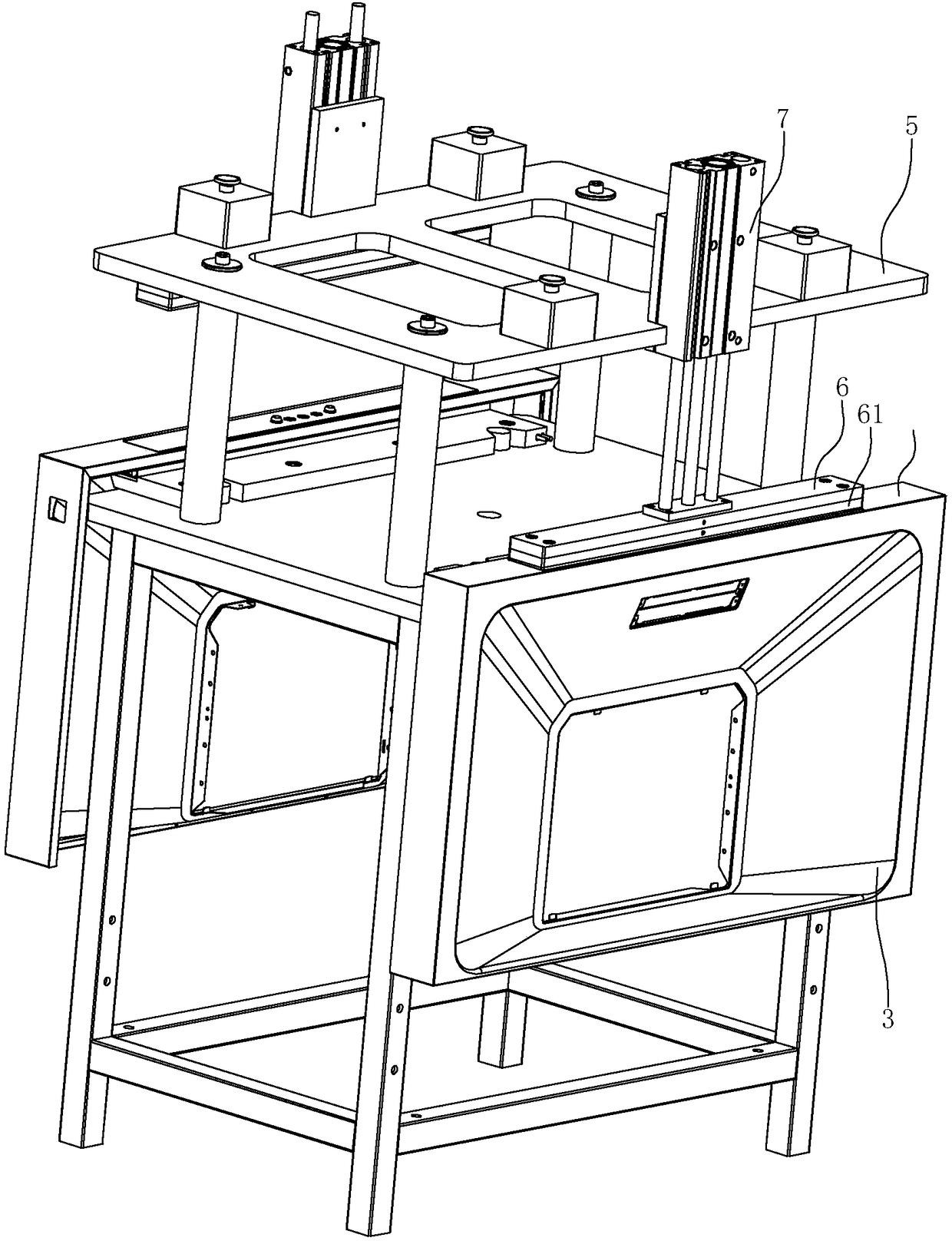

[0026] Such as Figure 1-7 Shown is a preferred embodiment of the present invention.

[0027] A heating and bonding fixture for bonding a surface sticker to a fume collecting hood, including a table top 1, at least one side of the table top 1 is provided with an adhesive structure; in this embodiment, there are two sets of adhesive structures, which are respectively arranged on The front and rear sides of the table top 1. Wherein, the surface sticker 4 can also be a panel made of acrylic material, such as Figure 7 As shown, the smoke collecting hood 3 has a top surface 32 with an opening in the middle, and the front edge, left edge and right edge of the top surface 32 respectively have a front end surface 31, a left end surface 33 and a right end surface 34 extending upwards, the front end surface 31, the left end surface The position wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com