Bonding tooling for upper glass components that can be adjusted in size in any direction

A technology for adjusting size and arbitrary direction, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of low bonding efficiency, uneven bonding gap, easy misalignment, etc., and achieve high bonding efficiency and precision, bonding Fewer steps required and high bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

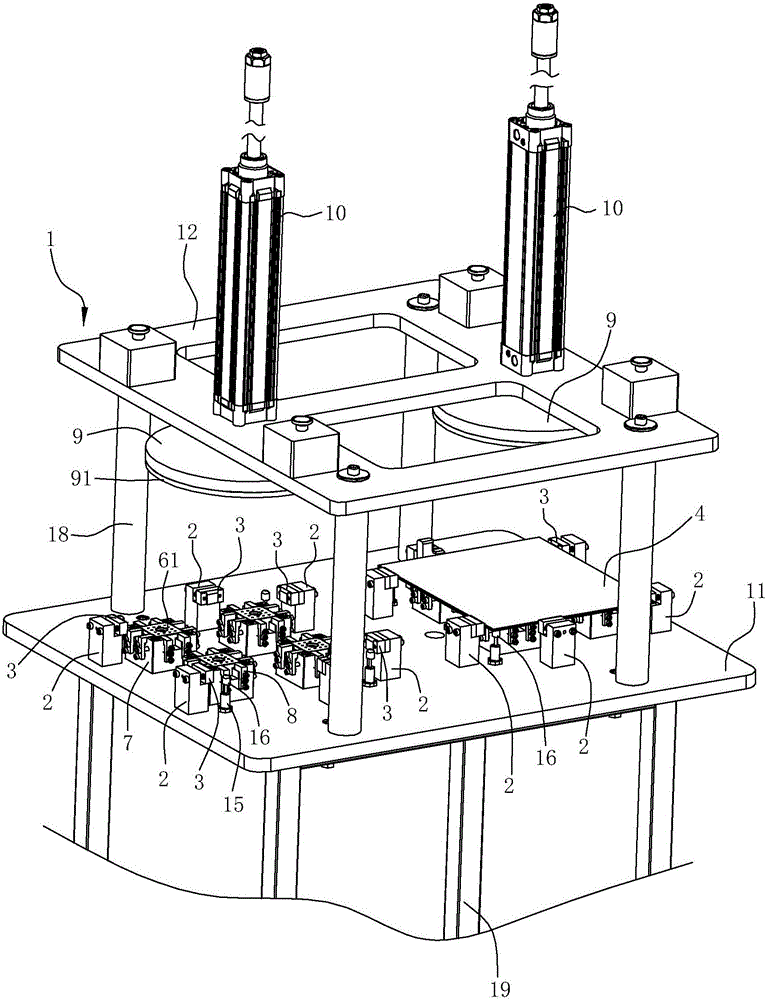

[0031] Such as Figure 1-13 Shown is a preferred embodiment of the present invention.

[0032] An upper glass component bonding tool that can be adjusted in size in any direction, such as Figure 13 As shown, the upper glass assembly of this embodiment includes a rectangular glass panel 4 and four buckle brackets 6 glued on the glass panel, each buckle bracket 6 has an adhesive surface 61 and a buckle 62 .

[0033] Specific bonding tooling includes

[0034] Such as figure 1 As shown, the frame body 1 has a table top 11 and an upper mounting plate 12 arranged at intervals up and down. The upper mounting plate 12 is located above the table top 11, and is supported by a column 18 between the table top 11 and the upper mounting plate 12. Below the table top 11 is provided 4 supporting feet 19 .

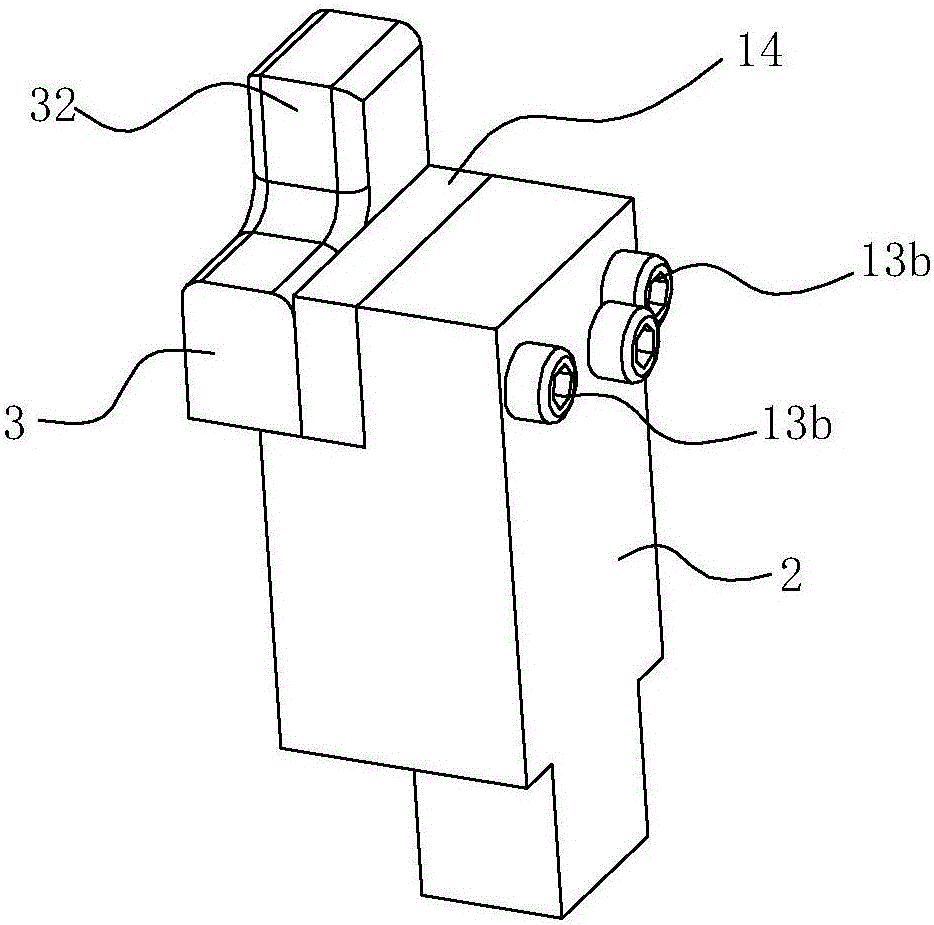

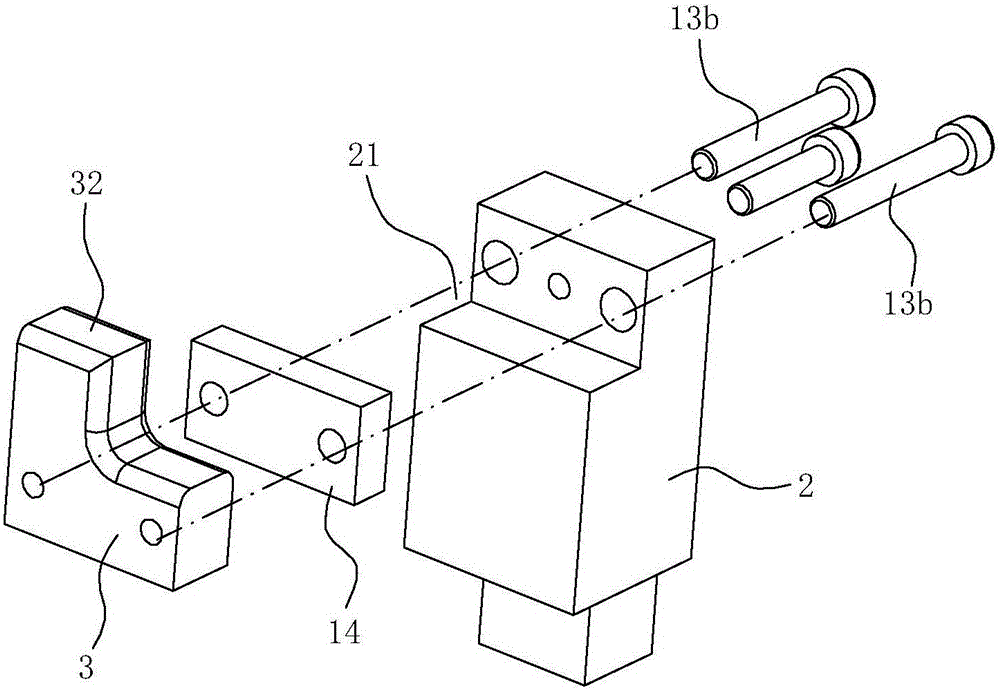

[0035] Such as Figure 3-8 As shown, the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com