Splicing tool used for splicing decoration panel to glass faceplate

A technology for glass panels and decorative panels, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problems of low bonding efficiency, inaccurate bonding position, easy misalignment of decorative panels and glass panels, etc., and achieve bonding efficiency And the effect of high precision and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

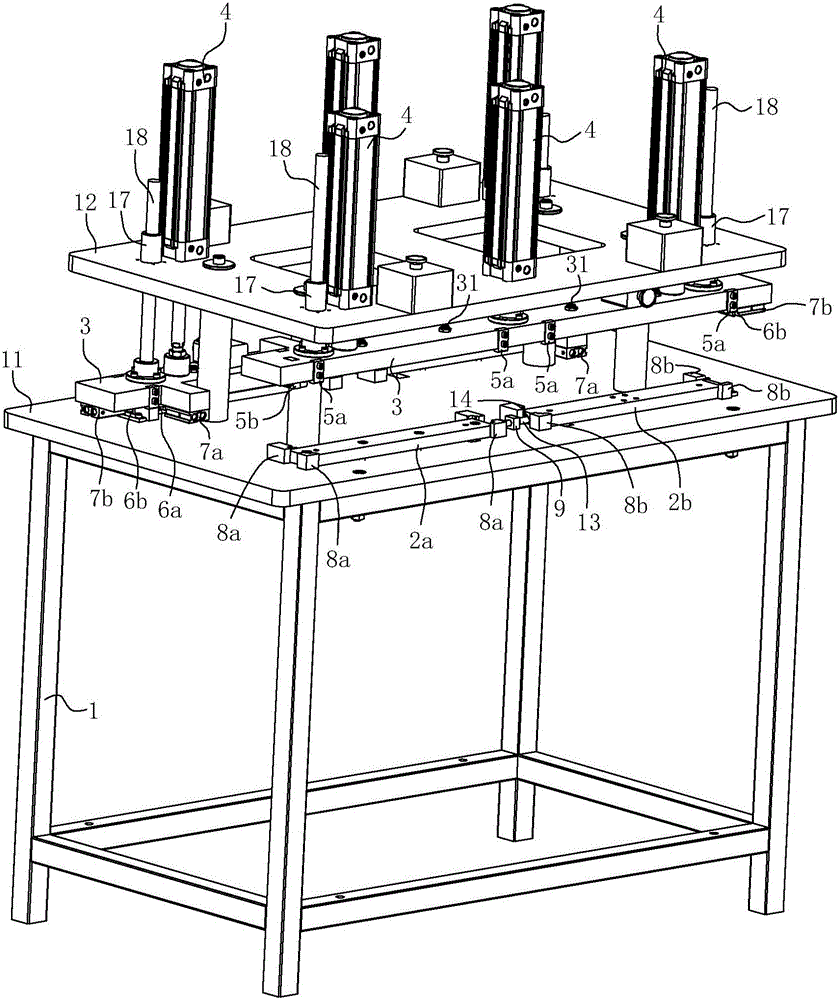

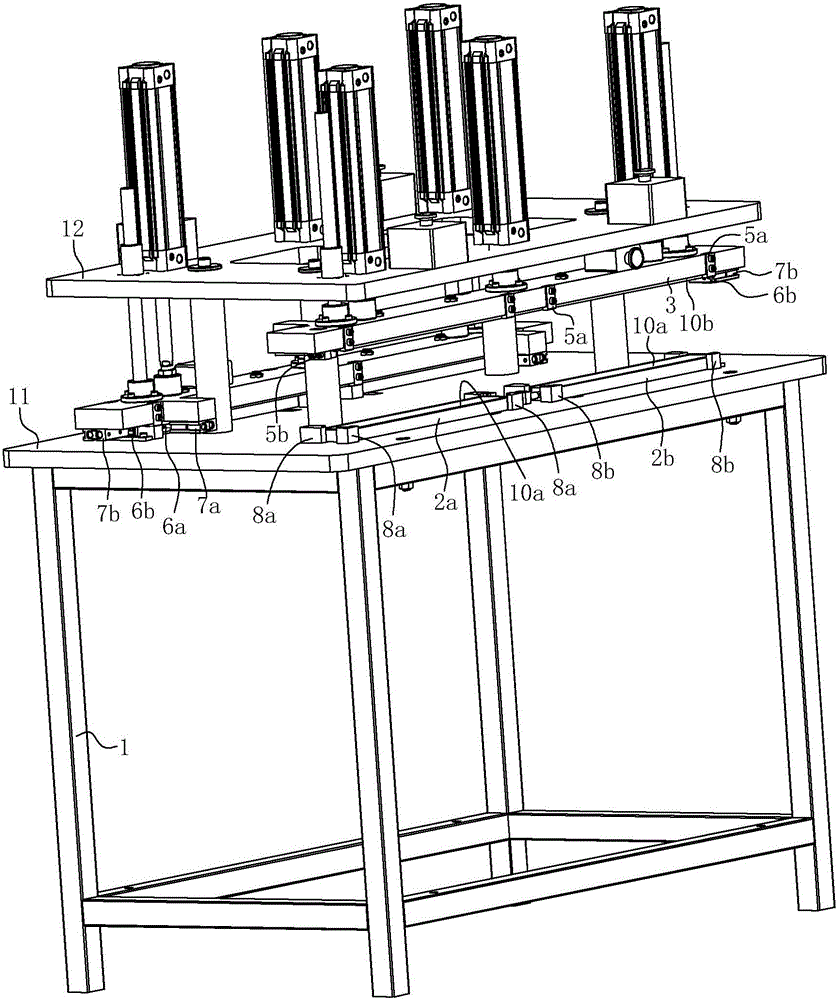

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] like Figure 1-8 Shown is a preferred embodiment of the present invention.

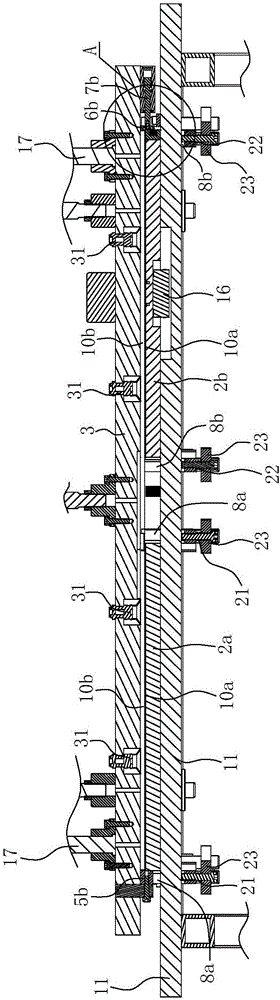

[0026] A bonding tool for bonding a decorative panel 10a to a glass panel 10b includes a frame body 1 with a table top 11 and an upper mounting plate 12 above the table top 11, and the table top 11 and the upper mounting plate 12 are supported by columns. At least one set of bonding structures is provided on the frame body 1 , and there are two sets of bonding structures in this embodiment, which are respectively arranged on the front and rear sides of the frame body 1 .

[0027] Each bonding structure includes

[0028] The left shelf 2a and the right shelf 2b for the decorative panel 10a to be placed at intervals on the left and right, wherein the left shelf 2a is fixed on the table 11, the right shelf 2b is bound on the table 11 and can slide left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com