Tool for automatically mounting O-shaped ring and method for mounting O-shaped ring

An automatic installation and O-ring technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as multiple sets or missing sleeves, slow leakage at the sealing part of the machine, and broken O-rings, so as to reduce production The effect of cost, efficiency improvement and processing speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

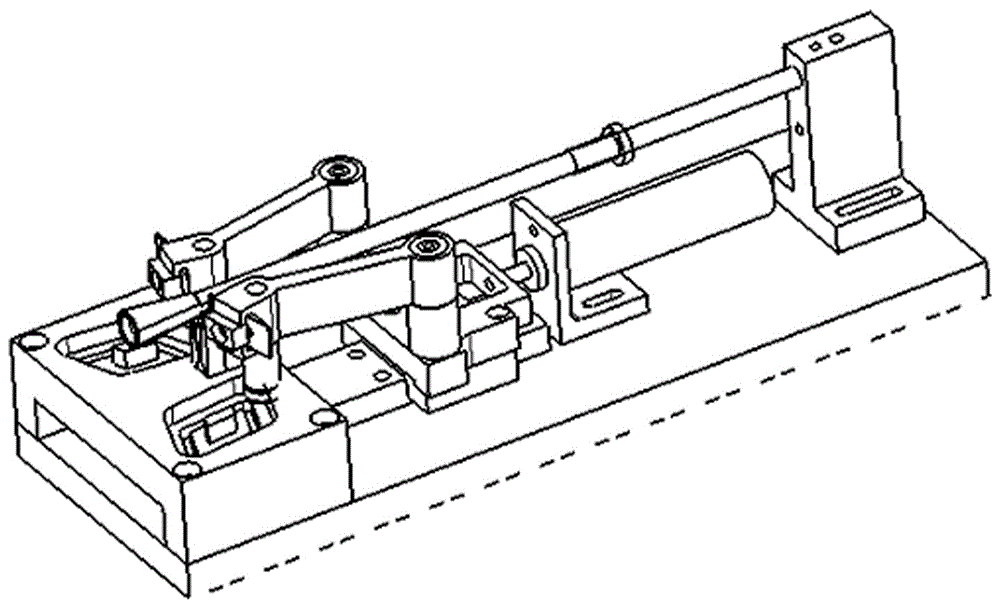

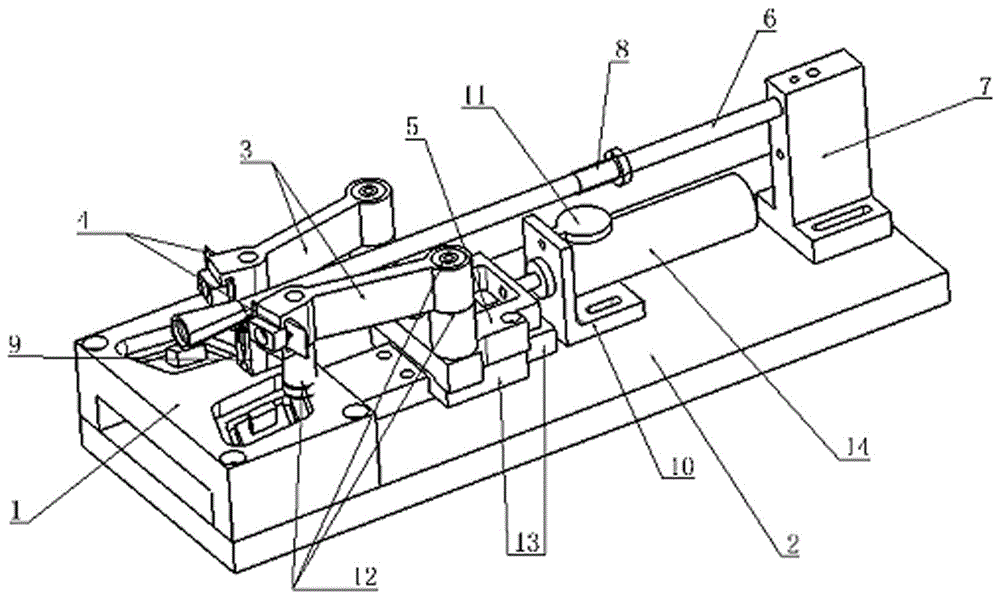

[0020] As shown in the figure, an automatic installation of O-ring tooling includes a base plate 2, which is characterized in that the base plate 2 is provided with

[0021] The O-ring mandrel 6, the front end of the O-ring mandrel 6 is provided with a counterbore, the O-ring is set on the O-ring mandrel 6, and the counterbore is used for installing a pipeline with an O-shaped groove;

[0022] Slider seat 5, described slider seat 5 is connected with cylinder 14, is driven slider seat 5 to move by cylinder telescopic rod, and the moving direction of described cylinder telescopic rod is identical with the extension direction of O-ring mandrel 6;

[0023] The paddle lever 3 is equipped with a paddle 4, the paddle lever 3 is installed on the slider seat 5, and the cylinder 14 pushes the slider seat 5 to move forward, driving the paddle lever 3 to move forward, The O-ring set on the O-ring core rod 6 is moved forward by the paddle 4 on the paddle rod 3, so that the O-ring is insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com