Automatic packaging system for bagging small-sized baked food in independent inflation mode

A technology of automatic packaging and inflatable packaging, which is applied in the field of food packaging, can solve the problems of no automatic packaging machinery, high labor intensity of workers, and low production efficiency, and achieve the effects of manpower saving, simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a deeper understanding of the present invention, a specific embodiment is listed below, and the present invention is further described in detail in conjunction with the accompanying drawings.

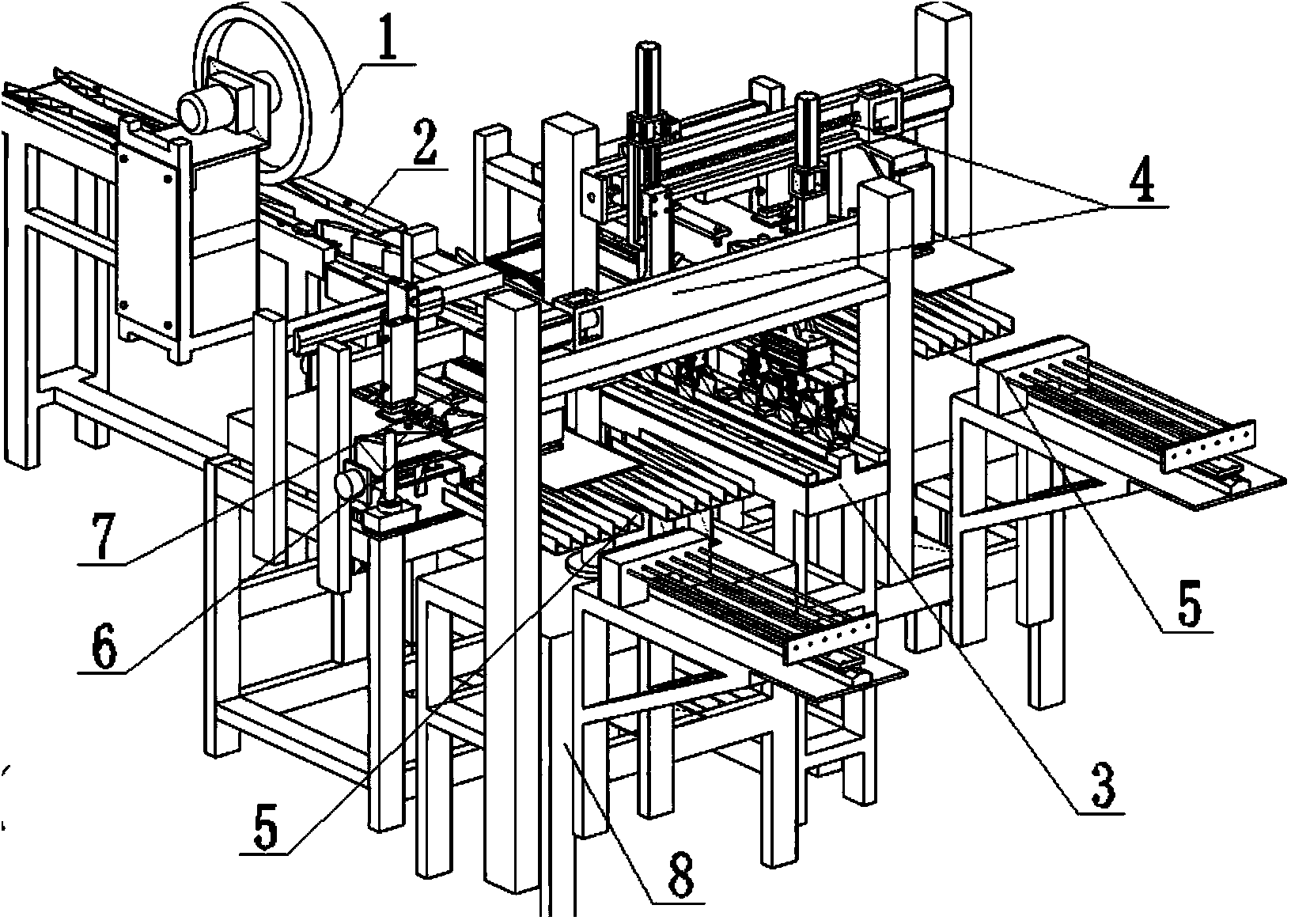

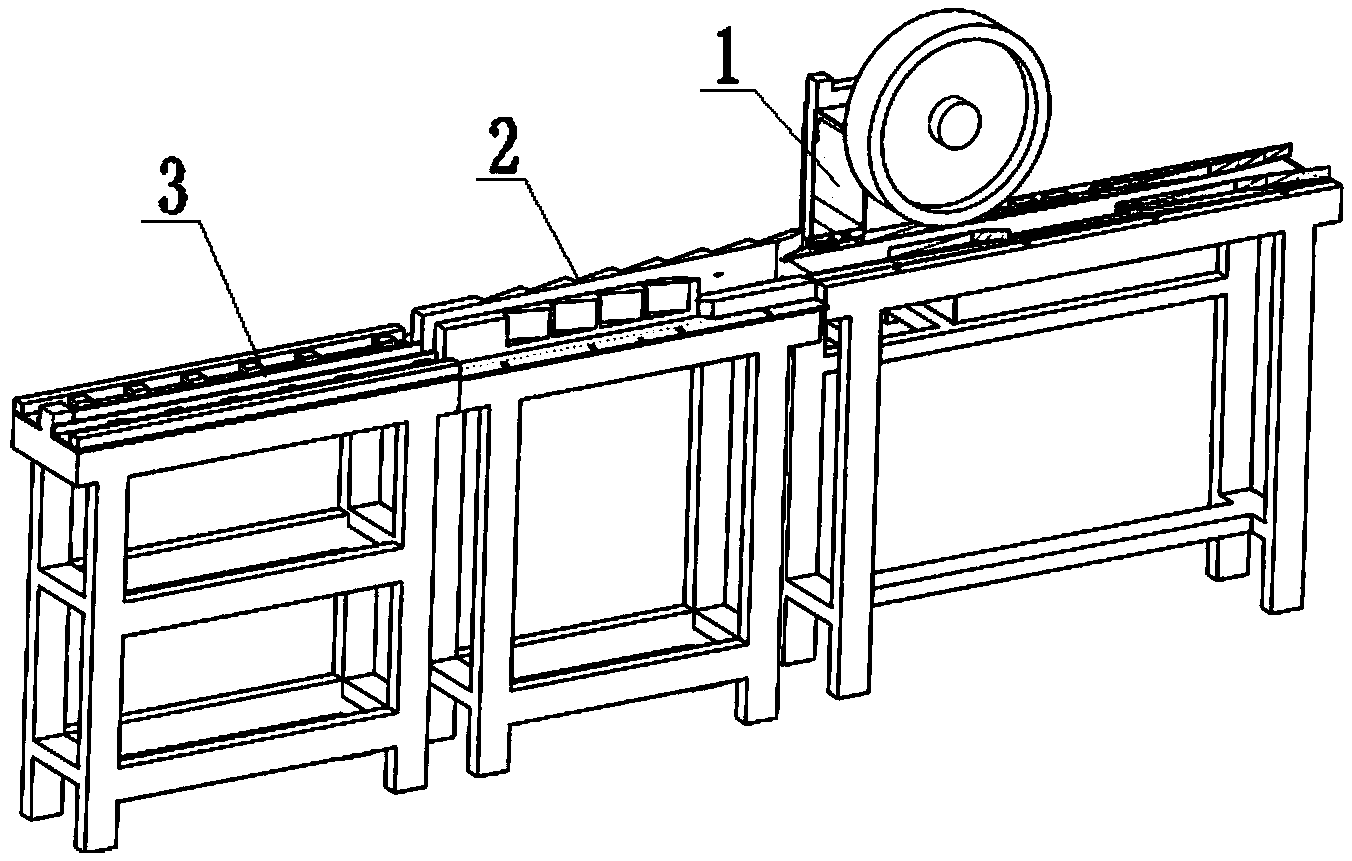

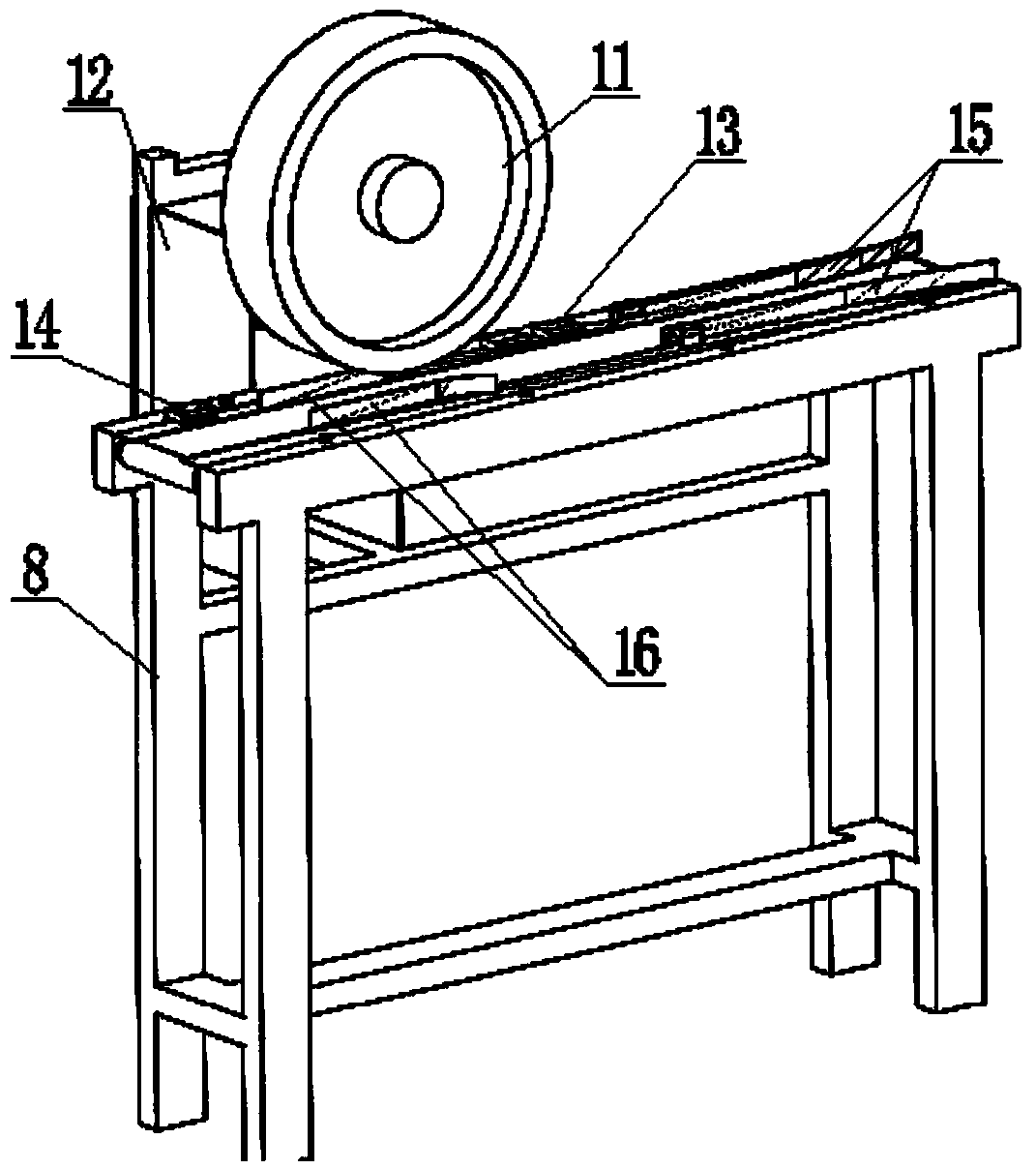

[0041] This embodiment is an automatic packaging system for bagging small baked food with independent air packaging, such as figure 1 , figure 2 As shown, it includes a feeding device, a whole material device and a bagging device that are arranged in sequence. The feeding device includes a guiding and monitoring device 1 for guiding and detecting whether the inflatable packaging bag is leaking. The positioning device 3 for sorting and positioning the inflatable packaging bags and the manipulator 4 for grabbing the inspected inflatable packaging bags. The bagging device includes a bag opening device 6 for opening the opening of the large packaging bag. The bag feeding device 7 of the bag and the pushing device 5 used to push the air-filled packaging bag into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com