Bulk cement delivery one-key start control system and method

A bulk cement, start-up control technology, applied in general control system, control/adjustment system, program control, etc., can solve problems such as high labor intensity, affecting delivery efficiency, and traffic inspection risk, so as to avoid overfilling or underfilling installation, reduce the amount of operation, and protect the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

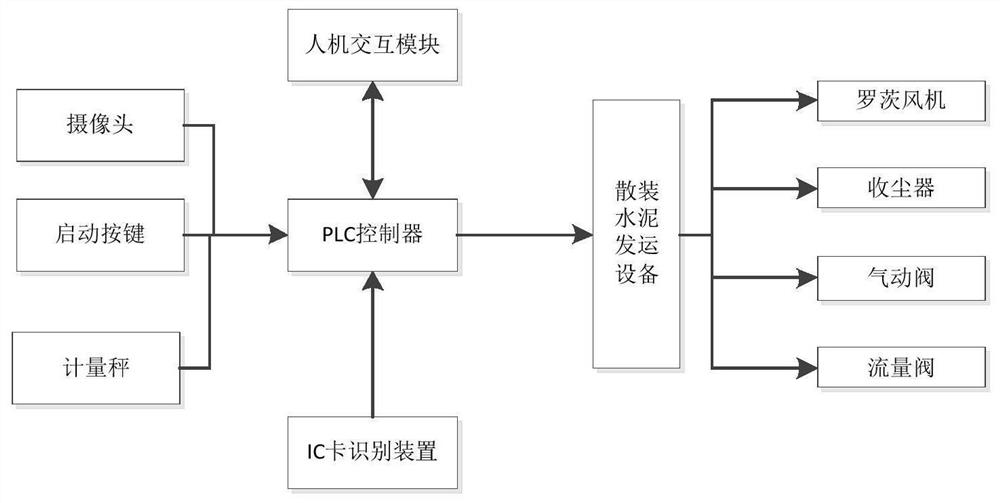

[0019] Bulk cement delivery equipment (bulk loader) is equipment for loading cement into transport vehicles, including pneumatic valves, flow valves, dust collectors, Roots blowers, etc. The control of bulk loaders in the prior art mostly relies on manual opening one by one and closing, this method will increase the work intensity of the operator; at the same time, the weight of the cement loaded on the truck is only estimated, the result is not accurate, and the actual cement data cannot be traced; therefore, the existing technology has low efficiency, high labor intensity, and Rely on defects such as manual experience control. Aiming at problems such as high labor intensity of employees, inability to effectively control the loading weight, and low shipping efficiency in the process of bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com