Patents

Literature

183results about How to "Improve pressing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

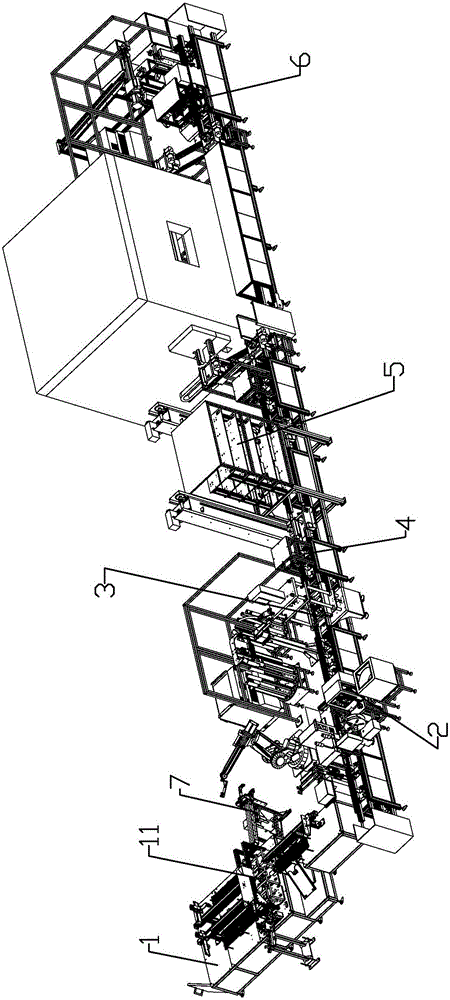

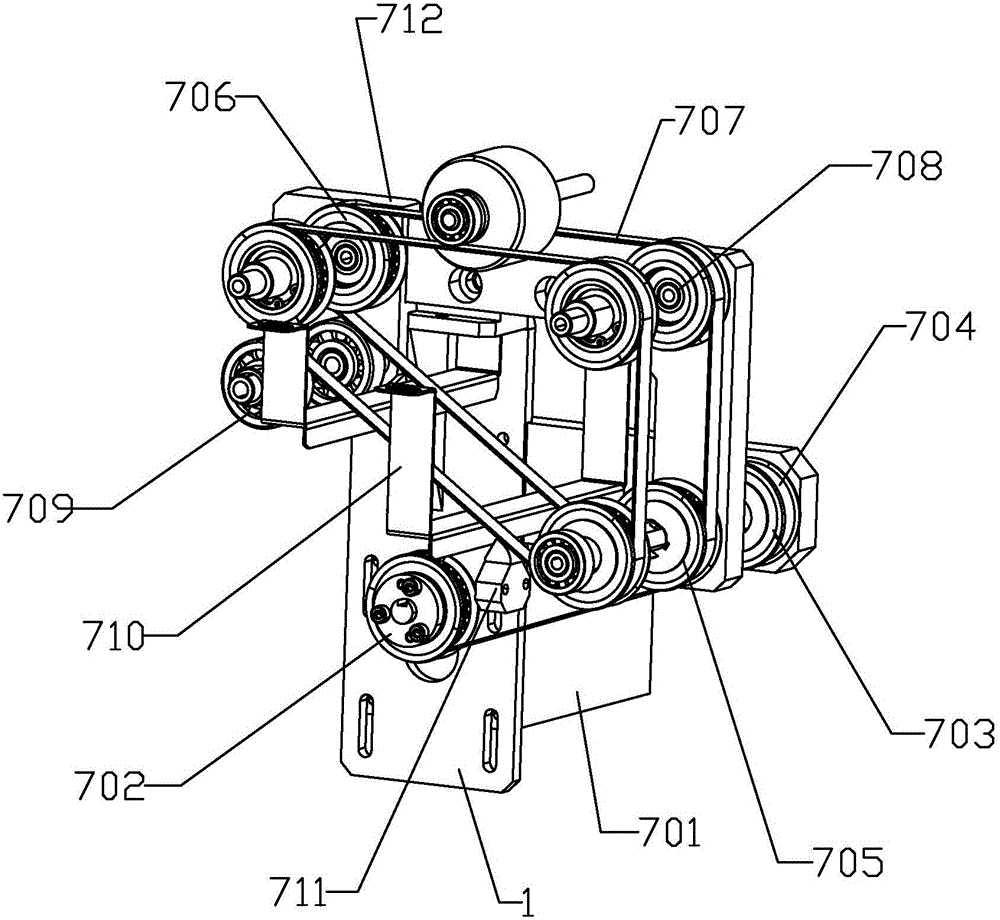

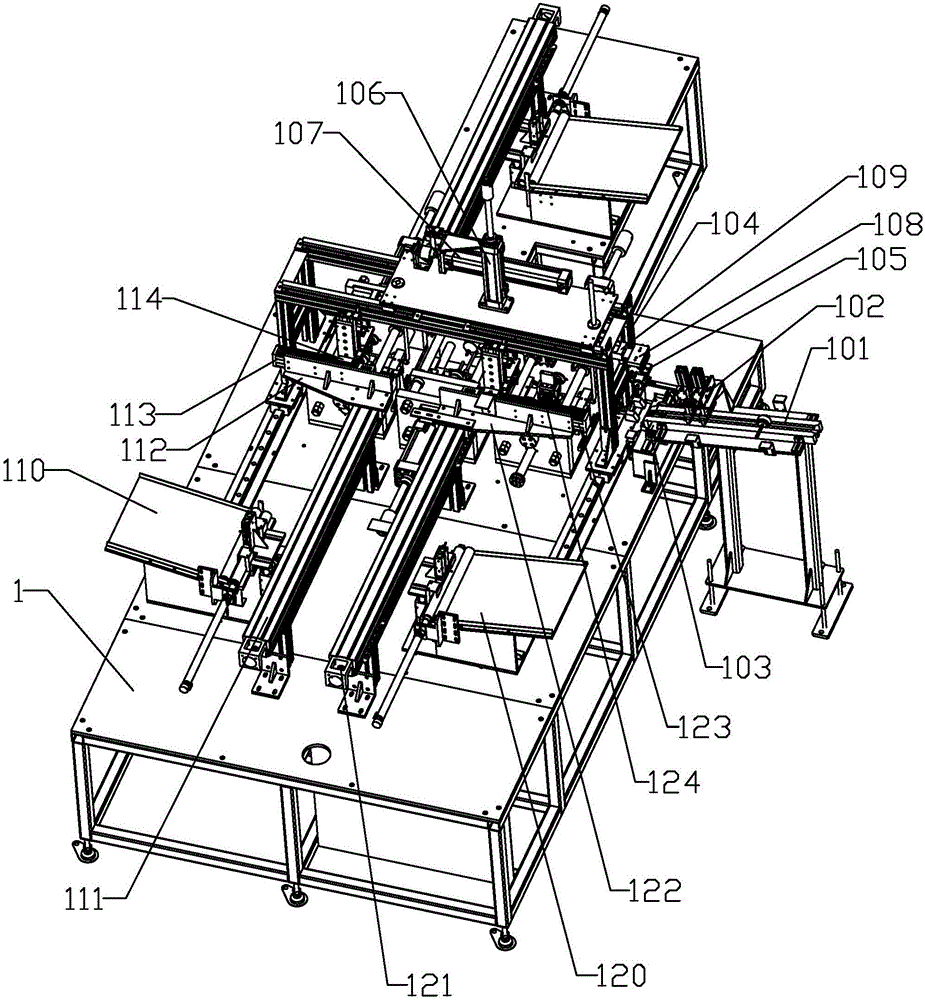

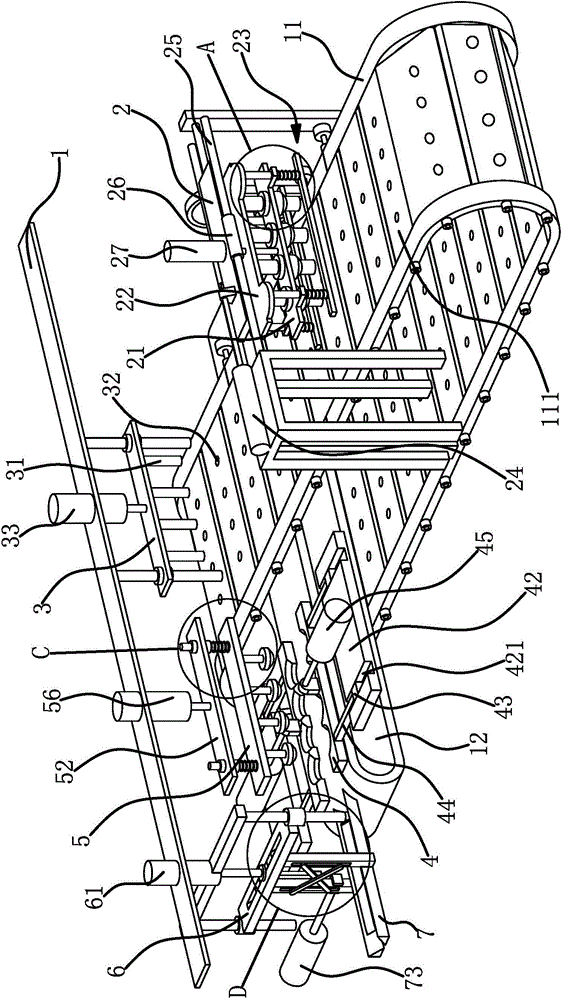

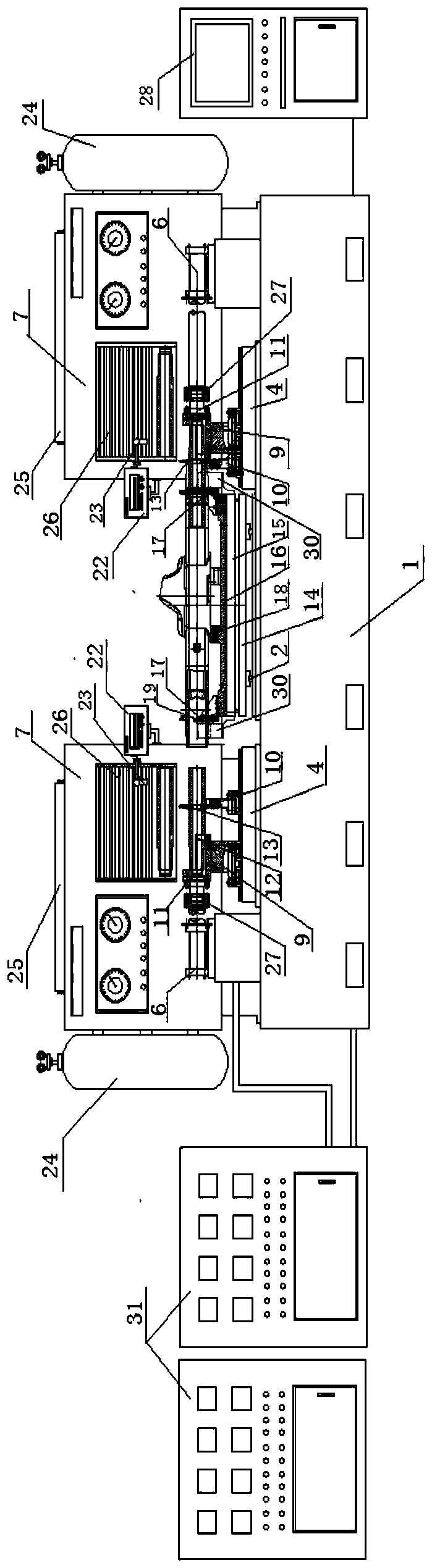

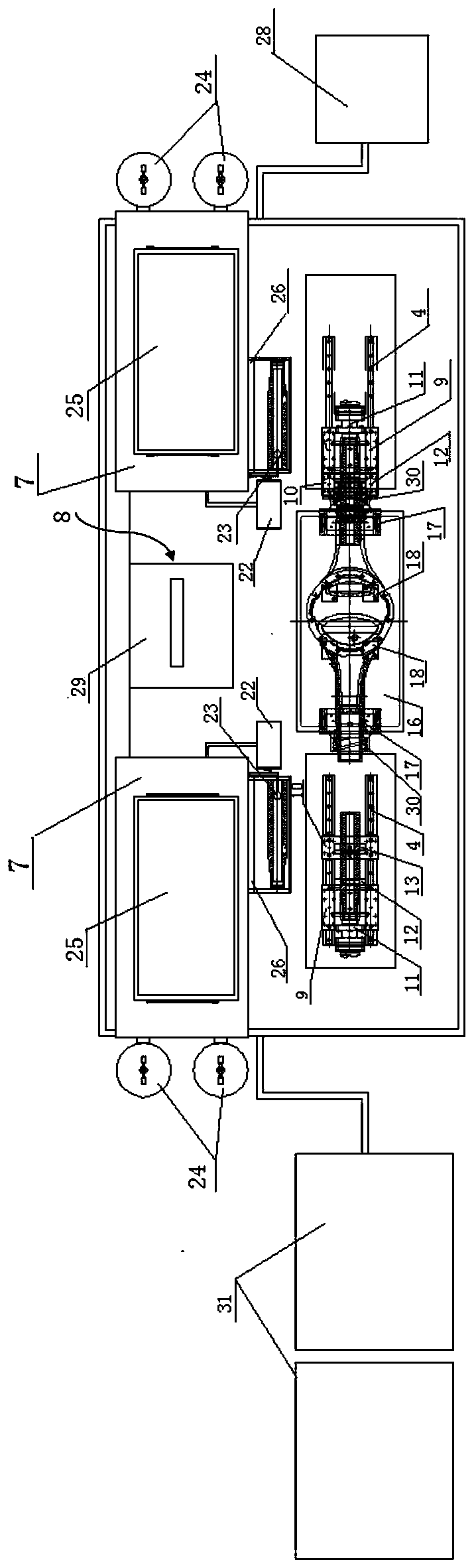

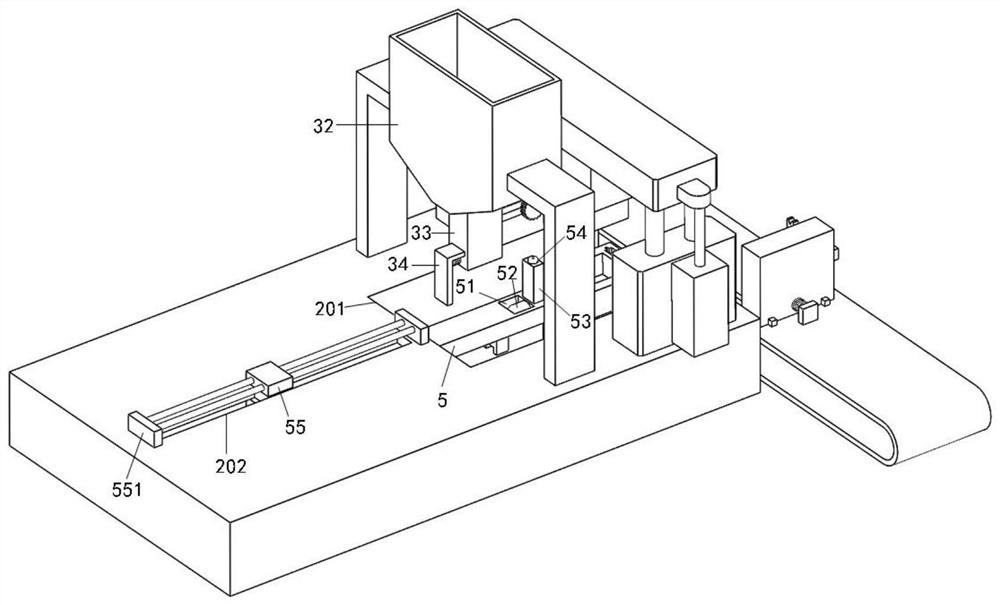

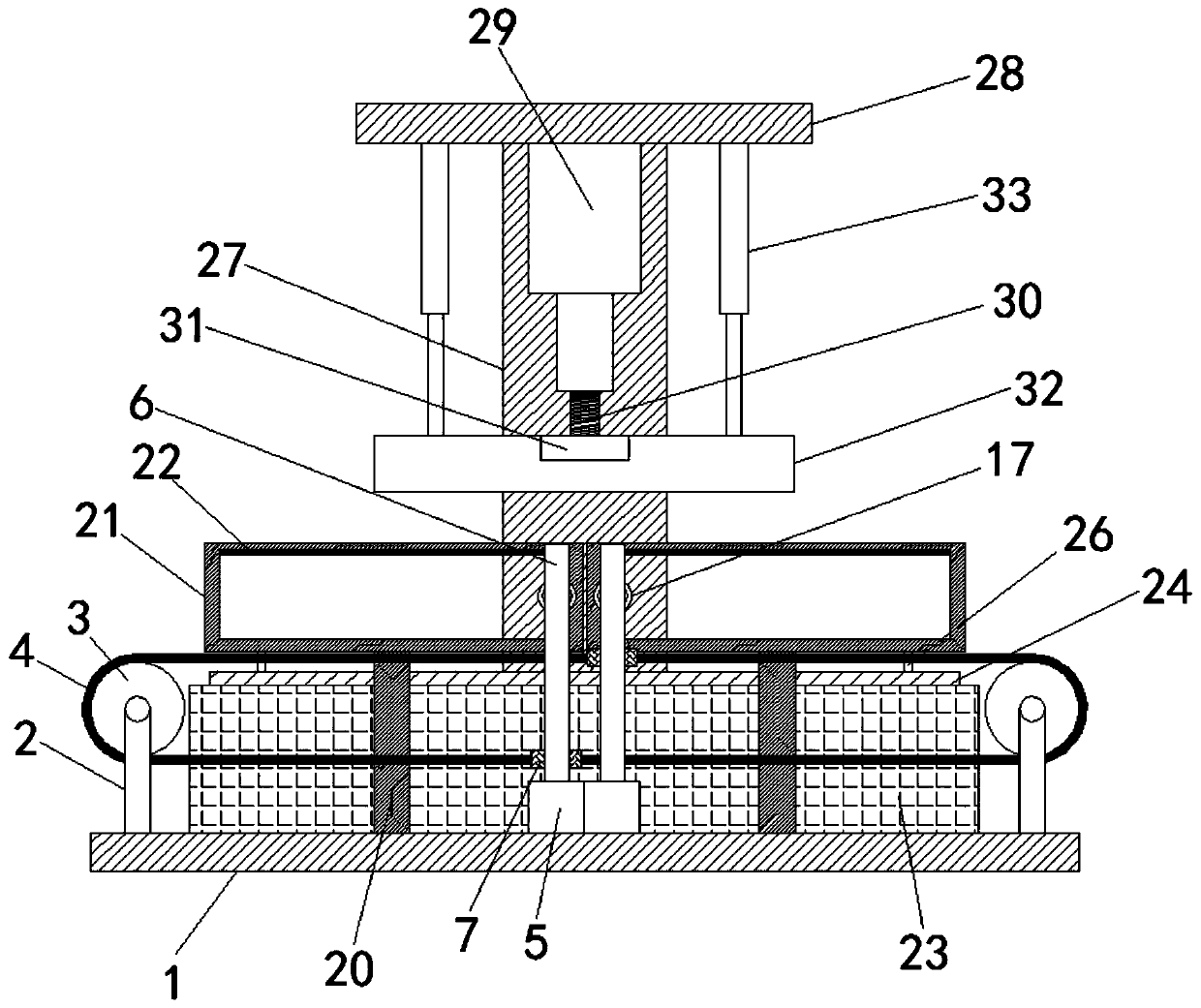

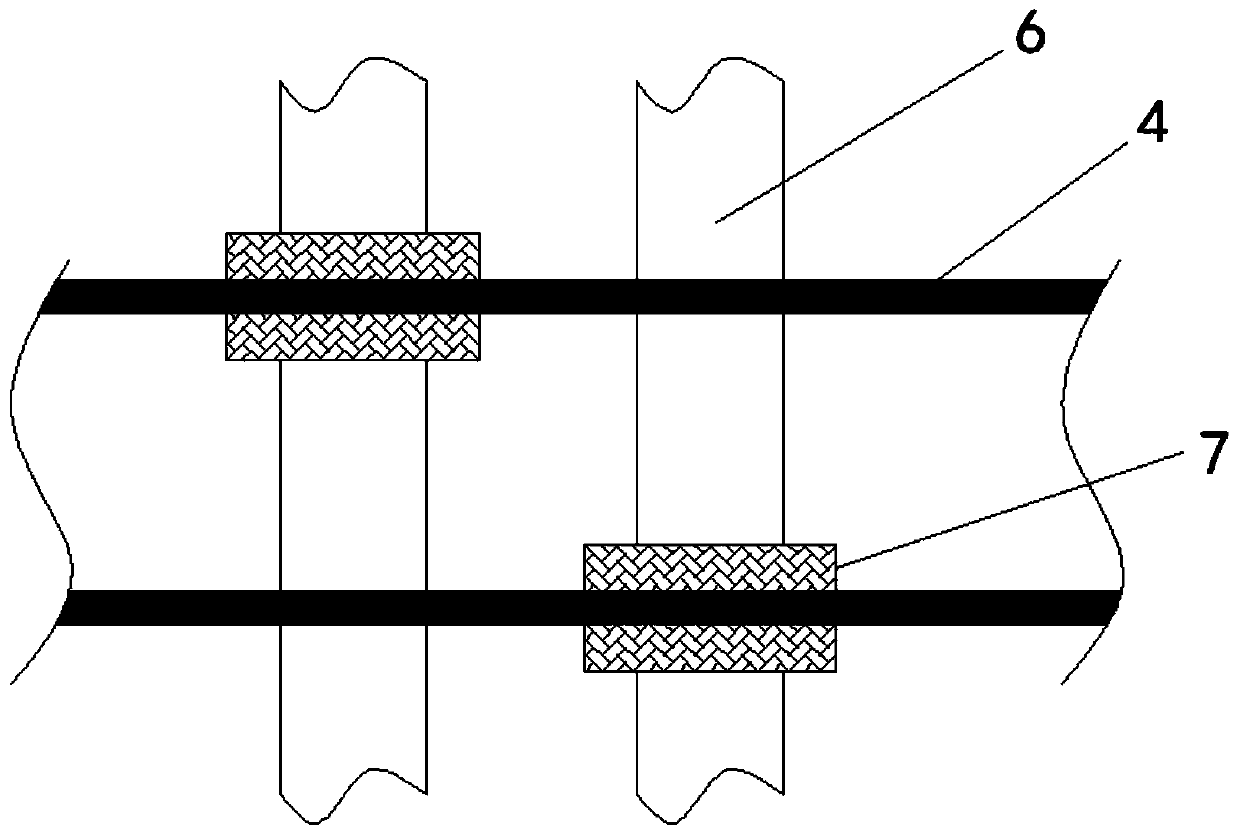

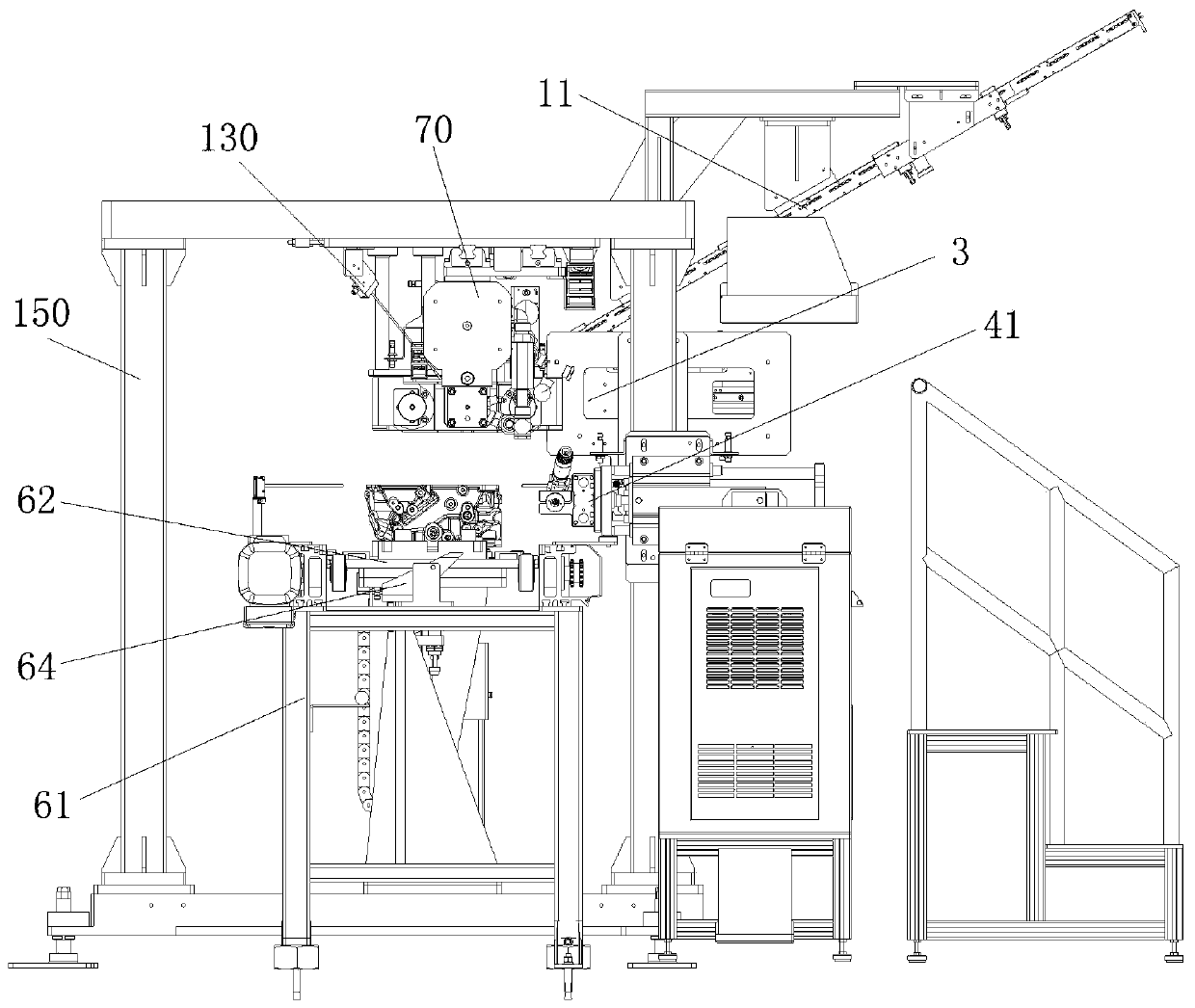

Automatic assembling line for motors

ActiveCN105871129AHigh degree of automationImprove assembly qualityManufacturing dynamo-electric machinesElectricityEngineering

The invention discloses an automatic assembling line for motors. The automatic assembling line for the motors comprises a frame, an automatic conveying belt, a motor rotor bearing bit synchronization oiling device, an automatic motor rotor bearing press-fitting device, an automatic spring washer distributing and detecting device, a motor end cap press-fitting device, an automatic motor bearing gap detecting device, an automatic motor ageing testing device and an automatic gluing air dryer for the motors, wherein the automatic conveying belt which is electrically connected with a circuit controller is arranged on the frame; and the motor rotor bearing bit synchronization oiling device, the automatic motor rotor bearing press-fitting device, the automatic spring washer distributing and detecting device, the motor end cap press-fitting device, the automatic motor bearing gap detecting device, the automatic motor ageing testing device and the automatic gluing air dryer for the motors are successively connected together by the automatic conveying belt and are electrically connected with the circuit controller. The automatic assembling line for the motors is high in assembling stability and good in assembling quality, and testing automation of components of the motors can be realized.

Owner:GUANGDONG LXD ROBOTICS CO LTD

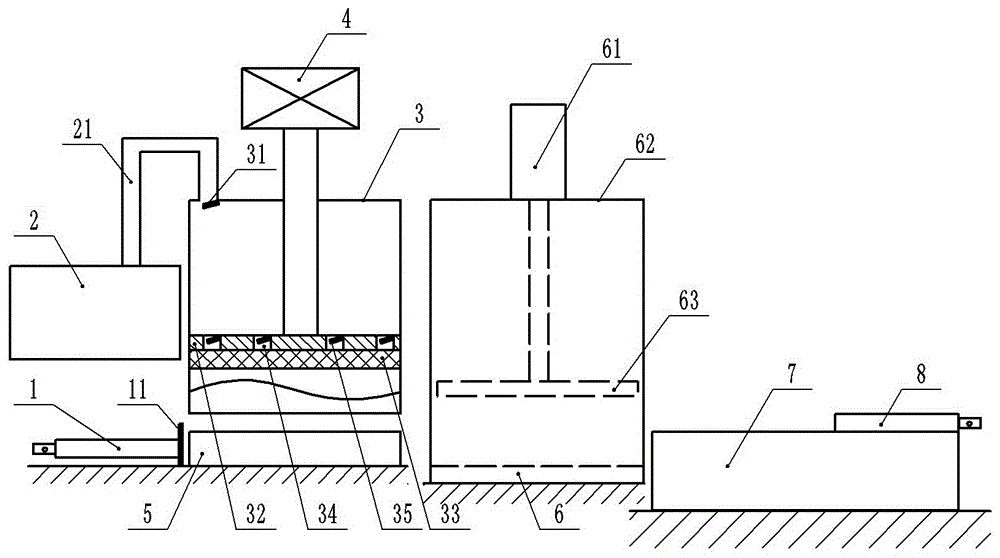

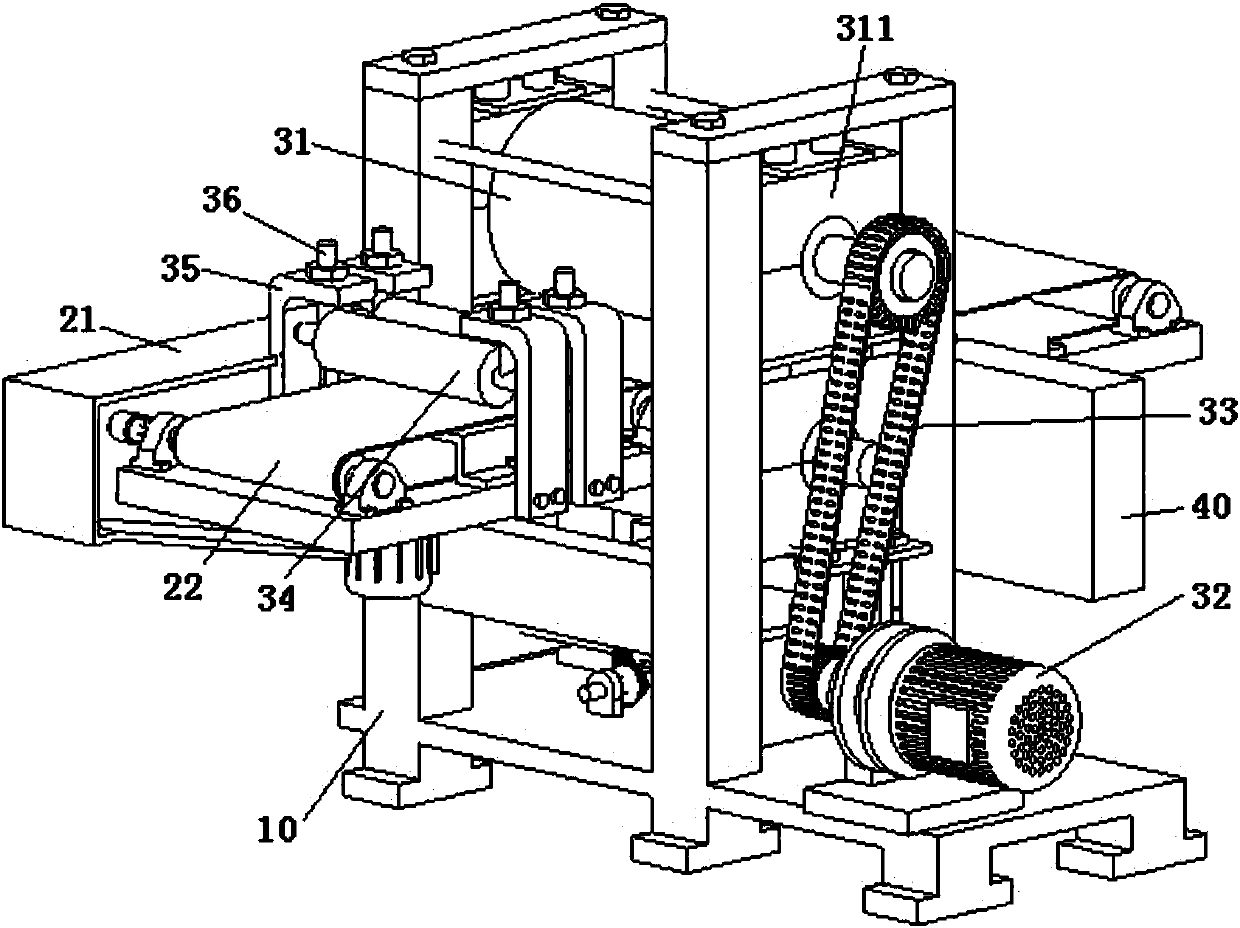

Plate press machine with glue coating function

ActiveCN106738100AAccelerate solidificationLighten the laborPlywood pressesMulti-purpose machinesWood machiningPulp and paper industry

The invention belongs to the technical field of wood working equipment, and particularly discloses a plate press machine with glue coating function. The plate press machine comprises a first horizontal push hydrocylinder, a glue coating device, a plate presser and a feeder from left to right, wherein the glue coating device comprises a bracket, a glue tank, an air cylinder and a glue supply tank; the glue supply tank is a tank body with an opening on the lower end; the glue supply tank is fixed to the bracket; a piston is arranged in the glue supply tank, and driven by the air cylinder; the air cylinder is positioned above the glue supply tank; the side wall of the glue supply tank communicates with a glue suction pipe; one end of the glue suction pipe is positioned in the glue tank; the joint between the glue suction pipe and glue supply tank is provided with a first one-way valve; the piston is provided with a through hole, and the through hole is provided with a one-way valve; the lower surface of the piston is provided with a sponge layer; the feeder comprises an elevating table and a second horizontal push hydrocylinder; and the second horizontal push hydrocylinder is positioned on the elevating table. By adopting the technical scheme, the wood plate can be pressed immediately after finishing glue coating, and the glue coating and pressing processes are continuous, so the production efficiency is high.

Owner:重庆汇升套装门有限公司

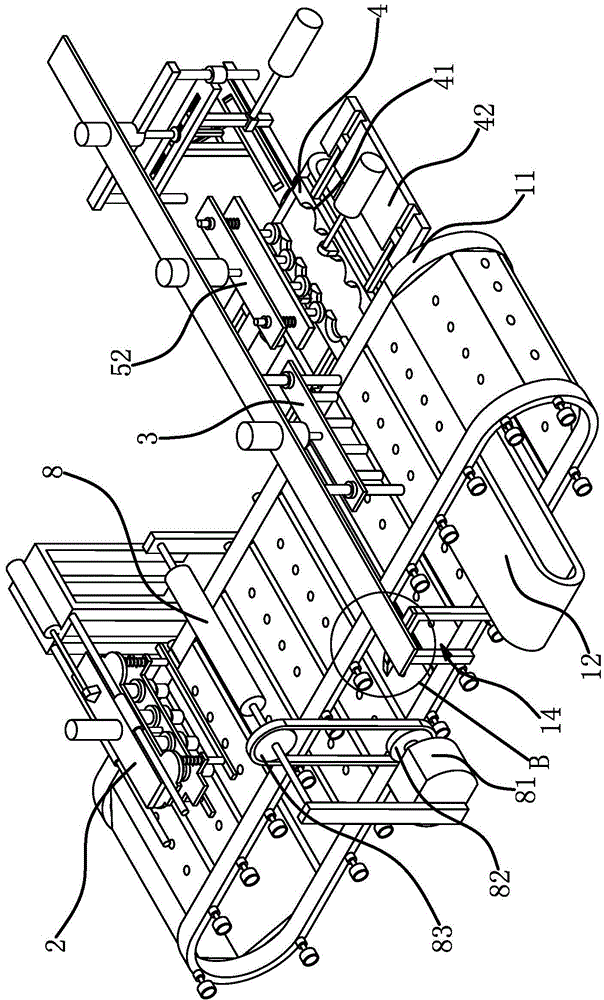

Automatic egg tart skin processing machine

InactiveCN104957204AAvoid taking awayImprove cut qualityDough dividingDough processingEngineeringFood processing

The invention provides an automatic egg tart skin processing machine, and belongs to the technical field of food processing equipment. The problem of lower egg tart skin processing efficiency in the prior art is solved. The automatic egg tart skin processing machine comprises a machine frame, wherein two longitudinal conveying belts and a transverse conveying belt are arranged on the machine frame; the machine frame is slidably connected with a moving plate; the moving plate is slidably connected with a lifting plate; a plurality of cutters are fixedly connected to the lifting plate; the machine frame is slidably connected with a stripper plate; a stripper column is fixedly connected to the stripper plate; a plurality of stripper holes are formed in a supporting plate; the machine frame is slidably connected with two positioning plates; a positioning groove is formed in each positioning plate; the machine frame is slidably connected with a material pressing plate; a material pressing mold head is connected to the material pressing plate; the machine frame is slidably connected with a blanking plate; two blanking rods are slidably connected to the blanking plate. According to the automatic egg tart skin processing machine, dough can be automatically cut into a circular egg tart skin, and the egg tart skin can be automatically pressed into an egg tart mold, so that the processing efficiency is high.

Owner:南通盛净环保设备有限公司

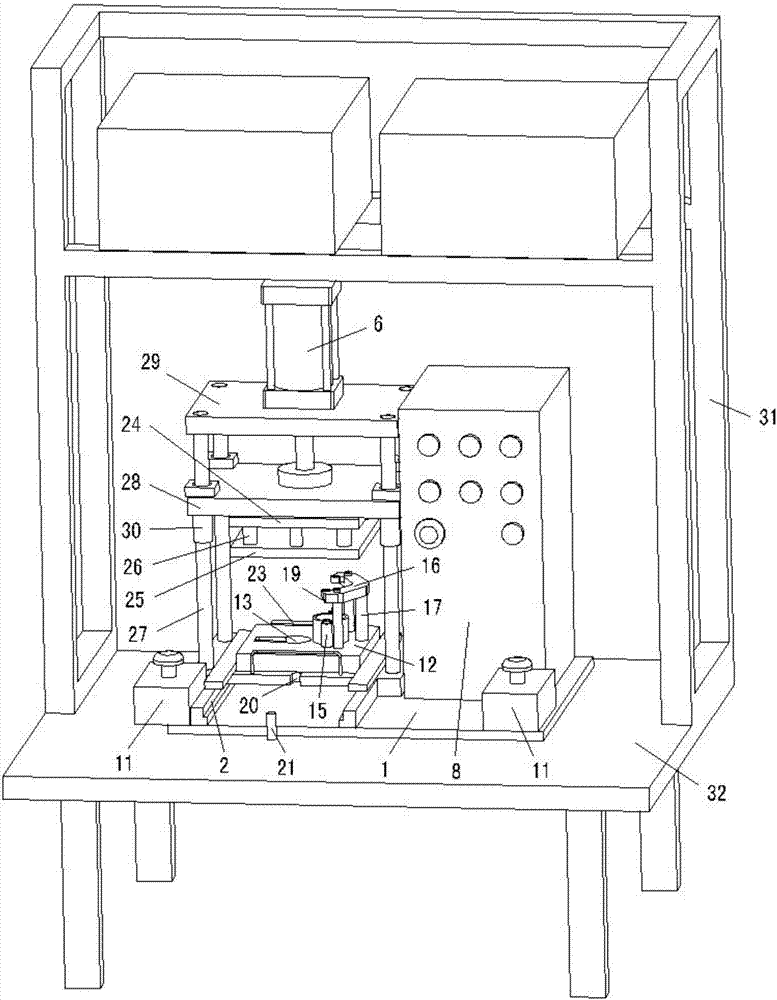

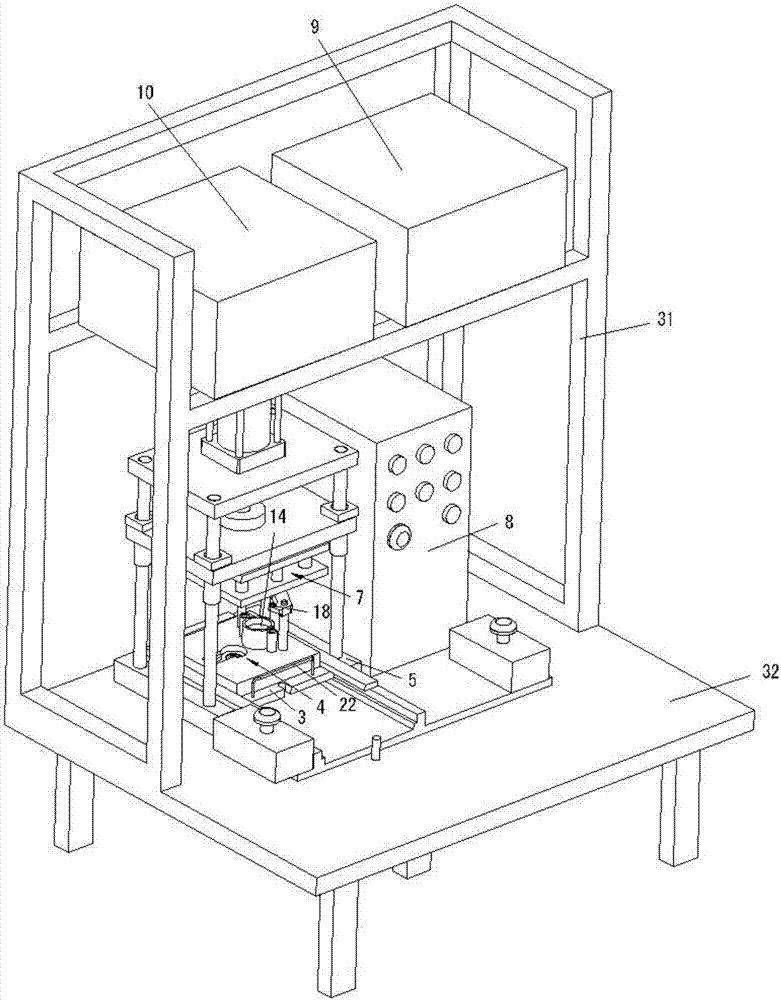

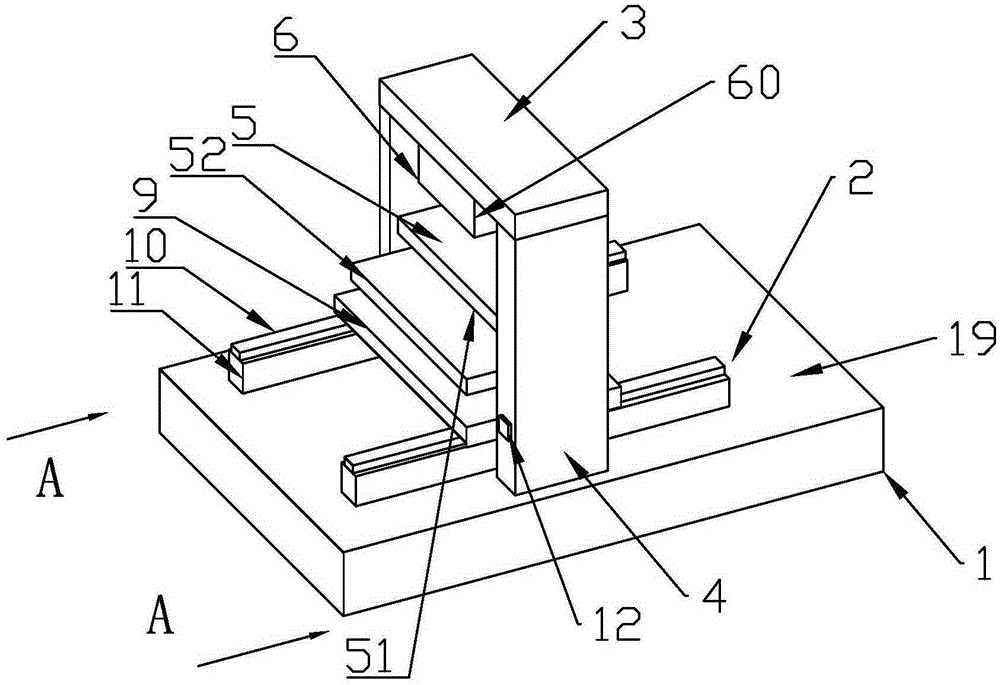

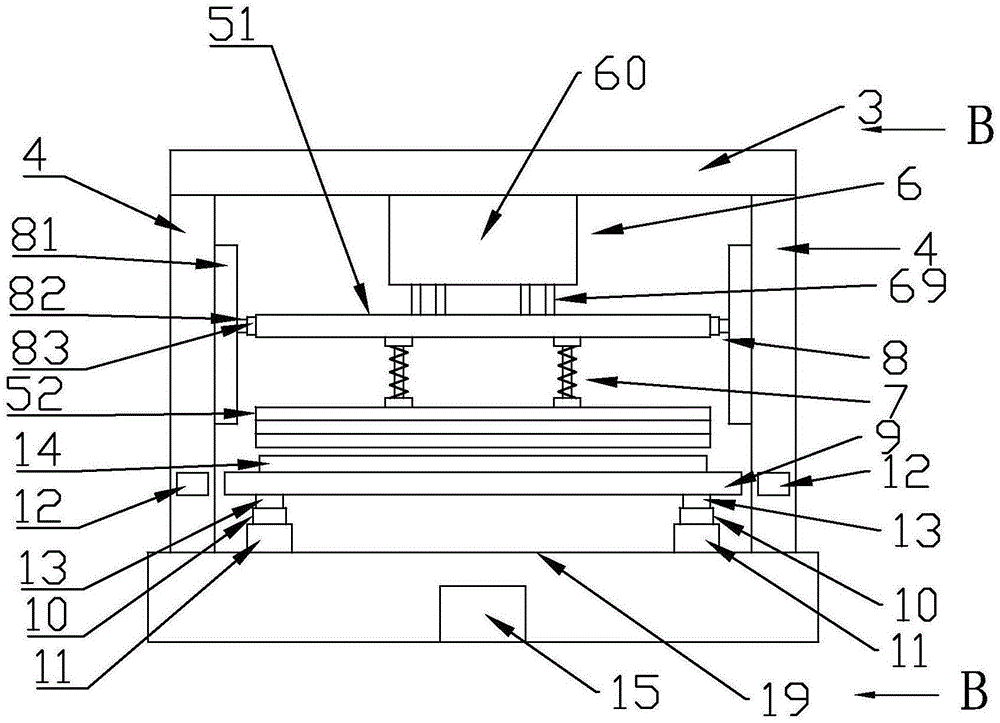

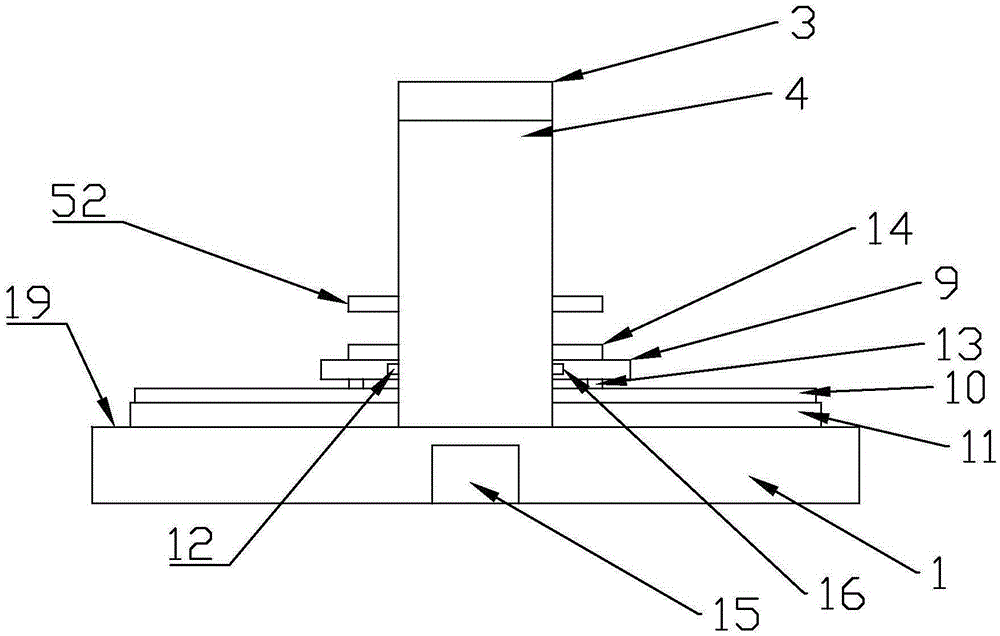

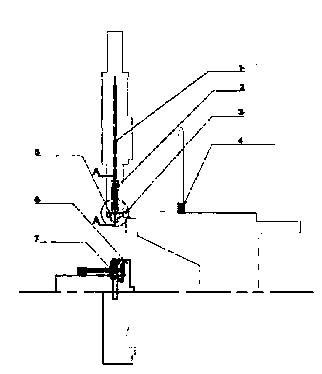

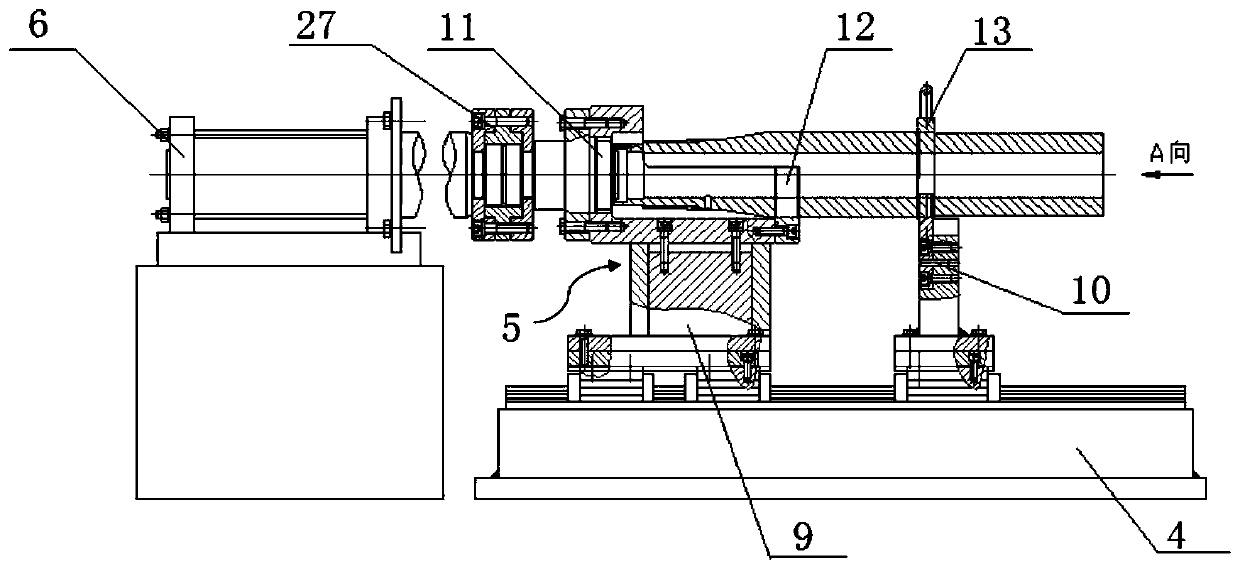

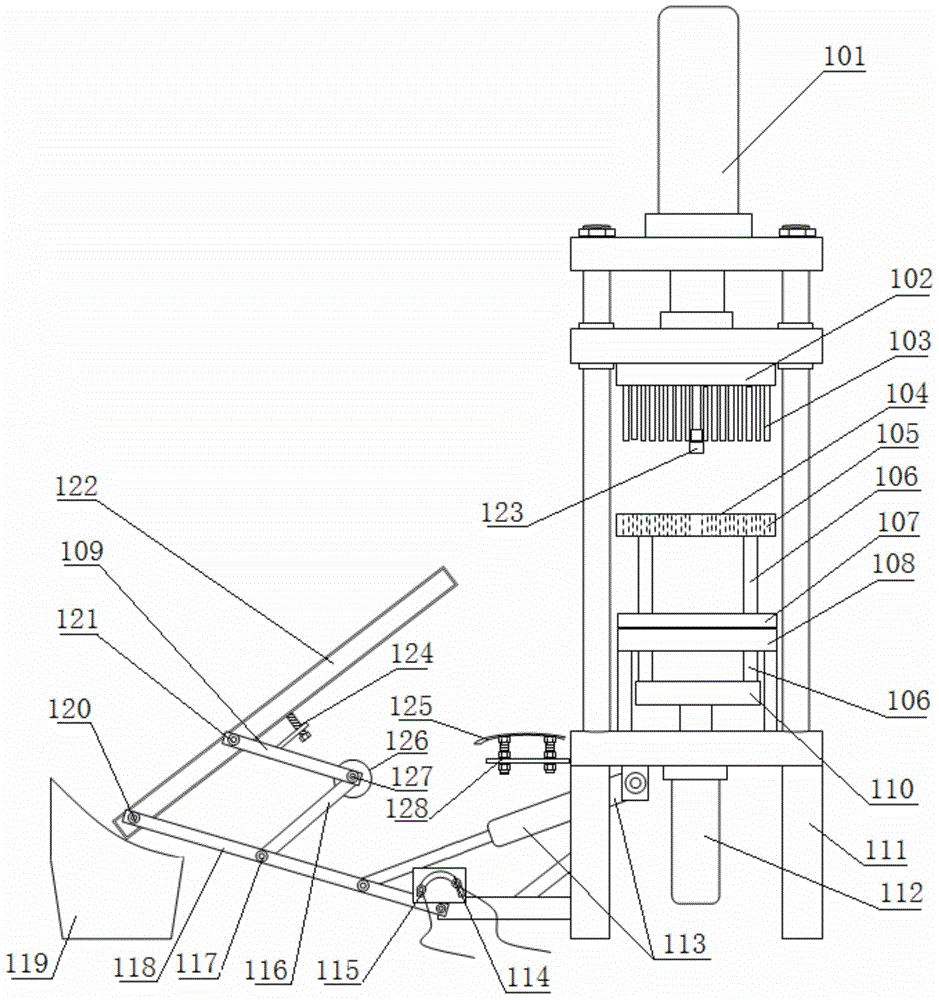

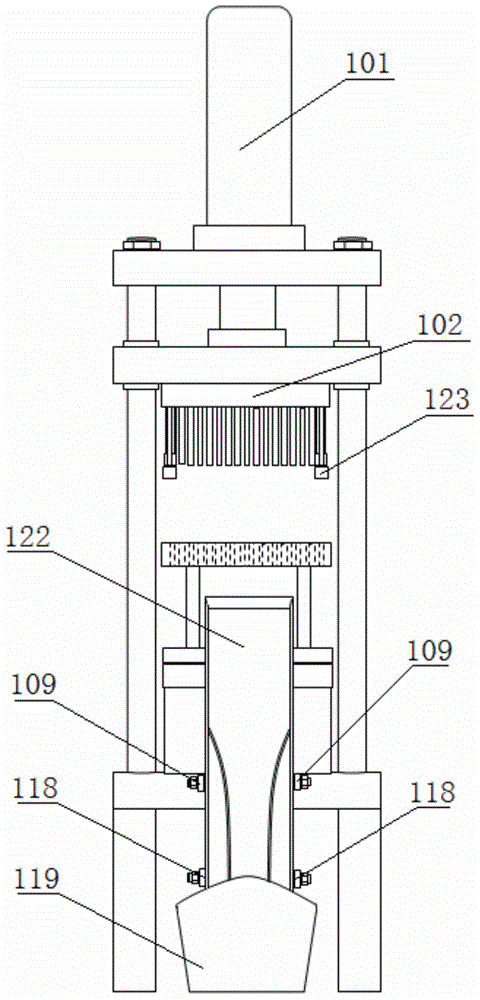

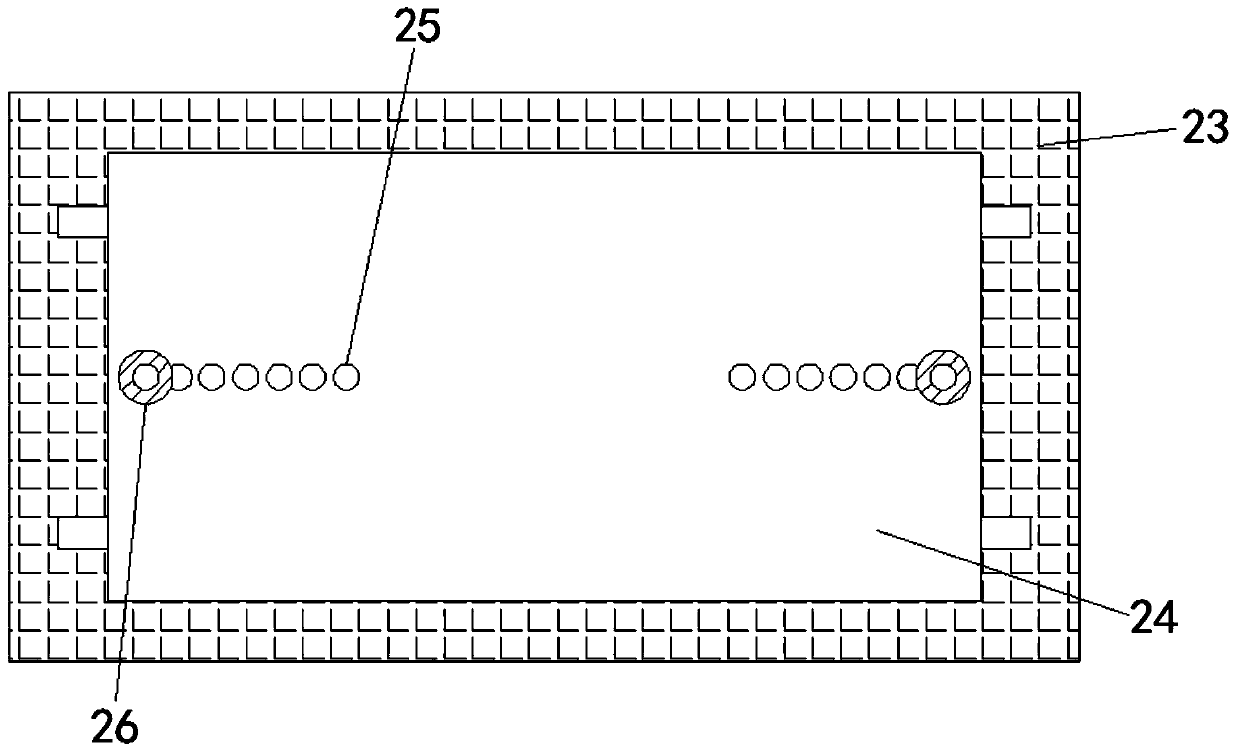

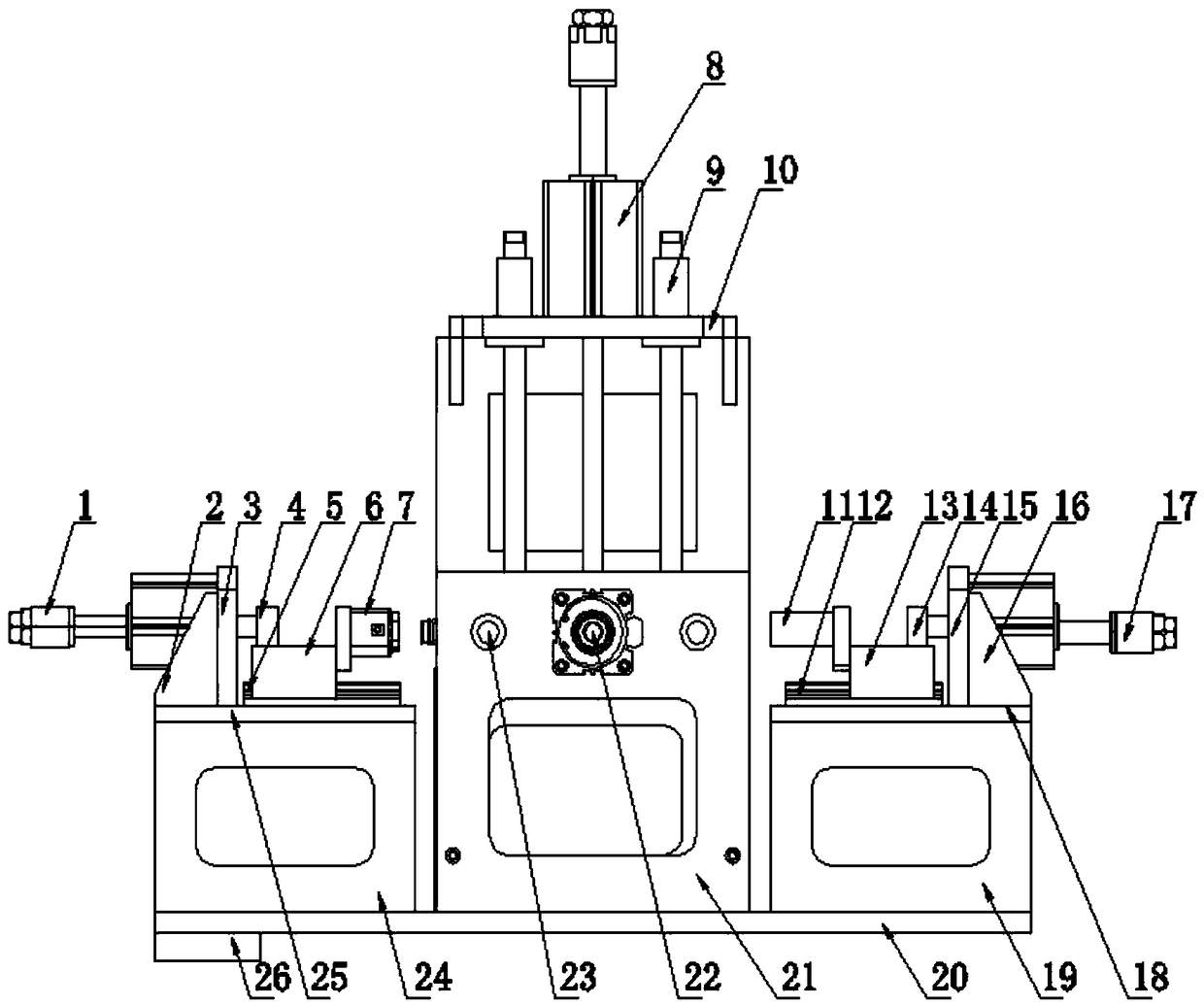

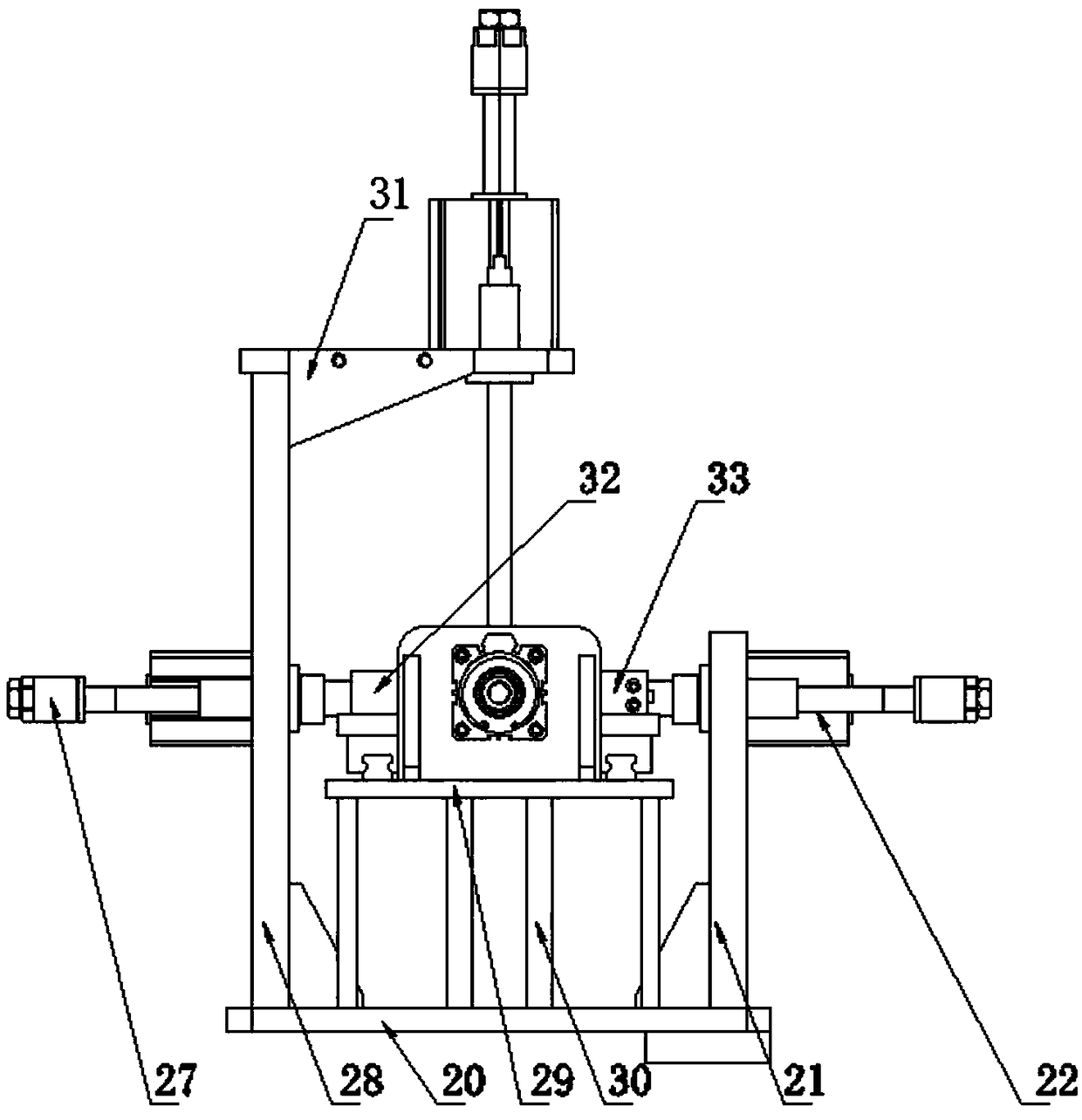

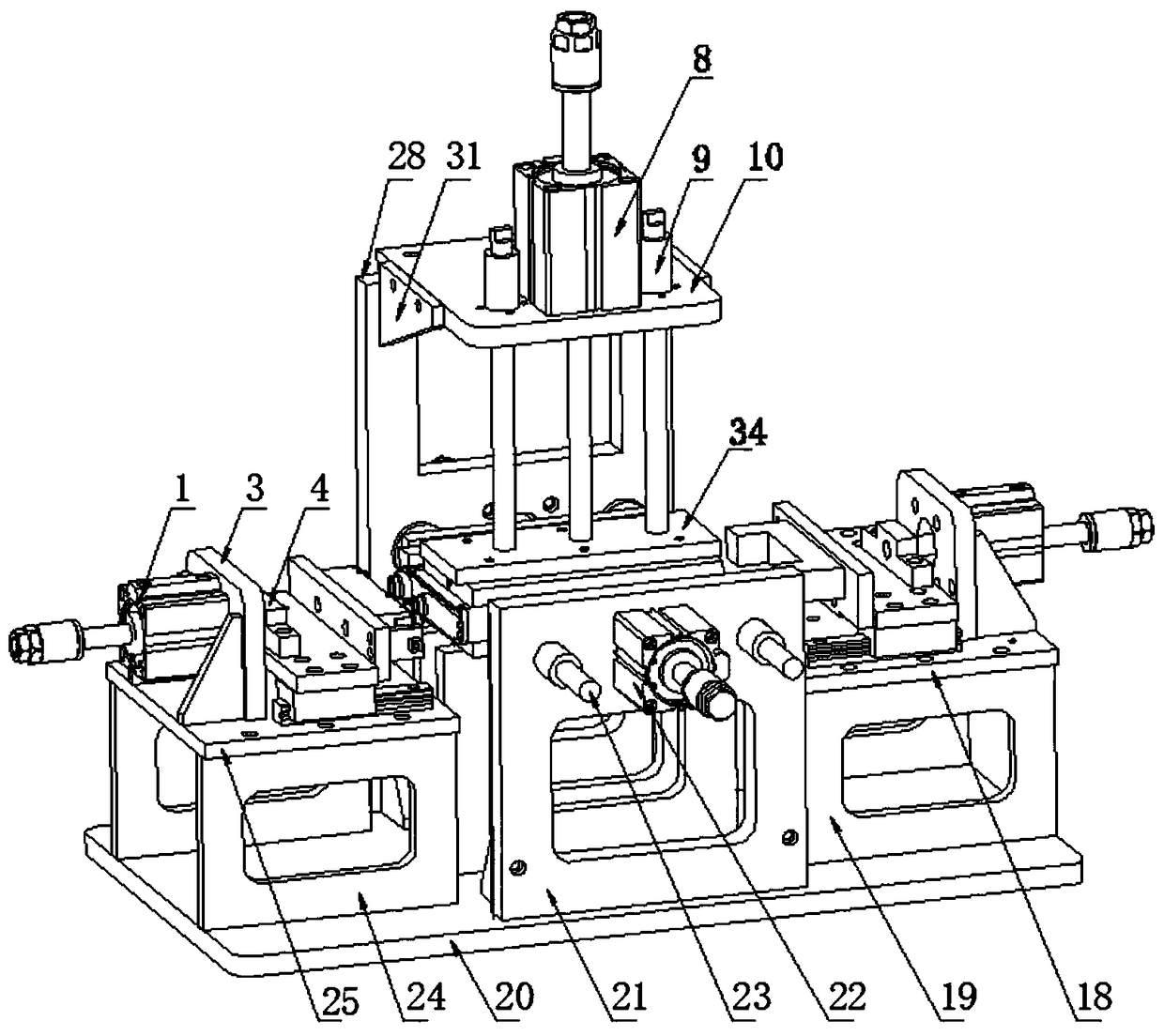

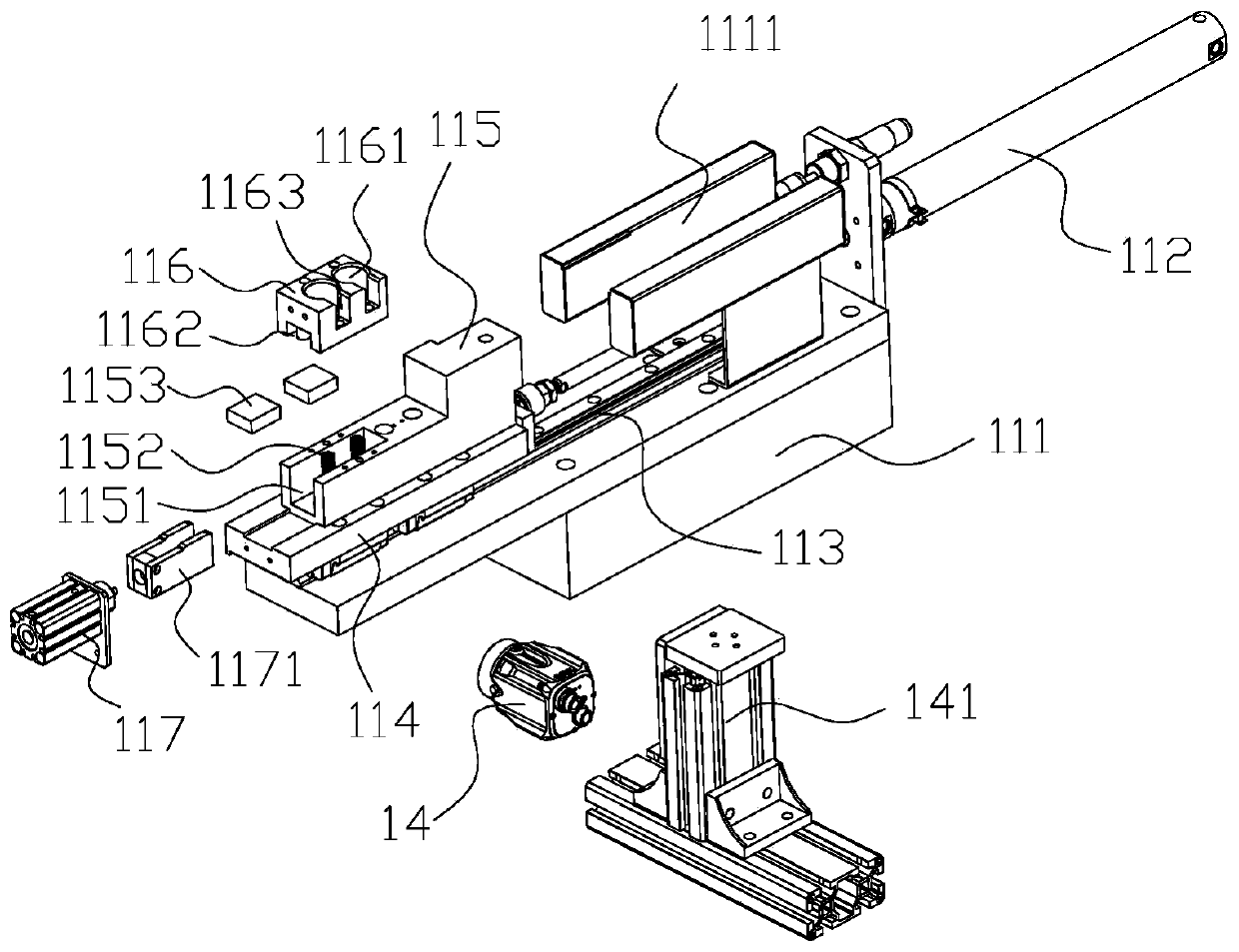

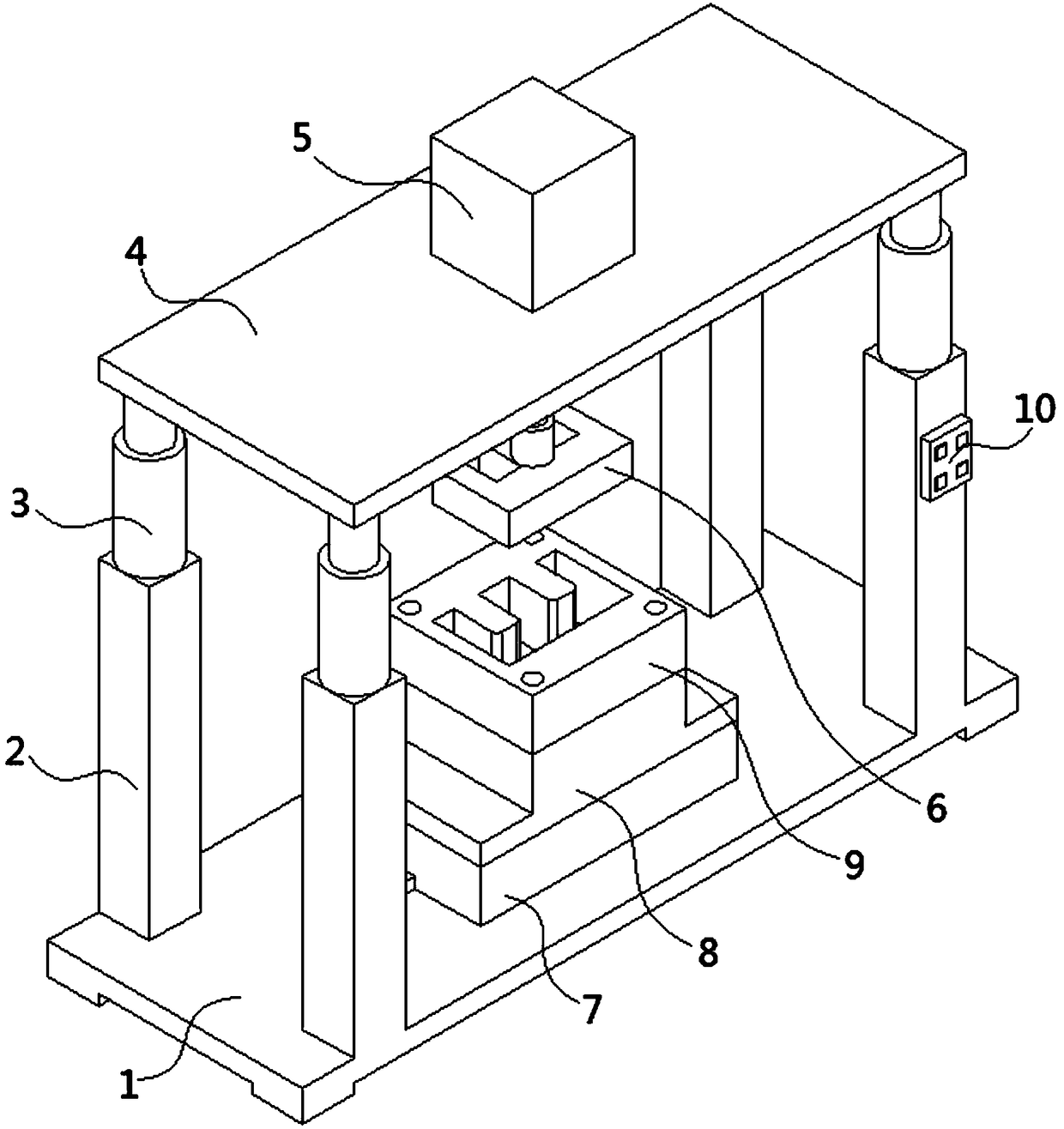

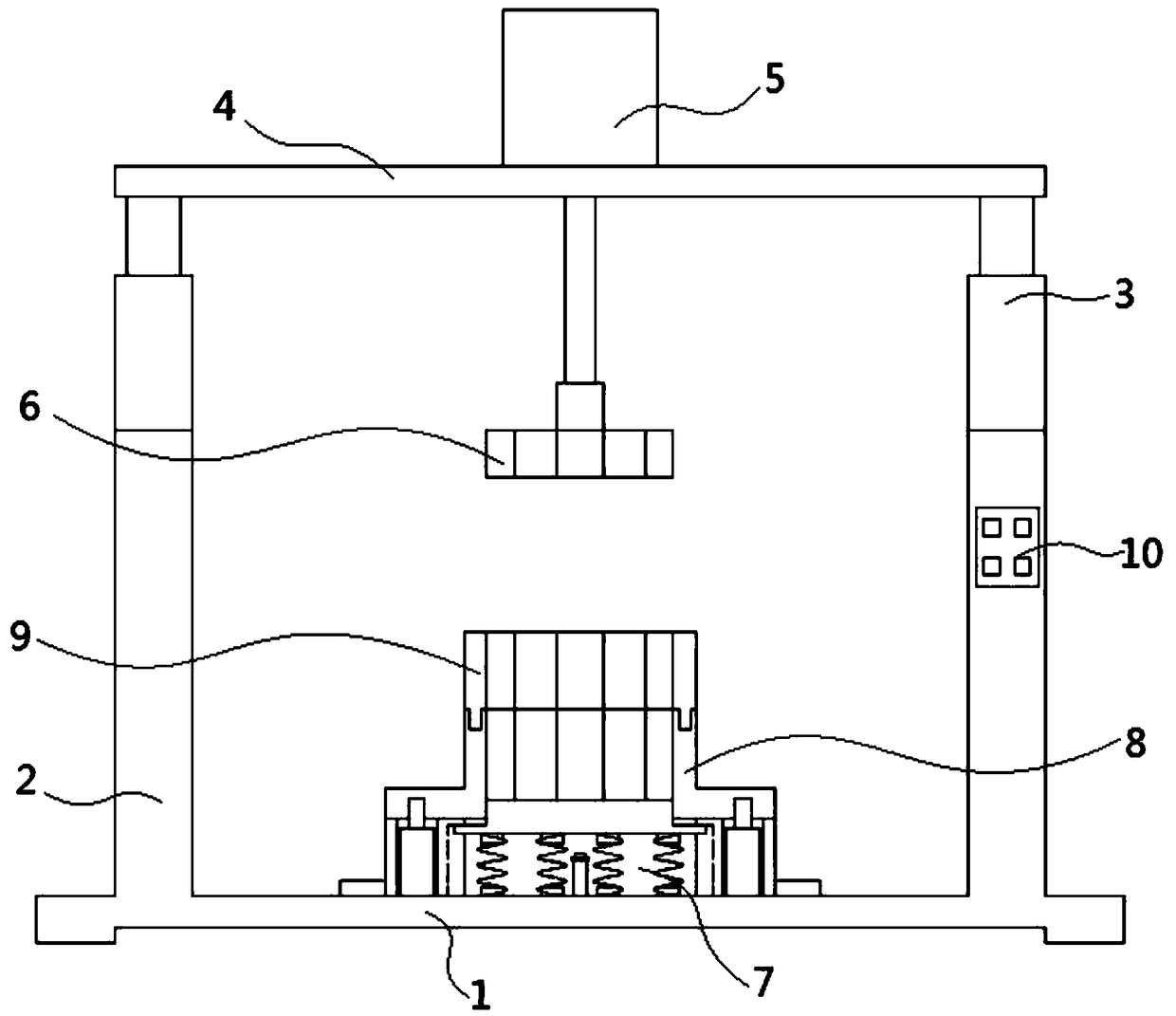

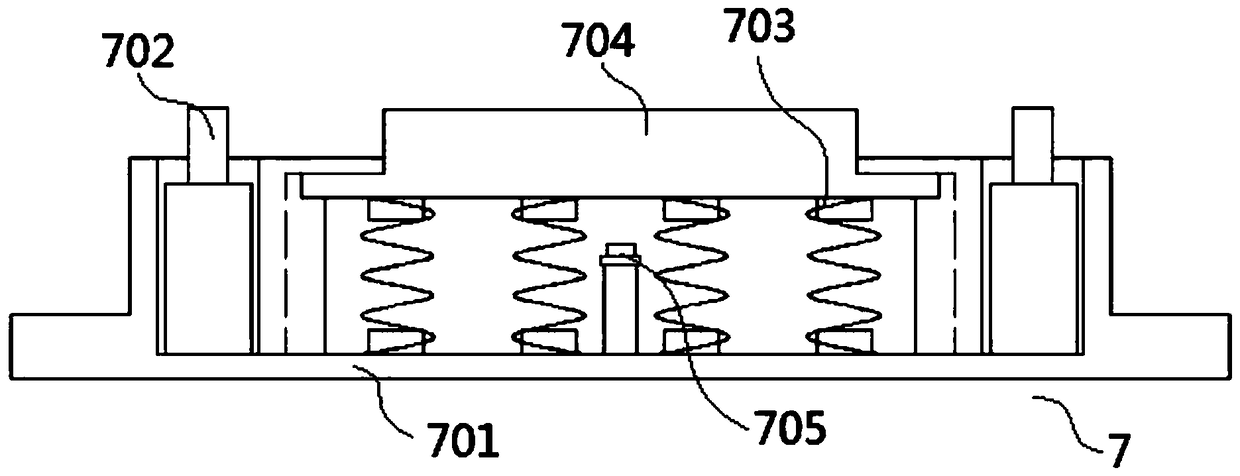

Automatic detecting and press-fitting device for automobile accessory gearbox

ActiveCN107052768AImprove pressing qualityAccurate detectionMachine gearing/transmission testingMaterial strength using tensile/compressive forcesEngineeringSupport plane

The invention relates to the technical field of gearboxes for automobile accessories, in particular to an automatic detecting and press-fitting device for an automobile accessory gearbox. The automatic detecting and press-fitting device comprises a base frame, a worktable, a guide rail, a bottom plate, a die seat, a fixing plate, a supporting frame, a lifting air cylinder, a pressing plate, a detection display, a pressure-resisting detector, a sealing detector and a controller. During use, the gearbox is firstly put on the die seat, and a shaft sleeve is arranged in a device hole of a pressing block; afterwards, the bottom plate and the die seat move to the position below the pressing plate, and then the lifting air cylinder is driven to descend downwards to press the pressing block so that the shaft sleeve can be pressed into a connecting hole of a base; and meanwhile, the pressure-resisting detector is used for conducting pressure-resisting detection on the base, a sleeve and a connecting seat, and sealing detection is conducted on the sleeve through the sealing detector. Thus, shaft sleeve press-fitting and pressure-resisting and sealing detection can be automatically completed at a time, in addition, the press-fitting quality is good, detection is accurate, operation is simple, and the work efficiency is high.

Owner:CIXI SANPEI MACHINE

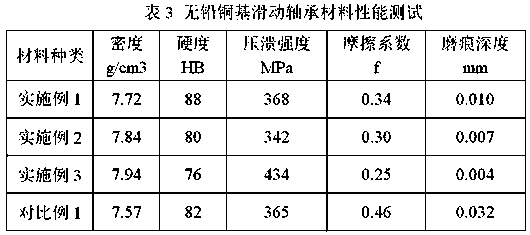

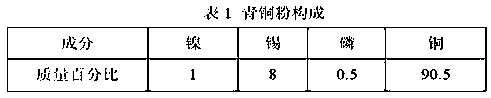

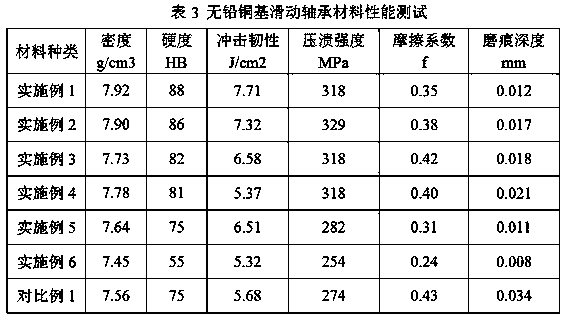

High-strength antifriction lead-free copper-based sliding bearing material

InactiveCN108277379AImprove the phenomenon of easy reunionResolve inhalationCopper atomChemical reaction

The invention discloses a high-strength antifriction lead-free copper-based sliding bearing material. A ball milling process is adopted to enable copper powder, iron powder and copper sulphide powderto be mechanically alloyed, and CuS and Fe mixed powder can generate superfine particle nanocrystalline FeS in a high-energy guide-in manner through a mechanically induced chemical reaction. The reaction in situ composite process is used for solving the problems that enhanced particles are added externally, air suction and wettability are poor, and the interface combination is poor; meanwhile, through the ball milling process, the phenomenon that when ferrous sulfide is directly added, agglomeration is easily caused is avoided; in the ball milling process, the other part of Fe atoms is added into copper atoms in a solid solution manner so as to achieve the solid solution reinforcing effect, and the copper base composite is reinforced. The antifriction and anti-sticking capacity of FeS is mainly used for replacing lead in the original copper base bearing material, lead pollution is avoided, meanwhile, through Fe solid solution, the copper-based sliding bearing material is reinforced, and effective unifying of high strength and good lubricating characteristics of the lead-free copper-based sliding bearing material is achieved.

Owner:HEFEI UNIV OF TECH

Thrust wheel floating oil seal press-fitting machine

InactiveCN104191207AImprove assembly efficiencySo as not to damageMetal working apparatusEngineeringMechanical engineering

The invention discloses a thrust wheel floating oil seal press-fitting machine and belongs to the field of tool equipment production. The thrust wheel floating oil seal press-fitting machine structurally comprises a worktable, a rack, an air cylinder, a fixed press head and a movable press head. The worktable is arranged on the lower portion on the inner side of the rack, an air cylinder body is fixed to one side of the rack, an air cylinder rod extends to the upper side of the worktable in the rack, the movable press head is fixed to the end of the air cylinder rod, the fixed press head is fixed to the other side of the rack, and the fixed press head and the movable press head are arranged oppositely and coaxially and are provided with oil seal positioning parts. Compared with the prior art, the thrust wheel floating oil seal press-fitting machine has the advantages of being convenient to operate, high in assembling efficiency and the like, and has good application and popularization value.

Owner:济宁金牛重工有限公司

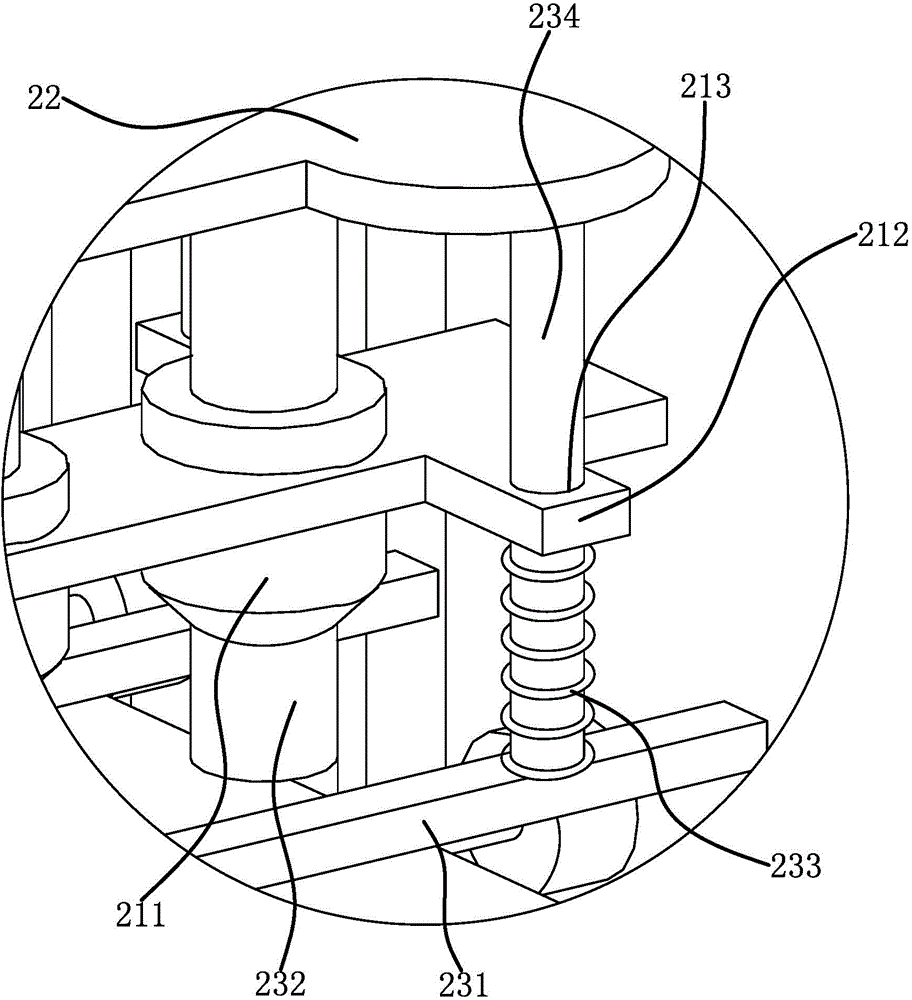

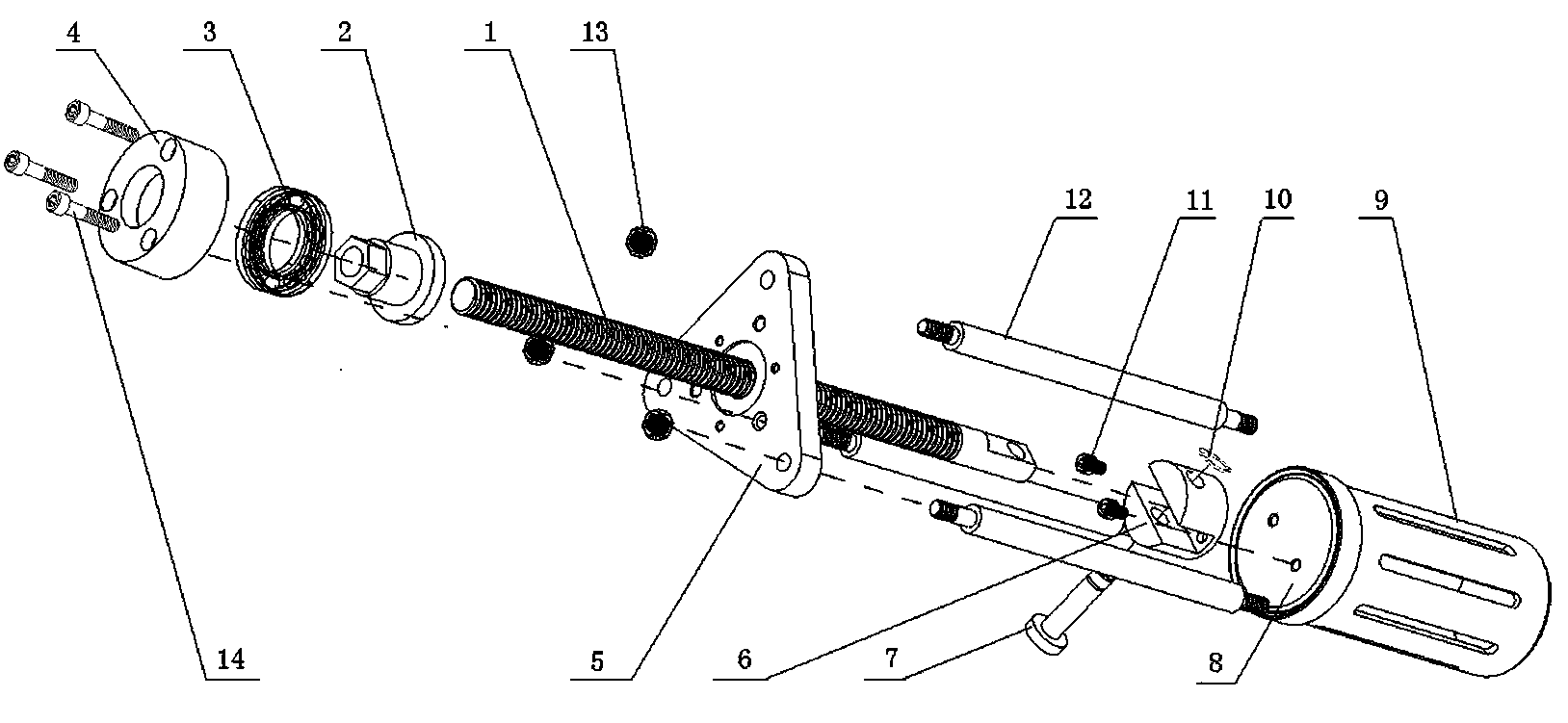

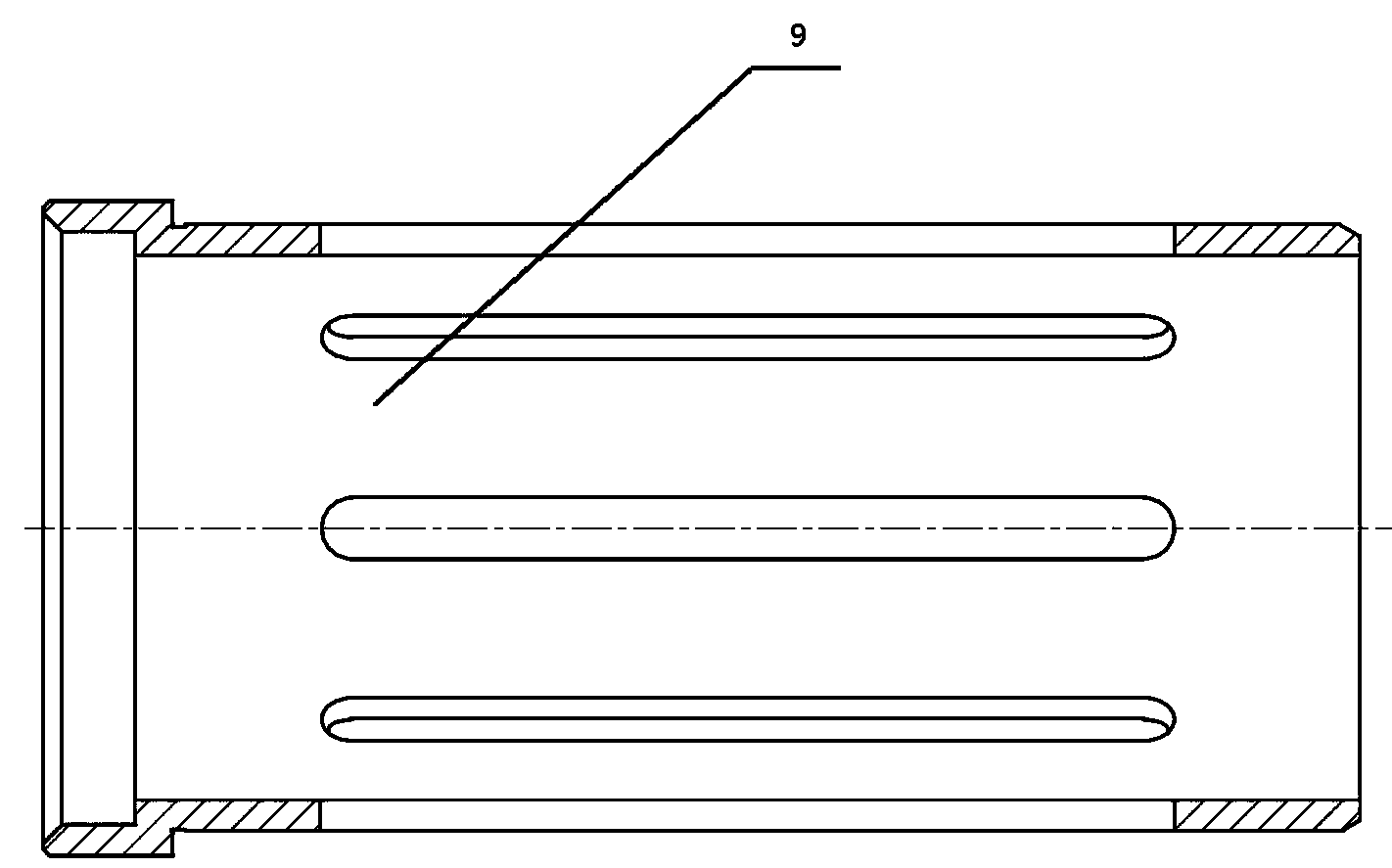

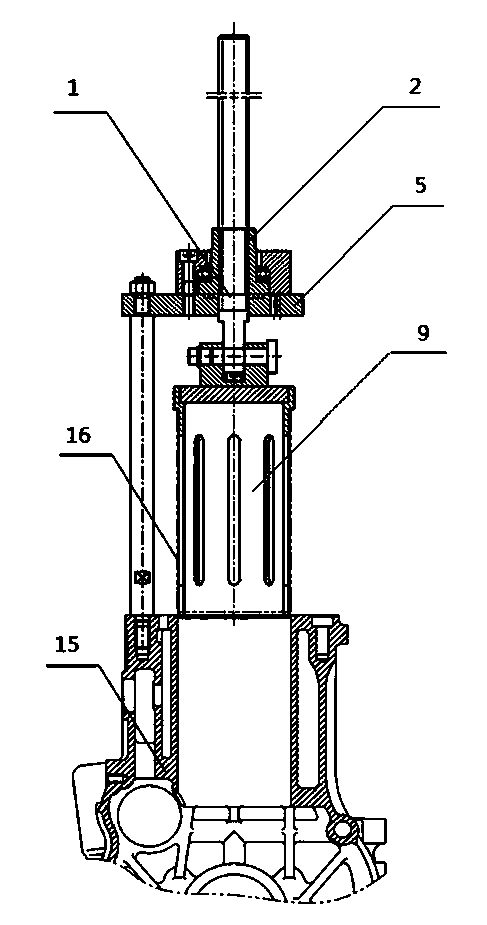

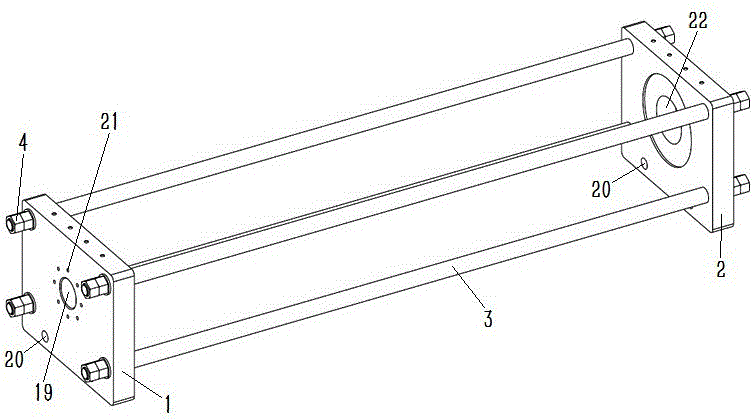

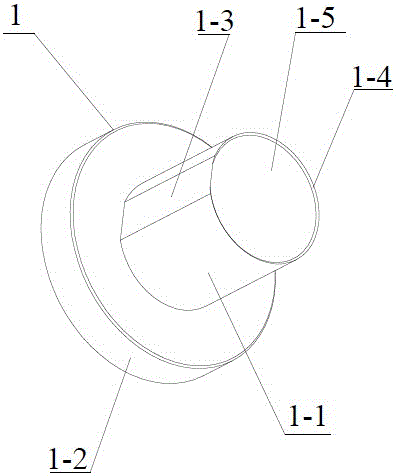

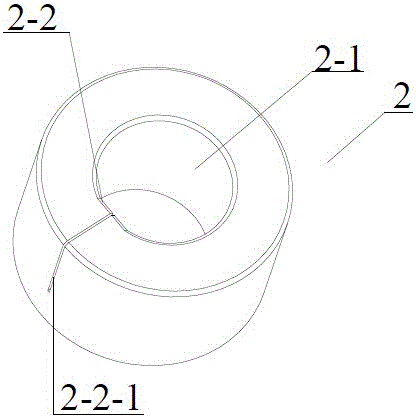

Press fitting tool for thin-walled cylinder sleeve

ActiveCN103481236AImprove press qualitySmall deformation of cylinder linerMetal-working hand toolsThin walledEngineering

The invention discloses a press fitting tool for a thin-walled cylinder sleeve. The press fitting tool comprises a pressing rod, a supporting plate combination piece, a plurality of supporting rods and a pressing head and sleeve assembly, wherein the pressing rod is in the shape of a threaded shaft; the pressing head and sleeve assembly is barrel-shaped; one end of the pressing head and sleeve assembly is closed; the other end of the pressing head and sleeve assembly is provided with an opening; the supporting plate combination piece is sleeved on the pressing rod; one end of the pressing rod is fixedly connected with the closed end of the pressing head and sleeve assembly; the supporting plate combination piece comprises a bearing pressing plate, a thrust ball bearing, a bearing nut and a supporting plate; and the pressing head and sleeve assembly comprises a pressing head and a sleeve. The press fitting tool has the advantages that press fitting of the cylinder sleeve can be quickly and effectively finished under the condition that an engine is not required to be detached from a whole machine, the press fitting quality is high, the degree of deformation on the cylinder sleeve is low, and the requirement on the quality of the cylinder sleeve after press fitting can be met completely; and an operation process is convenient, and the working efficiency is greatly improved.

Owner:ANHUI QUANCHAI ENGINE

Automatic stamping machine applied to garment production

ActiveCN105200750ASimple structureStrong targetingIroning apparatusTextiles and paperEngineeringAutomation

The invention discloses an automatic stamping machine applied to garment production. The automatic stamping machine comprises a machine frame and a machine frame table top, wherein a conveying device and a stamping device are arranged on the machine frame table top; the conveying device transversely passes through the whole machine frame table top and comprises a conveying table; a stamping support plate is arranged on the conveying table; the stamping device is positioned in the middle of the machine frame table top, and comprises a stamping frame and a stamping mechanism; the stamping frame comprises a stamping transverse frame and a stamping vertical frame; the stamping vertical frame is fixedly arranged on the machine frame table top; the stamping transverse frame is connected with the stamping vertical frame; the stamping mechanism is arranged on the stamping vertical frame, and comprises a stamping assembly and a stamping seat; a buffer mechanism is arranged between the stamping assembly and the stamping seat; the upper end of the stamping seat is provided with a sliding mechanism and a stamping transmission mechanism; the sliding mechanism is positioned on the stamping vertical frame; the stamping transmission mechanism is positioned on the stamping transverse frame. The automatic stamping machine has the advantages that the structure is simple; scientificity and convenience are realized; the pertinency is high; the automation degree is high; the cloth stamping problem is well solved.

Owner:浙江新月朗服饰股份有限公司

Wiring terminal contact pin press-fitting device and method

InactiveCN112164952AGuaranteed accuracyAvoid fixed situationsLine/current collector detailsMechanical engineeringBackplane

Owner:董存清

Press fitting equipment for rubber bushing

InactiveCN103831623APrevent deviationAvoid wrong loadingOptical detectionMetal working apparatusIdentification deviceEngineering

The invention relates to press fitting equipment for a rubber bushing. The press fitting equipment comprises a lower clamp used for fixing a work-piece, an upper clamp matched with the lower clamp, arranged above the lower clamp and used for pressing the bushing into the work-piece, a driving device pushing the upper clamp to move vertically, a neglected-installation-preventing detection device arranged on one side of the upper clamp and used for detecting the bushing inside the upper clamp, and an automatic identification device arranged on one side of the lower clamp and used for identifying the type of the lower clamp. The lower clamp comprises a supporting column fixing the work-piece. The upper clamp comprises a second base plate and a pressing rod towards the second base plate. The second base plate is provided with a locating clamp matched with the supporting column and used for arranging the bushing. A containing cavity which penetrates through the locating clamp and is used for containing the bushing is formed in the locating clamp. The pressing rod can extend into the containing cavity and press the bushing in the containing cavity into the work-piece. According to the press fitting equipment, deflection of the bushing in the press fitting process is prevented, mistaken installation and neglected installation are prevented, and the overall work efficiency and the press fitting quality can be improved.

Owner:SIP GOLDWAY TECH

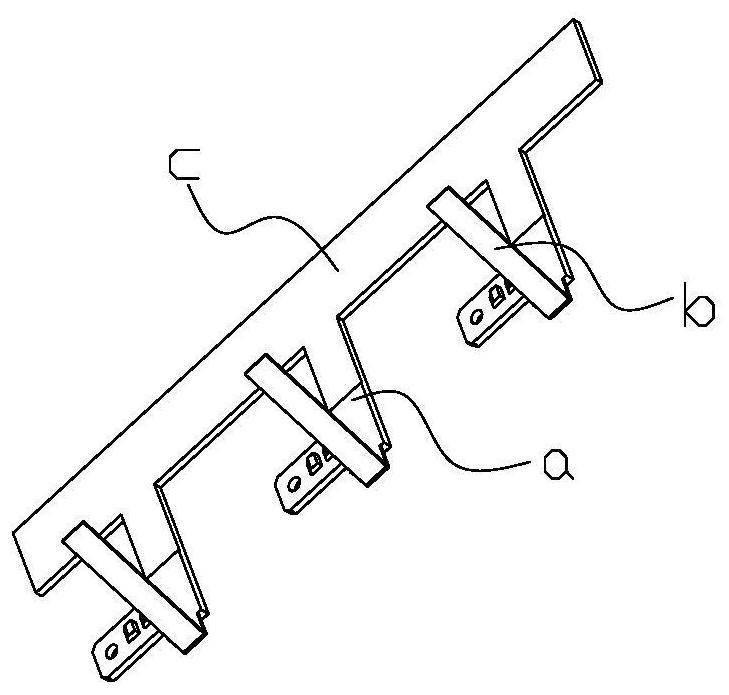

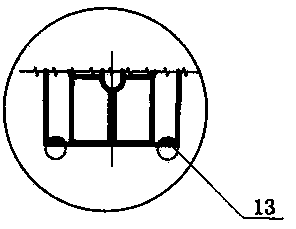

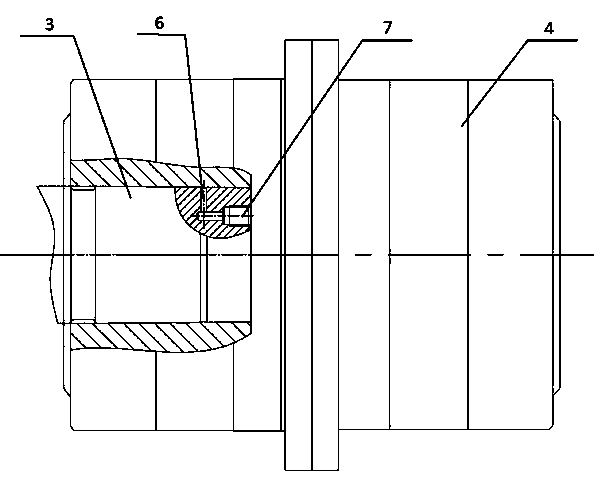

Device and method for assembling steelwire snap ring in piston

ActiveCN104175103AAvoid scratchesImprove assembly qualityMetal working apparatusEngineeringMechanical engineering

The invention provides a device and a method for assembling a steelwire snap ring in a piston. The device is characterized by comprising a taper sleeve and a feeding mechanism capable of feeding the steelwire snap ring into the taper sleeve; a center pin and an elastic pressure head are arranged above the taper sleeve and can move up and down relative to each other; a fixed seat for placing a piston and supporting a piston connecting rod is arranged below the taper sleeve; a downward jacking rod which can move up and down and clasp the steelwire snap ring together with a piston pin is arranged in the fixed seat. According to the invention, the inner wall of the piston hole is effectively prevented from being scratched by the tension function of the steelwire snap ring, so that good assembly quality is guaranteed, the device is basically suitable for assembling all steelwire snap ring parts, and is low in cost, strong in practicability and high in press-mounting quality.

Owner:COMAU SHANGHAI ENG

IGBT series crimping packaging unit and DC circuit breaker with same

ActiveCN106298756AGuaranteed pressing effectImprove pressing qualitySolid-state devicesSemiconductor devicesDc circuit breakerFlange

The invention provides an IGBT series crimping packaging unit and a DC circuit breaker with same. The IGBT series crimping packaging unit comprises a supporting frame and an IGBT valve string. The end of the IGBT valve string on the supporting frame is provided with a crimping stress cone. The supporting frame comprises a first flange plate which is next to the end of the crimping stress cone. The first flange plate is in threaded connection with a pressure adapter which forms a lead screw nut mechanism with the first flange plate. The pressure adapter is provided with a through hole for passing of a pushing rod of the crimping stress cone. The pressure adapter has a crimping end which matches the crimping stress cone. The IGBT series crimping packaging unit and the DC circuit breaker are advantageous in that the pressure adapter is in threaded fit with the first flange plate, thereby realizing precise inward movement of the IGBT series crimping packaging unit on the first flange plate through rotation of the pressure adapter until a clearance is precisely filled, thereby ensuring total consistency between an applied pressure and a kept pressure, realizing precise control on a crimping force, ensuring high crimping effect and improving crimping quality.

Owner:PINGGAO GRP +3

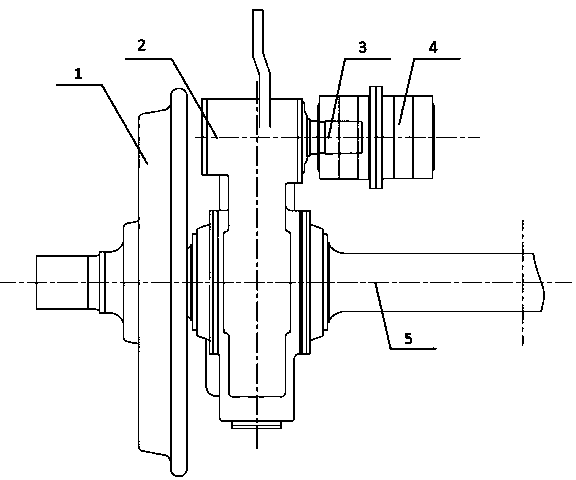

Driving gear shaft for gearbox

InactiveCN102852959AImprove pressing qualityAvoid slack problemsShaftsGear lubrication/coolingCouplingGear wheel

The invention discloses a driving gear shaft for a gearbox. In order to solve the problems that relaxation is generated between a driving gear shaft and a coupling when a gearbox of the conventional urban mass transit vehicle works and the matching surface is scratched in the process of mounting and dismounting the coupling, the shaft end face of the driving gear shaft for the gearbox is provided with an oil injection hole; an oil groove communicated with the oil injection hole is formed in the outer circumferential surface of the driving gear shaft; a spiral oil groove is formed in the outer circumferential surface of the driving gear shaft; and the spiral oil groove is communicated with the oil groove. The spiral oil groove is machined in a matching part of the gear shaft and the coupling, the press fitting quality of the coupling is greatly improved, the possible problem of relaxation between the coupling the driving gear shaft is solved, and the phenomenon that no scratch exists between the matching surfaces is ensured in the process of detaching the coupling.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

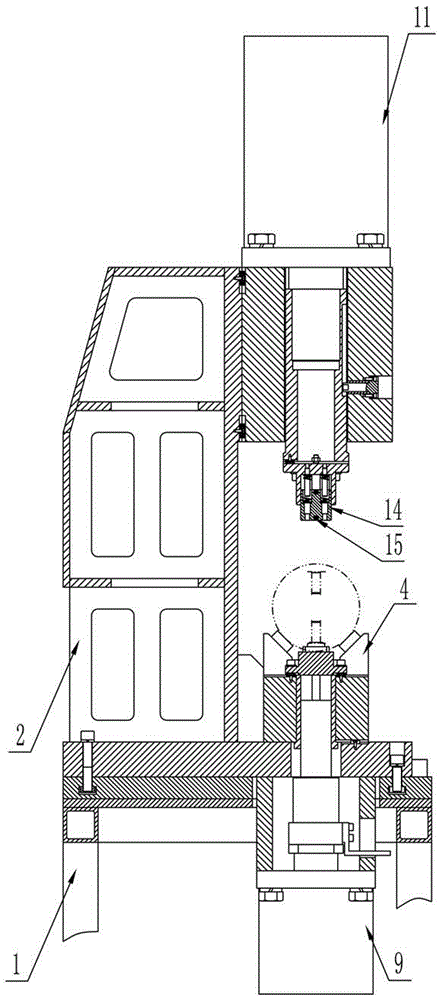

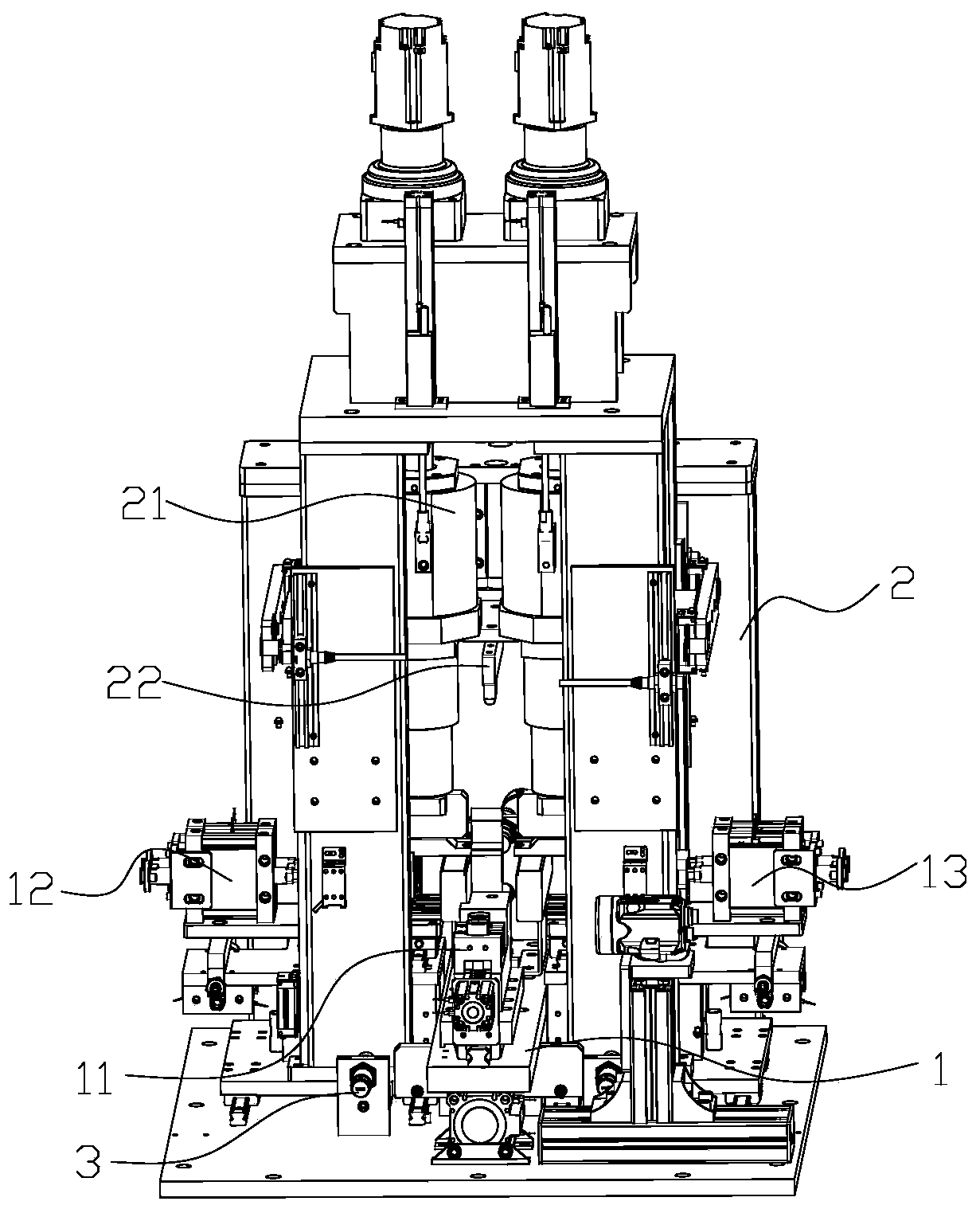

Press fitting device for shaft head and intermediate section of rear axle housing assembly of car

PendingCN110253266AGood automatic centering functionGuaranteed pressing depthMetal working apparatusHeating systemEngineering

The invention discloses a press fitting device for a shaft head and an intermediate section of a rear axle housing assembly of a car. The device comprises a lathe bed, a longitudinal sliding rail, a tray assembly, two pressing head assemblies, two hydraulic cylinders, two freezing systems and a heating system, wherein each pressing head assembly comprises a pressing head supporting seat and a sliding supporting seat; a pressing head and a positioning half ring are arranged on each pressing head supporting seat; a supporting half ring and a stroke fixing part are arranged at the upper part of each sliding supporting seat; the tray assembly comprises a lower tray, an upper tray, a supporting frame, two fixing brackets and four tray surface positioning blocks; positioning blocks are arranged on the fixing brackets; and a mandrel centering mechanism is arranged between the lower tray and the upper tray. With the adoption of the device, all press fitting technology processes of the shaft head can be performed; the operation is convenient; the press fitting efficiency is high; the accuracy is high; and the automation degree is high.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

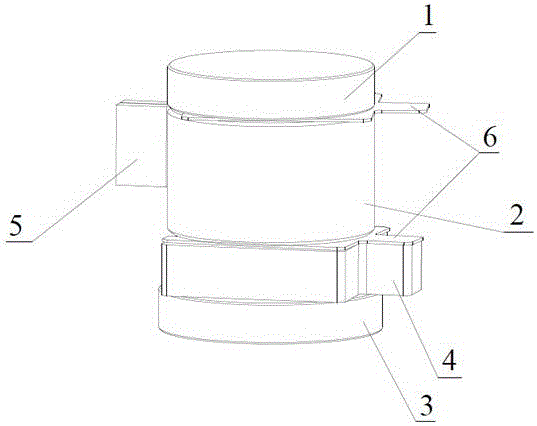

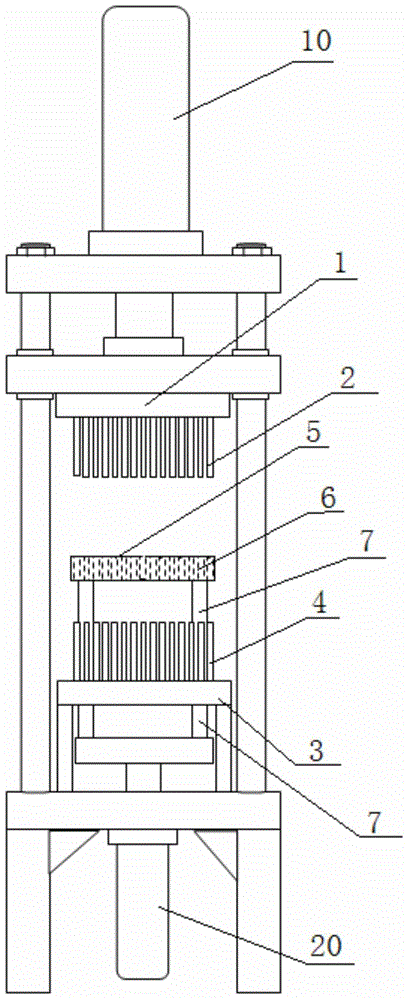

Special forming mold for circular tantalum core of tantalum capacitor and using method thereof

InactiveCN106611655ASimple structureImprove pressing qualityCapacitor manufactureManufacturing technologyTantalum capacitor

The invention discloses a special forming mold for the circular tantalum core of a tantalum capacitor and a using method thereof in order to solve the technical problem that most of the tantalum cores formed by the existing forming mold are of a long and thin cylindrical structure and a circular tantalum core cannot be formed using the existing forming mold is solved. The forming mold comprises an upper convex mold, a concave mold, a lower convex mold, an adjusting cushion block, a tantalum wire limiting block, and adjusting gaskets. The adjusting cushion block matches the lower convex mold. The concave mold matches the lower convex mold. The concave mold and the lower convex mold constitute a semi-closed circular forming cavity. Tantalum powder is poured into the semi-closed circular forming cavity, and a tantalum wire is placed on the tantalum powder. The tantalum wire limiting block is used for limiting the tantalum wire. After the tantalum wire is limited, tantalum powder is poured into the cavity. The upper convex mold matches the concave mold. The upper convex mold, the concave mold and the lower convex mold constitute a closed circular forming cavity to form a circular tantalum core through pressing. Adjusting gaskets of appropriate size can be selected according to the size of a tantalum core to realize layered pressing. The special forming mold for the circular tantalum core of a tantalum capacitor has the advantages of simple structure, good pressing quality, good batch consistency, convenient de-molding, and the like, and has a wide application prospect in the technical field of electronic component production and manufacture.

Owner:长春维鸿东光电子器材有限公司

Novel high-temperature-resistant magnesia carbon brick and manufacturing process thereof

The invention discloses a novel high-temperature-resistant magnesia carbon brick which is prepared from the following raw materials in parts by weight: 8-15 parts of crystalline flake graphite powder, 65-80 parts of fused magnesia granules, 2-4 parts of an additive, 6-10 parts of mullite powder, 1-3 parts of a binder and 5-12 parts of water. Magnesia carbon brick raw materials are put into a pressing mold box; a magnesia carbon brick blank is obtained through mechanical pressing forming; fireproof paint is smeared on the counter-fire face of the magnesia carbon brick blank through a paint roller, specifically, the pressing mold box is aligned with a vertical discharging box after rotating by 90 degrees; a mold box bottom plate and the paint roller are pushed out at the same time through a driving air cylinder; the die box bottom plate pushes the magnesia carbon brick blank into the vertical discharging boxl and the coating roller just smears the fireproof coating on the counter-fire face of the magnesia carbon brick blank in the process that the pressing die box moves backwards to be reset. In the whole process from compression molding to final drying and roasting of the magnesia carbon brick blank, manual work or a machine is prevented from making contact with the surface of the magnesia carbon brick blank, and the quality of the magnesia carbon brick blank is improved.

Owner:CHANGXING HONGFENG CHARGING

Central axle housing and semi-axial casing pipe assembly positioning pin pressing machine

PendingCN106624731AGuaranteed pressing accuracyUniform and stable pressureVehicle componentsMetal working apparatusHydraulic cylinderPiston rod

The invention provides a central axle housing and semi-axial casing pipe assembly positioning pin pressing machine. The pressing machine includes a rack; a bed is arranged on the rack; the bed and the rack are slidingly connected; a positioning mechanism and a pressing mechanism are arranged on the bed; the positioning mechanism includes an axial positioning mechanism and a radial positioning mechanism; the radial positioning mechanism includes two V-shaped positioning plates; the axial positioning mechanism includes a thin oil cylinder and an axial limiting plate, and the thin oil cylinder is horizontally fixed; a push rod is arranged on a piston rod of the thin oil cylinder; the push rod and the axial limiting plate are arranged coaxially; the pressing mechanism includes a first hydraulic cylinder, a second hydraulic cylinder, a third hydraulic cylinder, and a fourth hydraulic cylinder; the first hydraulic cylinder and the second hydraulic cylinder are vertically arranged on the lower end of the bed; the third hydraulic cylinder and the fourth hydraulic cylinder are vertically arranged on the upper end of the bed; the fourth hydraulic cylinder and the second hydraulic cylinder are arranged correspondingly; the third hydraulic cylinder and the first hydraulic cylinder are arranged correspondingly; lower positioning sleeves are arranged on piston rods of the first hydraulic cylinder and the second hydraulic cylinder; and upper positioning sleeves are arranged on piston rods of the third hydraulic cylinder and the fourth hydraulic cylinder. The pressing machine is good in pressing quality, can reduce the working intensity of workers, and can improve the assembly efficiency.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

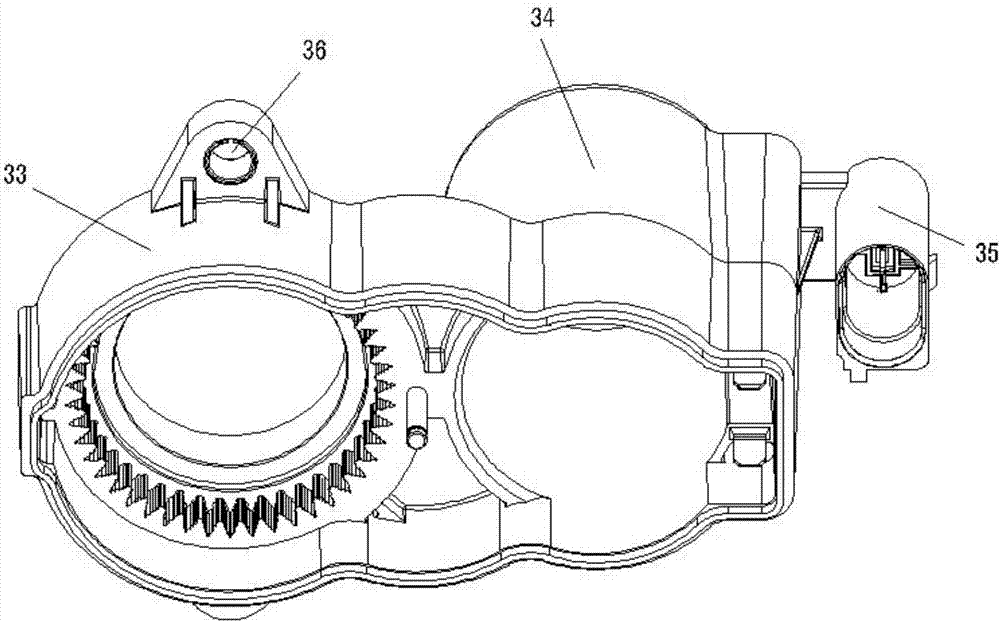

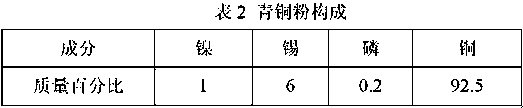

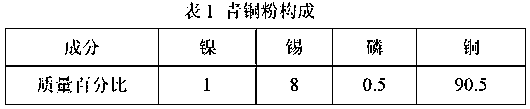

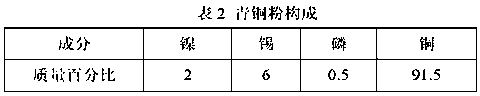

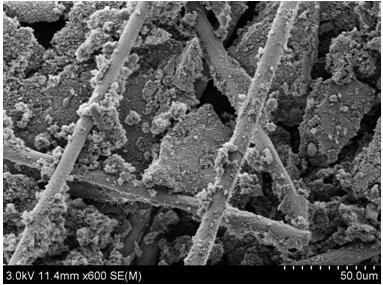

Antifriction lead-free copper-based sliding bearing material and preparation method thereof

InactiveCN108486404AImprove friction and wear propertiesAchieve lead-freeShaftsBearing componentsWear resistantBronze

The invention discloses an antifriction lead-free copper-based sliding bearing material and a preparation method thereof. The ferrous sulfide powder, the bismuth powder and the bronze powder are subjected to mechanical alloying by adopting a ball milling technology to improve the interface adhesive strength of the ferrous sulfide, the bismuth and the bronze, and the phenomenon that the ferrous sulfide is easy to agglomerate when the content of copper matrix is relatively high is improved, the structure of FeS is good in oil storage capacity, the stability of the liquid-solid lubricating film is enabled to be good, so that the process of Bi spalling, the fusion of the low-melting-point component Bi and separating out of the low-melting-point component Bi are relieved, and the liquid-solid lubricating film can also be repaired and completed, so that the antifriction performance of the material is improved; in conclusion, the antifriction and wear-resistant properties of the copper-basedsliding bearing material are improved, the lead which is used as a lubricant in the copper-based bearing material is replaced by the good synergistic effect of the ferrous sulfide and the bismuth, sothat the pollution of lead is avoided; and the antifriction lead-free copper-based sliding bearing material and the preparation method thereof have the advantages of being low in cost and suitable forindustrial production.

Owner:HEFEI UNIV OF TECH

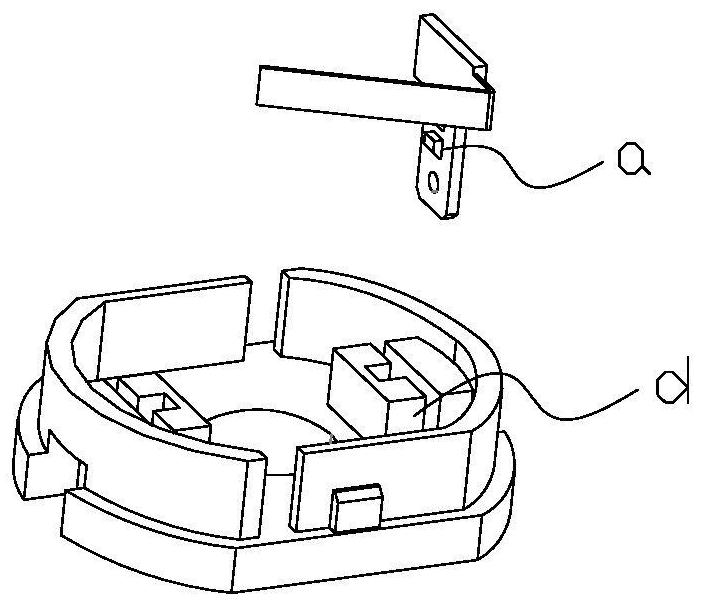

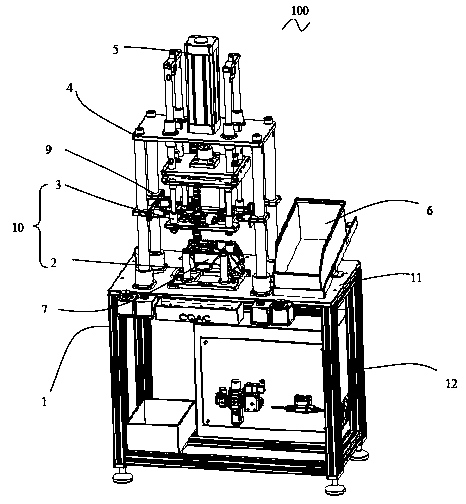

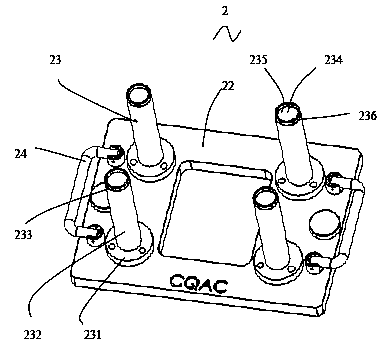

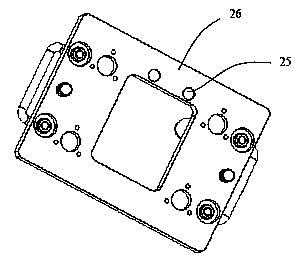

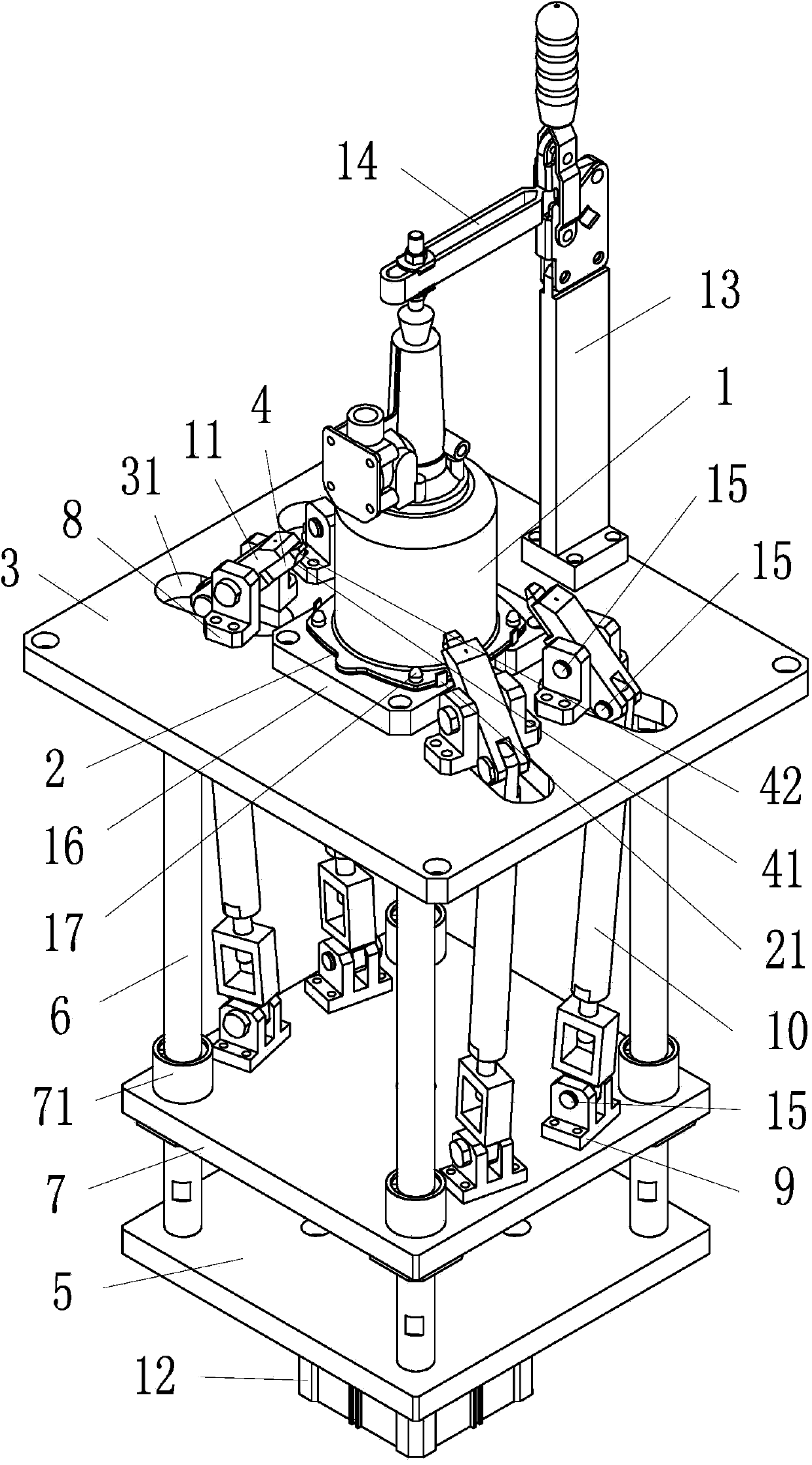

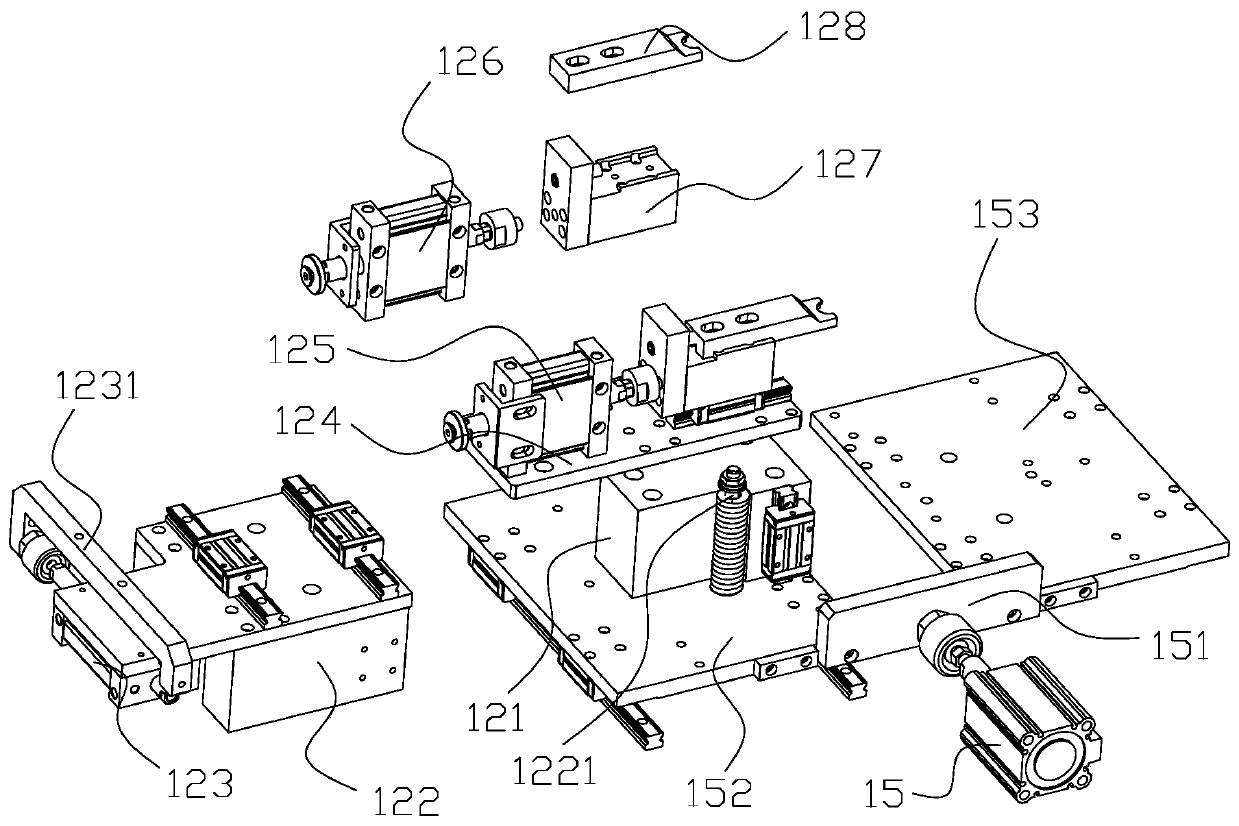

Pressing fitting device of shell of clutch booster

The invention relates to the field of assembly of clutch boosters and aims to provide a pressing fitting device of a shell of a clutch booster. The pressing fitting device of the shell of the clutch booster comprises a working table, a shell locating assembly, a shell fixedly-holding assembly and a clamping strip bending mechanism, wherein the shell locating assembly, the shell fixedly-holding assembly and the clamping strip bending mechanism are fixedly connected with the working table. When the pressing fitting device of the shell of the clutch booster is used, a shell cover 2 and a shell with parts well assembled are placed on the shell locating assembly and are fixedly held by the shell fixedly-holding assembly firstly, the clamping strip bending mechanism is started so that a clamping strip can be bent towards the inner side and tightly clamp and buckle a flange of the shell, and therefore press fitting is achieved. By the adoption of the pressing fitting device of the shell of the clutch booster, press fitting operation is easy, the press fitting efficiency is high, and the press fitting quality is high.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

Firework grain automatic pressing and shaping device

The invention discloses a firework grain automatic pressing and shaping device which comprises an upper base plate connected with an upper oil press. Multiple pressing columns are arranged on the upper base plate in a matrix manner; the firework grain automatic pressing and shaping device further comprises a lower base plate fixed on the rack; the lower base plate is provided with a plastic isolation buffer layer; a powder charging plate is arranged between the upper base plate and the lower base plate; multiple powder charging holes in matrix arrangement are formed in the powder charging plate; the pressing columns and the powder charging holes are arranged correspondingly; the powder charging plate is connected with the lower oil press sequentially through the connecting rod and a thrust plate. According to the firework grain automatic pressing and shaping device, an upward ejecting column is cancelled, equipment is simplified, manufacturing cost is reduced, each pressing time is shortened, and production efficiency is increased; due to the arrangement of the plastic isolation buffer layer, direct contact and pressure applying effect between the gunpowder and metal is reduced, and safety and corrosion resistance of the equipment is improved in comparison with original equipment; meanwhile, as a pressure-bearing surface with certain softness, improvement of the pressing quality of the shaped grain is benefited; the shaped grain drops automatically onto a material receiving tray rather than being swept manually, so that personal safety is ensured.

Owner:江西省江丰花炮连锁实业有限公司

Press-ironing device for garment production and capable of increasing yield

ActiveCN110804826AImprove yieldAvoidance of Laundry SituationsTextile shapingConveyor beltThreaded rod

The invention relates to the technical field of clothing, and discloses a press-ironing device for clothing production and capable of increasing yield, which comprises a base; supports are arranged onthe upper left side and upper right side of the base; each support is provided with a roller; a conveyor belt is arranged between the rollers; sliding blocks are slidably connected to the left side and right side of the upper end of the base and positioned in front of the conveyor belt; an extension rod is fixedly connected to the top of each sliding block; a locking block is fixedly mounted behind each extension rod; the rear end of each extension rod is fixedly connected with a press-holding rod; and the upper end of each press-holding rod is provided with a groove. According to the press-ironing device for garment production and capable of increasing yield, the conveyor belt rotates to drive the extension rods to partially move, the extension rods drive the press-holding rods to correspondingly move, an electromagnet is electrified to mutually repel a magnet block, and a freely adjustable threaded rod us provided, so that the manufacturing cost is saved, personal safety is protected, better press-ironing quality is ensured, and the yield is increased.

Owner:南通帝美好服饰有限公司

Transverse high-efficiency press fitting machine for automotive heat dissipator

InactiveCN108857390AEasy to fixImprove press fit accuracyAssembly machinesEngineeringMechanical engineering

The invention relates to a transverse high-efficiency press fitting machine for an automotive heat dissipator. A left press fitting air cylinder is fixedly mounted on a left supporting plate, a left slide block is slidably mounted on a left press fitting mechanism mounting rack, and a left pressure block is fixedly mounted at the right end of the left slide block; a right press fitting air cylinder is fixedly mounted on a right supporting plate, a right slide block is slidably mounted on a right press fitting mechanism mounting rack, and a right pressure block is fixedly mounted at the right end of the right slide block; a front positioning air cylinder is fixedly mounted on a front positioning plate, a front positioning block is arranged on the end part of the front positioning air cylinder, a back positioning air cylinder is fixedly mounted on a back positioning plate, a back positioning block is arranged on the end part of the back positioning air cylinder, a top plate is horizontally mounted at the top end of the back positioning plate, an upper positioning air cylinder is fixedly mounted on the top plate, and an upper positioning block is arranged on the end part of the upperpositioning air cylinder. The transverse high-efficiency press fitting machine provided by the invention is scientific and reasonable in structural design, so that a core body of the heat dissipator is stably fixed, the press fitting precision of a blanking cap and the core body of the heat dissipator and the product quality are improved, and the core bodies of the heat dissipator of different sizes can be processed by press fitting, so that the transverse high-efficiency press fitting machine is wide in application range.

Owner:TIANJIN YAXING RADIATOR

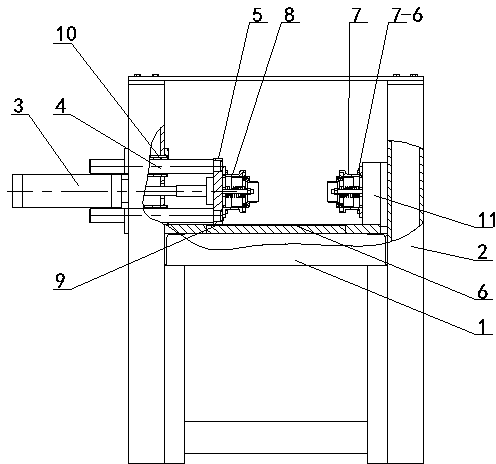

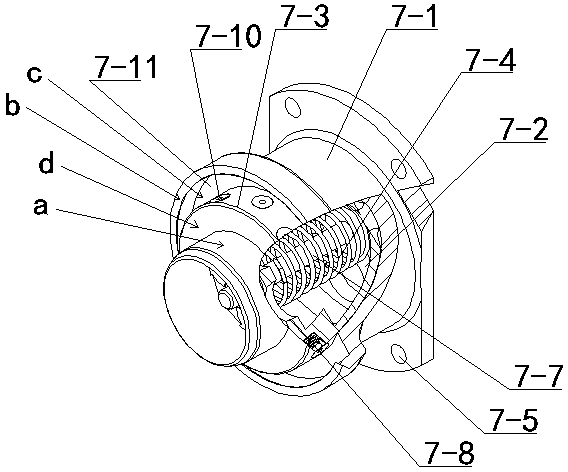

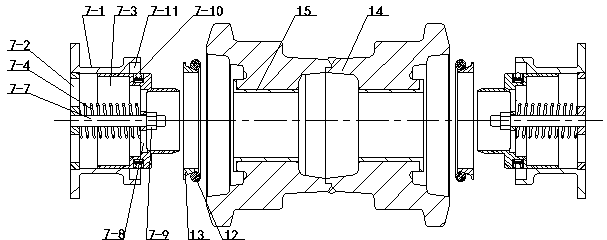

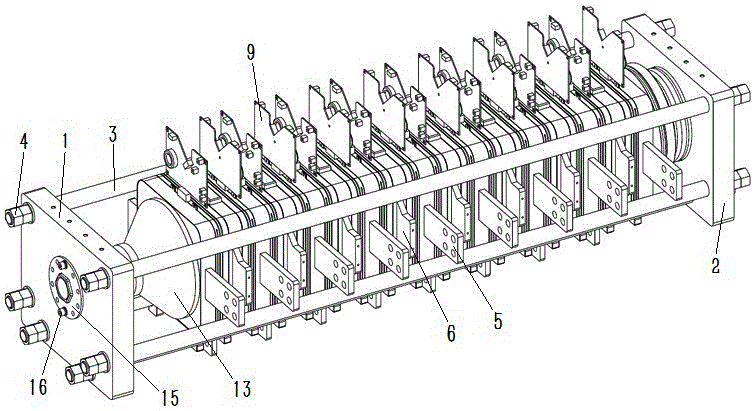

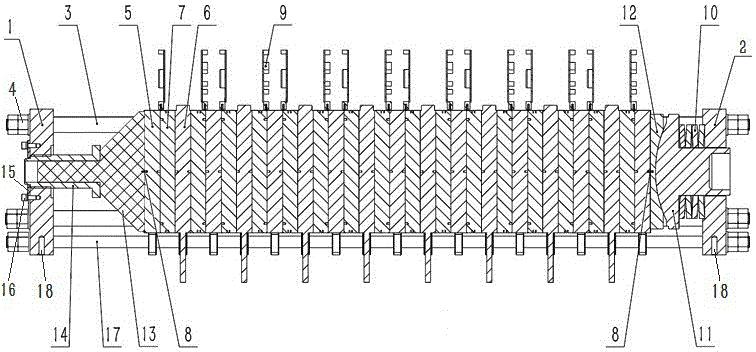

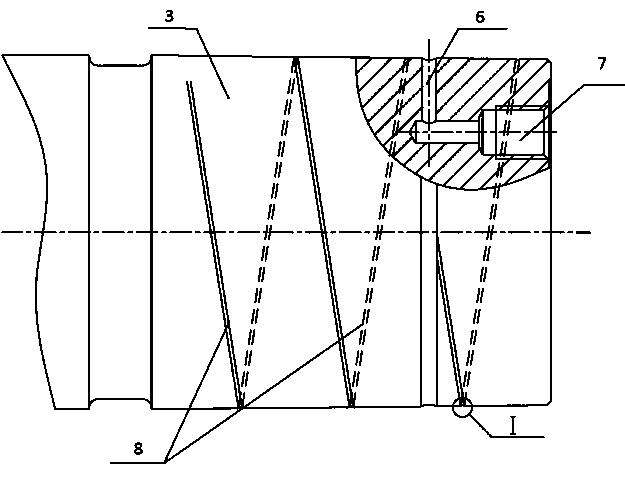

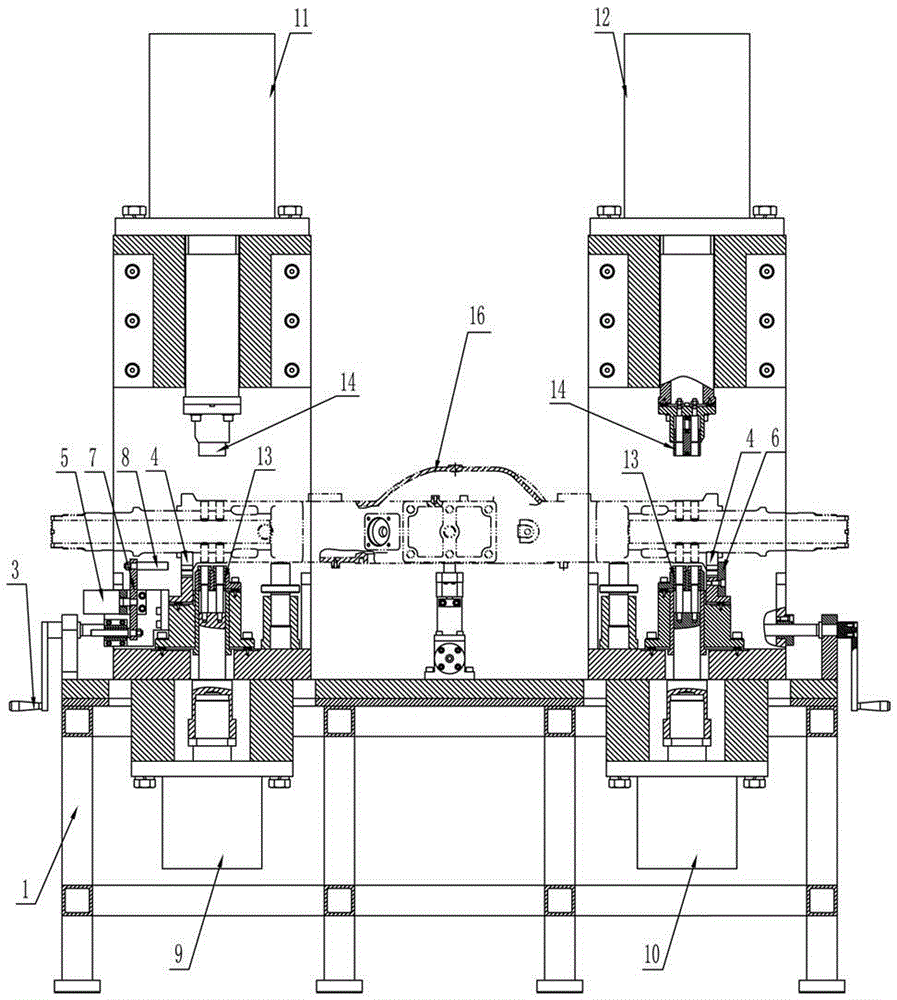

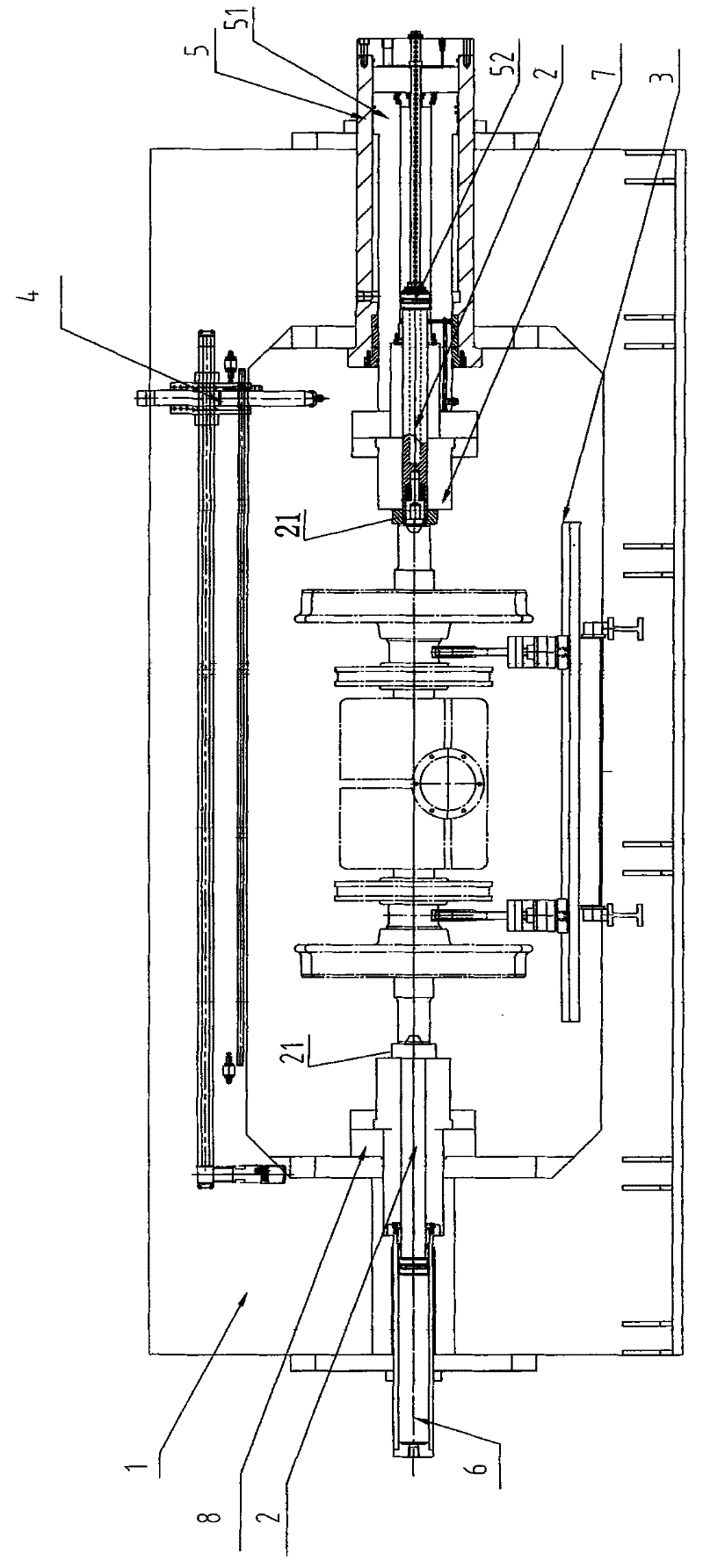

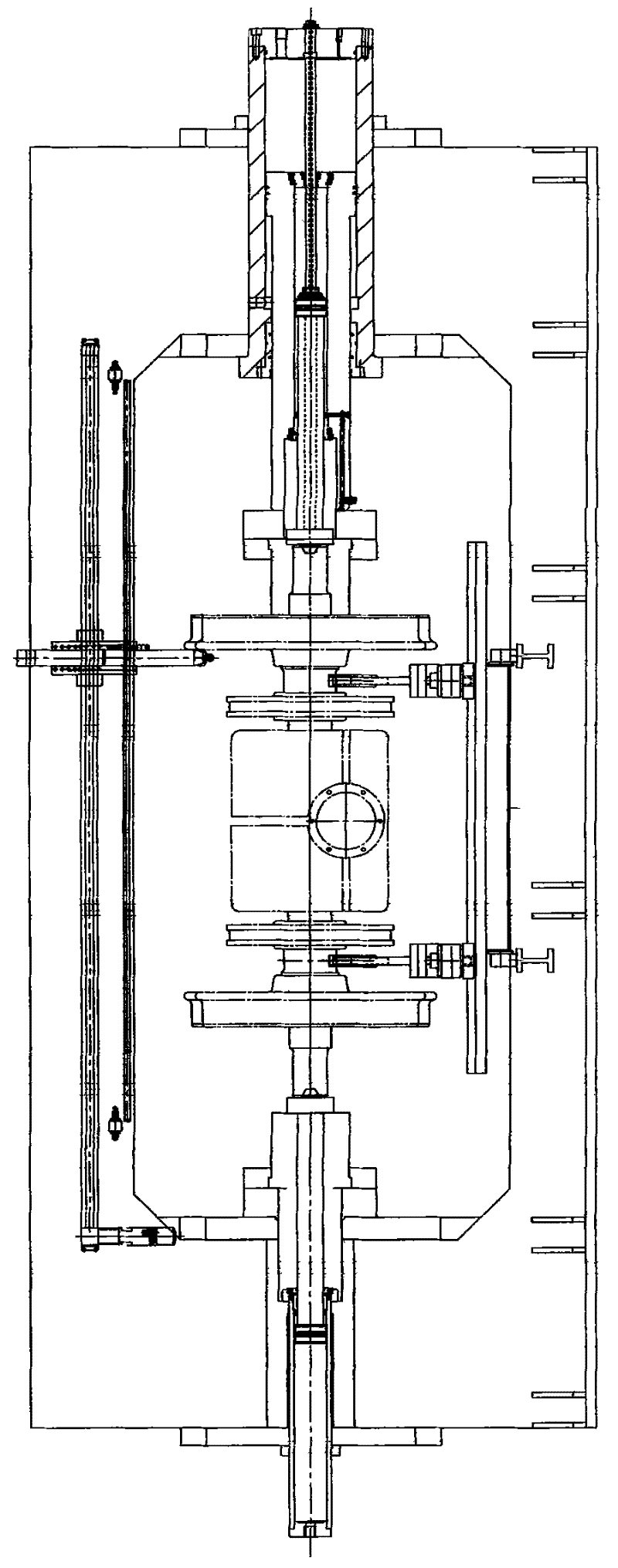

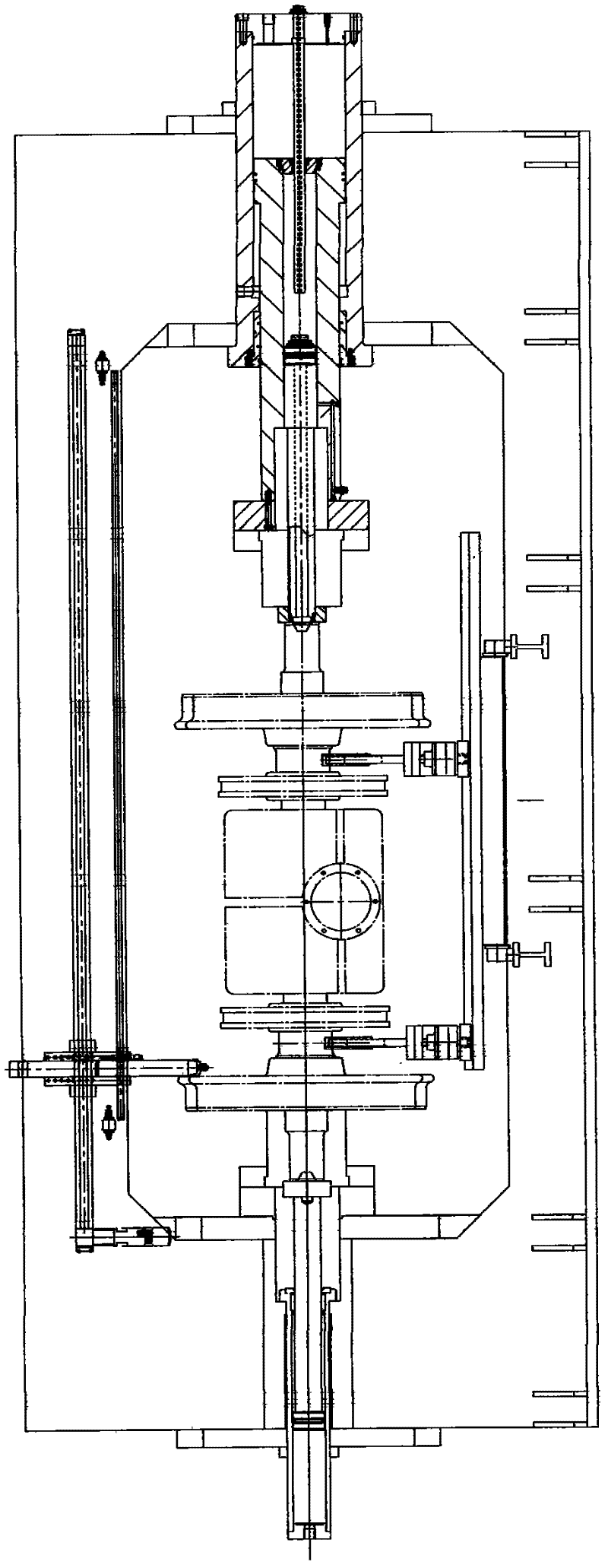

Center hole positioning wheel set press machine

ActiveCN102294580AImprove securitySimple structureMetal working apparatusLocking mechanismElectronic control system

The invention discloses a central hole positioning wheel pair press mounting machine, which comprises a machine frame, an oil tank device, thimble devices, a trolley, a detection device, a hydraulic system and an electronic control system, wherein the oil tank device, the thimble device, the trolley, the detection device, the hydraulic system and the electronic control system are axially and symmetrically arranged in the machine frame; one end of the oil tank device is provided with a main pressure oil tank; the other end of the oil tank device is provided with an auxiliary oil tank; a big piston rod is arranged in the main pressure oil tank; a small piston rod is arranged in the big piston rod; a right pressure head base is arranged on the end part of the big piston rod; a thimble deviceis arranged on the end part of the small piston rod; a thimble device is arranged on the end part of a piston rod of the auxiliary oil tank; and a left pressure head base is sleeved outside the auxiliary oil tank and is fixed on the inner side at the left of the machine frame. When the central hole positioning wheel pair press mounting machine is compared with a dual-head oil tank press mounting machine, a movable beam and an inserting plate as well as a positioning groove (hole) and a locking mechanism are eliminated, so the structure and a control part are simplified; and the auxiliary oil tank at the other end is very small, so the cost is reduced. When the central hole positioning wheel pair press mounting machine is compared with a lengthened rod and pendulum press mounting machine, press mounting is finished through central hole positioning, so a shaft and a shaft end are not damaged, and the press mounting quality and the train safety are improved.

Owner:HUBEI HEQIANG MACHINERY DEV LIMITED BY SHARE

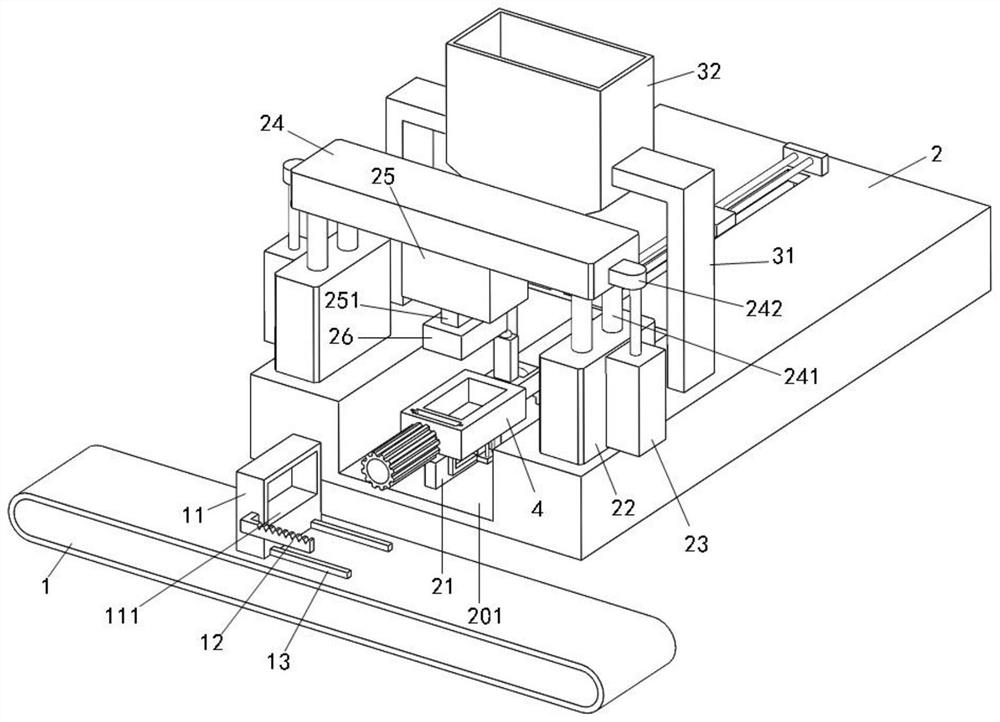

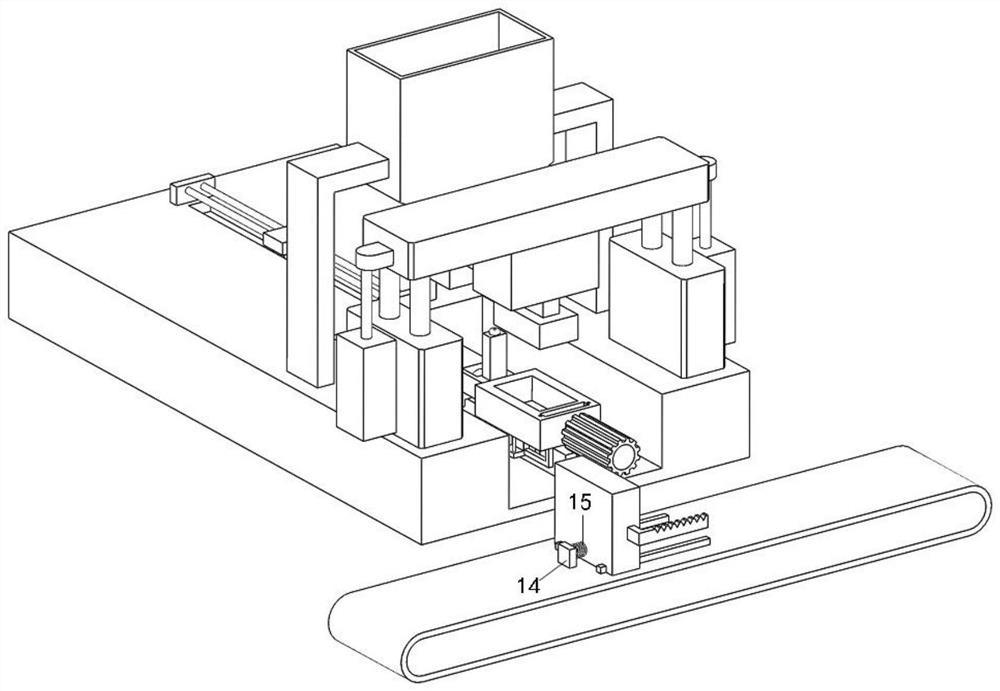

Wiring terminal, automatic press fitting device of wiring terminal, and method

InactiveCN111416258AAvoid damageImprove delivery stabilityContact member manufacturingCoupling contact membersEngineeringMechanical engineering

The invention belongs to the technical field of wiring terminal production and provides an automatic press fitting device of a wiring terminal. The device comprises a rack, a conveying and clamping device and a press fitting device, wherein the conveying and clamping device and the press fitting device are arranged on the rack; the conveying and clamping device comprises a terminal conveying assembly, a first horizontal clamping assembly and a second horizontal clamping assembly; the terminal conveying assembly is used for conveying a terminal to the position between the first horizontal clamping assembly and the second horizontal clamping assembly; and the first horizontal clamping assembly and the second horizontal clamping assembly are used for horizontally clamping the terminal. With the press-fitting device adopted, conveying stability is improved, stability in a press-fitting process is improved, the wiring terminal is e prevented from being damaged, and press-fitting quality andpress-fitting efficiency are improved.

Owner:温州源利智能科技有限公司

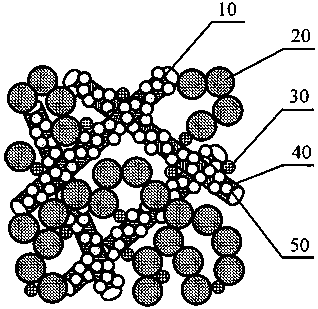

Multi-component hybrid VIP core material and preparation method thereof

ActiveCN111559902AReduce heat transferHigh strengthClimate change adaptationInsulation improvementFiberPore diameter

The invention discloses a multi-component hybrid VIP core material and a preparation method thereof, and belongs to the technical field of heat insulation materials. The multi-component hybrid VIP core material comprises 1-15 parts of chopped fibers, 20-85 parts of fused SiO2, 0-50 parts of precipitated SiO2, 0-30 parts of a siliceous heat insulation filler and 0-25 parts of an opacifier, and is prepared by preparing a fiber / powder loose mixture, preparing a multi-component hybrid VIP core material blank and preparing the finished product. The preparation method comprises the following steps:stirring materials at a high speed; heating at the temperature of 20-250 DEG C, and pressurizing at the pressure of 0.1-5 MPa to make Si-O bonds formed between the chopped fibers and SiO2 to increasethe breaking strength of the core material to 0.1 MPa or above; carrying out graded pressurization for 1-4 times; and performing pressure maintaining for 0.1-15 min to make all the materials tightly connected, reduce the pore diameter of the core material to 40-250 nm and reduce the expansion rate to 0.1-10%. The core material is very suitable for the field of vacuum heat insulation of buildings.

Owner:JIANGNAN UNIV

Pastry pressing apparatus

InactiveCN107711941AReduce labor intensityCompact structureDough-sheeters/rolling-machines/rolling-pinsDrive motorEngineering

The invention discloses a pastry pressing apparatus. The pastry pressing apparatus comprises a base, a pressing mechanism, a conveyor belt and a controller, wherein the pressing mechanism comprises apressing tube and a first compression conveyor roller group which are arranged along a conveying direction of the conveyor belt and are erected above the conveyor belt, two ends of the pressing tube are separately and rotatably erected on a stander by virtue of a stander block, the first compression conveyor roller group comprises at least one compression roller with adjustable height, and two ends of the compression roller are separately and rotatably erected on the stander by virtue of an L-shaped plate; and a control mechanism comprises the controller fixed on one side of the stander, and the controller is electrically connected with a driving motor. The pastry pressing apparatus is simple in structure, convenient to use and capable of pressing dough into pastry and greatly alleviatingthe labor intensity of operation personnel.

Owner:嘉善信息技术工程学校

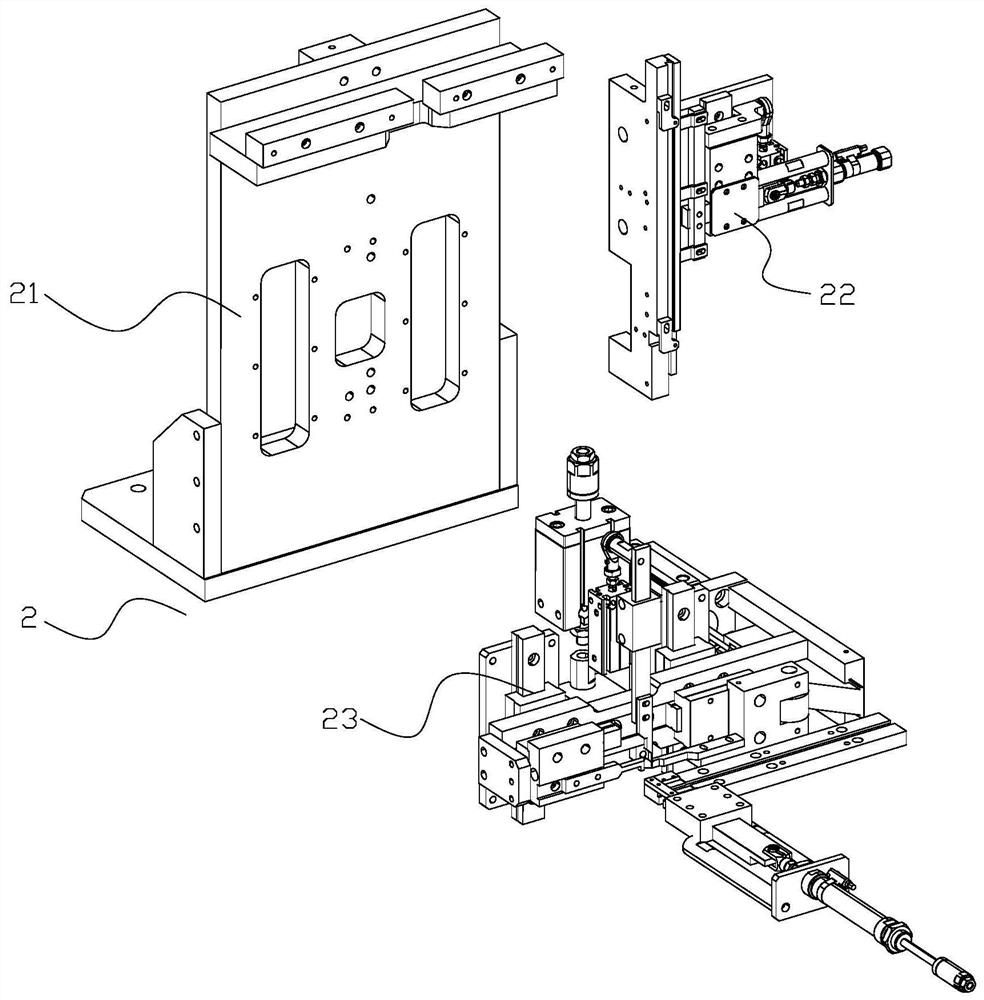

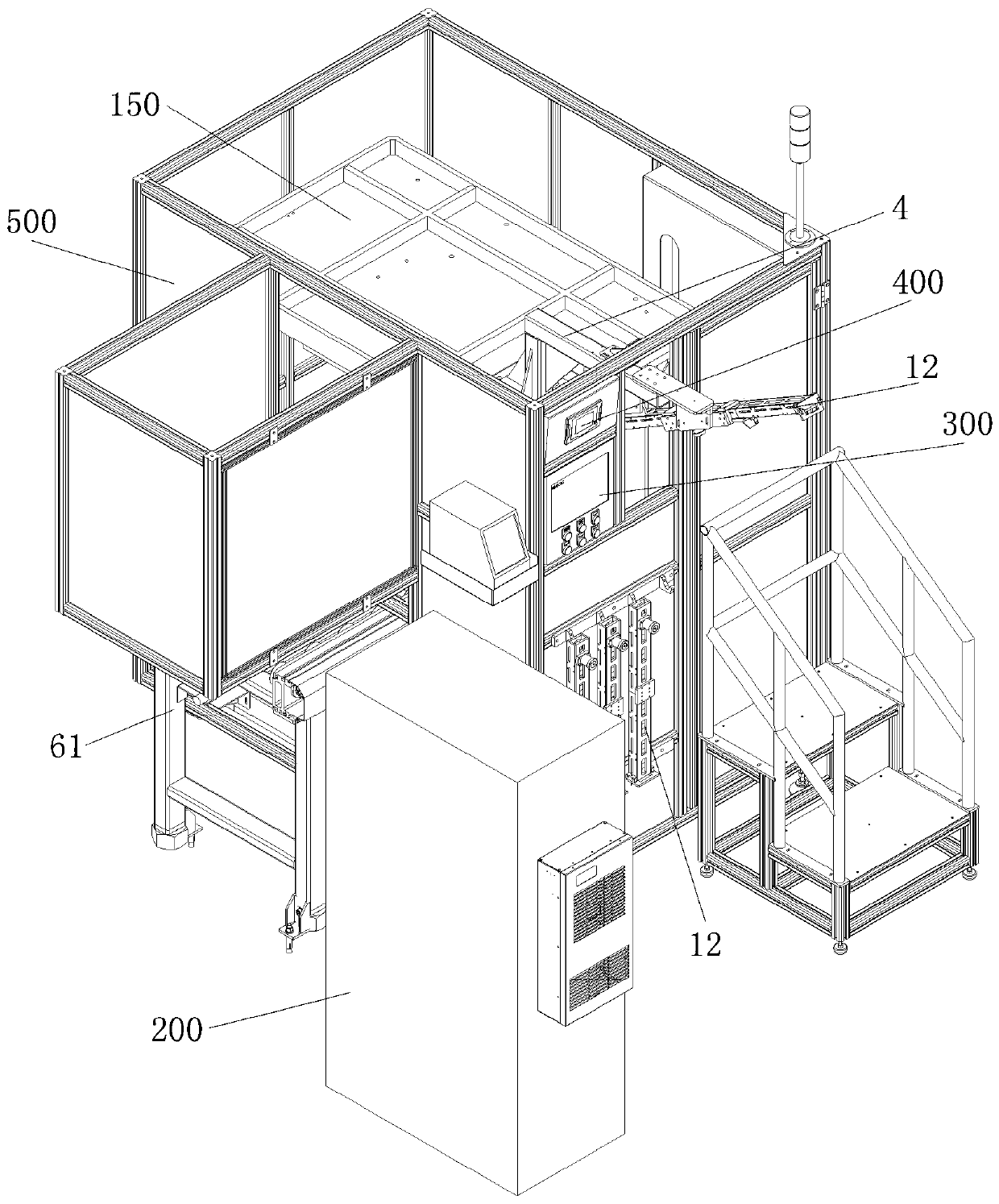

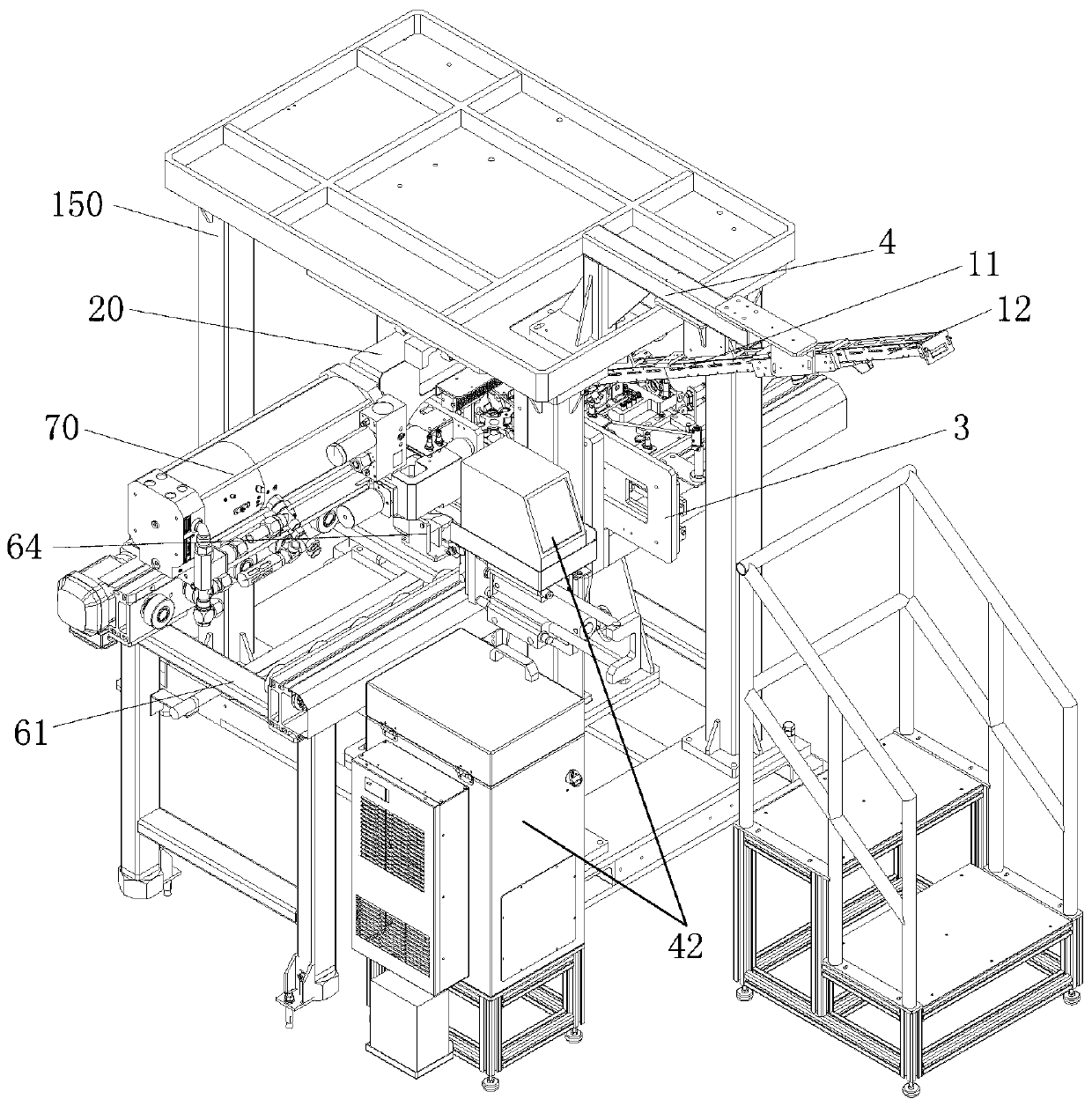

Intelligent press fitting system for water outlet pipe joint of automobile engine cylinder head

InactiveCN110977394AReduce human involvementImprove the beat of the whole lineLiquid surface applicatorsCoatingsProcess engineeringAutonomation

The invention discloses an intelligent press fitting system for a water outlet pipe joint of an automobile engine cylinder head. The intelligent press fitting system has a gluing station and a press fitting station, and the intelligent press fitting system comprises a cylinder head conveying unit, a gluing unit, a lifting mechanism, a feeding unit and a press fitting mechanism, wherein the cylinder head conveying unit is used for conveying the engine cylinder head; the gluing unit is used for automatically gluing a water outlet of the cylinder head at the gluing station, and the gluing stationis arranged on a conveying line of the cylinder head conveying unit; the lifting mechanism is used for realizing position switching of the cylinder head between the gluing station and the press fitting station; the feeding unit is used for conveying the water outlet pipe joint to a to-be-pressed position of the press fitting station; and the press fitting mechanism is used for horizontally pressing the water outlet pipe joint into the water outlet of the cylinder head at the press fitting station, and the cylinder head conveying unit, the gluing unit, the lifting mechanism, the feeding unit and the press fitting mechanism cooperate to complete automatic press fitting of the water outlet pipe joint. According to the intelligent press fitting system, the efficiency and quality of press fitting between the water outlet pipe joint and the cylinder head can be improved, and the intelligent press fitting system has the characteristic of being high in automation degree.

Owner:合肥森曼智能科技有限公司

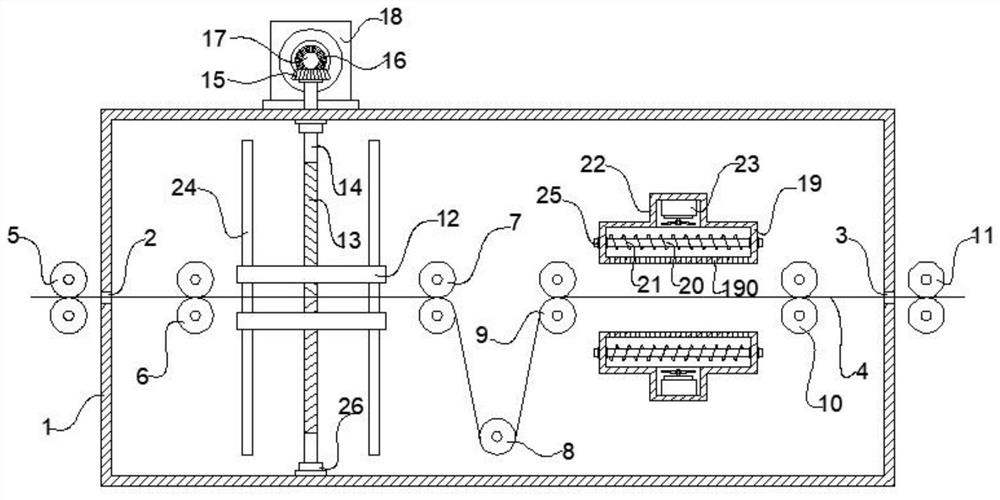

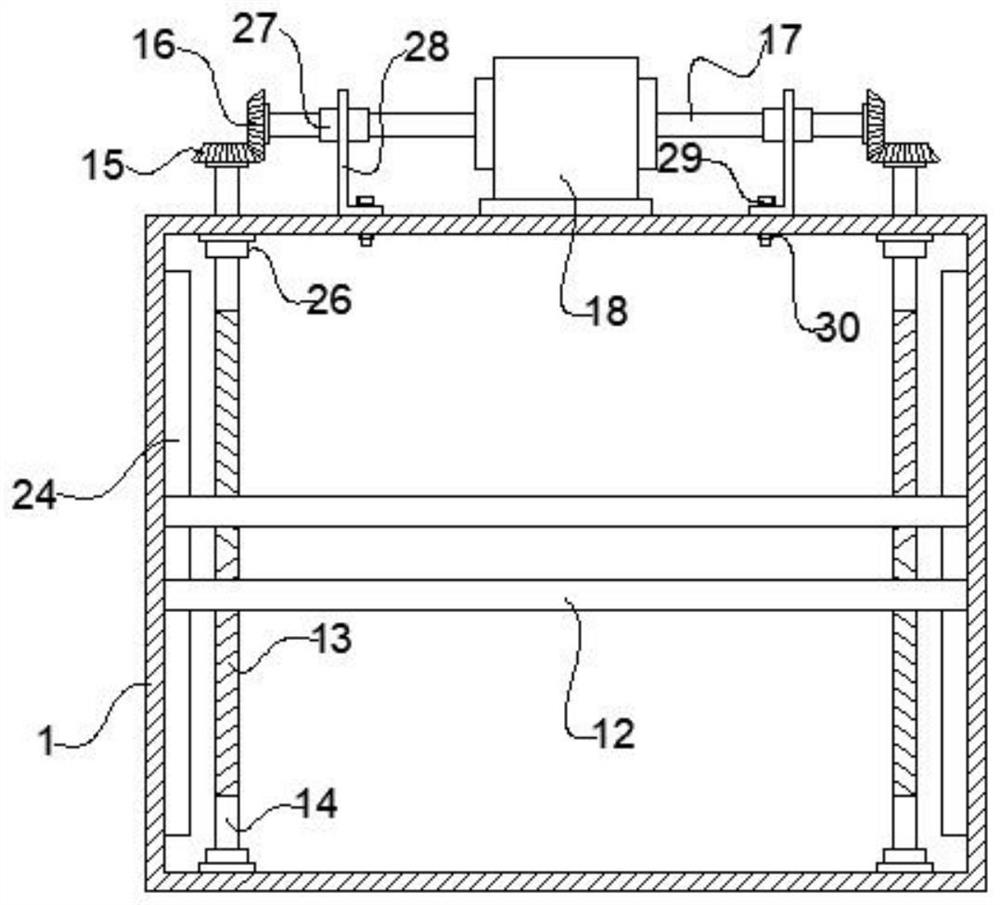

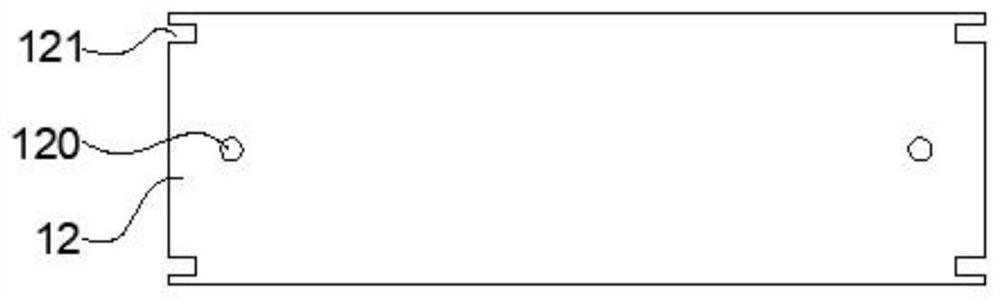

Fabric pressing device for clothing processing

InactiveCN112342723AFacilitates efficient press handlingImprove pressing efficiencyDrying gas arrangementsDrying machines with progressive movementsStructural engineeringIndustrial engineering

The invention discloses a fabric pressing device for clothing processing. The fabric pressing device comprises a processing box, a first guide pressing roller set, a second guide pressing roller set,a redirection pressing roller, a third guide pressing roller set and a fourth guide pressing roller set are sequentially and rotationally installed in an inner cavity of the processing box from left to right, and fabric is conveyed out of the processing box through guide rolling of a fabric outlet and an outlet pressing roller set. Pressing plates are symmetrically arranged on the upper side and the lower side of the distance between the first guide pressing roller set and the second guide pressing roller set, the pressing plates on the upper side and the lower side are in threaded transmission connection with the upper end and the lower end of a left-right rotating lead screw correspondingly, and drying air bellows are symmetrically arranged on the upper side and the lower side of the distance between the third guide pressing roller set and the fourth guide pressing roller set. By adopting the technical scheme of the fabric pressing device for clothing processing, the pressing qualityis improved, the pressing efficiency is high, and the operation is convenient.

Owner:临泉县明飞服饰有限公司

Efficient silicon steel sheet pressing device with protection function

PendingCN108717899AImprove pressing qualityAvoid damageInductances/transformers/magnets manufactureEngineeringSilicon

The invention discloses an efficient silicon steel sheet pressing device with a protection function and relates to the technical field of silicon steel sheet pressing devices. The efficient silicon steel sheet pressing device comprises a base plate and a supporting column, wherein a lifting mechanism is fixed at the top of the supporting column, a supporting plate is fixed at the top of the lifting mechanism, a hydraulic mechanism is fixed at the top of the supporting plate, a pressure head is fixed at the bottom of a pressure bar of the hydraulic mechanism, a protector is fixed at the top ofthe base plate, a limit slot is formed in clearance fit at the top of the protector, and a splicing slot is formed in the clearance fit at the top of the limit slot. The efficient silicon steel sheetpressing device disclosed by the invention has the advantages that a pressed silicon steel sheet is automatically located, manual lifting and locating are avoided, location accuracy is improved, amount of labor of a worker is reduced, and silicon steel sheet pressing quality is improved and personal safety of the worker and use of the protector are guaranteed, so that the condition that the silicon steel sheet is damaged when the silicon steel sheet is pressed is avoided.

Owner:江阴市南闸中天电器有限公司

Really-through ceramic tile preparation method

The invention discloses a really-through ceramic tile preparation method. Really-through ceramic tiles are prepared from, by weight, 35-40% of clay, 25-30% of kaolin and 30-40% of gravel stone, and total aluminum content of raw materials is 14.5-18% while total iron content of the same is less than or equal to 1%. The method includes following steps: A, grinding the raw materials and water until granularity is 40-45um, spray-drying to form granules, and aging until water content is 6.5-7%; B, drying at temperature of 200-250 DEG C for forming, and controlling water content of tile blanks to 0.5-1%; C, spraying glaze water to the surfaces of the tile blanks, putting into a roller kiln, drying at a temperature interval of 200-400 DEG C, and feeding into a temperature interval of 1210-1220 DEG C for firing until water absorptivity is 1-3%. By the method, the problem that existing really-through ceramic tiles are poor in compression resistance and anti-freezing performance, high in water absorptivity, unitary in pattern color and poor in texture.

Owner:广西梧州市远方陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com