Press fitting device for shaft head and intermediate section of rear axle housing assembly of car

A technology of rear axle housing and assembly, which is applied to the field of axle head and middle section press-fitting equipment of the rear axle housing assembly in automobiles, can solve the problems of low automation, large assembly stress, difficulty in accurate pressing of workpieces, etc., and achieves good automatic setting. Heart function, reduce enterprise cost, ensure the effect of pressing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

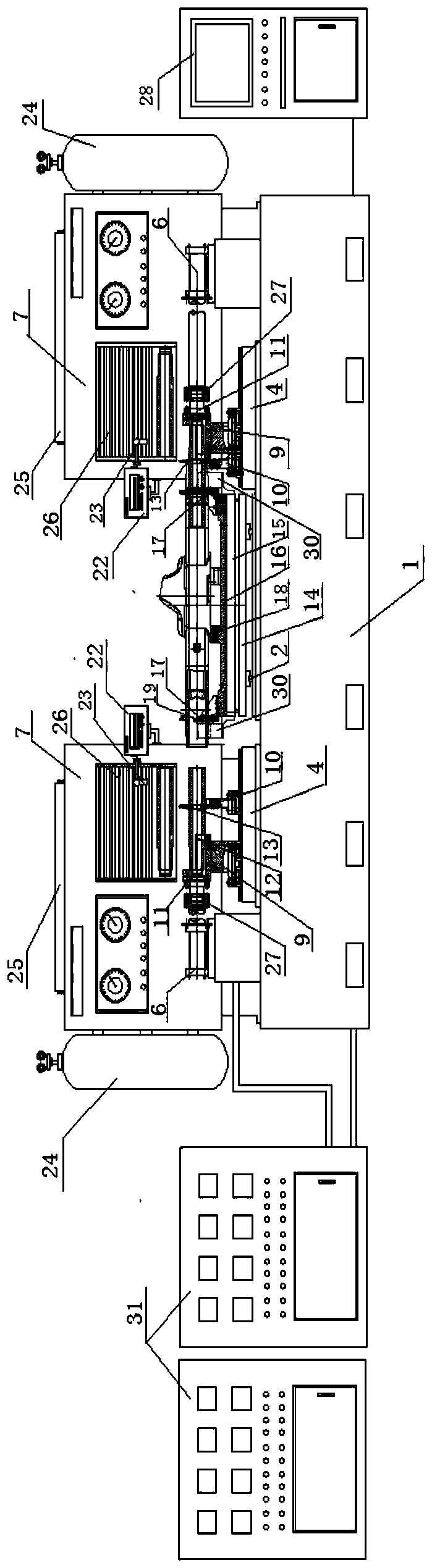

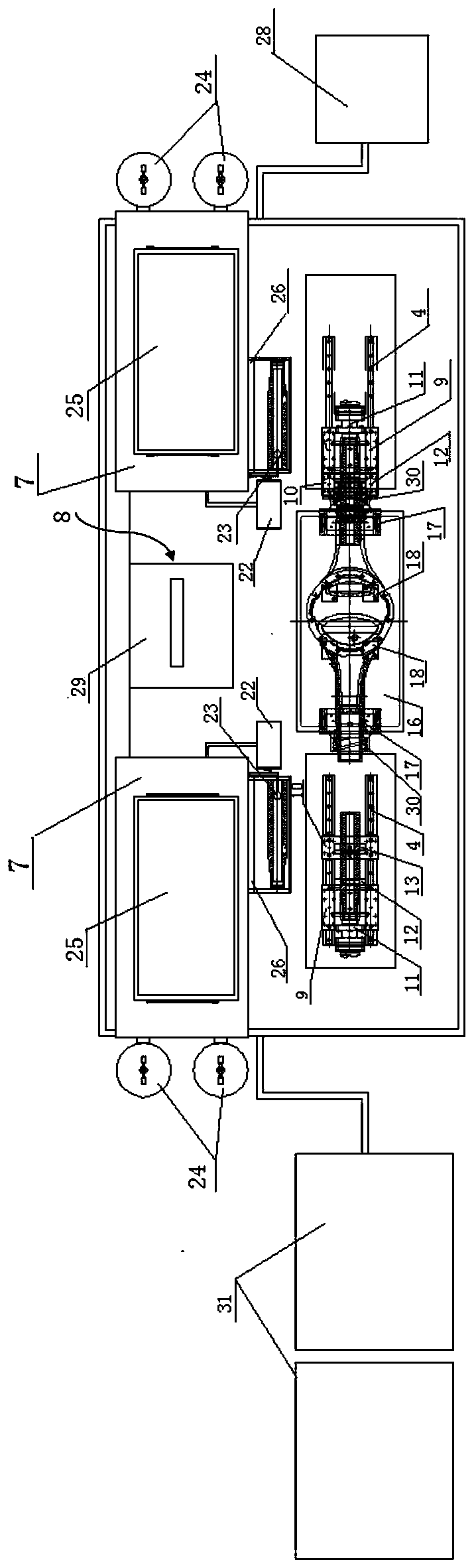

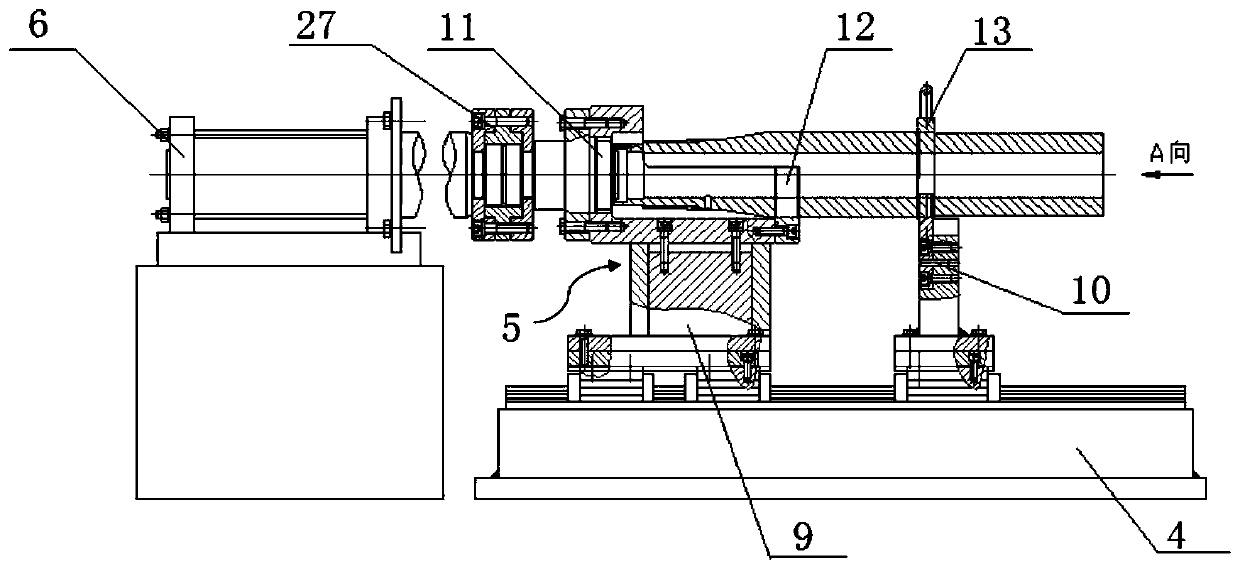

[0042] according to figure 1 , 2 As shown, the automobile middle rear axle housing assembly axle head and the middle section press-fitting equipment of the present invention include a bed 1, a pallet assembly 3 arranged on the bed 1 through a longitudinal slide rail 2, and a tray assembly 3 arranged on the bed 1 through a slide guide rail 4. Two pressure head assemblies 5 on the bed 1, two hydraulic cylinders 6, two refrigeration systems 7 for freezing the shaft heads, and heating for the shaft heads pressed into the middle section of the axle housing assembly The heating system 8, the tray assembly 3 is located between the two press head assemblies 5, one hydraulic cylinder 6 is connected to one press head assembly 5 correspondingly, and one refrigeration system 7 is correspondingly arranged to one press head assembly 5. In this embodiment, the two indente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com