Angle type nozzle can be installed with press-fit device

A press-fitting device and angle-shaped technology, which is applied in transportation and packaging, metal processing equipment, vehicle parts, etc., can solve problems such as difficulty in press-fitting angle-shaped nozzles, low press-fit efficiency, and poor press-fit effect, achieving Accurate positioning and replacement, fast replacement, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

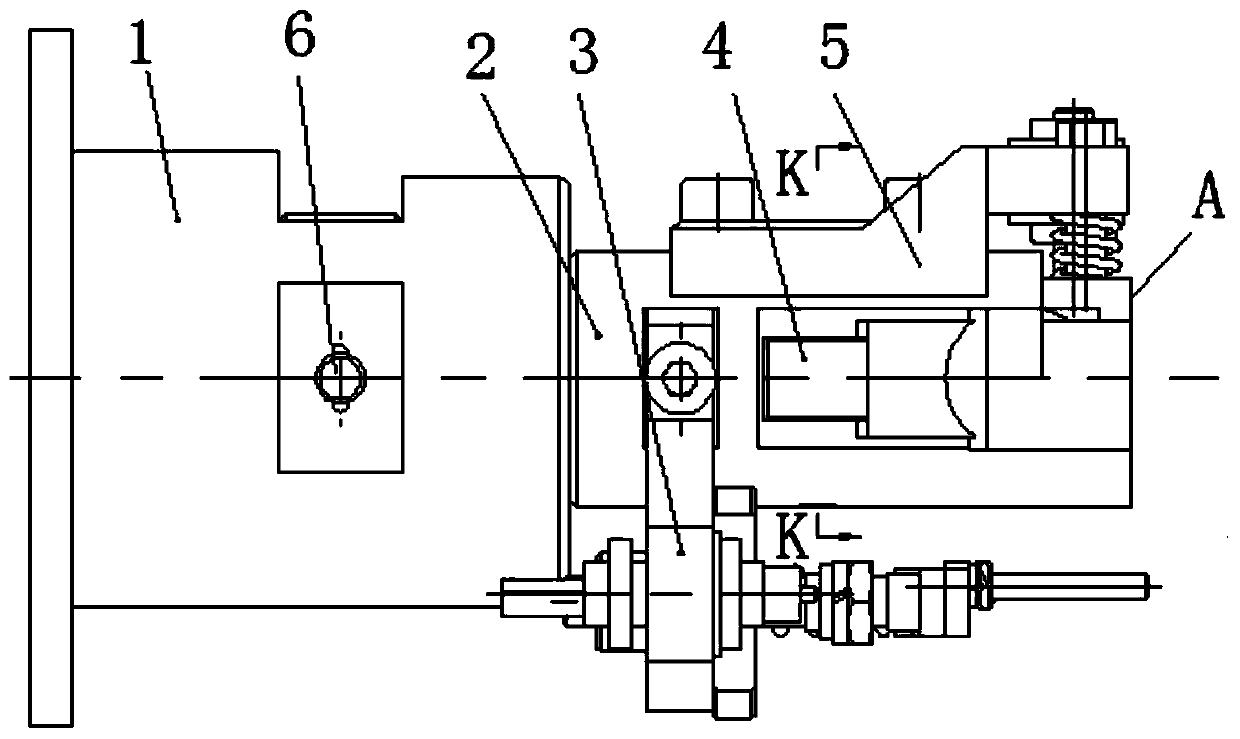

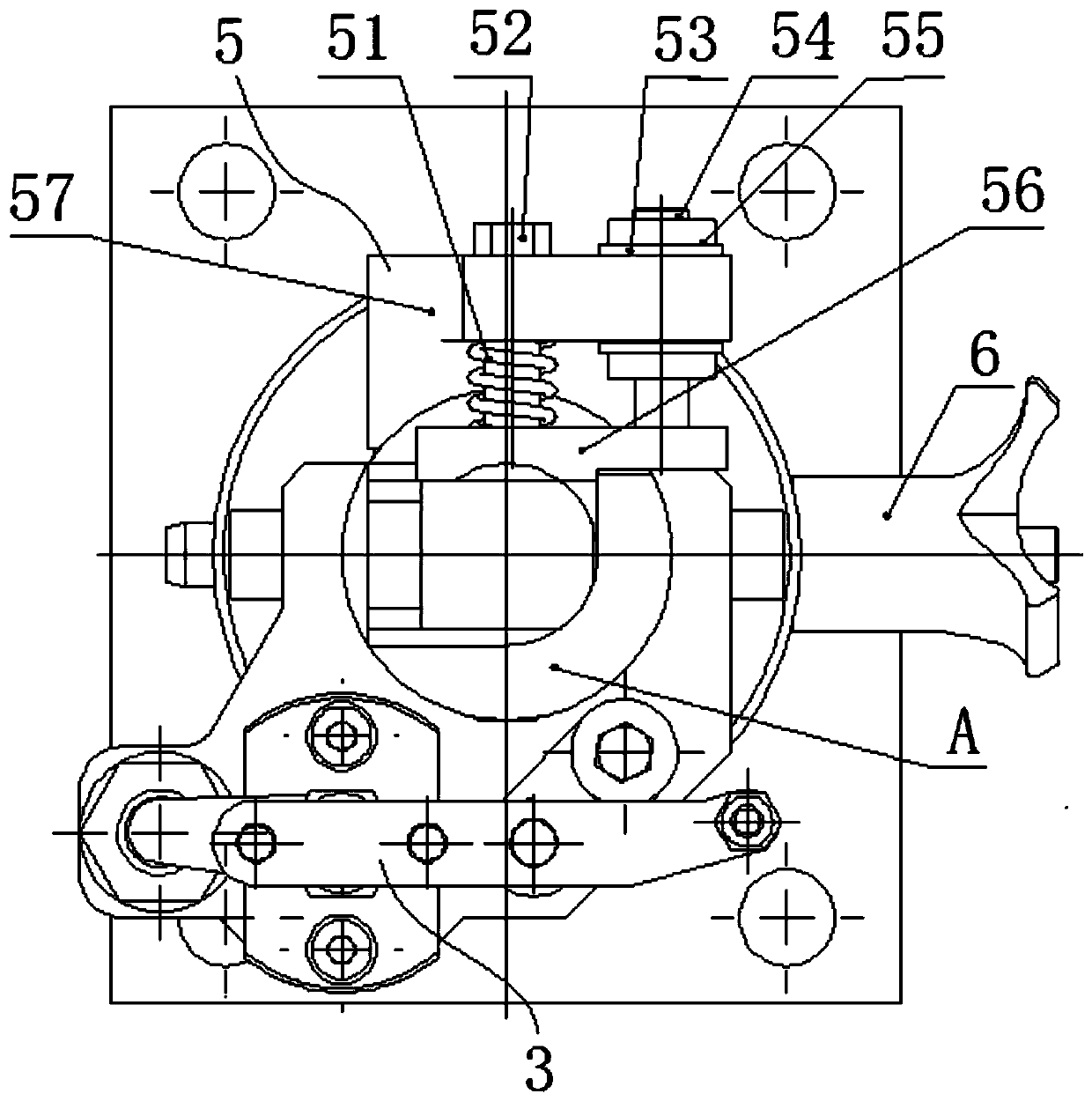

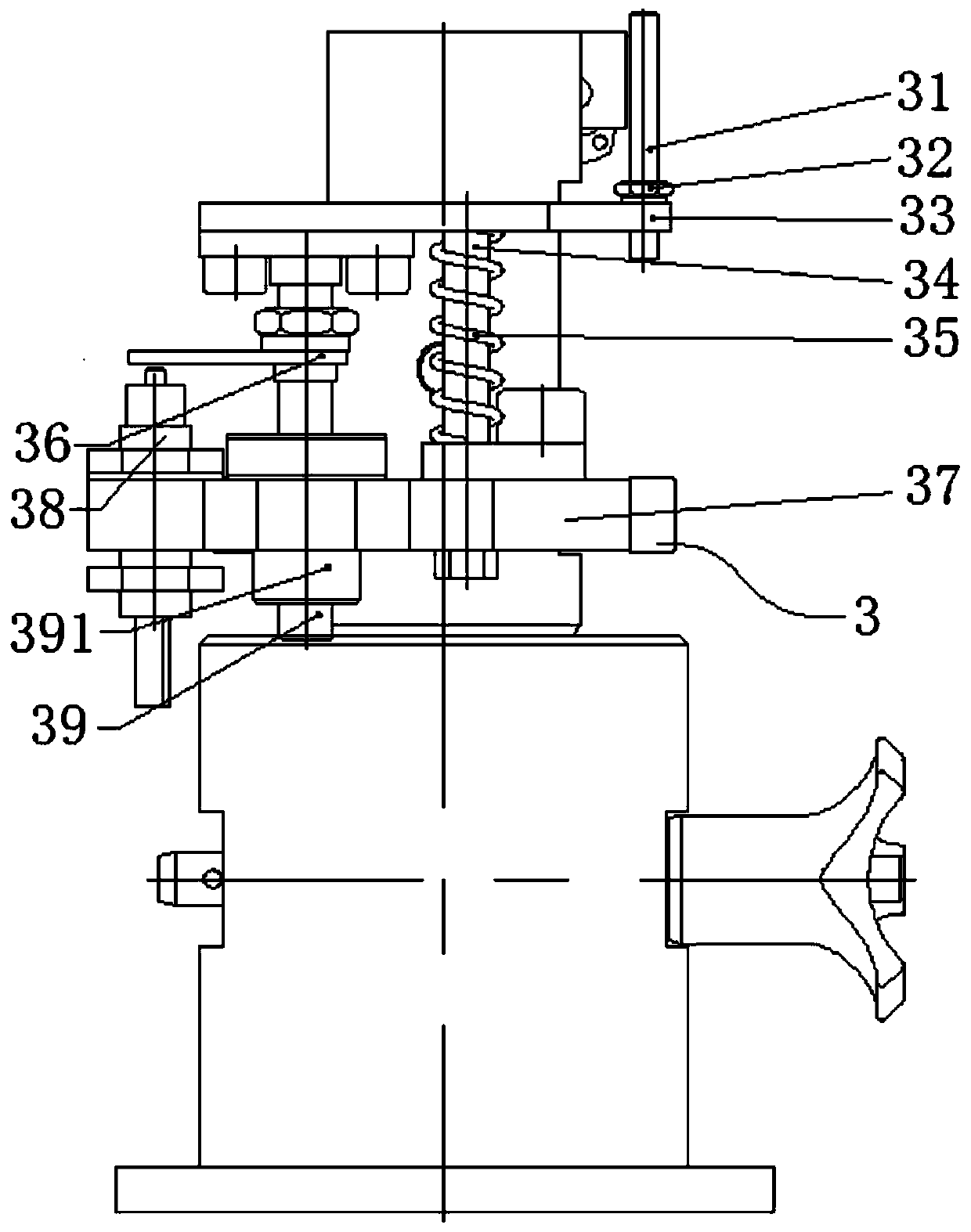

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 1~4 As shown, the present invention includes an indenter base 1, an indenter body 2, an axial self-adaptive module 4, a radial compression positioning mechanism 5, and a press fit detection mechanism 3, wherein the indenter base 1 is connected to the power of the equipment At the source, the indenter base 1 is connected to the indenter body 2 through a manual plug-in pin 6, and the end of the indenter body 2 away from the indenter base 1 is provided with a press-fitting groove. When the equipment is working, the angle Type nozzle 7 is placed in the press-fitting groove, as figure 1 and Figure 4 As shown, a stepped shaft-shaped inner hole is provided at the end of the pressing groove close to the indenter base 1, and the axial self-adaptive module 4 is installed in the stepped shaft-shaped inner hole through a pin shaft 41, And the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com