Dual-purpose electric transfer trolley for erecting wind power blade web and transferring main beam

A dual-purpose electric technology for wind turbine blades, which is applied in the field of dual-purpose electric transfer vehicles for wind turbine blade web vertical placement and main girder transfer, which can solve the problem that the transfer vehicle cannot effectively exert the overall efficiency of the equipment, the high cost of forklift maintenance and repair, and the unfavorable company Business development and other issues, to achieve the effect of improving the limitation of site power requirements, improving the efficiency of transshipment operations, and avoiding flanging damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

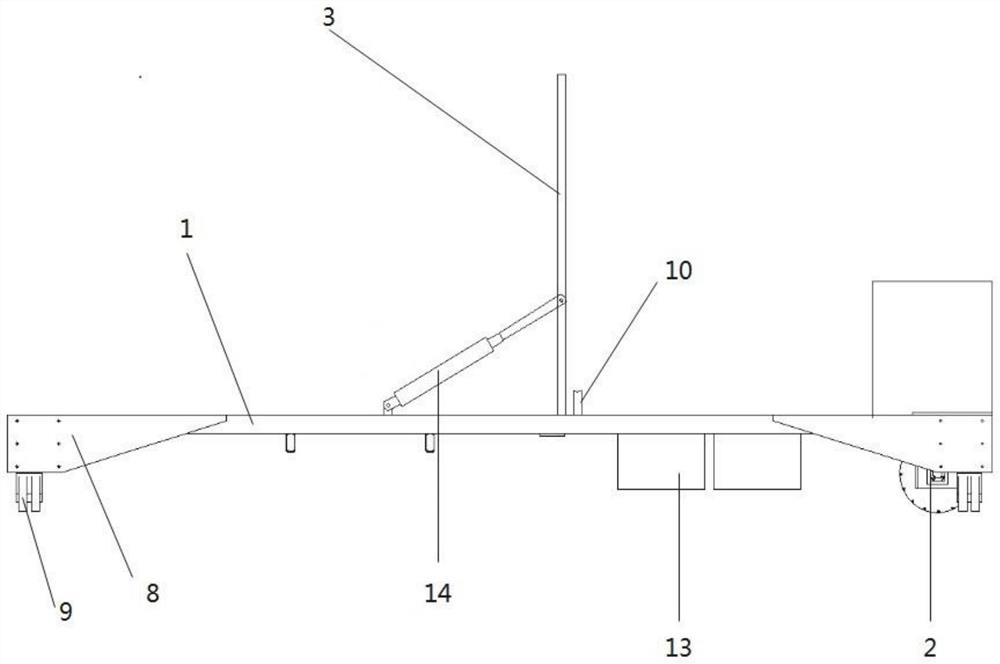

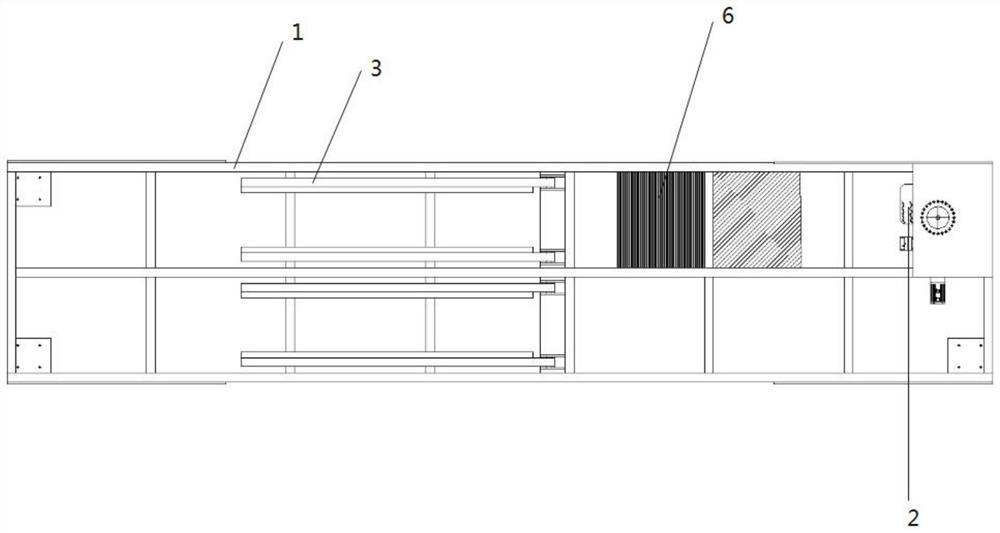

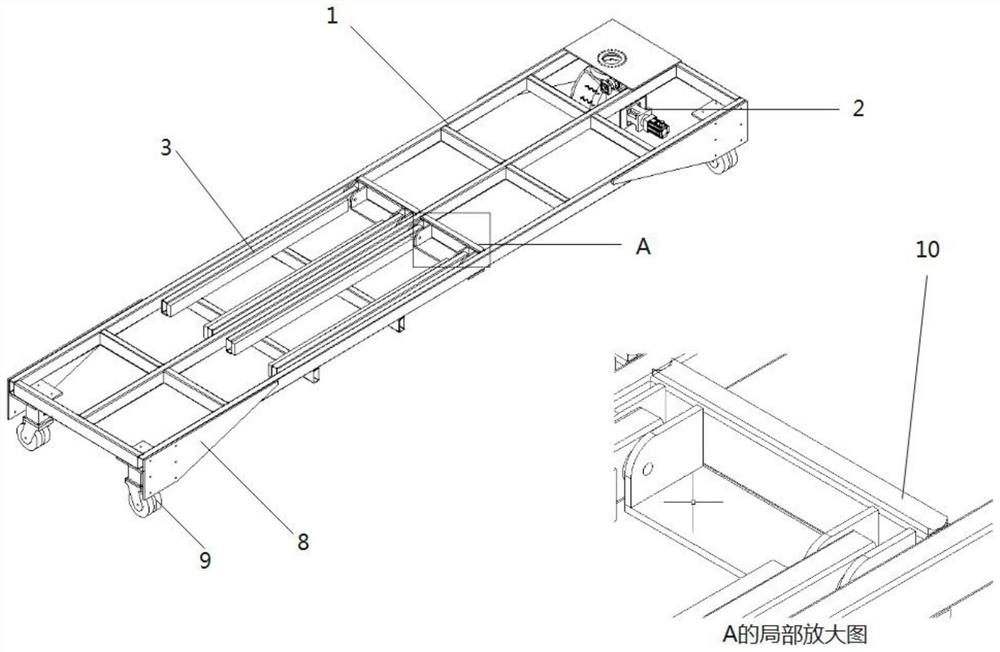

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , 2 , 3 shows a dual-purpose electric transfer vehicle for wind power blade web vertical placement and main girder transfer, including a transfer vehicle frame 1, a drive system 2, a control system and a battery combination 6, and the drive system 2 and the control system are arranged on the transfer vehicle One end of the vehicle frame 1 is separately arranged on the upper and lower sides of the transfer vehicle frame 1, the battery assembly 6 is arranged under the transfer vehicle frame 1, and a wheel 9 is rotated under the other end of the transfer vehicle frame 1; the transfer vehicle Four web storage poles 3 are arranged on the frame 1 .

[0026] In order to realize the vertical transfer of wind power blade webs, the web storage struts 3 are arranged in the middle of the transfer vehicle frame 1 and distributed along the width direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com