Manufacturing process of multifunctional protective clothing

A manufacturing process and technology of protective clothing, which is applied in the field of manufacturing technology of multi-functional protective clothing, can solve the problems of troublesome production and heavy overall weight of protective clothing, and achieve the effects of high fit, neck protection and gap avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

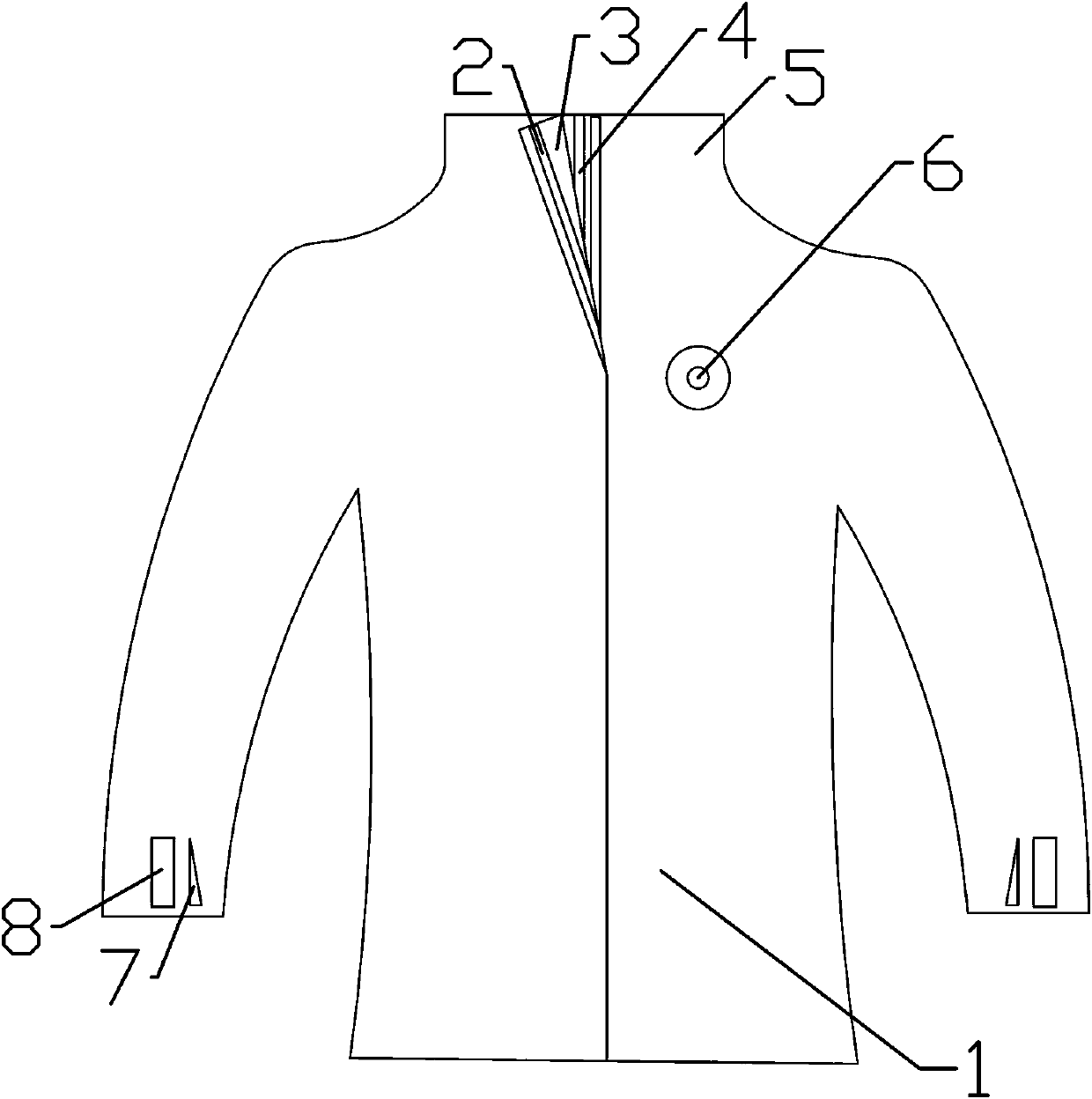

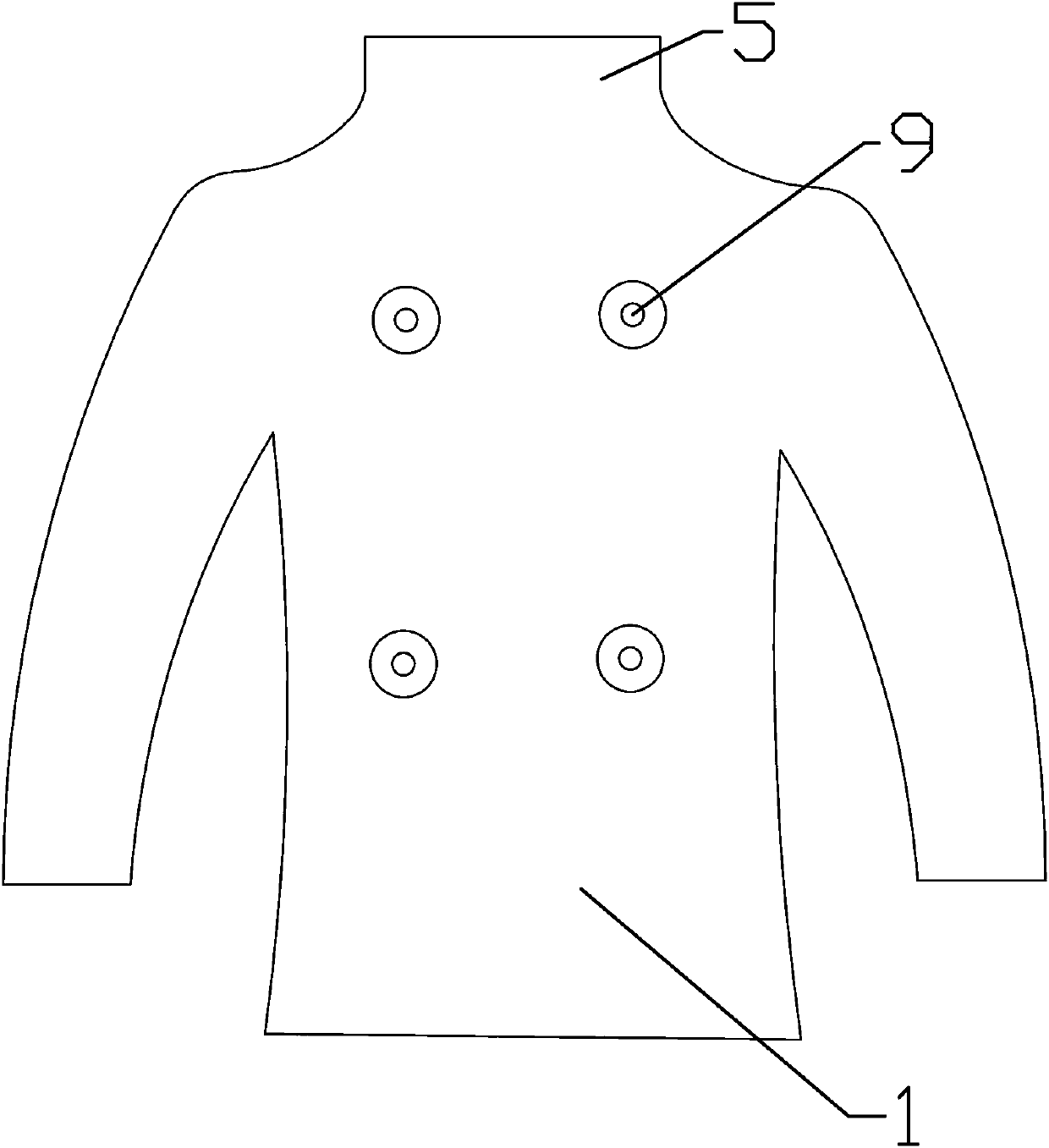

[0032] A manufacturing process for multifunctional protective clothing, comprising the following steps,

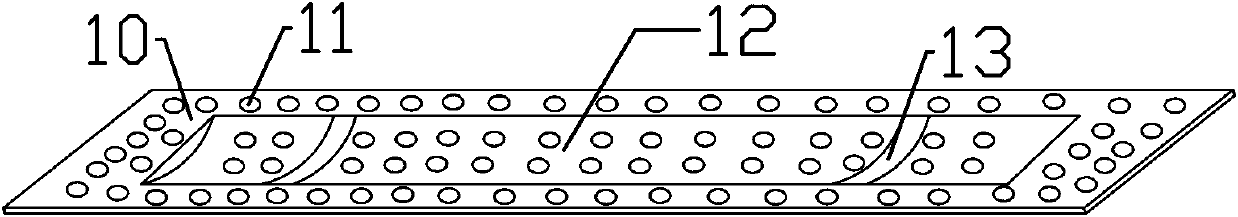

[0033] Step 1: Blending the silver fibers processed by nano-silver ion vacuum high-energy beam electroplating technology with pure cotton fibers to obtain radiation-proof fabrics. Since silver is a precious metal, it has good conductivity, but the hardness of silver fibers is relatively high. Heavy weight, the weight ratio of silver fiber to pure cotton fiber is 5:95, which can ensure the conductivity of the radiation-proof fabric and form a radiation-proof fabric with electromagnetic shielding function, low cost, soft fabric and light weight;

[0034] Step 2, blending ceramic fibers and polyester fibers to obtain heat-insulating and insulating fabrics, wherein the weight ratio of ceramic fibers to polyester fibers is 3:7, ceramic fibers have good heat insulation properties, polyester fibers have high modulus, high strength, With the advantages of high elasticity, good sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com