Automatic strip inlaying and pasting device for various metal strips for floor and vehicle interior decoration

A technology for interior decoration and metal strips, applied to floors, hand-held tools, manufacturing tools, etc., can solve problems such as labor, time waste, and low efficiency, and achieve simplicity, complexity reduction, and rapid adjustment and movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

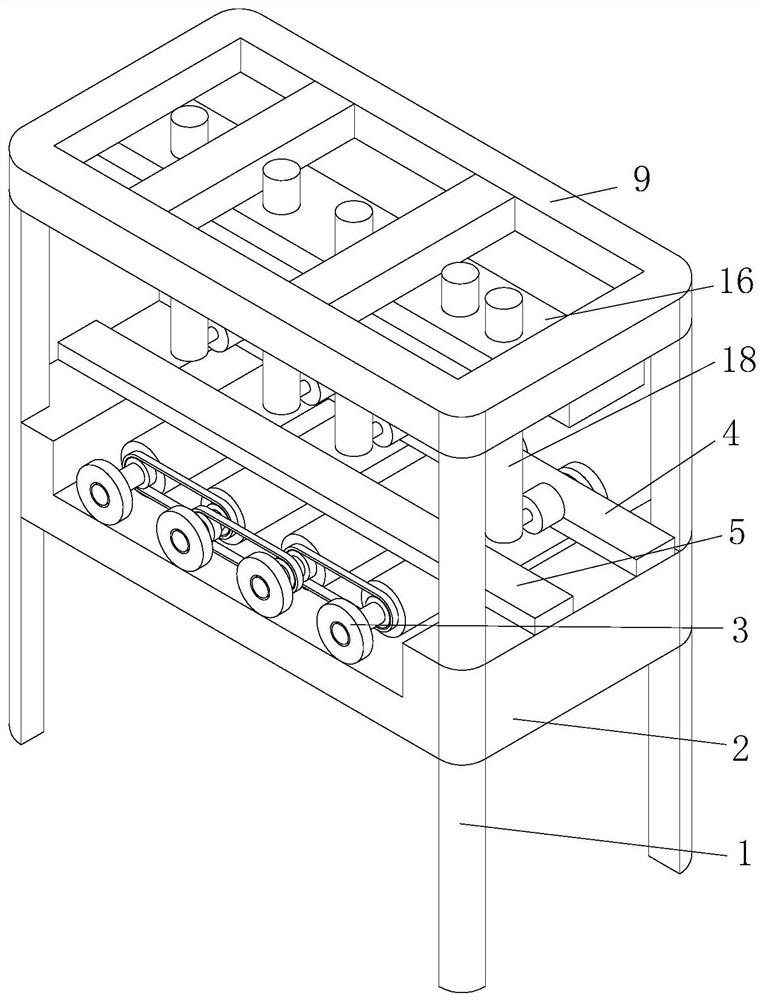

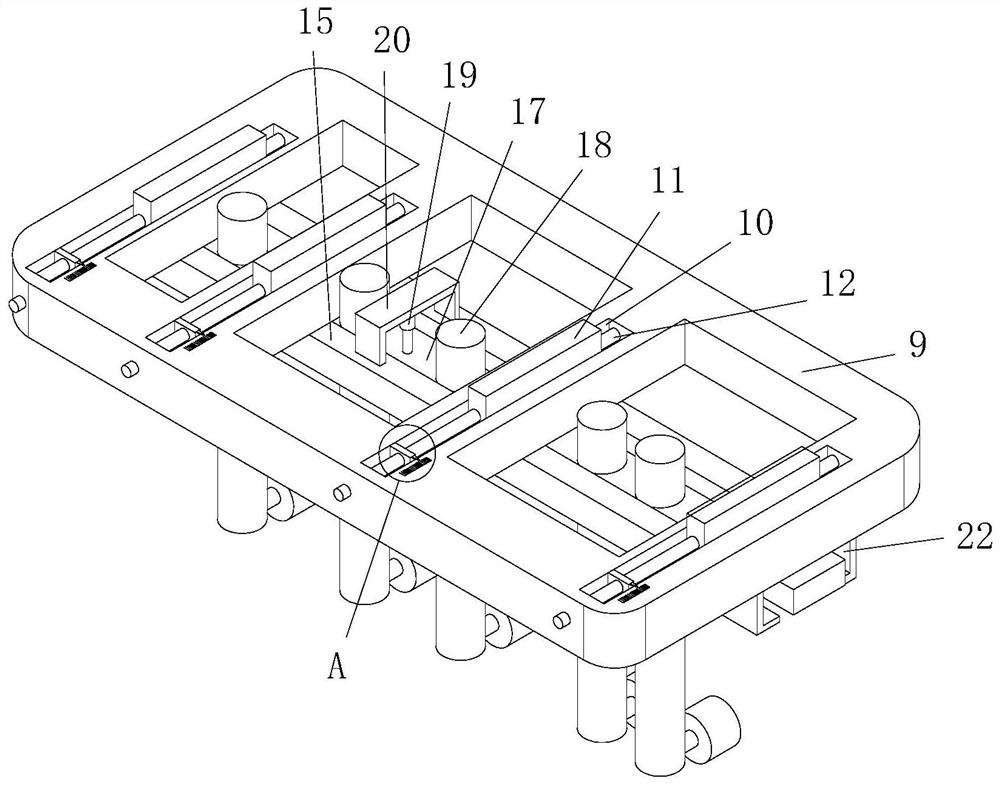

[0034] see Figure 1-6 , the present invention provides a technical solution: an automatic mosaic and pasting equipment for various metal strips for floor and car interior decoration, including a support leg 1, the inner side of the support leg 1 is fixedly connected with a base 2, and the upper side of the base 2 The right transmission mechanism 3 is set, the upper side of the base 2 is fixedly connected with a fixed plate 4, the upper side of the base 2 is slidably connected with a movable plate 5, the movable plate 5 is located on the left side of the fixed plate 4, and the inside of the movable plate 5 is slidably connected with a sliding plate. Rod 6, the left end of the sliding rod 6 is fixedly connected to the right side of the base 2, the surface of the sliding rod 6 is slidingly sleeved with a return spring 7, and the left and right ends of the return spring 7 are respectively fixedly connected to the right side of the base 2 and the movable plate 5 On the left side o...

Embodiment 2

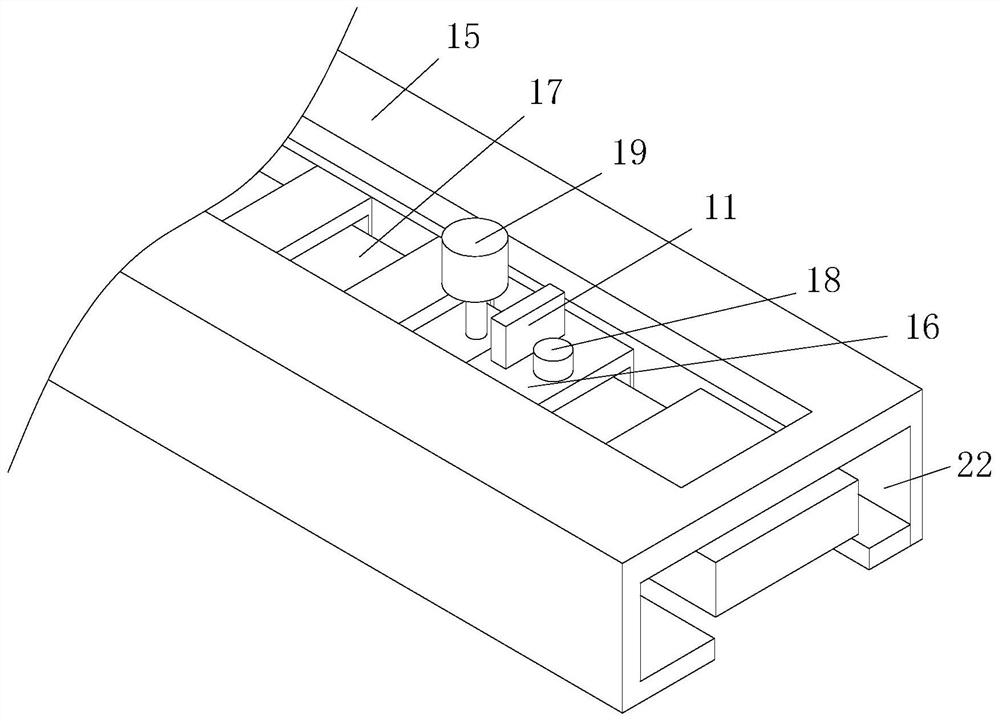

[0037] see Figure 1-5 , on the basis of Embodiment 1, the adjustment device includes a slide plate 11, the surface of the slide plate 11 is slidably connected to the inside of the chute 10, the inside of the slide plate 11 is threaded with a threaded shaft 12, and the right end of the threaded shaft 12 is rotatably connected to the support plate 9 Inside, the left end of the threaded shaft 12 runs through the inside of the support plate 9 and extends to the left side of the support plate 9, the right end of the threaded shaft 12 is threaded with the interior of the support plate 9, and the surface of the threaded shaft 12 is rotatably connected with a scale plate 13, The surface of the scale plate 13 is slidably connected to the inside of the chute 10, the upper side of the support plate 9 is provided with a scale 14, the lower side of the support plate 9 is fixedly connected with an auxiliary plate 15, and the lower side of the auxiliary plate 15 is provided with a limiting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com