Press mounting method for shaft head and middle section of automobile middle and rear axle housing assembly

A technology of rear axle housing and assembly, which is applied to the field of press fitting of the axle head and middle section of the rear axle housing assembly in automobiles, can solve the problems of poor press fitting quality, large assembly stress, and low press fitting efficiency, and avoid thermal deformation. Larger size, high press-fitting accuracy, and the effect of reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

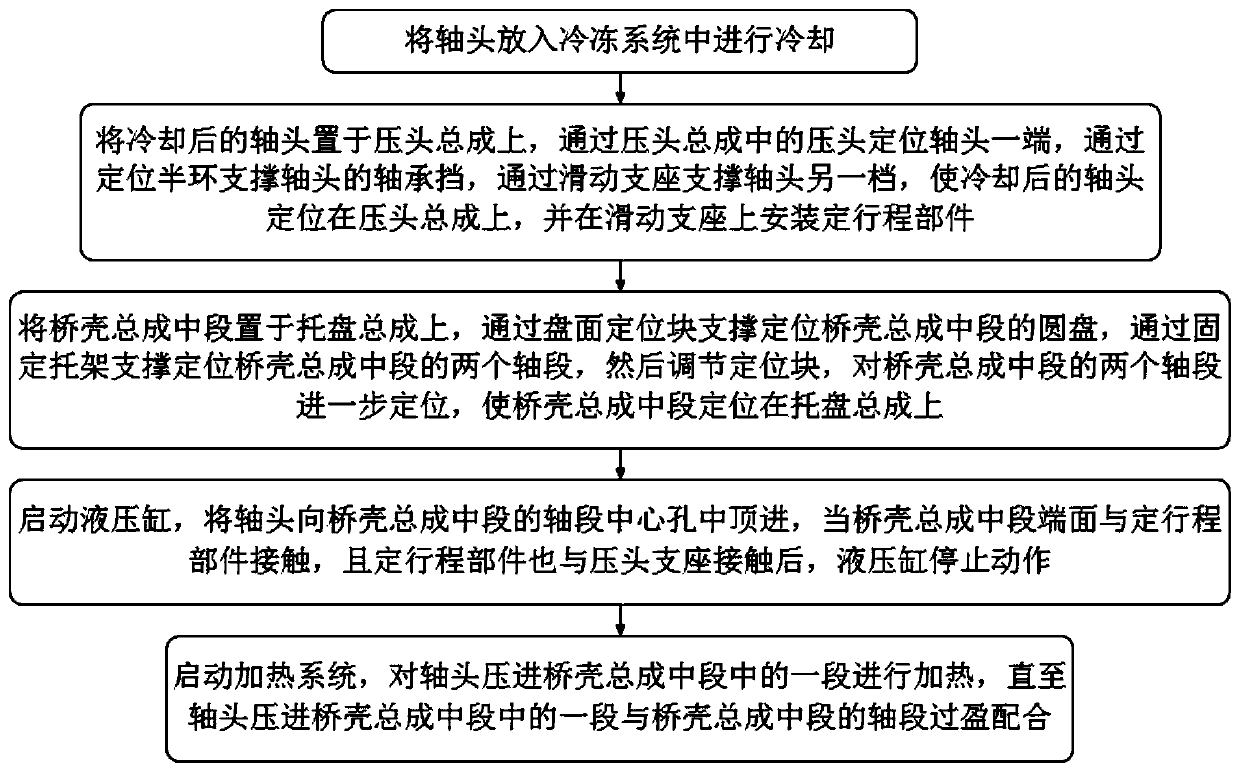

[0045] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

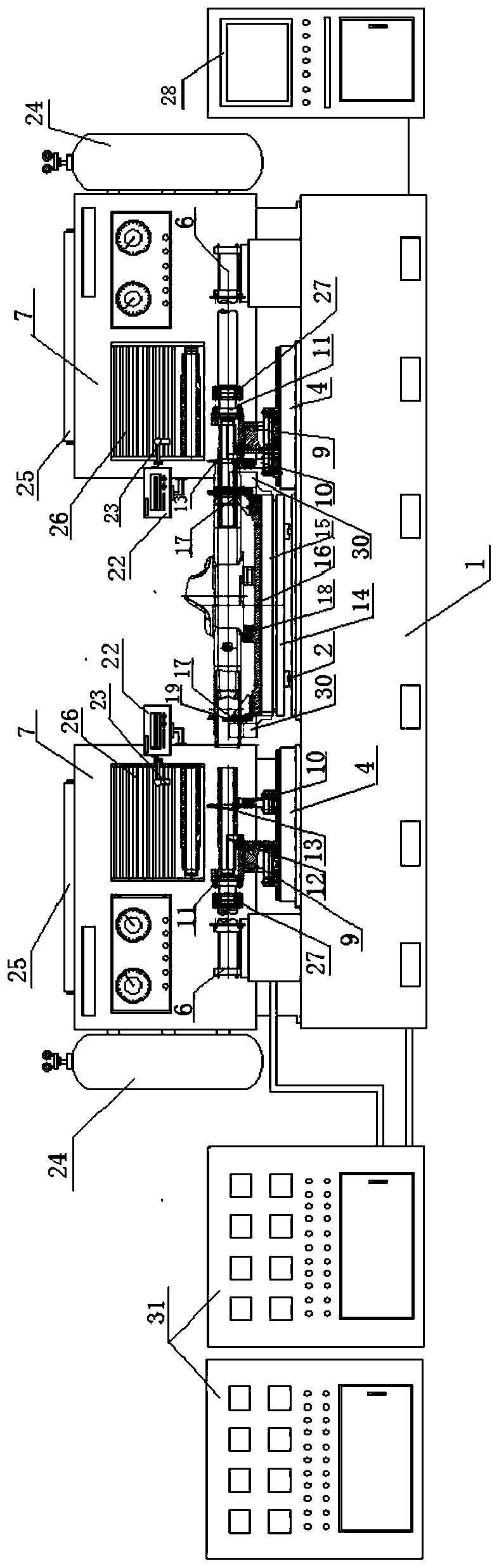

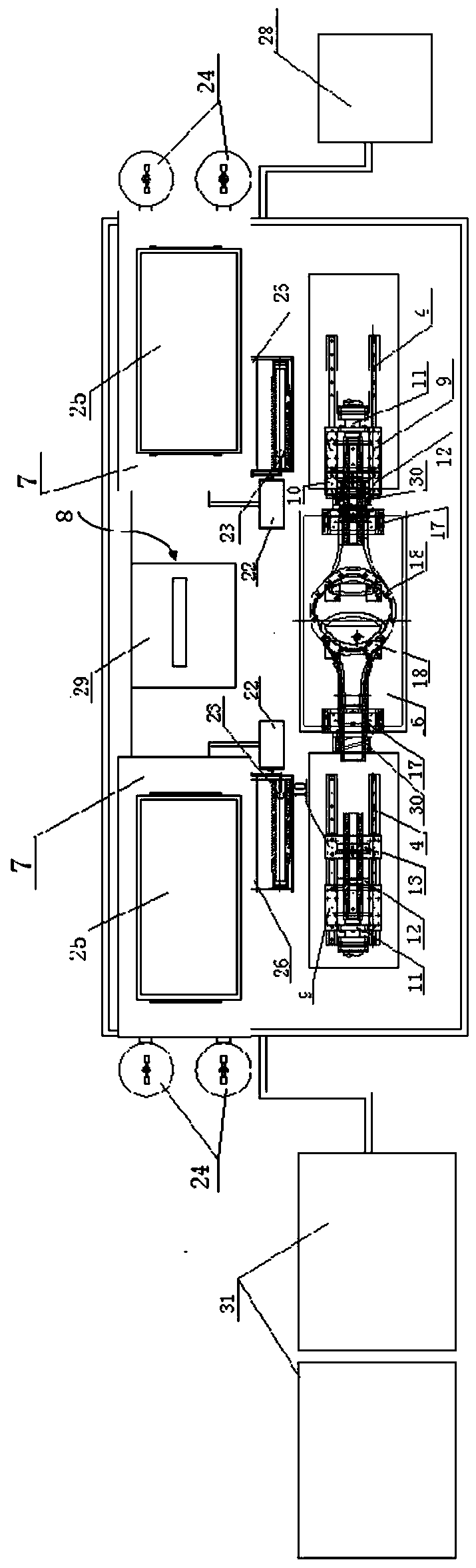

[0046] according to figure 2 , 3 As shown, the axle head of the rear axle housing assembly and the middle section press-fitting equipment used in the present invention include a bed 1, a pallet assembly 3 arranged on the bed 1 through a longitudinal slide rail 2, and a tray assembly 3 arranged on the bed 1 through a slide guide rail 4. Two pressure head assemblies 5, two hydraulic cylinders 6, two refrigeration systems 7 for freezing the shaft heads, and two refrigeration systems 7 for freezing the shaft heads that are pressed into the middle section of the axle housing assembly are arranged on the bed 1. Heated heating system 8, the tray assembly 3 is located between two press head assemblies 5, one hydraulic cylinder 6 is connected to one press head assembly 5 correspondingly, and one refrigeration system 7 is set correspondingly to one press head assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com