IGBT series crimping packaging unit and DC circuit breaker with same

A DC circuit breaker and press-fit technology, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of inconsistent voltage equalization, increased components of press-fit units, and low press-fit quality, so as to ensure the press-fit effect and improve Press-fit quality, achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

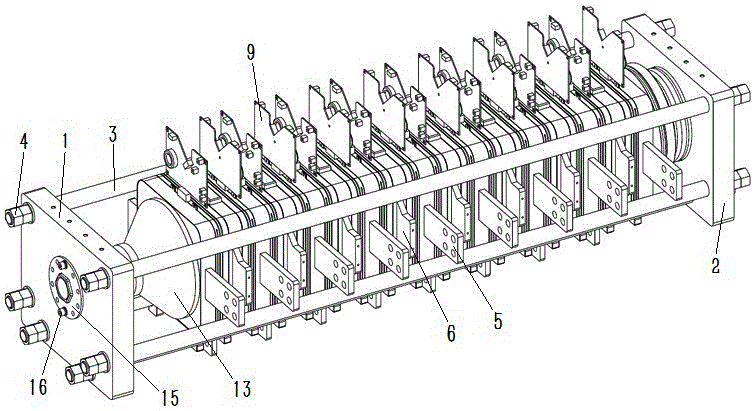

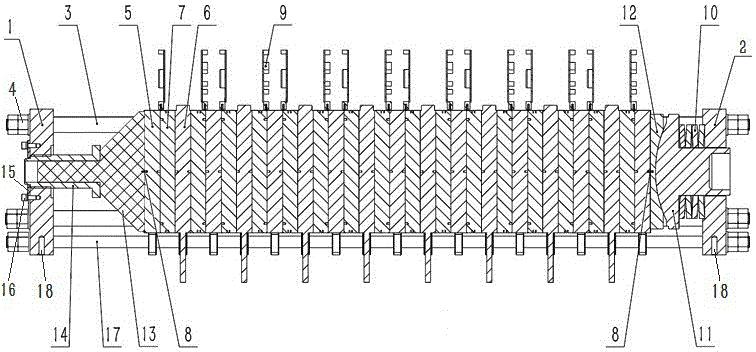

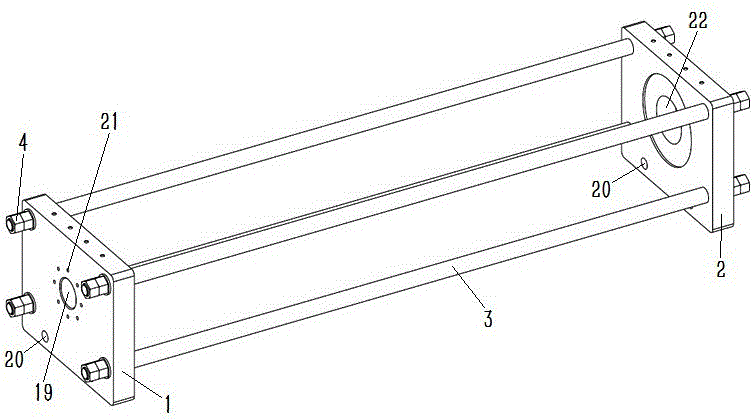

[0035] An example of a DC circuit breaker is Figure 1~Figure 13 As shown, it includes a capacitor bank (not shown in the figure) and an IGBT series crimping package unit connected to the capacitor bank. The IGBT series crimping package unit includes a support frame and an IGBT valve string located in the support frame. The support frame includes The first flange plate 1, the second flange plate 2 arranged along the left and right, and the insulating pull rod 3 fixed between the first flange plate 1 and the second flange plate 2, the first flange plate 1 and the second flange plate 2 The two flange plates 2 are both high-strength metal plates to ensure the fixing and supporting effect on the IGBT valve string. The insulating tie rod 3 includes a high-strength metal tie rod and an insulating sleeve coated on the outside of the metal tie rod, which ensures the strength and insulation performance of the insulating tie rod 3. Shaft shoulders are formed at the center, and external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com