Rail vehicle positioning joint press fitting device

A technology for press-fitting devices and positioning nodes, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of positioning node loss, complex disassembly process, and low press-fitting efficiency, so as to reduce the time for replacing positioning nodes, It is convenient for workers to operate and improve the effect of press-fitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

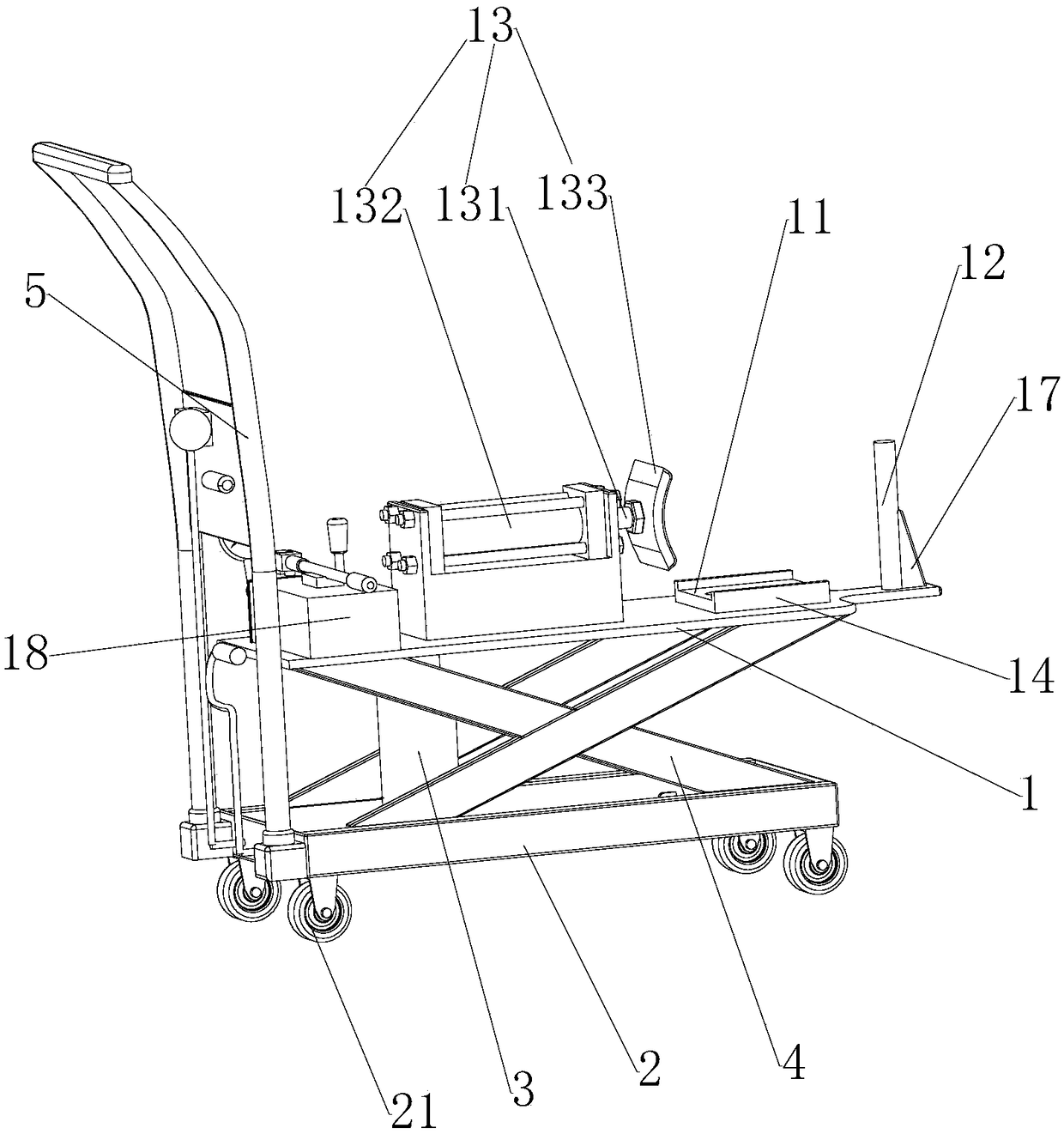

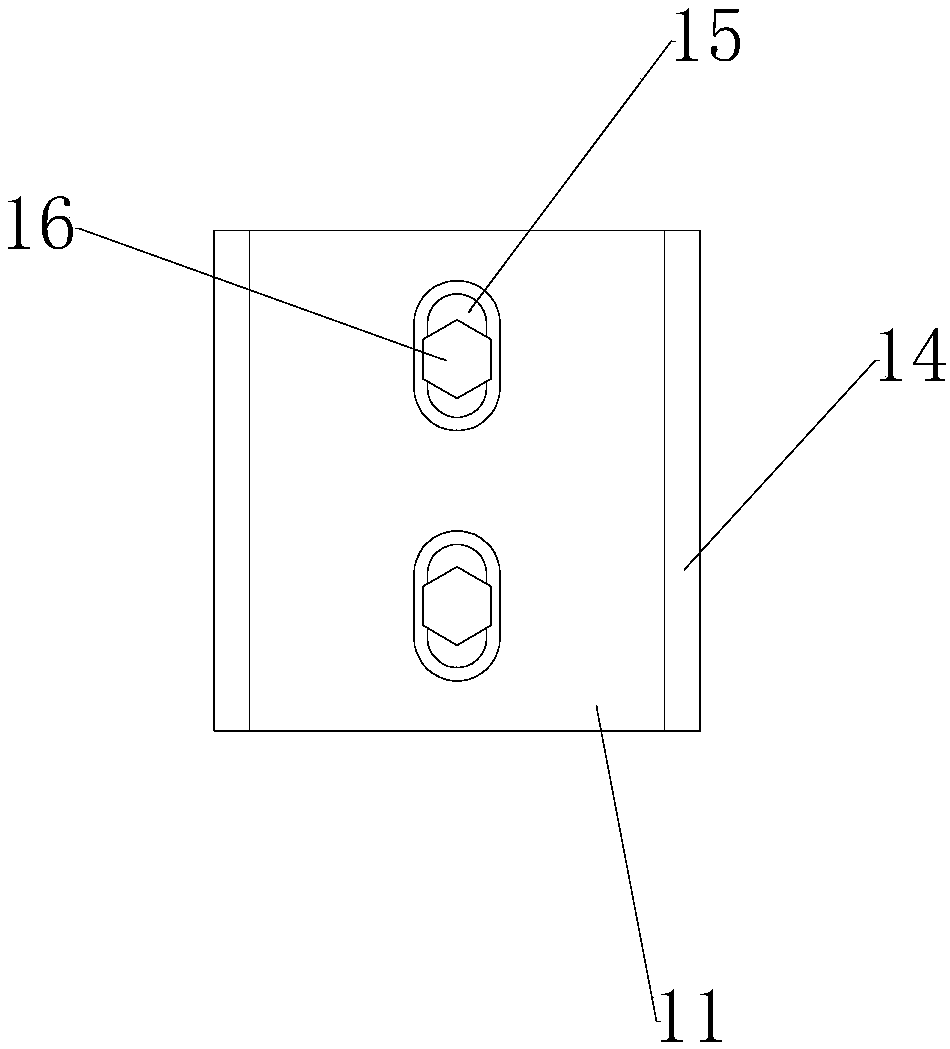

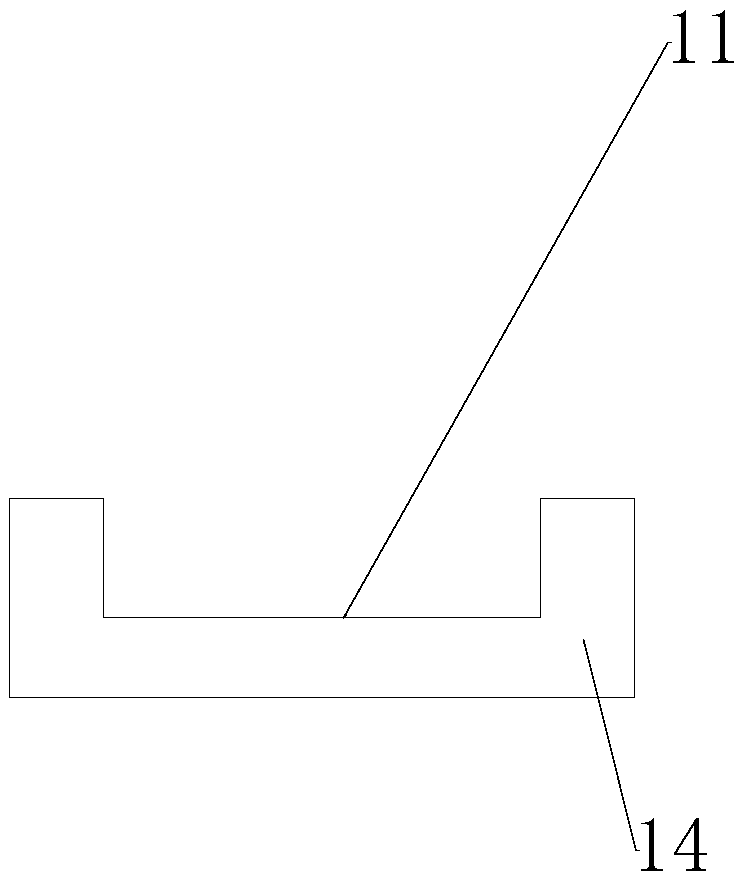

[0020] refer to figure 1 , a rail vehicle positioning node press-fitting device, including a press-fitting platform 1, the press-fitting platform 1 is arranged on a mobile trolley 2, the described press-fitting platform 1 is lifted and lowered under the drive of a lifting device 3, and the press-fitting platform 1 The platform 1 is provided with a positioning groove 11 for positioning the gland and the shaft box, and the two sides of the pressing platform 1 corresponding to the positioning groove 11 are respectively provided with a vertical positioning column 12 and a pushing and pressing device 13, The positioning column 12 is used for positioning the axle box, and the pushing and pressing device 13 includes a pushing rod 131 for pushing the gland, and a first drive for driving the pushing rod 131 to press against the positioning column 12. device 132. The mobile trolley 2 can be loaded with the press-fit table 1 and moved to the place where the rubber positioning node or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com