Automatic detecting and press-fitting device for automobile accessory gearbox

A technology for automatic detection of auto parts, applied in the field of gearboxes, can solve problems such as inconvenient operation, poor quality, and low efficiency, and achieve the effects of accurate detection, high work efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

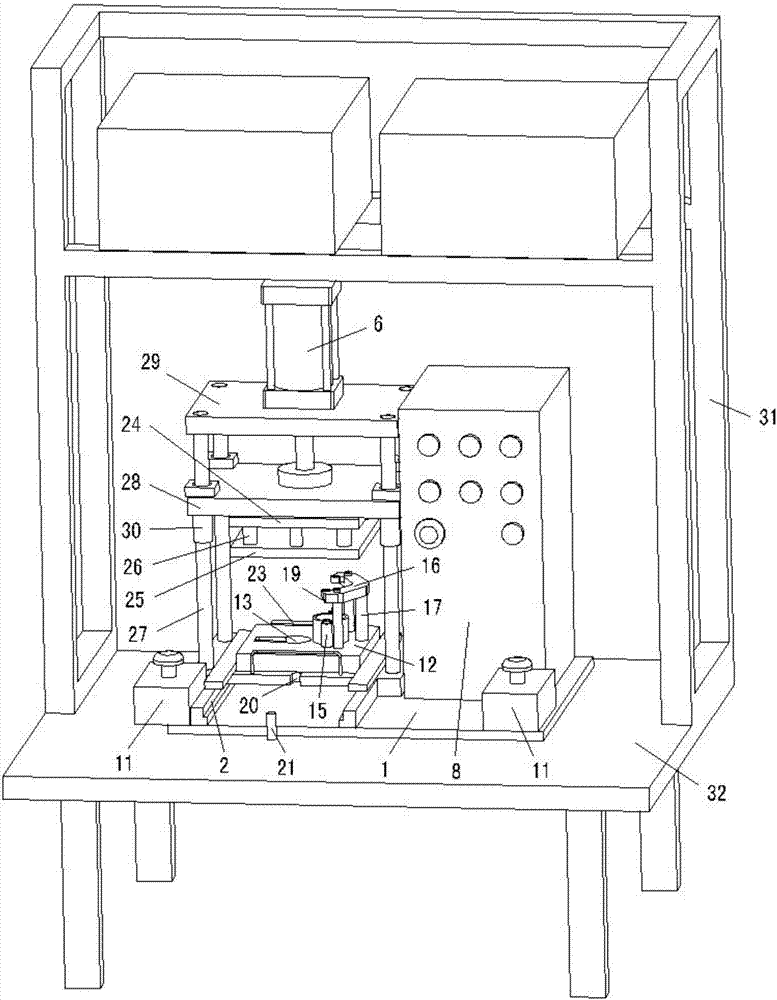

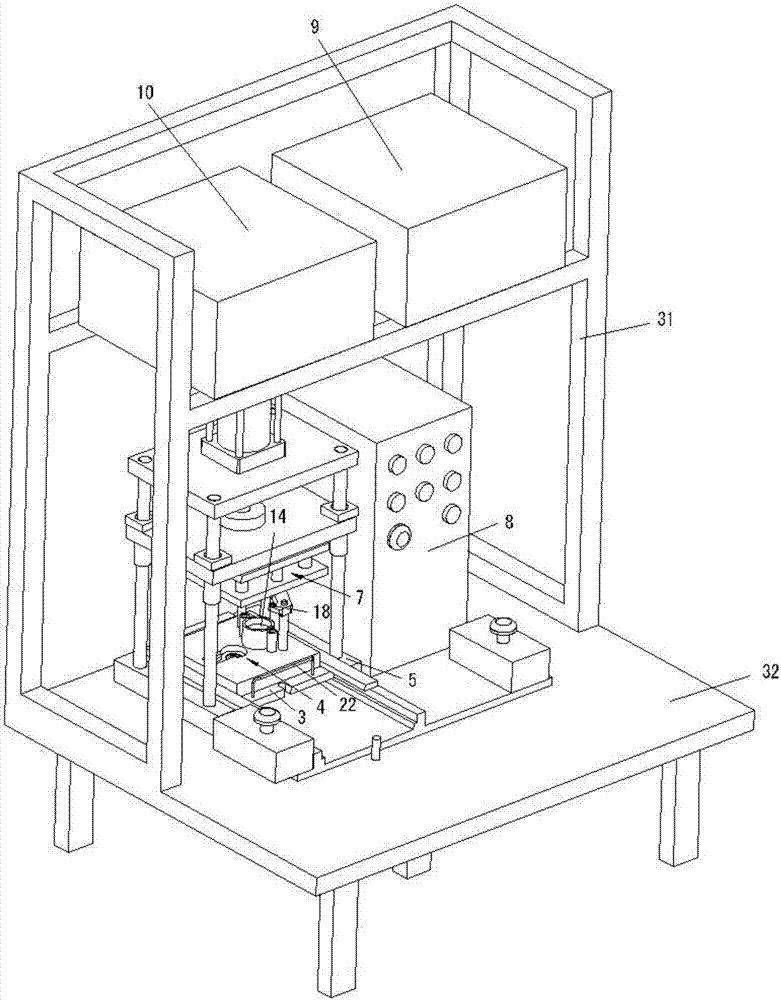

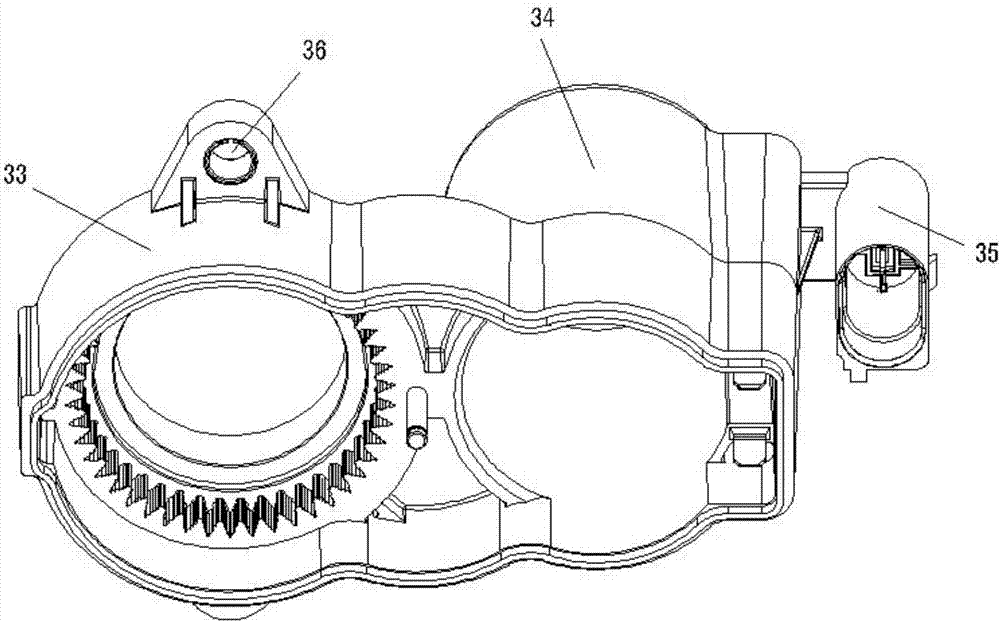

[0017] Embodiment one, such as figure 1 , figure 2 , image 3 As shown, an automatic detection and press-fitting device for an auto parts gearbox includes a base frame, a workbench 1 is provided on the lower part of the base frame, and two symmetrically arranged guide rails 2 are provided on the upper end of the workbench 1. The two guide rails 2 A movable bottom plate 3 is arranged between them, and the upper end of the bottom plate 3 is provided with a mold base 4 which is convenient for placing the gear box of an auto accessory. The upper end is provided with a lifting cylinder 6, the bottom end of the support frame is provided with a pressing plate 7 connected with the piston rod of the lifting cylinder 6, a detection display 8 is provided on one side of the support frame, and a detection display 8 is provided on the top of the base frame. The withstand voltage detector 9 and the sealing detector 10 electrically connected to the detection display 8 are provided with a c...

Embodiment 2

[0023] Embodiment 2. The difference between this embodiment and Embodiment 1 is that a push cylinder is connected to the rear end of the workbench 1, and the piston rod of the push cylinder is connected to the rear end of the bottom plate 3. The push cylinder The bottom plate 3 and the mold base 4 can be automatically pushed and pulled to move.

[0024] In this embodiment, the base frame includes a bottom frame 32 and an upper frame 31 arranged at the rear of the upper end of the bottom frame 32. Devices 10 are all arranged on the upper frame 31, and the pressure-resistant detector 9 and the sealing detector 10 are electrically connected with the detection display 8, and the detected data are displayed on the pressure-resistant detector 9 and the sealing detector 10, and the pressure-resistant detector 9 and the sealing detector 10 are displayed, and the pressure-resistant And whether sealing is up to standard, then show red light or green light by detection display 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com