Special forming mold for circular tantalum core of tantalum capacitor and using method thereof

A technology of tantalum capacitors and forming molds, which is applied in the field of electronic components production and manufacturing, can solve the problems that tantalum cores with a circular structure cannot be formed, limit the development of electronic components production and manufacturing technology, etc., and achieve simple structure and high pressing quality Good, good batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

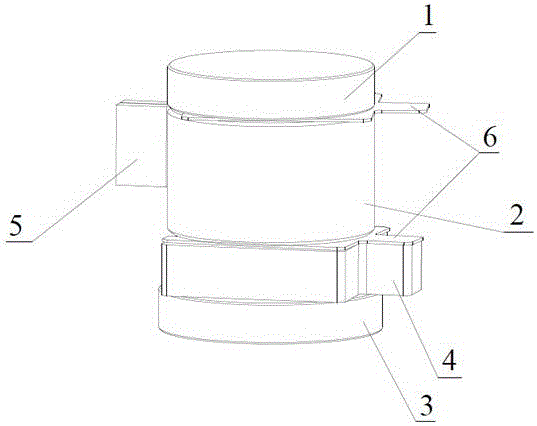

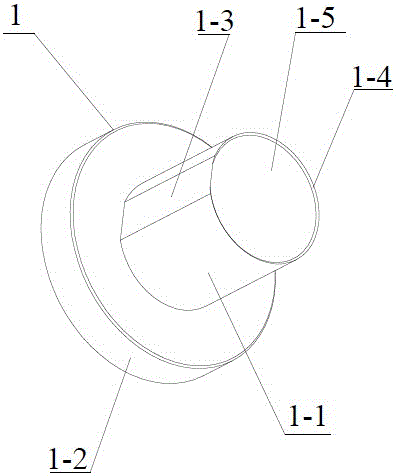

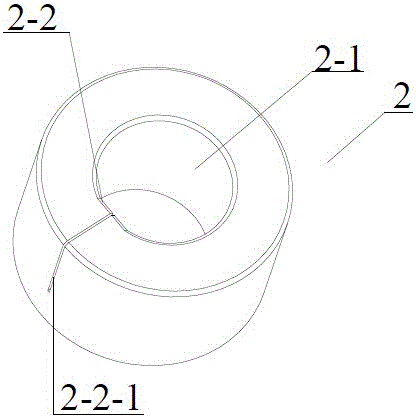

[0016] Specific implementation mode one: combine picture 1 ~ picture 7 This embodiment will be described. This embodiment provides a specific implementation of a special molding die for a round tantalum core of a tantalum capacitor. The special molding die for the round tantalum core of the tantalum capacitor consists of an upper punch 1, a concave die 2, a lower punch 3, an adjustment spacer 4, a tantalum wire limiter 5 and an adjustment spacer 6.

[0017] The upper punch 1 is provided with a die circular mating surface-1-1 structure, and the upper punch 1 is also provided with an operation circumferential surface-1-2 structure, and the upper punch 1 is also provided with a mating plane-1-2 structure. 1-3 structure, the upper punch 1 is also provided with an outer chamfer-1-4 structure, the upper punch 1 is also provided with an upper punch molding surface 1-5 structure; the concave mold 2 is provided with a convex Die mating surface one 2-1 structure, said die 2 is al...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment provides a specific embodiment of the method of using a special forming mold for a round tantalum core of a tantalum capacitor. The method of using the special molding die for the circular tantalum core of the tantalum capacitor is as follows.

[0020] The lower punch 3 is arranged on the operating table, and the lower punch mating surface 4-1 of the adjusting pad 4 cooperates with the concave die circular mating surface 2 3-1 of the lower punch 3 to realize the adjustment pad 4 and The mating connection of the lower punch 3, the punch mating surface 1 2-1 of the die 2 cooperates with the die circular mating surface 2 3-1 of the lower punch 3 to realize the cooperation of the die 2 and the lower punch 3 Connected, the punch matching surface 1-2-1 of the die 2 and the lower punch molding surface 3-3 of the lower punch 3 form a semi-closed circular molding cavity, pour tantalum powder into the semi-closed molding cavity and place the tantalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com