Patents

Literature

77results about How to "Good batch consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

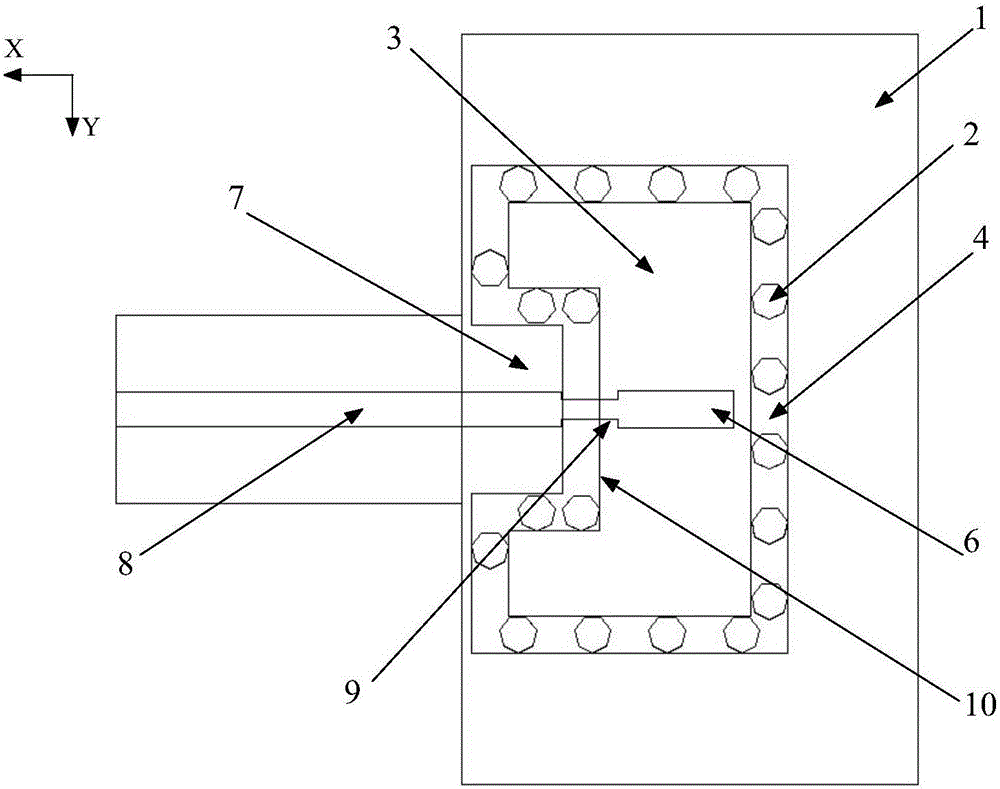

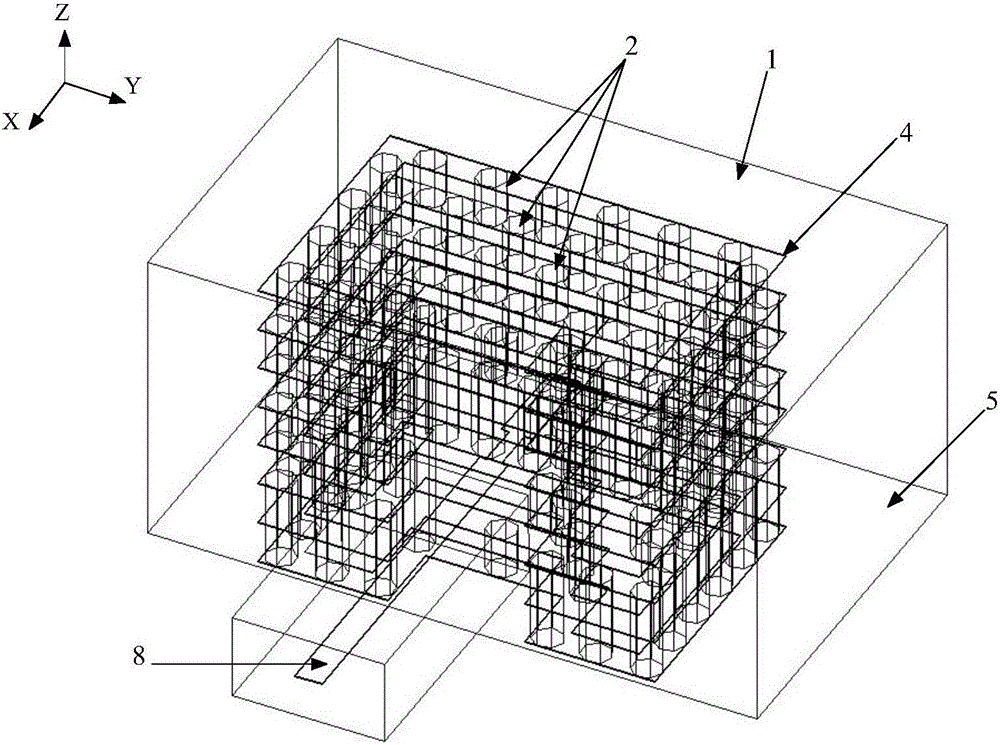

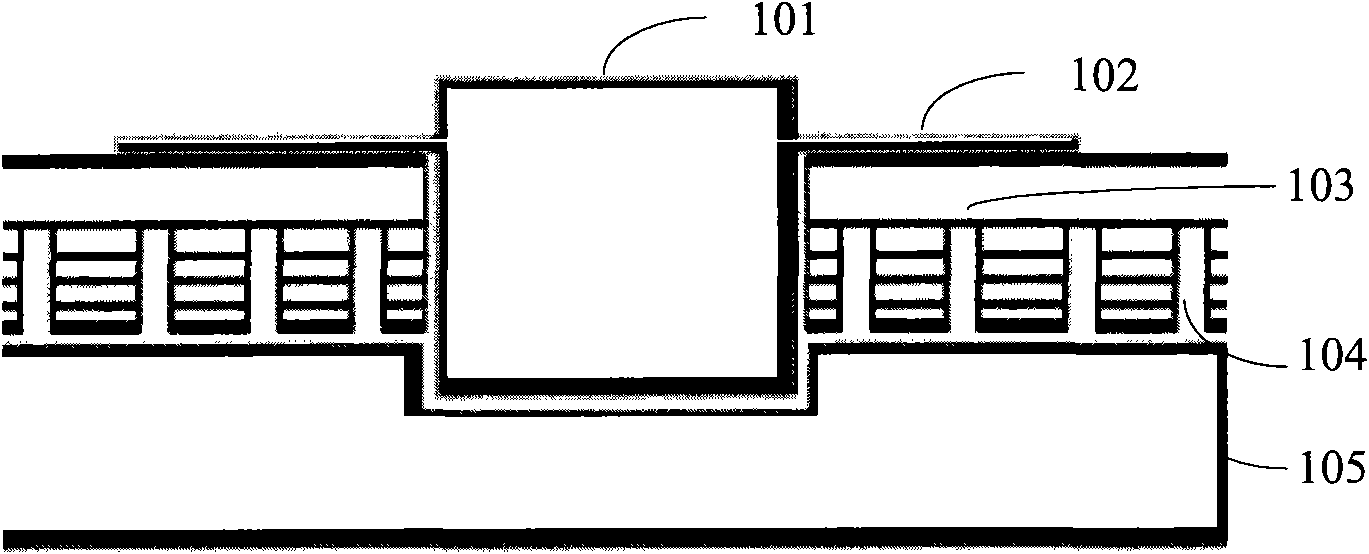

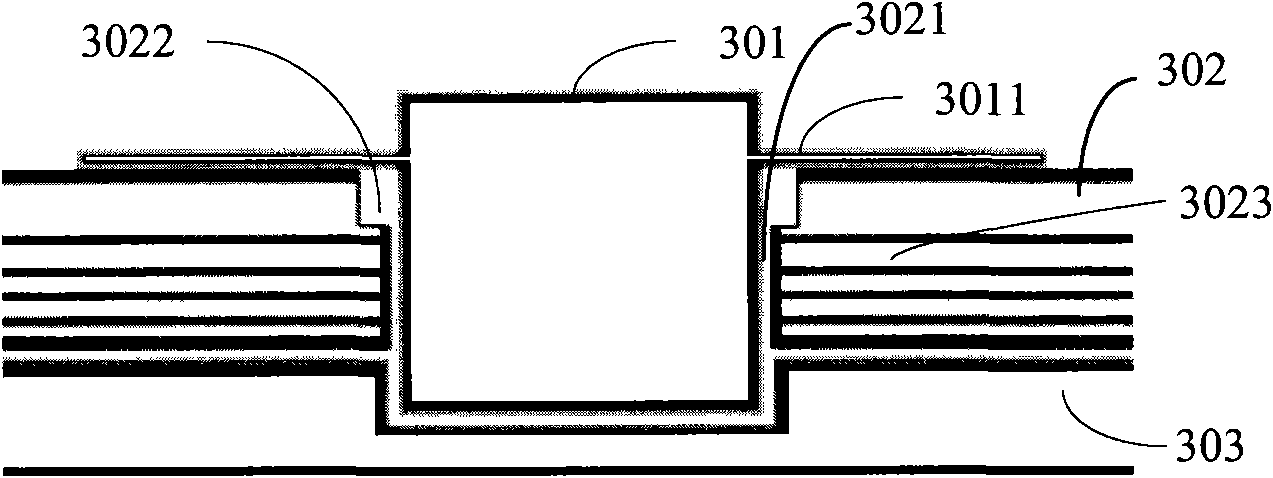

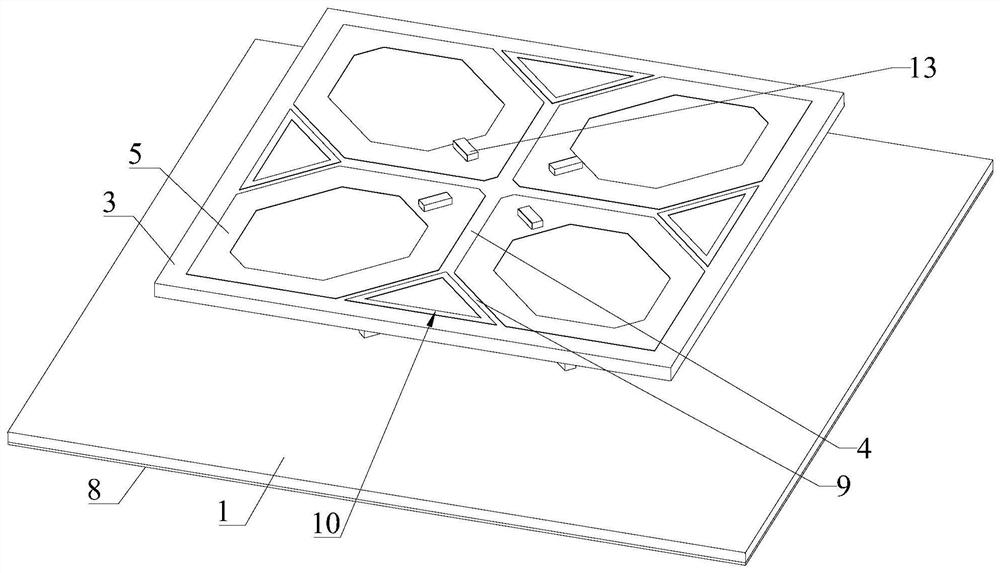

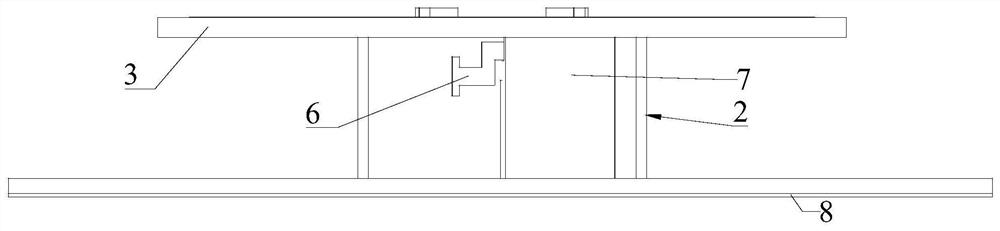

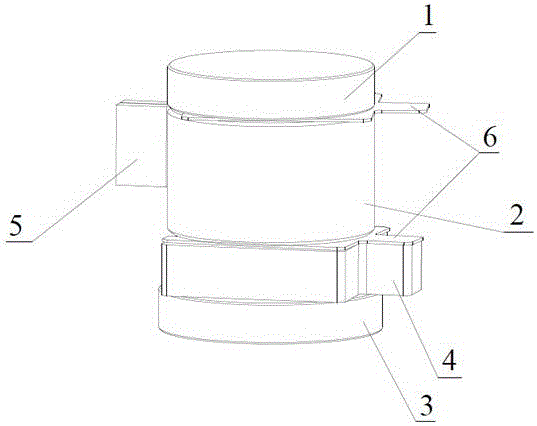

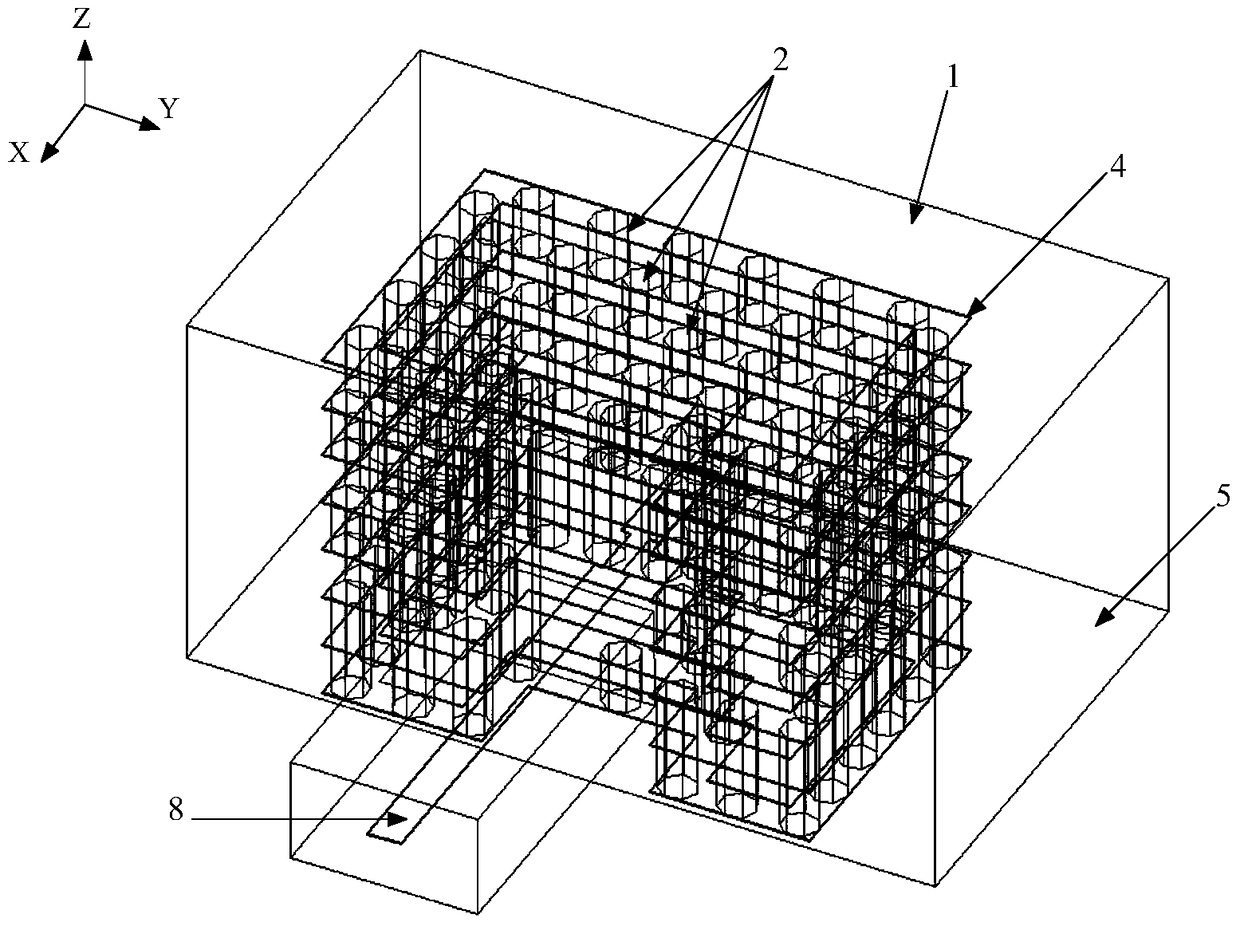

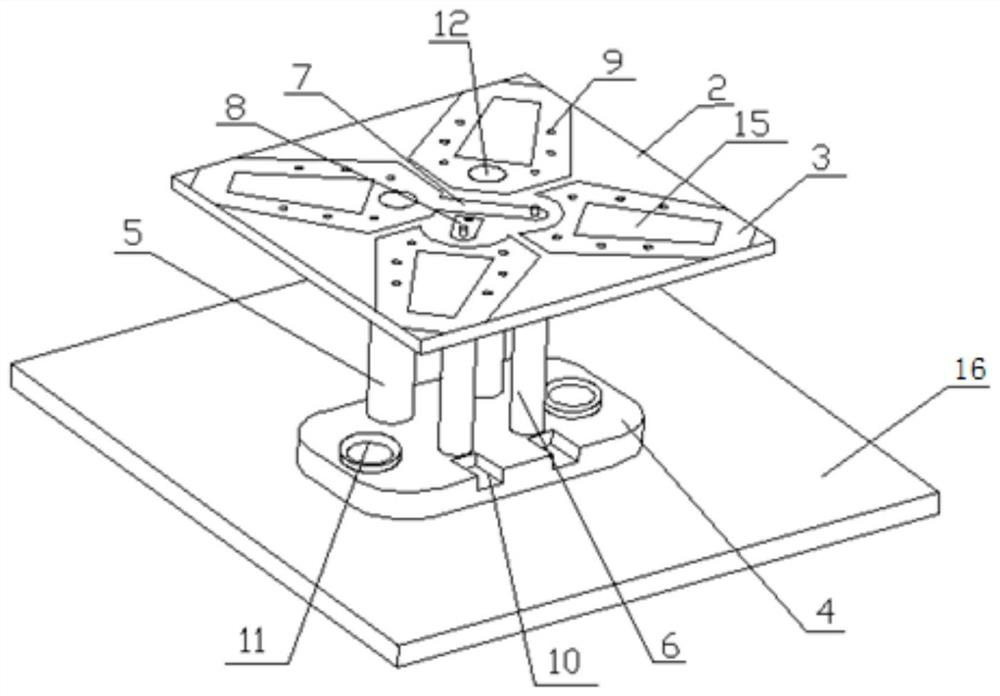

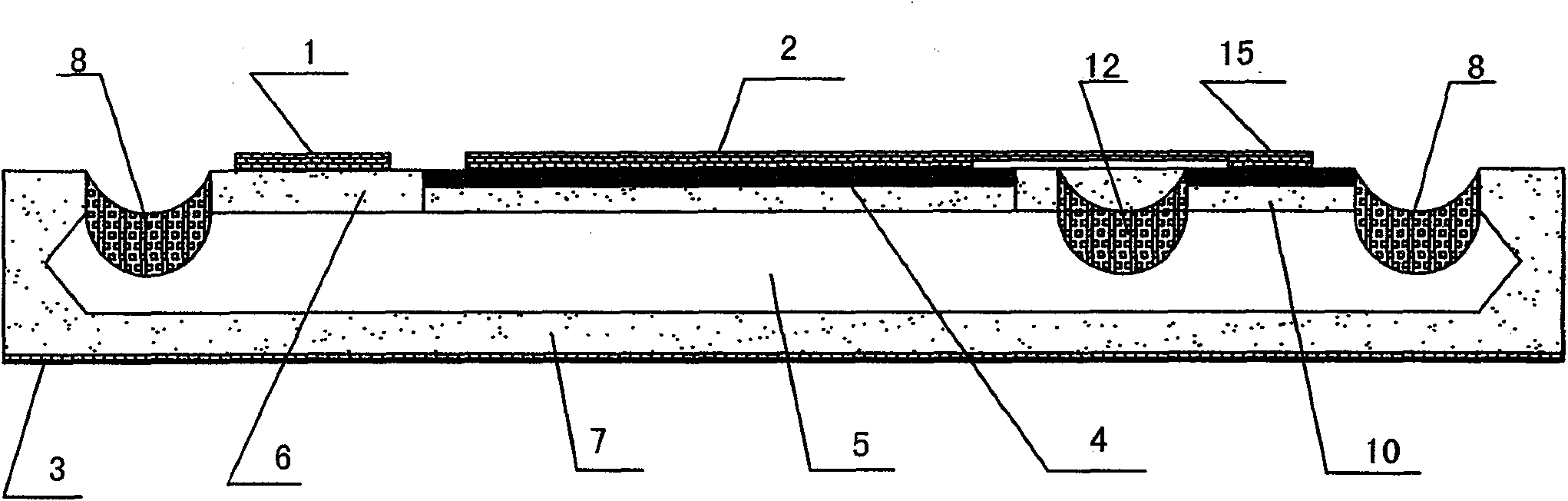

Inter-board perpendicular interconnection circuit structure for substrate integrated ridge waveguide

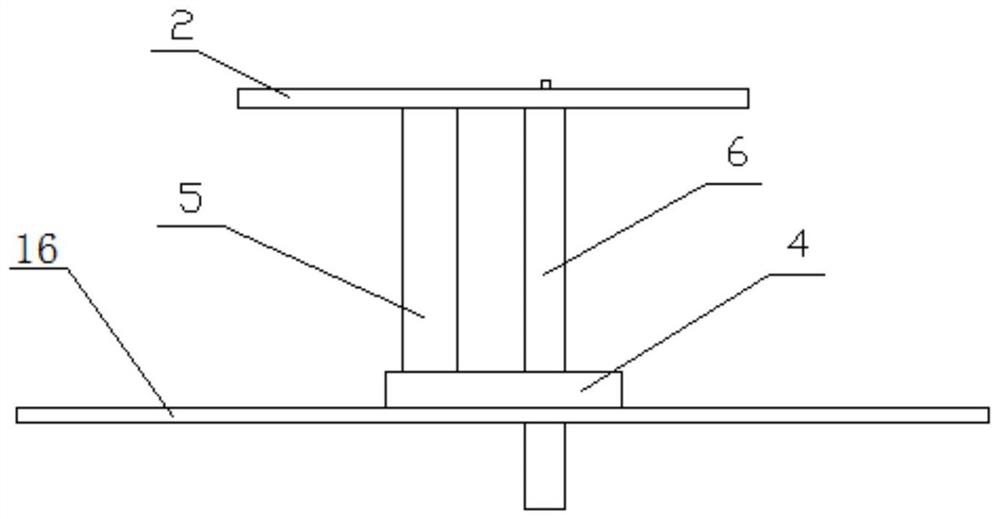

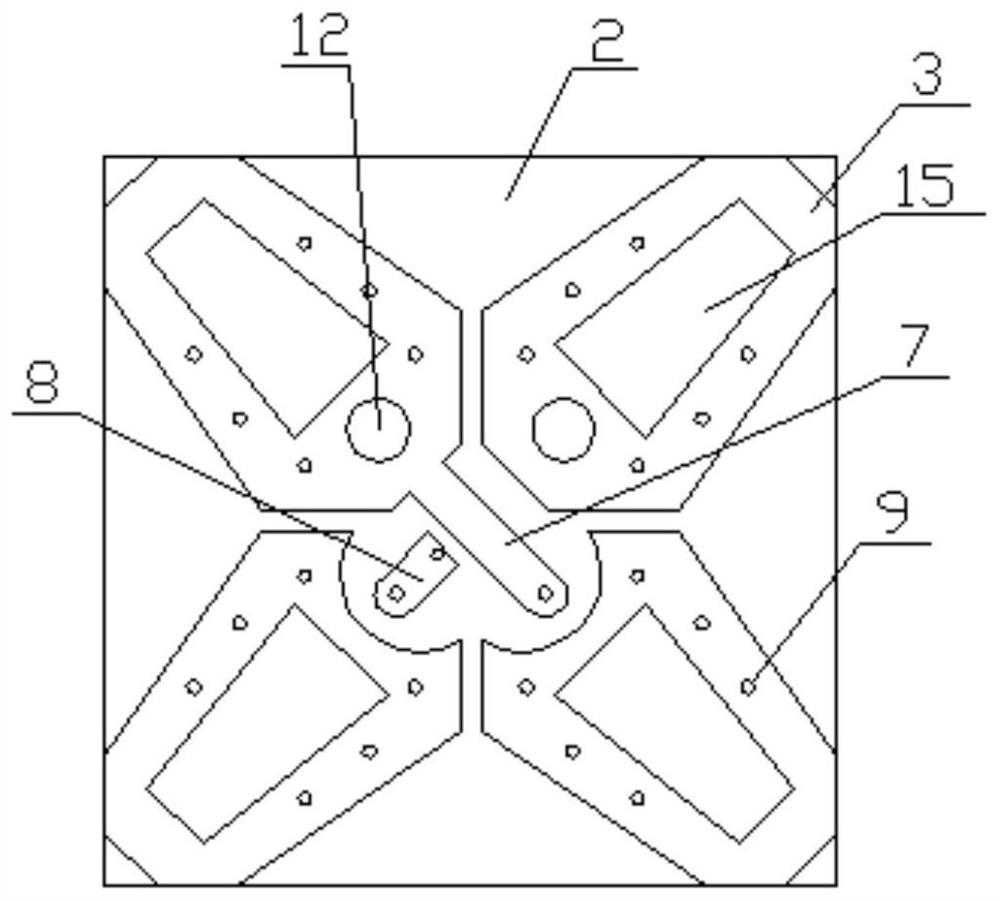

The invention provides an inter-board perpendicular interconnection circuit structure for a substrate integrated ridge waveguide (SIRW), and aims to provide a millimeter wave inter-board perpendicular interconnection circuit structure with small volume, easy integration, high interconnection property and long-term reliability. The inter-board perpendicular interconnection circuit structure is implemented by the following technical scheme: the SIRW (3) perpendicular to the surface of a base board is integrated on an LTCC multilayered circuit board (1); a substrate integrated ridge waveguide opening is etched in a corresponding outlet in the metal ground on the surface of the LTCC multilayered circuit board (1); Z-direction metalized filling holes (2) are arranged to form a metal hole gate array to equivalently form the waveguide wall and single-side ridges in the waveguide; metallic shield holes and probe restraining cavities (7) on the two sides of a 50-ohm strip line (8) are arranged at the equal spacing; and the alignment pressing and connection of the SIRW interfaces on the opposite sides between two boards is realized through pin hole alignment, so that the perpendicular interconnection transition of the millimeter wave signal between two boards in a way of 50-ohm strip line-SIRW-SIRW-50-ohm strip line is realized consequently.

Owner:10TH RES INST OF CETC

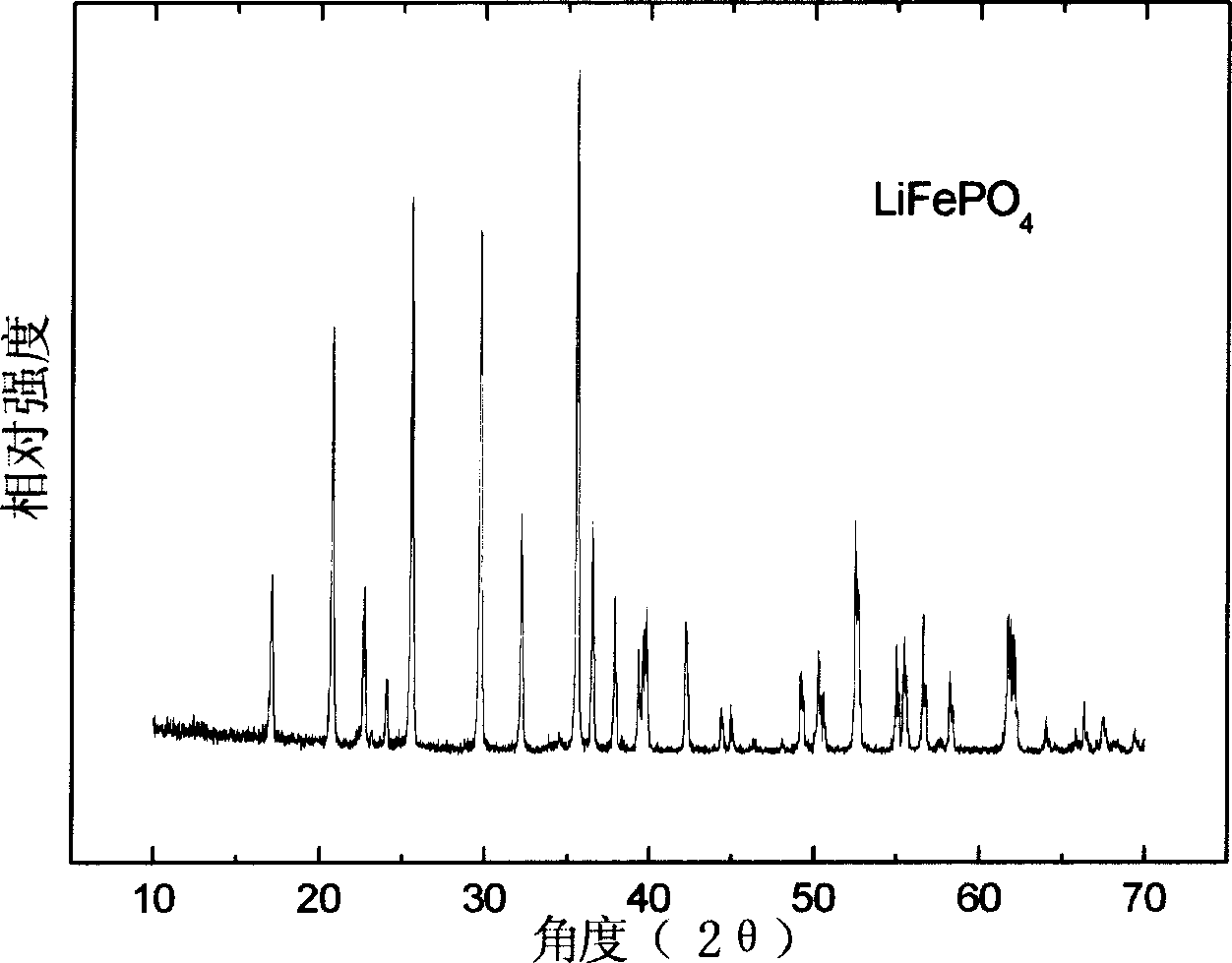

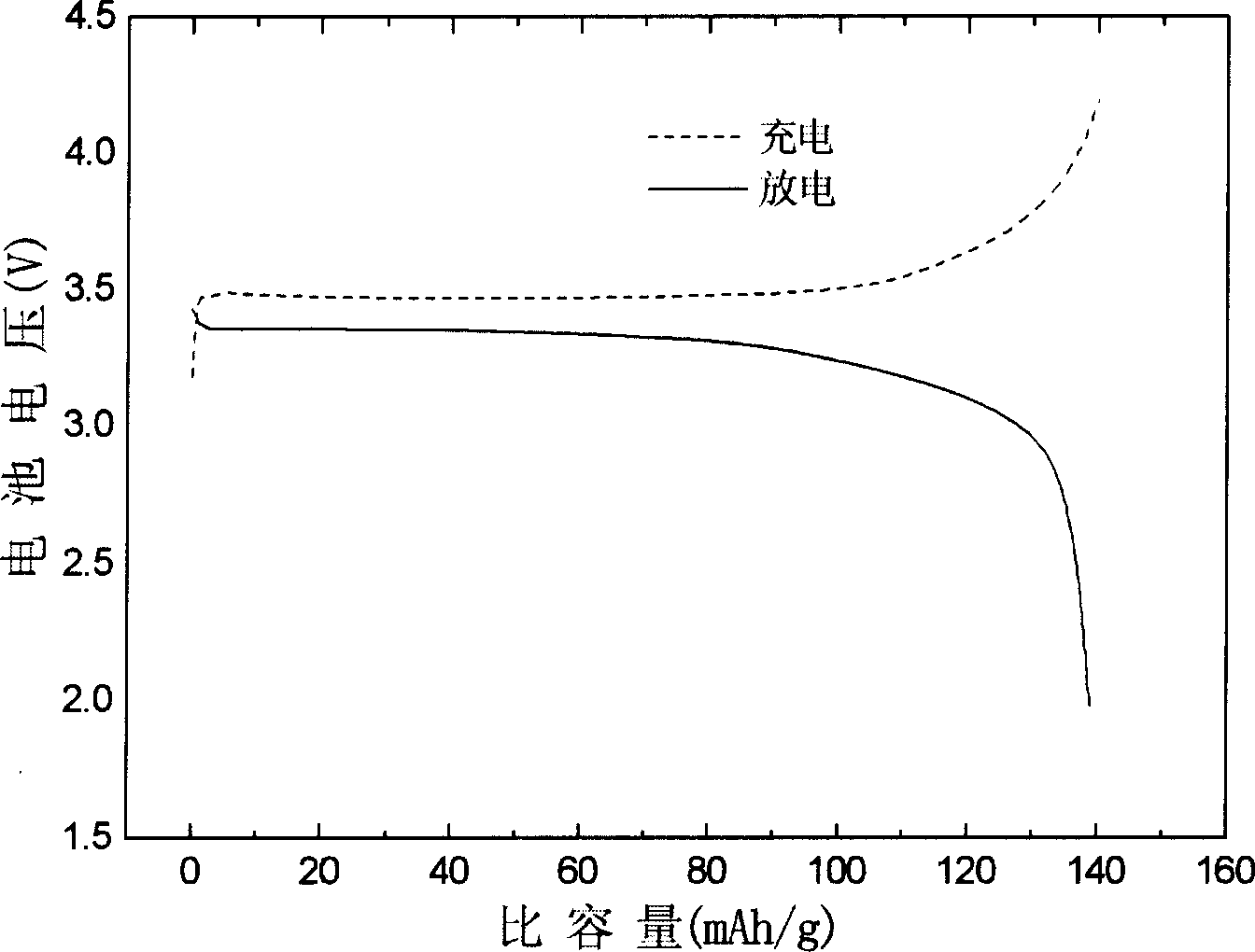

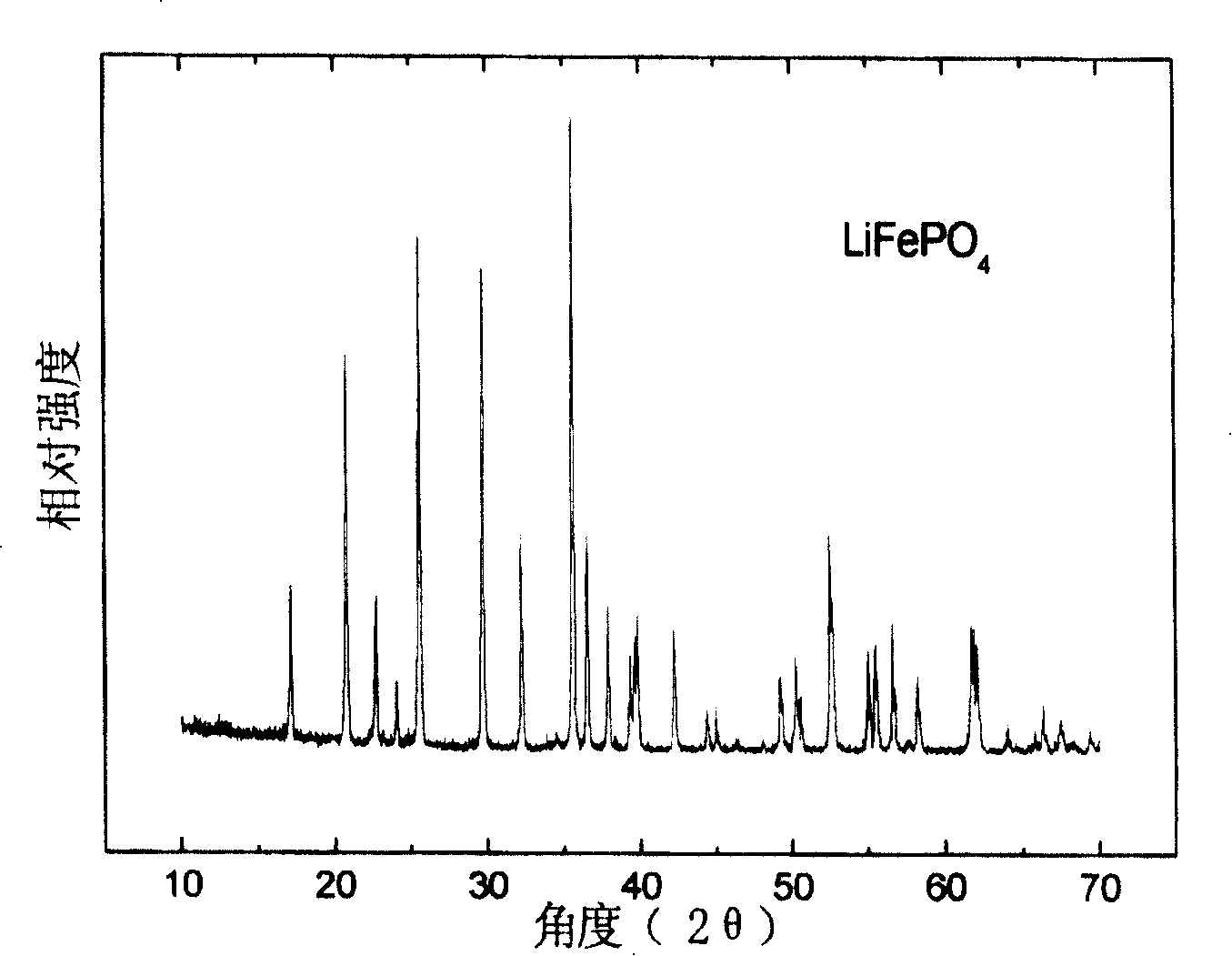

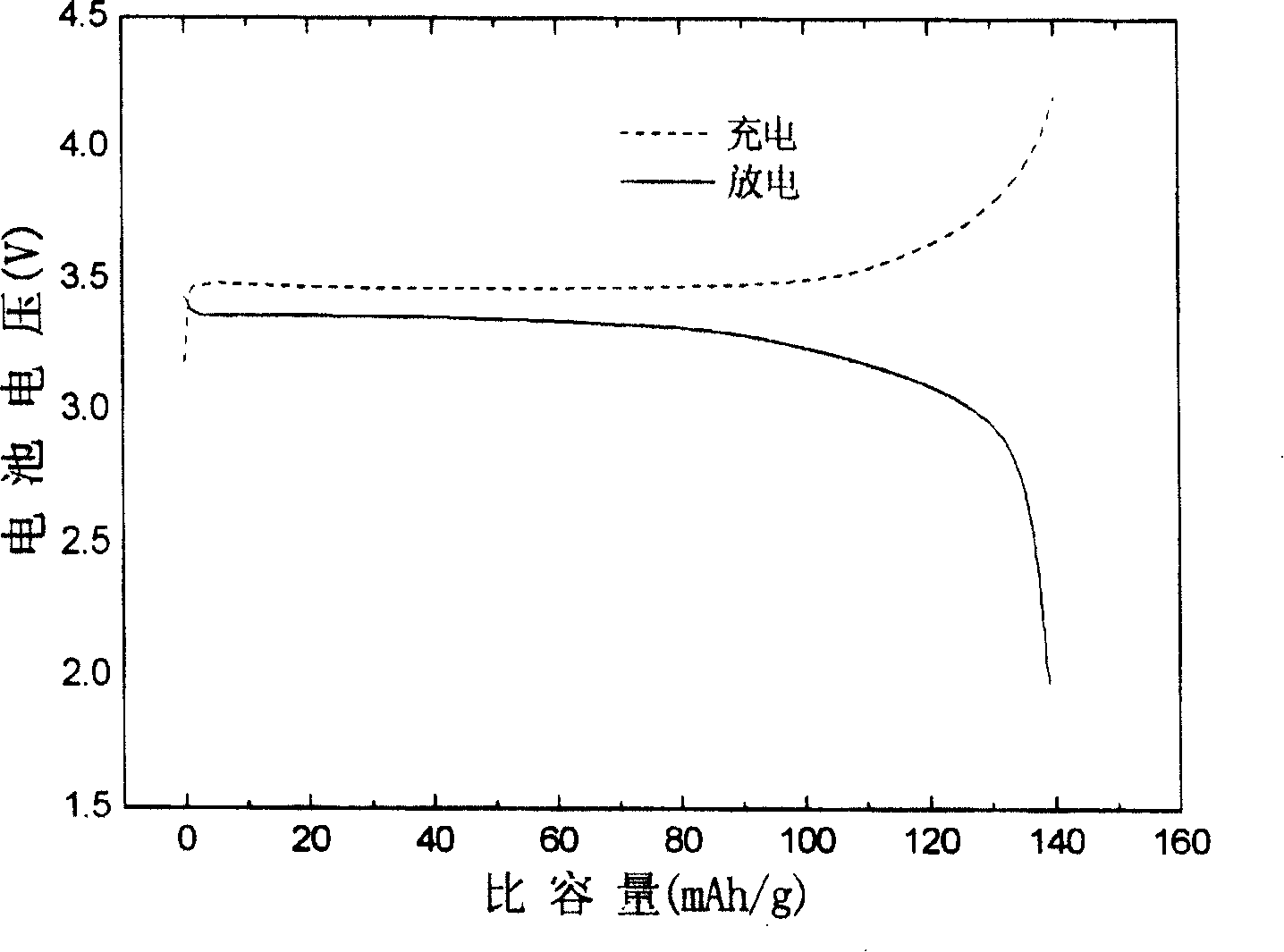

Method for preparing composite material of carbon coated lithium ferrous phosphate through iron phosphate

InactiveCN1915804AImprove completenessSuitable for industrial productionCell electrodesPhosphorus compoundsFerrous ammonium phosphatePhosphoric acid

This invention discloses a method for carbon-coated ferrous lithium phosphate composite material from ferric phosphate. The method comprises: (1) reducing Fe3+ of ferric phosphate into Fe2+ by a liquid-phase reducer; (2) reacting with NH4+ in the solution to obtain ferrous ammonium phosphate; (3) reacting with Li source at a high temperature and in inert atmosphere to obtain ferrous lithium phosphate; (4) coating with carbon to obtain carbon-coated ferrous lithium phosphate composite material. The method adopts Fe3+ as the raw material, thus reducing the costs of the raw material and the processing. The obtained composite material has such advantages as high purity and good electrochemical performance, and can be used as the cathode material of Li-ion batteries.

Owner:SHANGHAI JIAO TONG UNIV

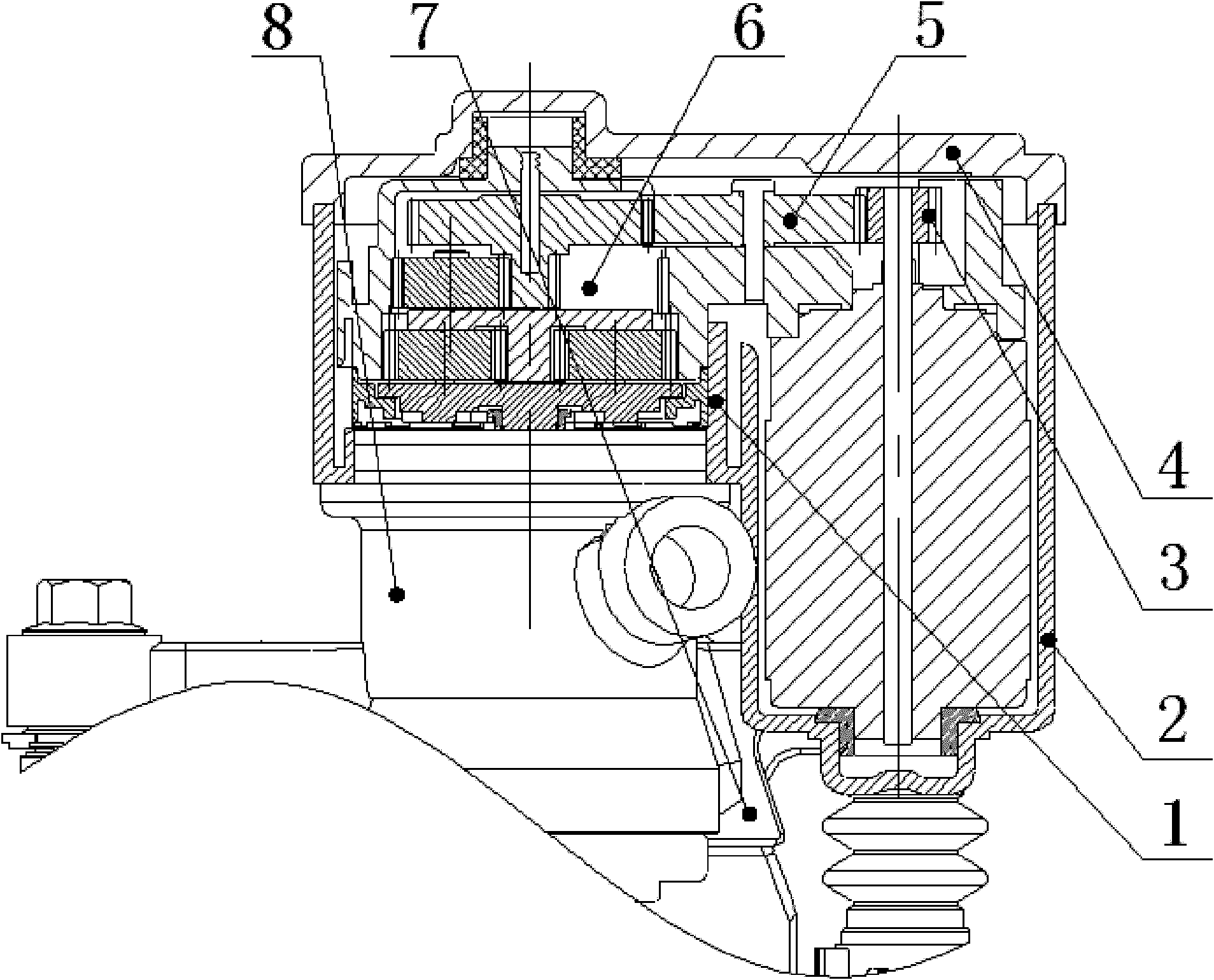

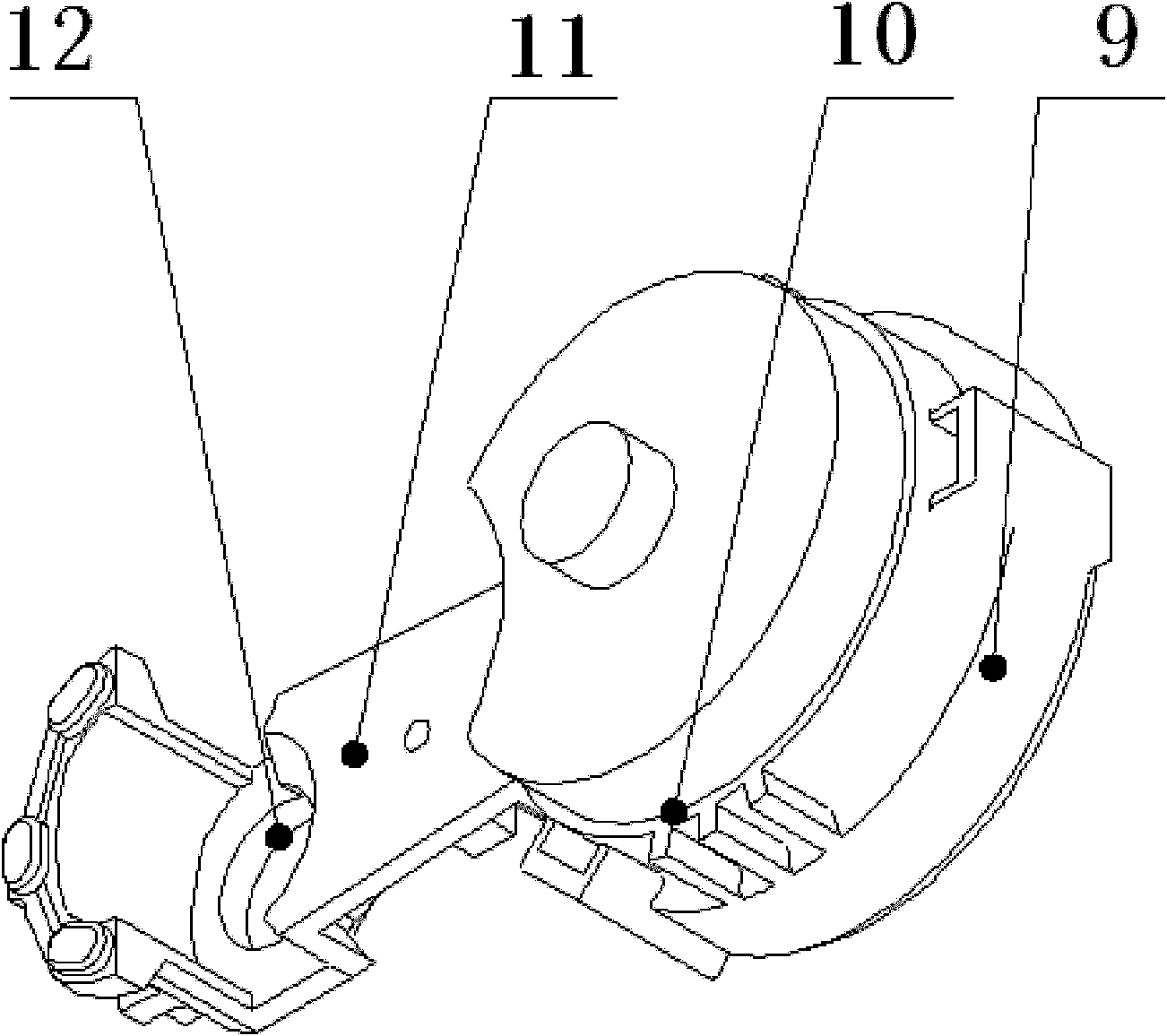

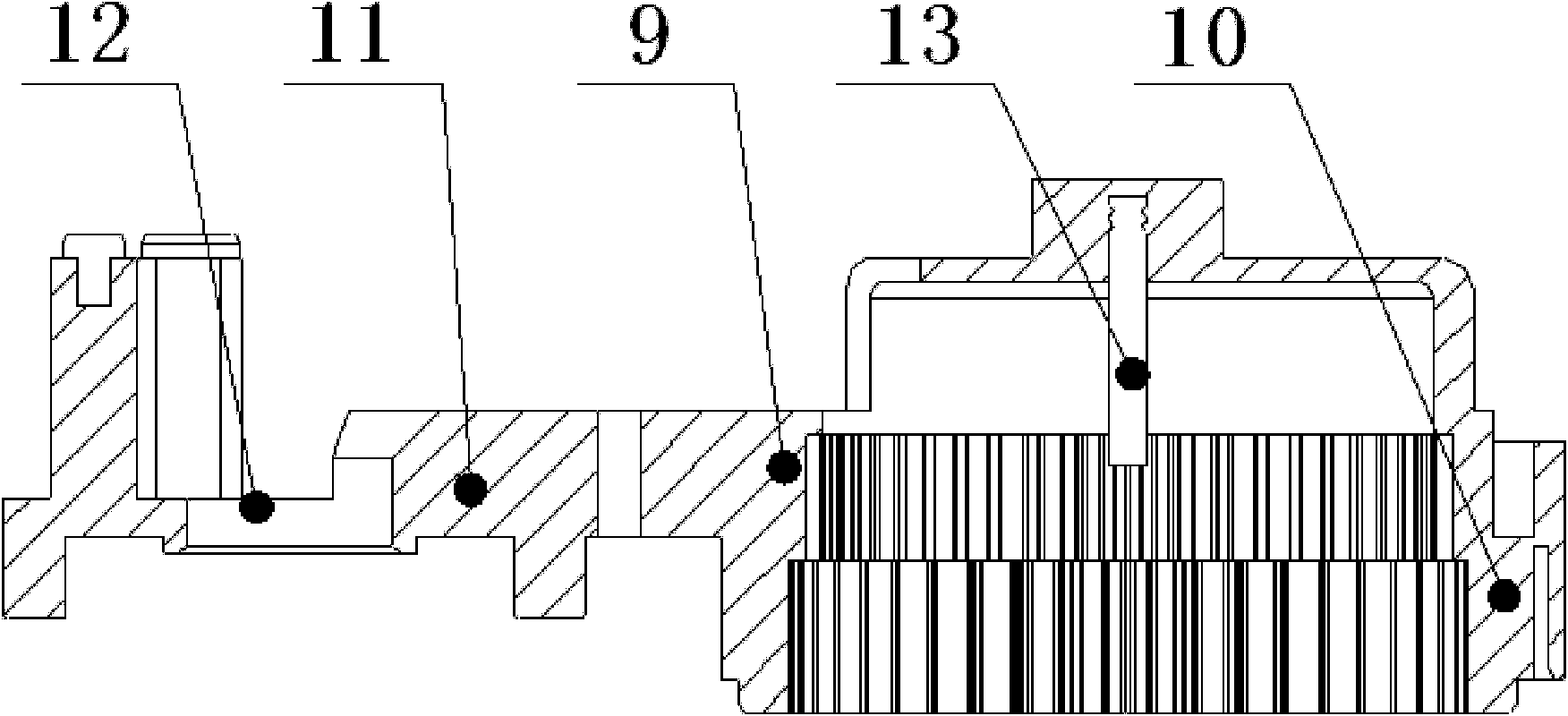

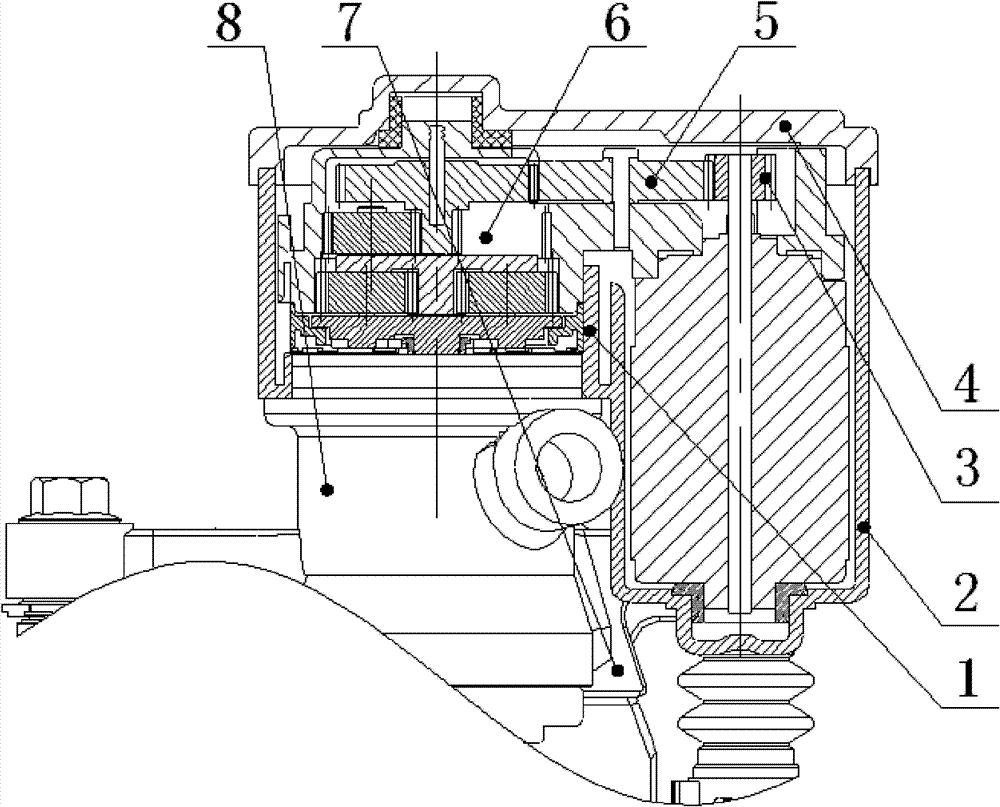

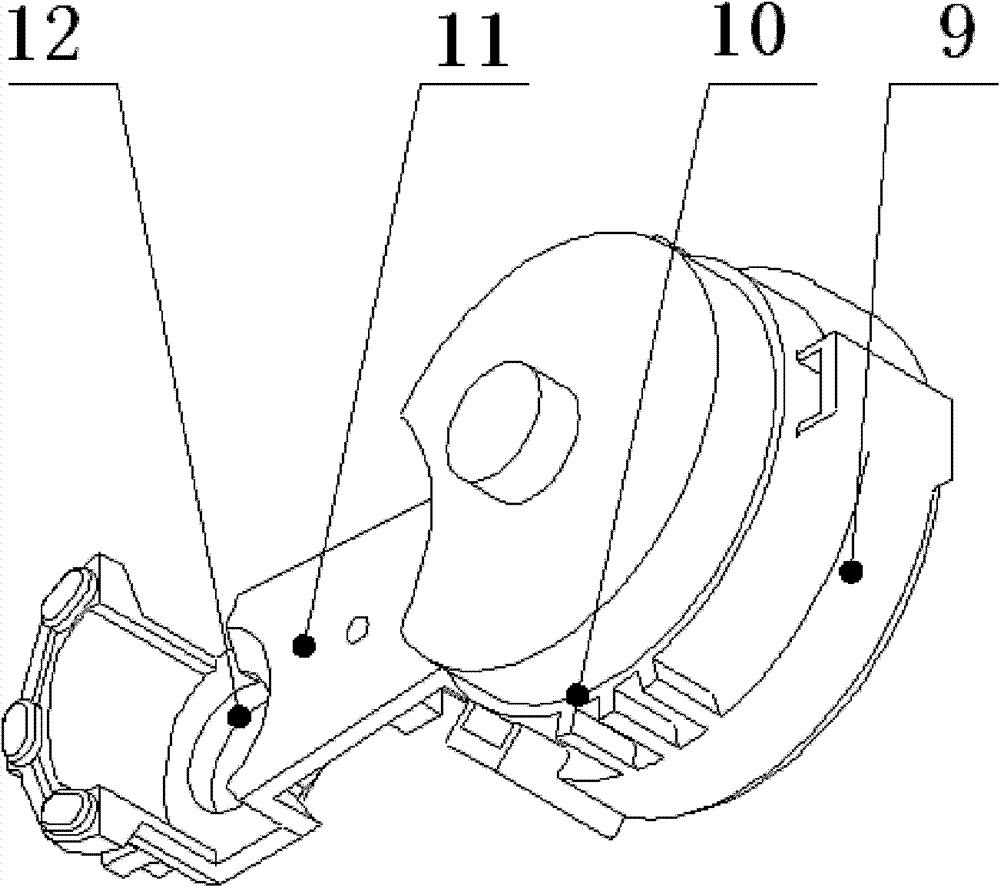

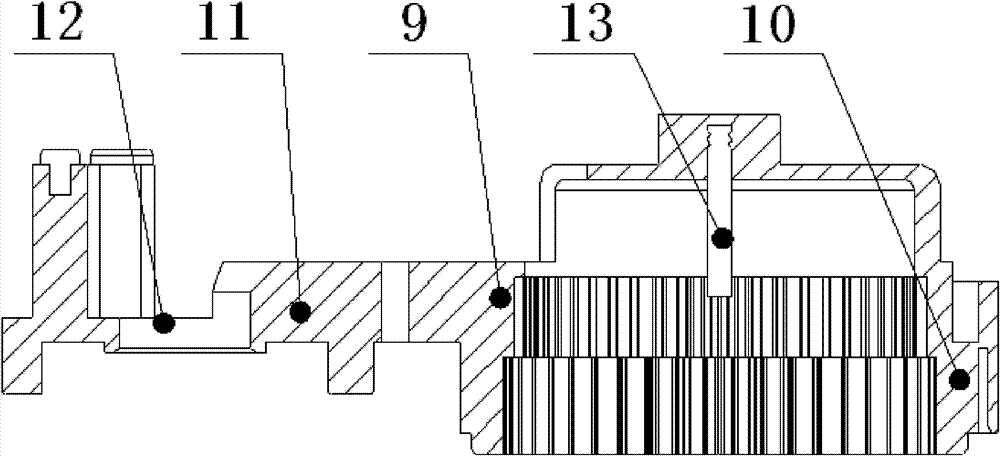

Electronic parking executor applied to motor vehicle brake system

ActiveCN102001334AImprove meshing accuracyIncrease product costBraking action transmissionBraking componentsGear transmissionMotor shaft

The invention discloses an electronic parking executor 1 applied to a motor vehicle brake system, which comprises a shell, a cover, a motor, motor accessories, a planetary gear transmission mechanism, parking brake calipers and the like. The electronic parking executor also comprises an integrated transmission mechanism frame, wherein a transmission mechanism and a planetary gear transmission mechanism from a motor shaft and a planetary gear main shaft are installed on a body in the integrated transmission mechanism frame, and the power transmission route of the transmission mechanism is from the motor shaft to the planetary gear main shaft. The technical scheme provided by the invention can effectively solve the problems of inconsistent assembly between rigid spacers and the motor shaft and the main shaft of the planetary gear transmission mechanism, axial nonparallelism and easy deformation of the rigid spacers after stressing in the prior art; meanwhile, the invention also has the characteristics of increasing the stability of internal transmission mechanism and the performance consistency after being connected with braking, reducing assembly cost, increasing assembly quality, benefiting tests, having good batch consistency and the like.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

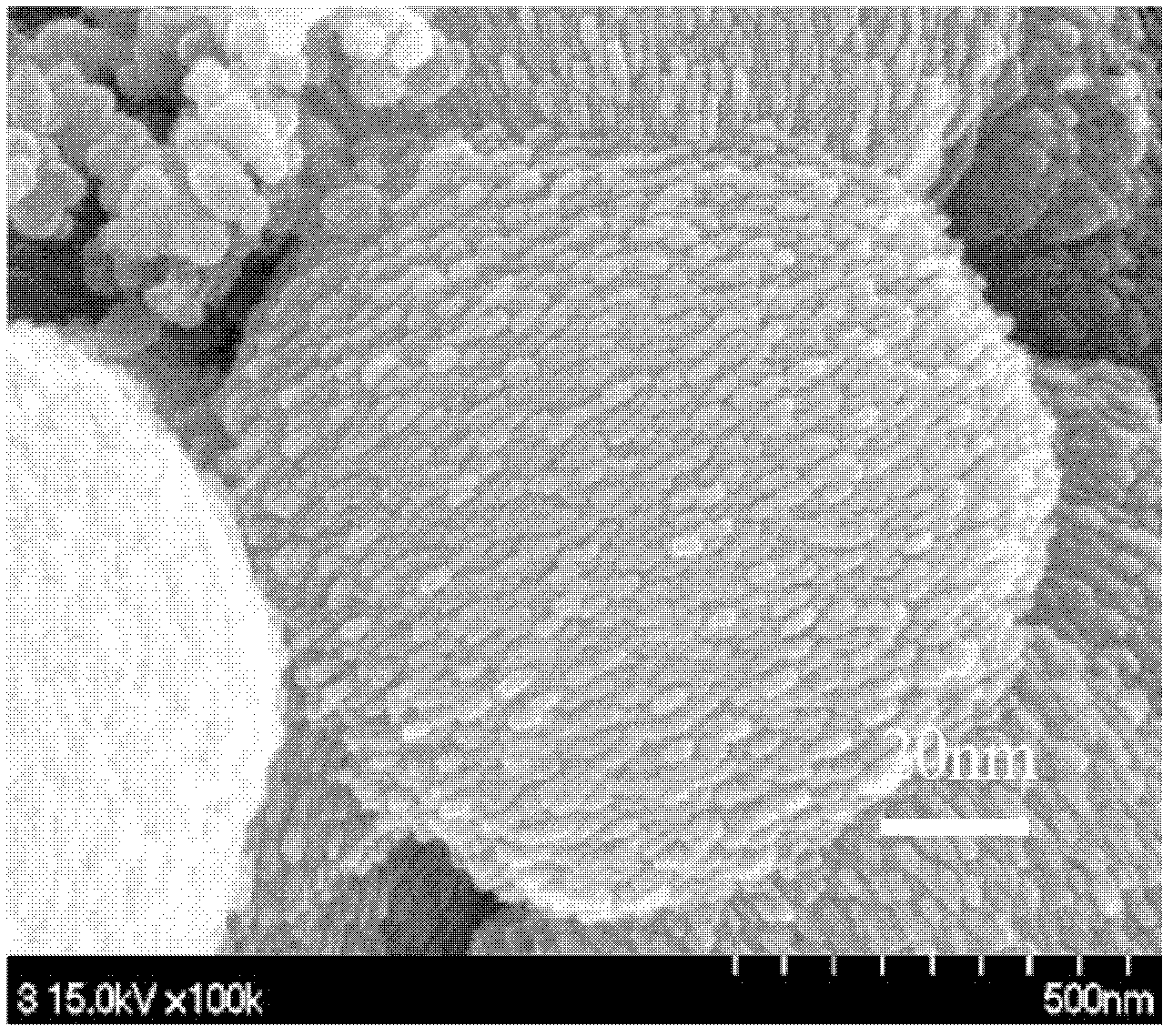

Industrial production method for preparing nanometer lithium iron phosphate by adopting solvent thermal method

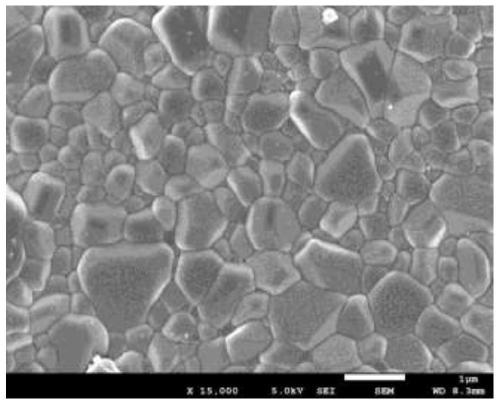

InactiveCN103030128ASmall particle sizeNarrow particle size distributionCell electrodesNanotechnologyRecovery methodDistillation

The invention discloses an industrial production method for preparing nanometer lithium iron phosphate by adopting a solvent thermal method. The industrial production method comprises the following steps that phosphorus source compounds, iron source compounds, lithium source compounds, carbon sources and solvents are proportionally and sequentially added into a sealed reaction kettle and are uniformly mixed and stirred, the stirring temperature rising reaction is carried out in inert atmosphere, primary products of the lithium iron phosphate are obtained, solid and liquid separation is carried out, washing and drying are carried out, the roasting is carried out in the inert atmosphere, and the lithium iron phosphate products are obtained. Waste water and waste organic solvents generated in the production process are recovered and reutilized through reduced pressure distillation. The obtained product of the lithium iron phosphate materials has fine primary particle size and narrow particle size distribution, in addition, the distribution is uniform, the conductivity is good, the electrochemical performance of products is good, the product batch consistency is good, the operation of a recovery method is simple, the control is easy, the energy consumption is low, and the method is suitable for industrial production and application.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

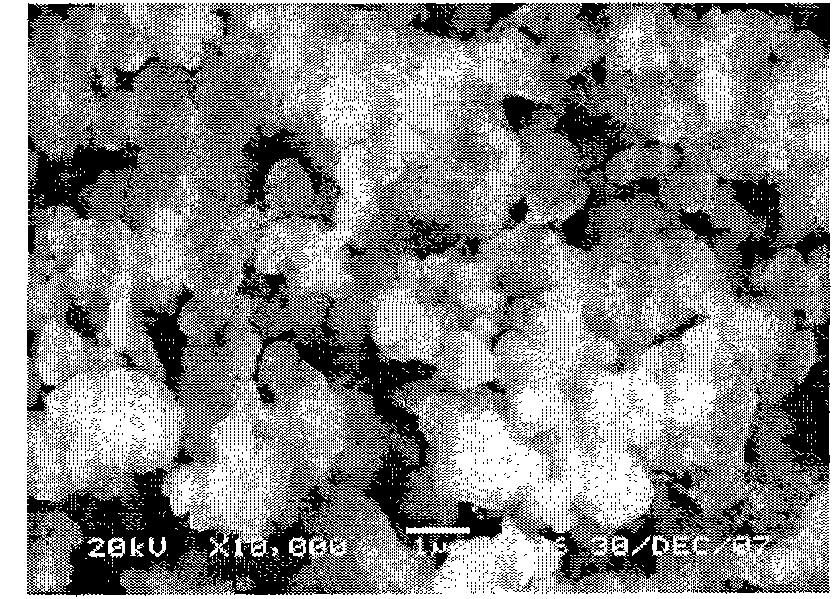

Secondary sintering synthesis method for lithium iron phosphate

InactiveCN101830453AGood coating effectPromote generationPhosphorus compoundsLithium iron phosphateSynthesis methods

The invention discloses a secondary sintering synthesis method for lithium iron phosphate, which comprises the following process steps of: 1, preparing materials in a molar ratio of lithium to iron to phosphorus element of (0.98-1.02): 1: 1, and mixing the materials uniformly; 2, heating the obtained mixture to between 350 and 550 DEG C, preserving the heat for 5 to 15 hours, then cooling the mixture along with a furnace to room temperature, and crushing the obtained material to obtain lithium iron phosphate powder; 3, mixing the obtained lithium iron phosphate powder, a carbon source and a solvent uniformly, drying the mixture and then heating the mixture to between 650 and 850 DEG C, preserving the heat for 10 to 20 hours, then cooling the mixture along with the furnace to room temperature, and crushing, screening and grading the mixture to obtain a screened product which is a lithium iron phosphate product produced by the method. The method is simple; the operation is convenient; the prepared lithium iron phosphate has high electric conductivity, good storage performance, good low-temperature performance and good batch consistency; and the method greatly improves the electric conductivity, low-temperature performance, storage performance and batch stability of the lithium iron phosphate. The method is suitable for industrialized production and can replace the conventional one-time high temperature sintering process.

Owner:谢朝华 +3

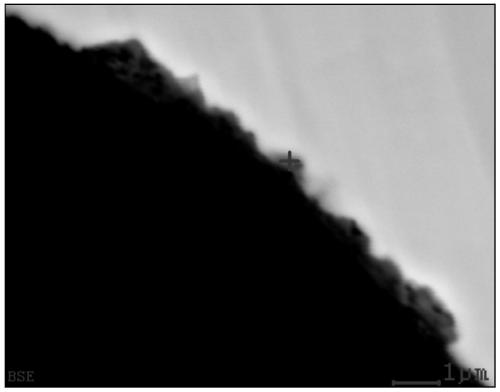

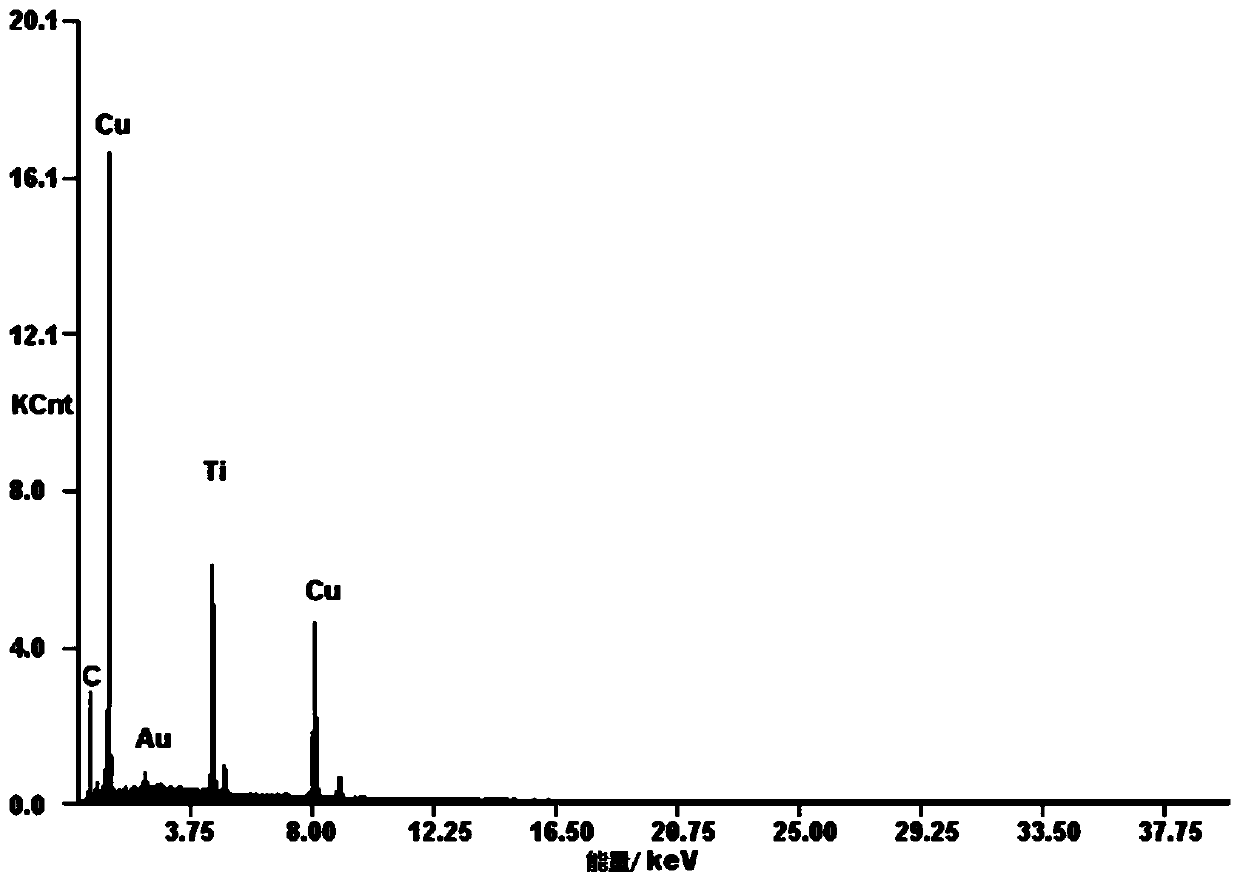

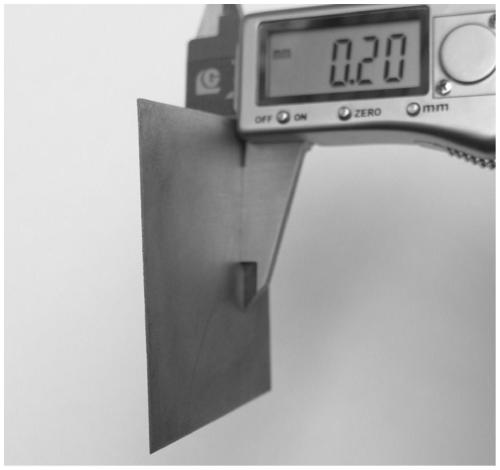

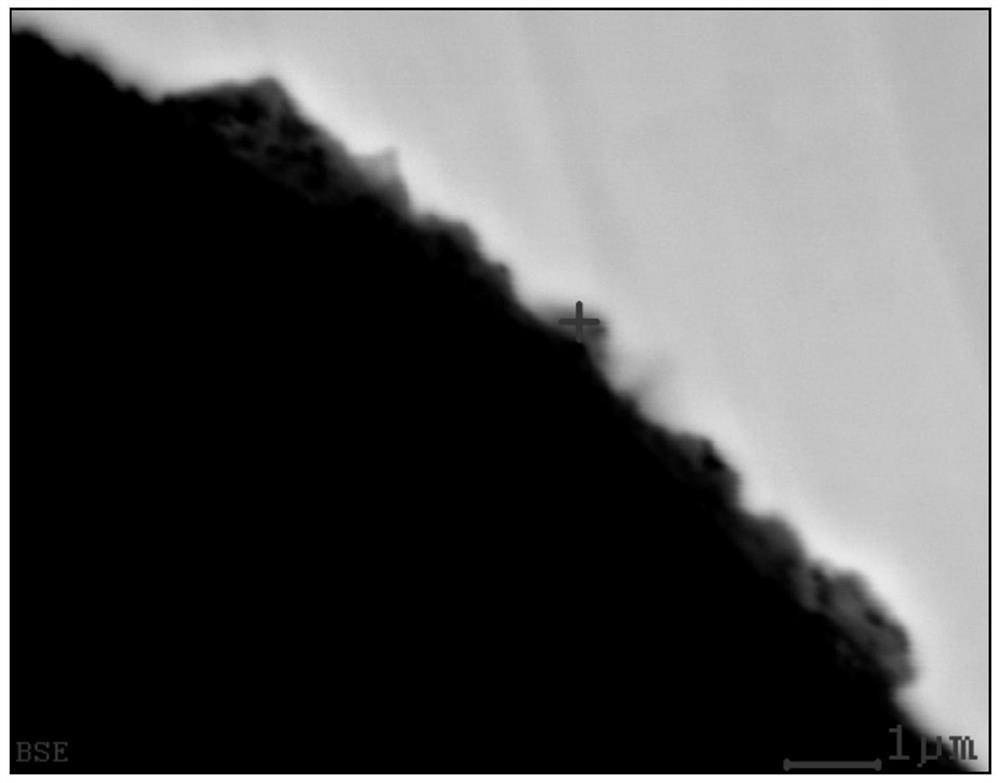

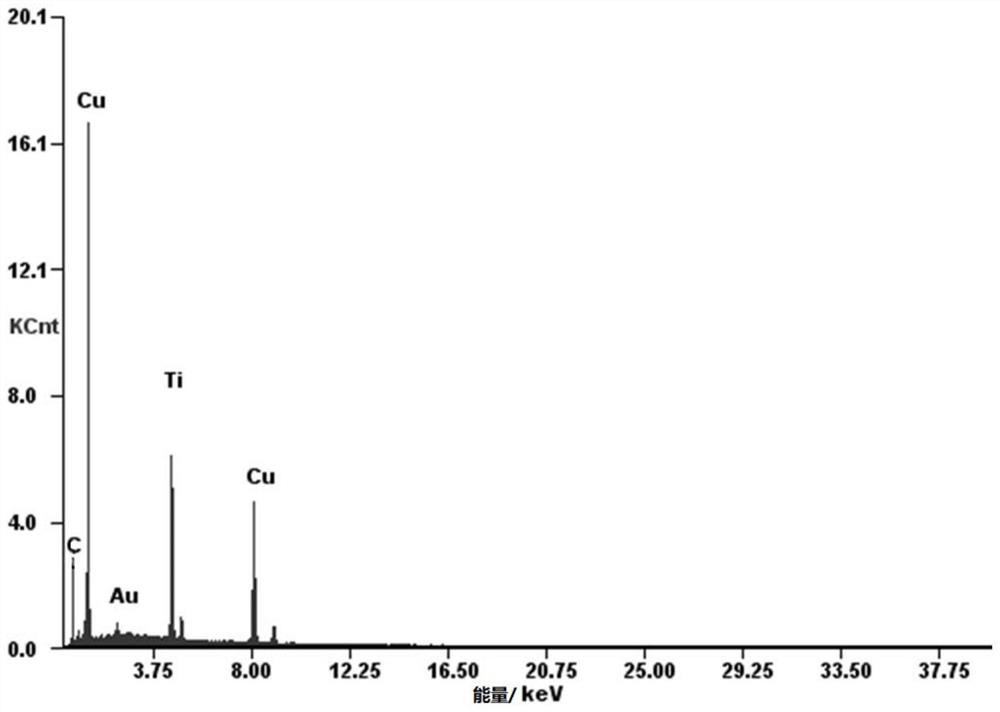

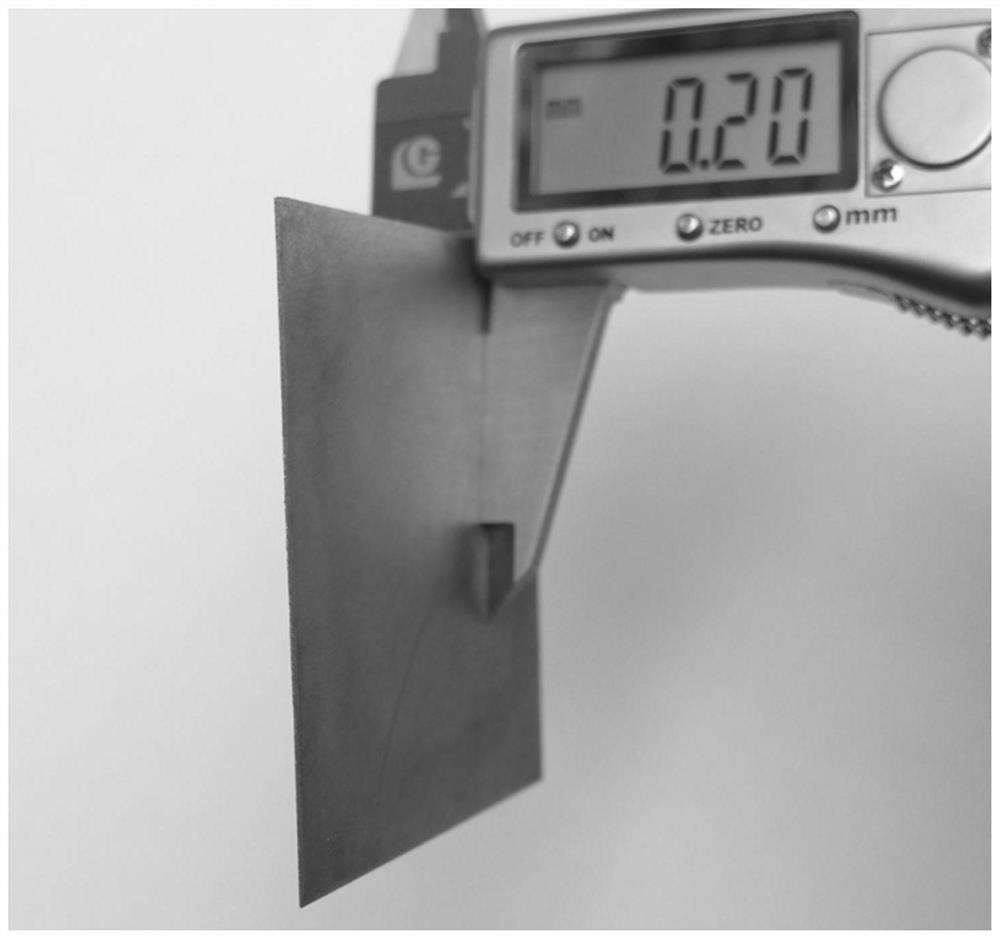

Preparation method for large-size slice-shaped and ultrahigh-heat-conductivity diamond/copper composite material

The invention provides a preparation method for a large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material and relates to the preparation method for the diamond / coppercomposite material. The purpose of the preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is to solve the problems of the low heat conductivity and the poor interfacial bonding strength of the diamond / copper composite material. The preparation method comprises the steps that diamond particles coated with metal films are filled intoa mold cavity of a graphite mold to obtain a prefabricated body; and the prefabricated body is placed into a crucible, block-shaped pure copper and copper alloy are placed at the upper portion of theprefabricated body inside the crucible to be placed into an air pressure leaching furnace, interfacial layer material tissue form adjusting and control are performed under an argon protective atmosphere, warming copper melting, heat preservation and pressure maintaining leaching are performed, and finally, pressure maintaining stepped cooling is performed. In an obtained composite material component, the diamond volume fraction is 60-85%, the heat conductivity reaches 1500 W / mK, the edge length reaches 60-130 mm, and the thickness reaches 0.2-4 mm. The preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is suitable for preparing the high-heat-conductivity diamond / copper composite material.

Owner:哈尔滨锦威科技有限公司

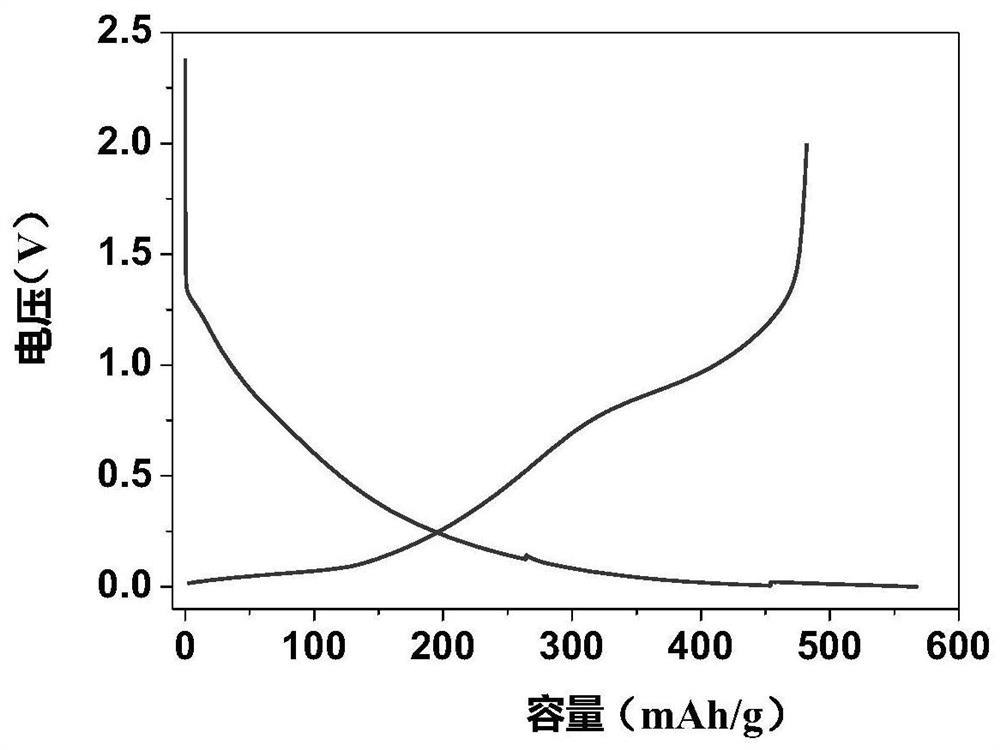

Hard carbon negative electrode material, lithium ion battery as well as preparation method and application of hard carbon negative electrode material

ActiveCN112645300AImprove structural propertiesThree-dimensional structure is stableSecondary cellsNegative electrodesModified carbonPhysical chemistry

The invention discloses a hard carbon negative electrode material, a lithium ion battery and a preparation method and application of the hard carbon negative electrode material. The preparation method comprises the following steps: (1) carrying out cross-linking reaction on carbon source precursor powder and an additive to prepare a modified carbon source precursor, wherein the additive comprises a cross-linking agent, a modifier and a dispersing aid; (2) sequentially carrying out heat treatment and cooling on the modified carbon source precursor, and mixing the modified carbon source precursor with a lithium-rich agent to prepare a modified hard carbon precursor; and (3) carrying out vacuum carbonization on the modified hard carbon precursor to obtain the hard carbon negative electrode material. The hard carbon negative electrode material prepared by the method belongs to typical amorphous carbon and is high in pyrolysis yield, and the lithium ion battery prepared by taking the hard carbon negative electrode material as the negative electrode material is high in first reversible capacity, high in first coulombic efficiency, stable in property and good in batch consistency.

Owner:SHANGHAI SHANSHAN TECH CO LTD +1

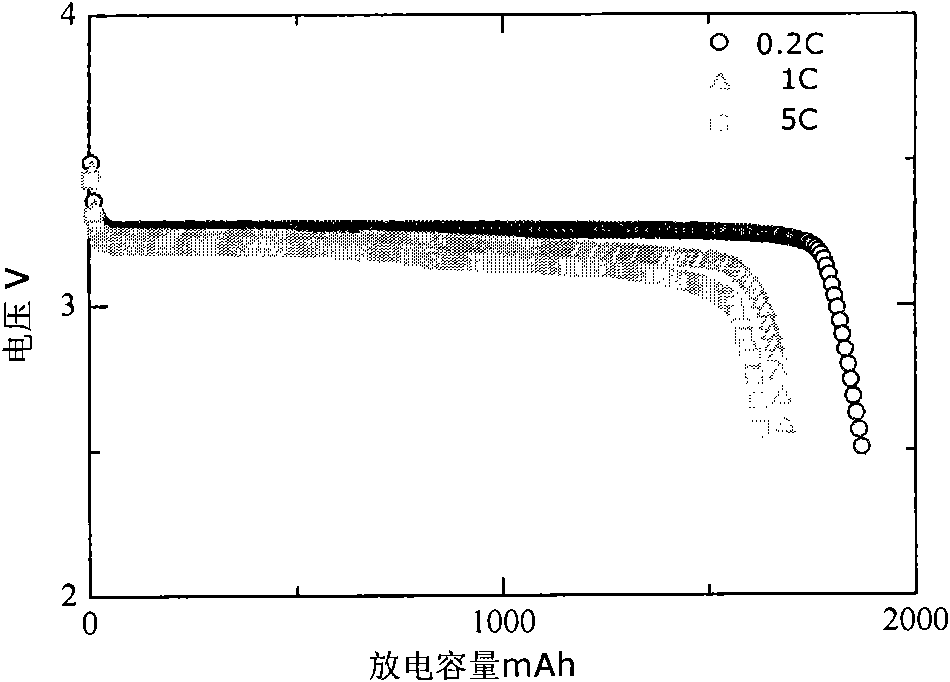

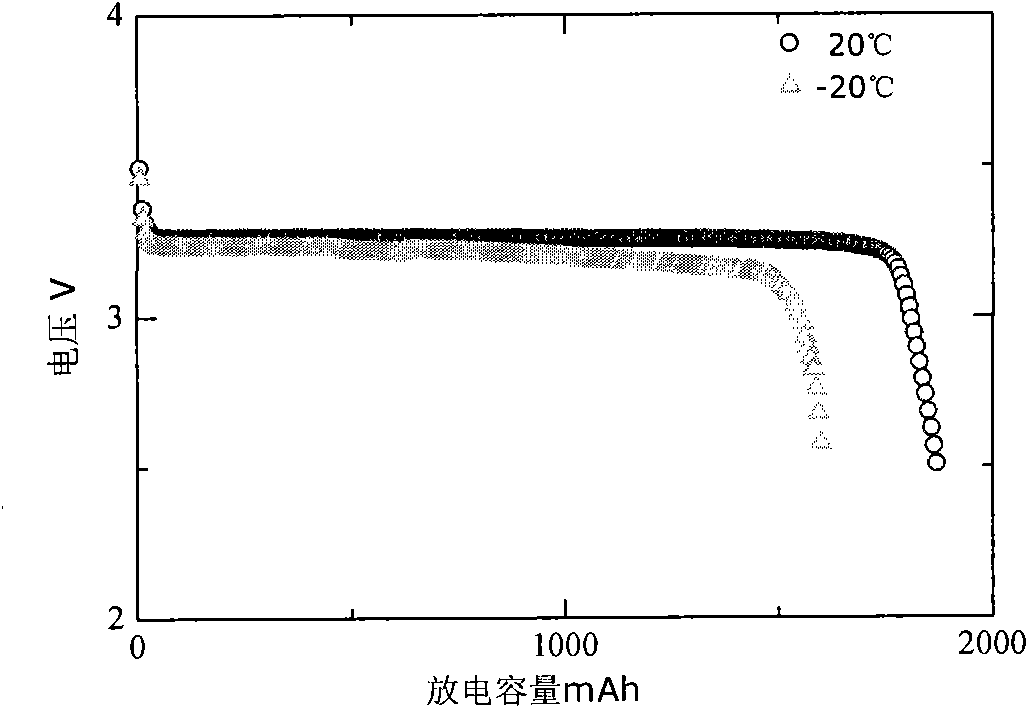

Lithium-ion battery and manufacturing method thereof

ActiveCN102683662ALow priceRich sourcesFinal product manufactureCell electrodesHigh energyPhysical chemistry

The invention discloses a lithium-ion battery and a manufacturing method thereof. The lithium-ion battery comprises a battery casing, a pole core and electrolyte, wherein the pole core and the electrolyte are accommodated in the battery casing in a sealed manner; the pole core consists of a positive pole, a negative pole and a septum layer located between the positive pole and the negative pole; the negative pole comprises a current collector and a negative sizing material coated on the current collector and made from a carbon silicon composite negative material; the carbon source of the carbon silicon composite negative material is an amphiphilic carbon material, and the carbon source is crystalline silicon with a particle size of 3-10 nm; the carbon silicon composite negative material adopts a core-shell structure with a carbon shell and a silicon core, the particle size is 30-50 nm, and the sophericity is 50-80 percent; and the specific capacity of the carbon silicon composite negative material is 503-1,028 mAh / g, and a 100-cycles capacity conservation rate is more than or equal to 85 percent. The lithium-ion battery manufactured by adopting the manufacturing method is high in battery specific capacity and low in cost, has the characteristics of high energy density and excellent multiplying factor, and is good in low-temperature performance.

Owner:DONGFANG ELECTRIC CORP LTD

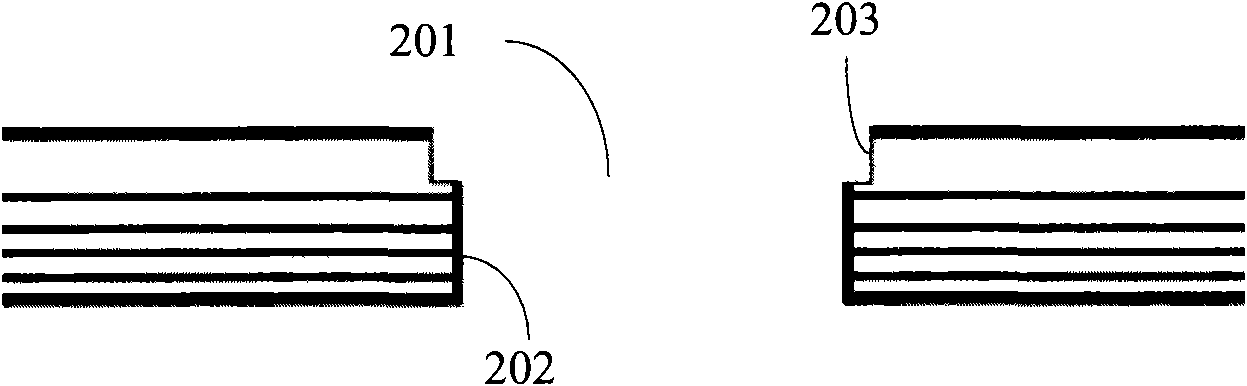

Printed circuit board as well as manufacture method and associated equipment thereof

InactiveCN101616541ASimple processing technologyGood batch consistencyPrinted circuit assemblingPrinted circuit aspectsEngineeringCopper

The embodiment of the invention relates to a printed circuit board and discloses a printed circuit board as well as a manufacture method and associated equipment thereof. The associated equipment comprises a device for solving the reflux of a radio-frequency power amplifier and communication equipment. The printed circuit board comprises a plurality of monolayer printed circuit boards, and the first surface of the printed circuit board is attached with a surface copper sheet; one reference monolayer printed circuit board of the printed circuit board is attached with a reference copper sheet which corresponds to the surface copper sheet and is different from the monolayer printed circuit board attached on the surface copper sheet; the printed circuit board comprises a window, and the side wall of the window is attached to side wall metal; and the side wall metal is electrically connected with the reference copper sheet and insulated with the surface copper sheet. The technical scheme does not need the complicated processing procedure of the printed circuit board when the problem of the reflux is solved.

Owner:HUAWEI TECH CO LTD

Manufacture method of carbon-silicon compound cathode material of lithium ion battery

ActiveCN102683660ARich sourcesEasy to achieve large-scale industrial productionCell electrodesOrganic solventNanoparticle

The invention discloses a manufacture method of a carbon-silicon compound cathode material of a lithium ion battery, belonging to the technical field of cathode materials of a lithium ion battery. The invention is a simple in a synthetic technology and a use device; and compared with the synthetic method of traditional carbon-silicon compound cathode materials such as a chemical vapor deposition method, the manufacture method is lower in the production cost; and by adopting the process method and the technological parameter, amphiphilic carbon material nanoparticles are manufactured through freezing and drying, so that the step of an organic solvent replacement process is saved, and the cost and the environmental pollution and the toxicity to the personal, caused by the organic solvent are reduced.

Owner:DONGFANG ELECTRIC CORP LTD

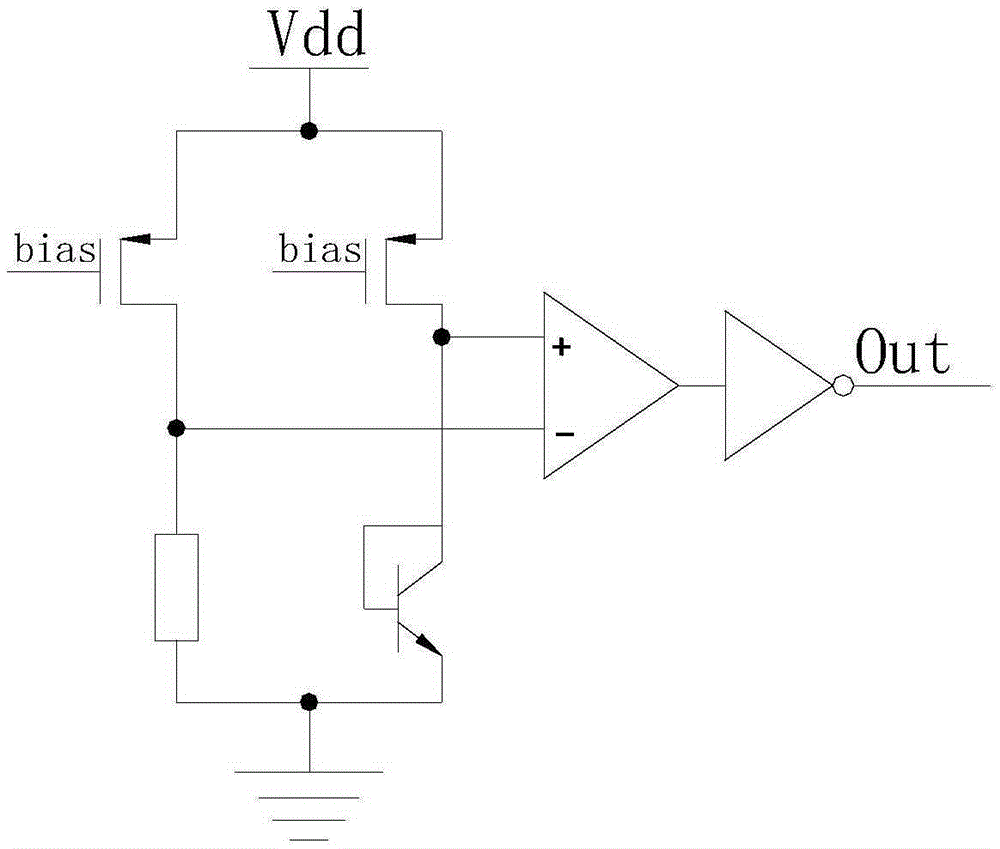

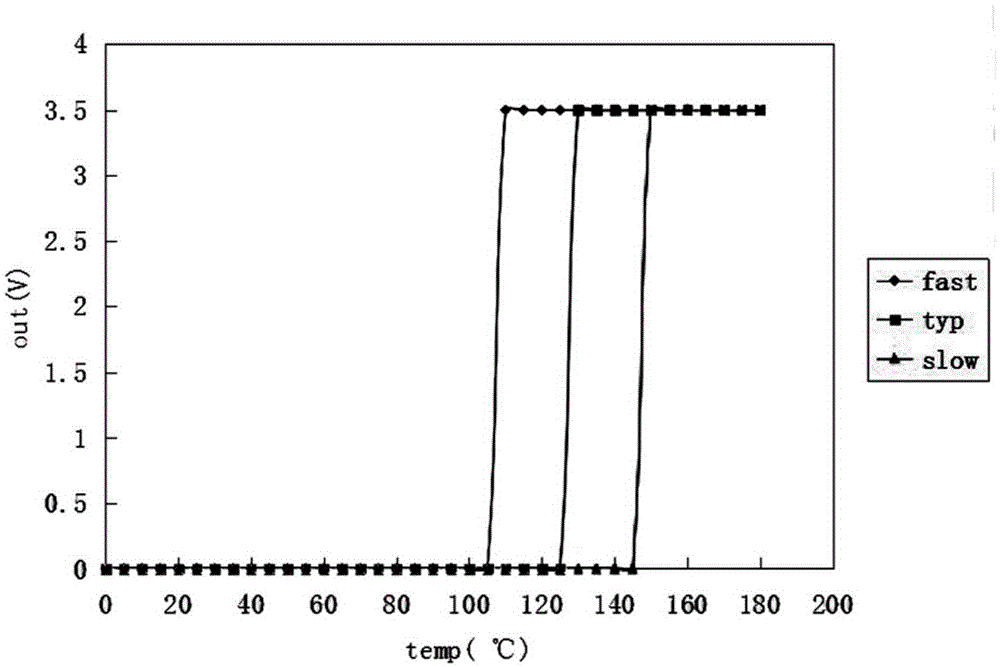

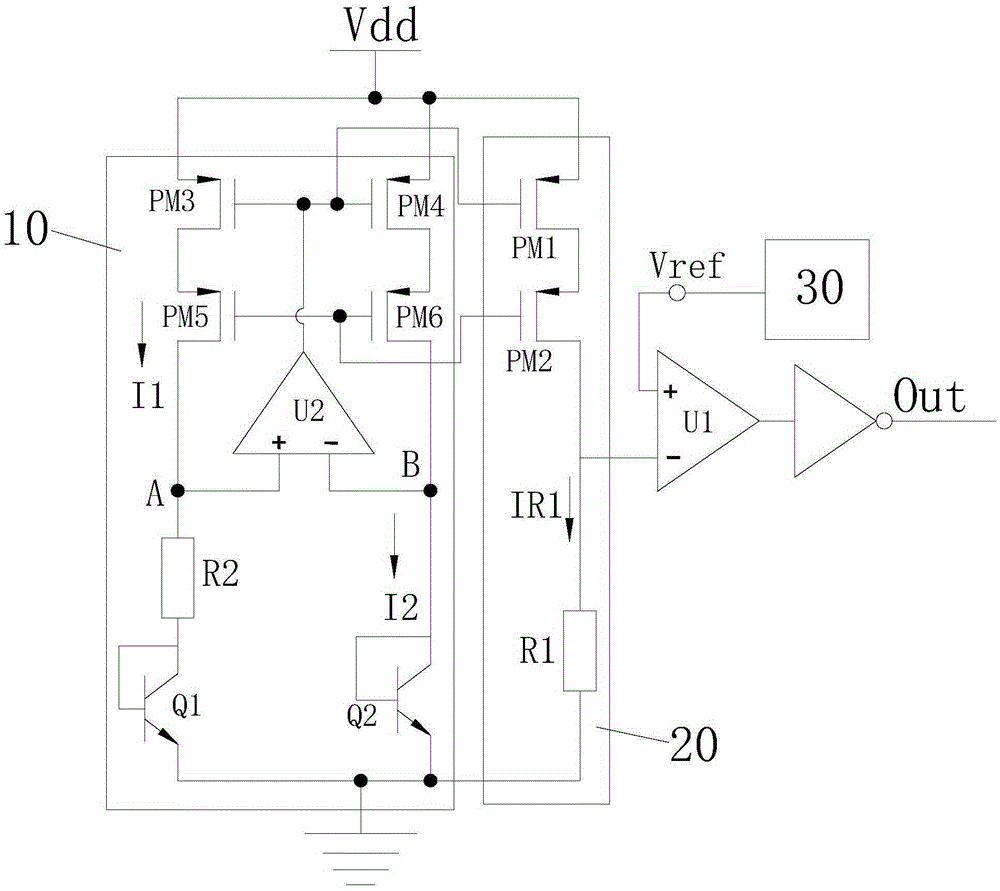

High-precision over-temperature protection circuit

InactiveCN105373181ASimple structureHigh precisionElectric variable regulationNegative phaseReference current

The invention provides a high-precision over-temperature protection circuit. The high-precision over-temperature protection circuit is characterized by comprising a PTAT reference current generation circuit, an over-temperature comparison voltage generation circuit, a reference voltage generation circuit and an over-temperature comparator, the over-temperature comparison voltage generation circuit and the PTAT reference current generation circuit serve as current mirror images of each other, the output end of the over-temperature comparison voltage generation circuit and the output end of the reference voltage generation circuit are connected with the negative phase input end and the positive phase input end of the over-temperature comparator respectively, and the output end of the over-temperature comparator serves as output of the over-temperature protection circuit. Whether temperature exceeds the over-temperature protection threshold value is judged by comparing the over-temperature comparison voltage and the constant reference voltage, so that when the product temperature is too high, an over-temperature protection signal is output, and a product is controlled to enter the temperature protection state. The circuit is simple in structure, the over-temperature protection trigger point is not influenced by the manufacturing process, and the high-precision over-temperature protection circuit is accurate, high in batch consistency and high in accuracy, can be used as an over-temperature protection module in products such as integrated circuit chips, MCU modules and switch power supplies, and has good market development value.

Owner:MIX DESIGN SEMICON TECH LTD

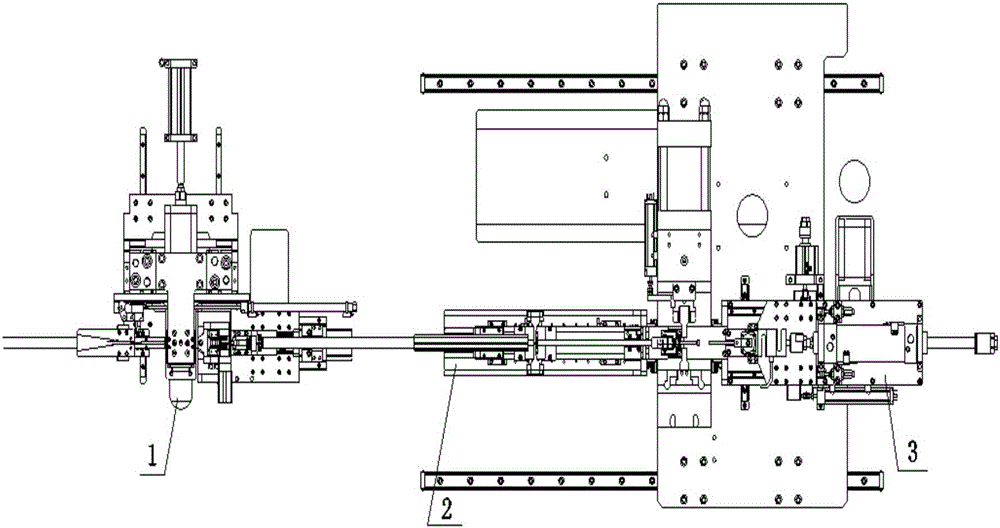

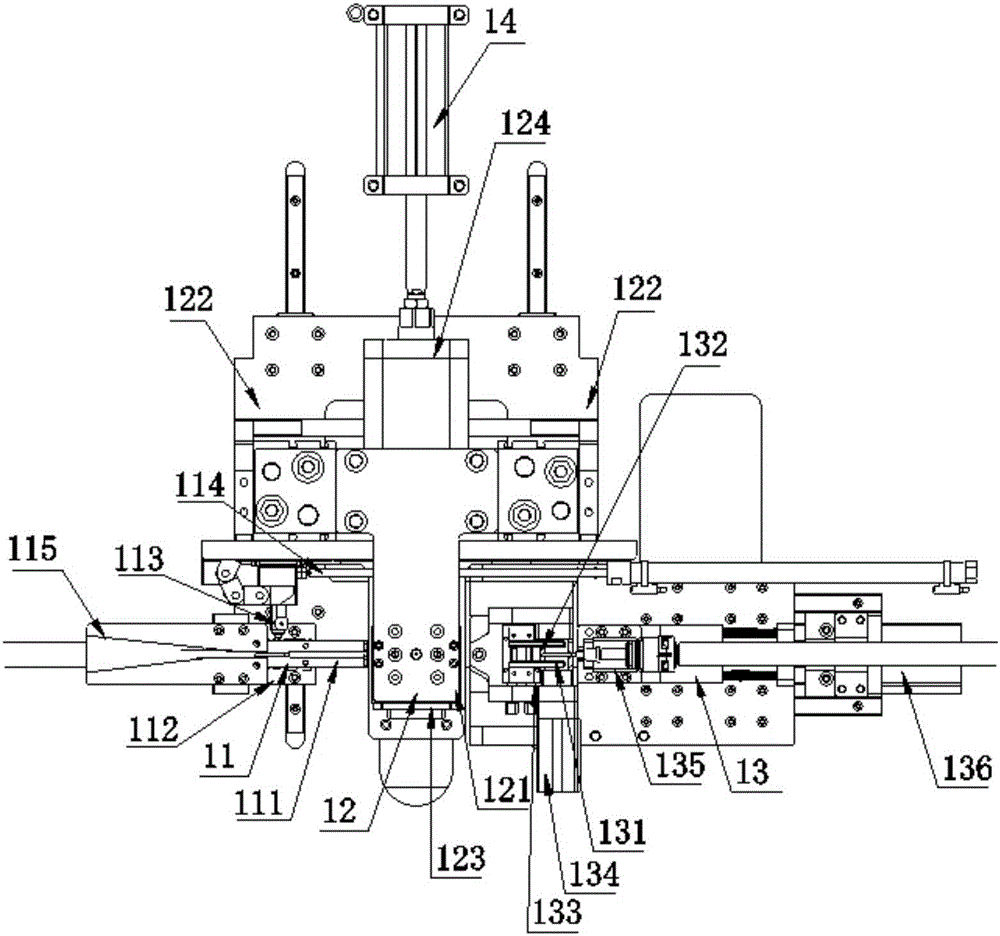

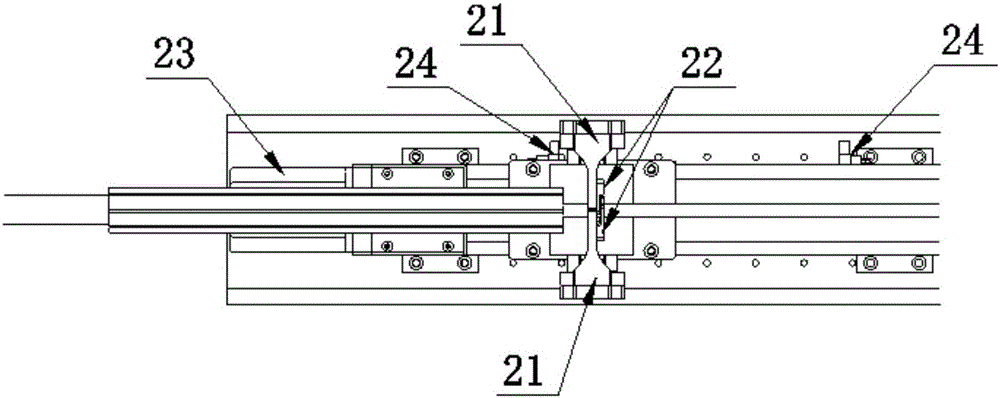

Production equipment of push-and-pull cables

ActiveCN105855873AHigh degree of automationGood batch consistencyAssembly machinesIndustrial engineeringFully automated

The invention discloses production equipment of push-and-pull cables. The production equipment comprises an oiling and threading device, a star-like sheath positioning device and an adapter rod riveting device which are sequentially connected from left to right. The production equipment has the following beneficial effects: a series of procedures, such as wire rope oiling and threading, adapter rod riveting and star-like sheath positioning, can be finished fully automatically, the degree of automation is high, and the production lot is excellent in consistency.

Owner:SHANGHAI WR CONTROLS CO LTD

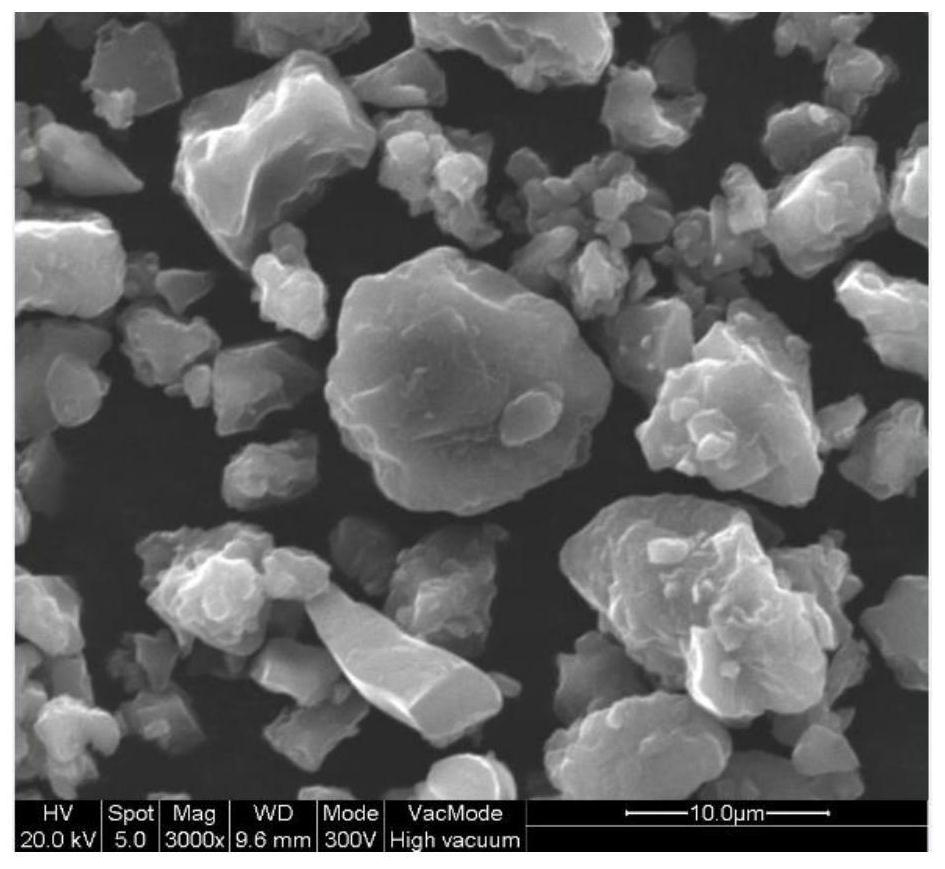

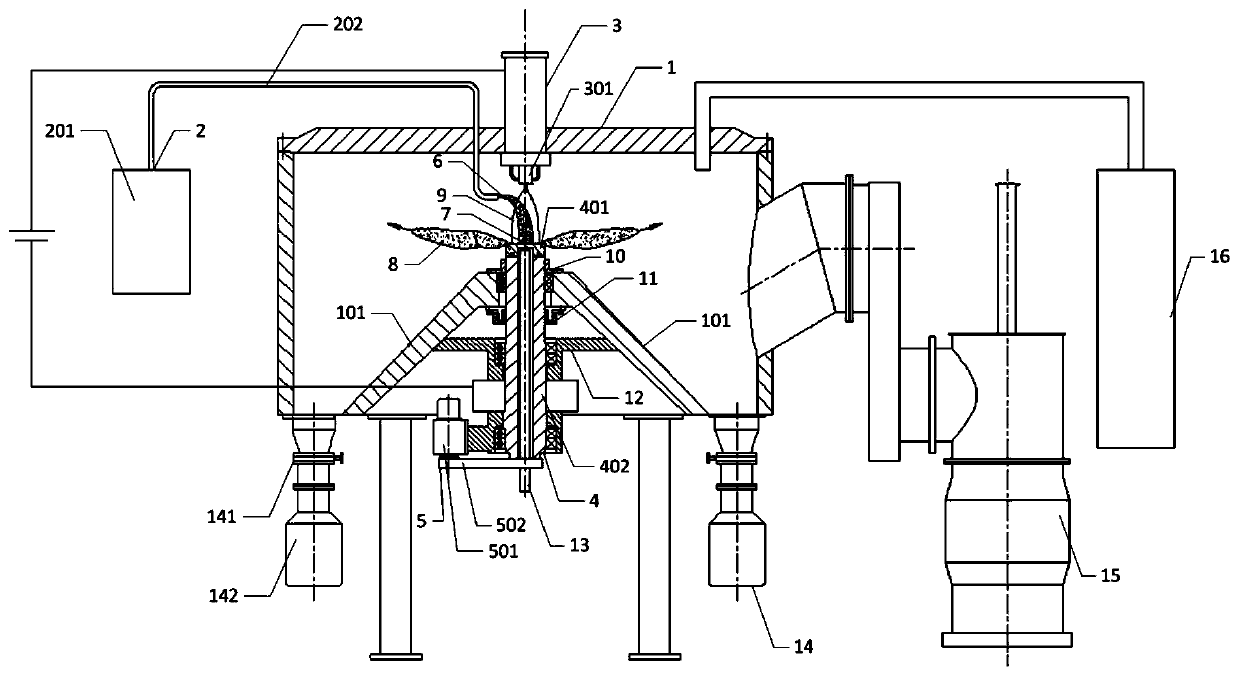

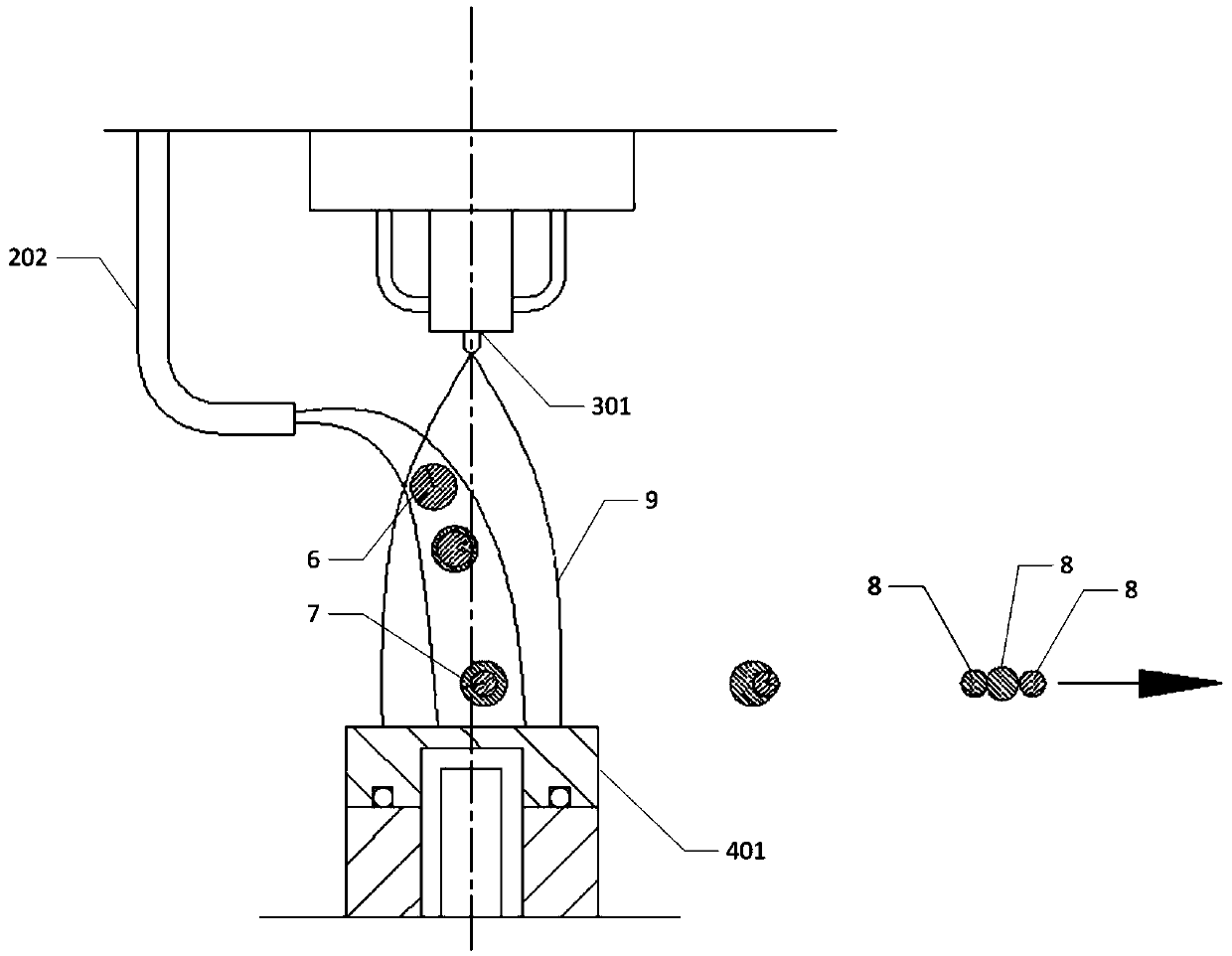

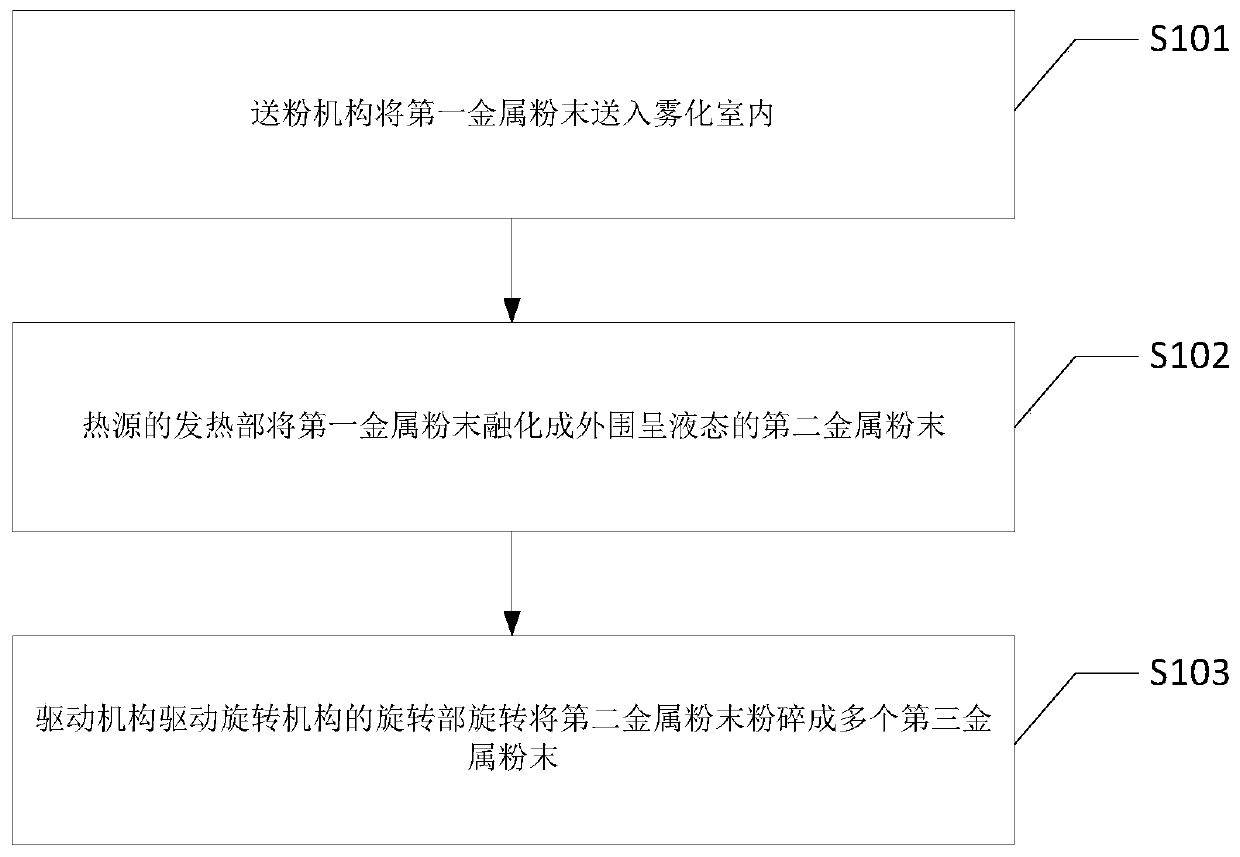

Device and method for preparing fine particle size metal powder through local melting of particles

ActiveCN110802236AImprove production efficiencyGood batch consistencyAdditive manufacturing apparatusTransportation and packagingMetallurgyLiquid state

The embodiment of the invention relates to a device and method for preparing fine particle size metal powder through local melting of particles. The device comprises an atomizing chamber, a powder feeding mechanism, a heat source, a rotating mechanism and a driving mechanism, wherein the powder feeding mechanism is used for feeding first metal powder into the atomizing chamber; the heating part ofthe heat source is arranged in the atomizing chamber and used for melting the first metal powder into second metal powder with the periphery in a liquid state; the rotating part of the rotating mechanism extends into the atomizing chamber and receives the second metal powder falling to the surface of the rotating part; and the driving mechanism is connected with the rotating mechanism, and the driving mechanism drives the rotating part to rotate to generate centrifugal force to crush the second metal powder into a plurality of third metal powder. According to the device and method, the coarseparticle size metal powder can be subjected to secondary crushing to prepare fine particle size metal powder, the quality and yield of the fine particle size metal powder can be increased, and the application range of the metal powder is expanded.

Owner:西安赛隆增材技术股份有限公司

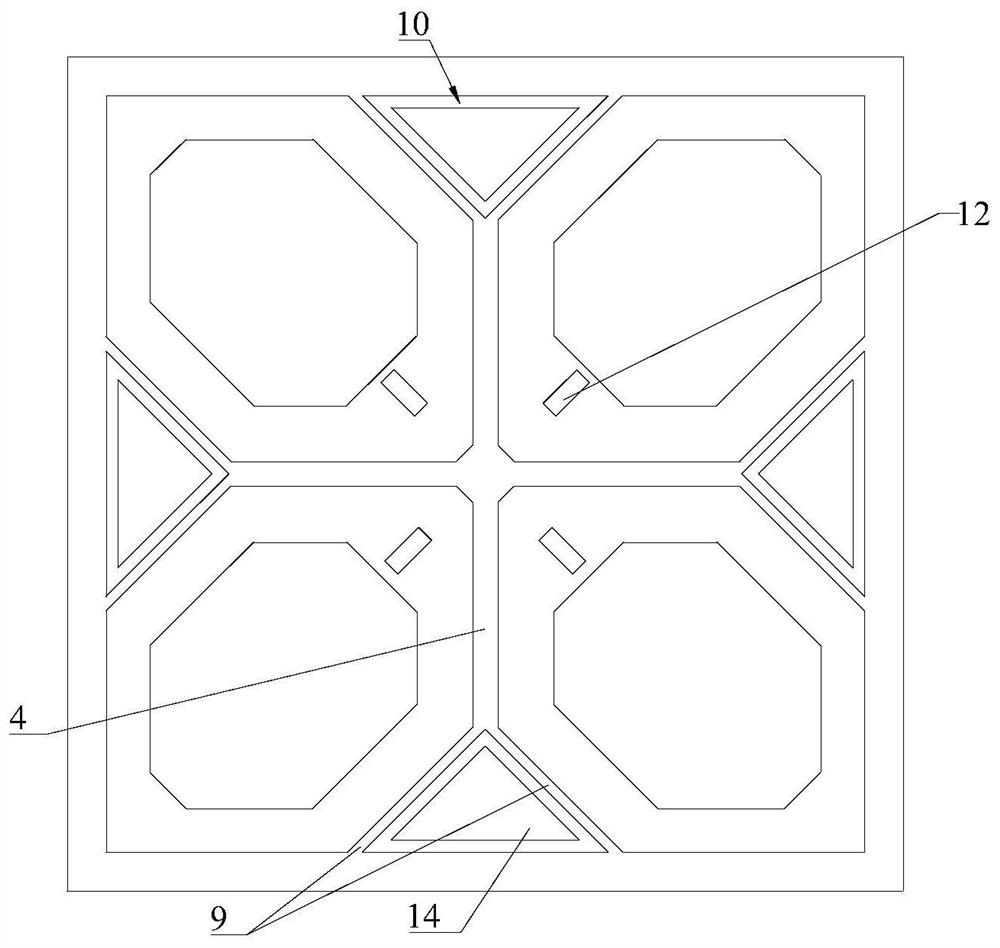

5G low-profile high-performance ultra-wideband antenna oscillator and base station antenna

PendingCN111786083AGood processing consistencyGood batch consistencyAntenna arraysAntenna supports/mountingsUltra wideband antennasElectrical conductor

The invention discloses a 5G low-profile high-performance ultra-wideband antenna oscillator and a base station antenna. The 5G low-profile high-performance ultra-wideband antenna oscillator comprisesa bottom plate, a bracket and a substrate which are connected in sequence; a metal layer is arranged on the top surface of the substrate; a cross groove is formed in the center of the metal layer; themetal layer is divided into four radiators by the cross groove; the support is provided with a feed line and a first conductor layer which are coupled with each other, the bottom plate is provided with a second conductor layer, the first conductor layer is respectively conducted with the metal layer and the second conductor layer, the end part of the cross-shaped groove is branched to form two sub-gaps which are respectively communicated with the edge of the metal layer, and a triangular resonance structure is formed between the two sub-gaps. According to the 5G low-profile high-performance ultra-wideband antenna oscillator, the triangular resonance structure is loaded through the unique polygonal radiator structure, the antenna oscillator has the advantages of being low in height, smallin size, light in weight and easy to integrate under the condition that the antenna size is not increased, and meanwhile the antenna frequency band and the antenna radiation performance index are effectively improved.

Owner:SHENZHEN SUNWAY COMM +1

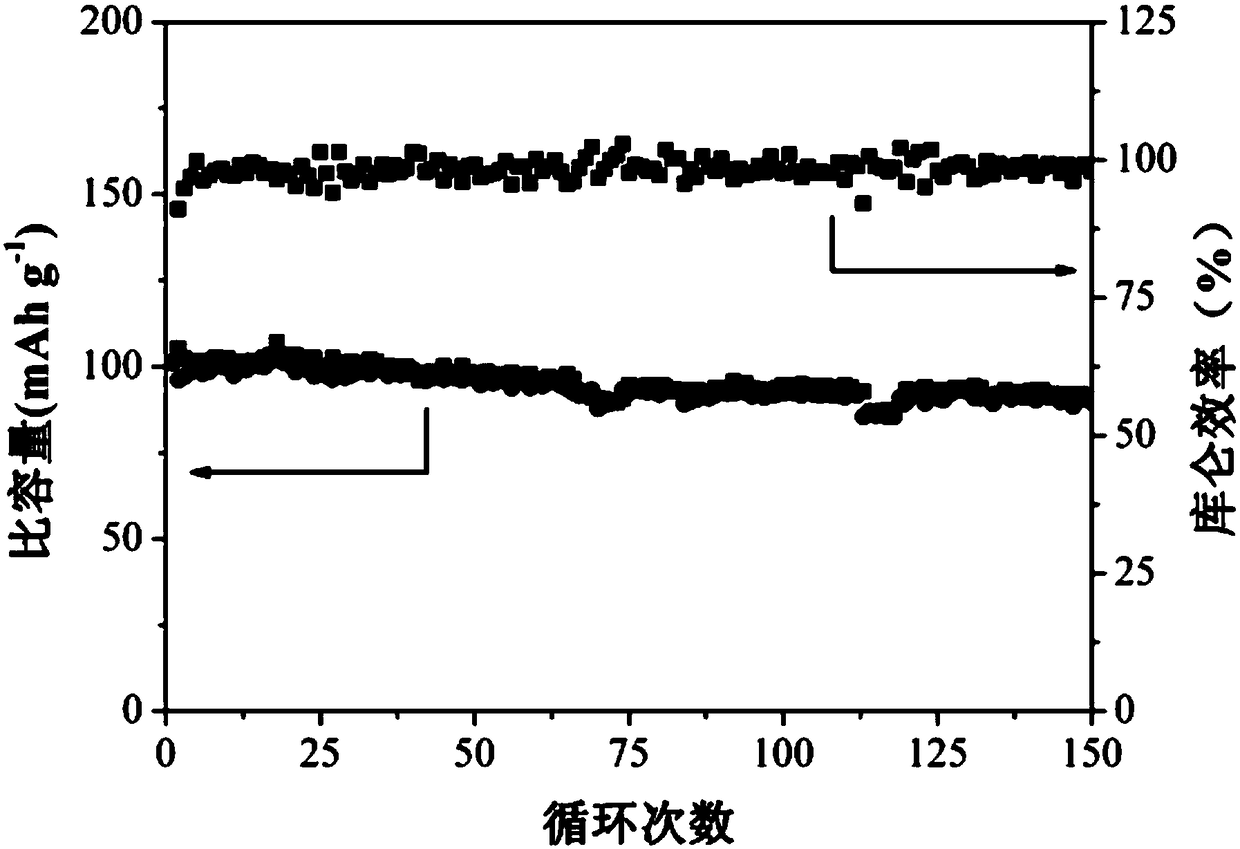

Stratified anode material of O3-type sodium-ion battery and preparation method and application thereof

InactiveCN108493396ACapacity test deviation is smallImprove consistencyNon-aqueous electrolyte accumulator electrodesSynthesis methodsMaterial synthesis

The invention discloses a stratified anode material of a O3-type sodium-ion battery and a preparation method and application thereof. The anode material is composed of NaNi1 / 2Co1 / 6Mn3 / 8O2. The preparation method of the anode material is a high temperature solid state method and includes the following steps that metallic oxides and a sodium source are mixed according to the stoichiometric ratio, after even mixing, tabletting is conducted, then temperature programming is conducted for a needed temperature, the temperature is maintained for a while, and then cooling is conducted to obtain the anode material, wherein the metallic oxides are NiO, Co2O3 and MnO2. The synthesis method of the stratified anode material of the O3-type sodium-ion battery is simple, and amplification application is easy; the material is stable in property and even in grain size and has excellent cycle performance and potential for being used by the sodium-ion battery for mass energy storage, and the application prospects are good.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

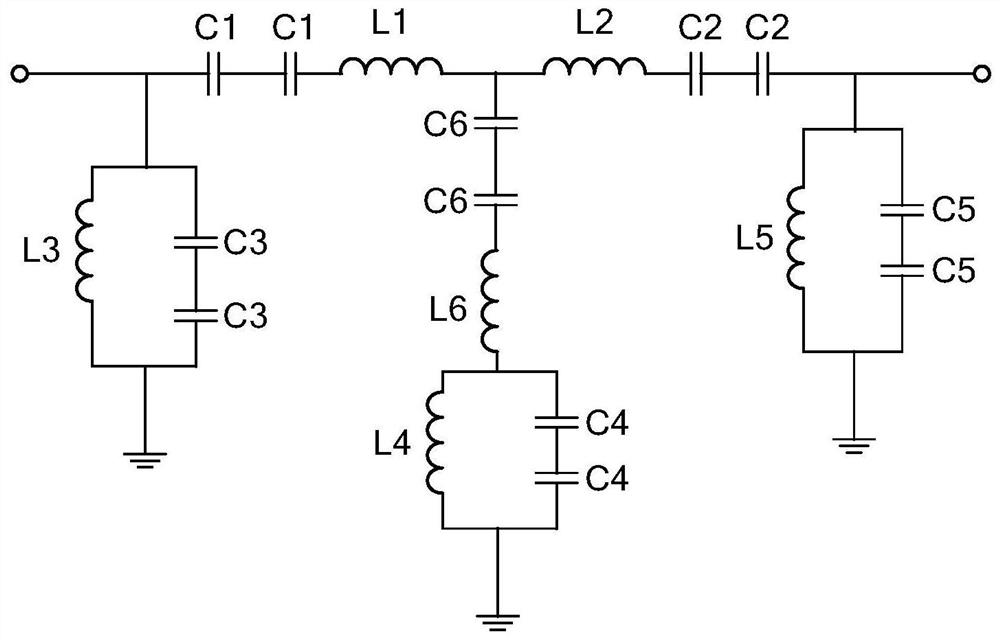

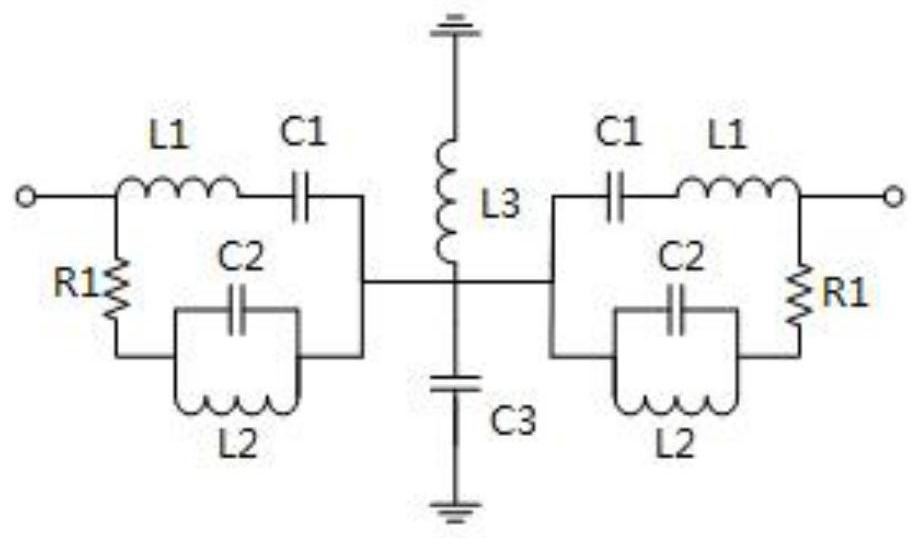

High-performance miniaturized IPD band-pass filter

PendingCN113949360ASmall sizeImprove stabilityMultiple-port networksTransformers/inductances coils/windings/connectionsCapacitanceBand-pass filter

The invention relates to the technical field of band-pass filters, in particular to a high-performance miniaturized IPD band-pass filter. The IPD band-pass filter comprises an input end, an output end, a large-area metal ground, a capacitor dielectric layer, a substrate and a band-pass filter circuit, wherein the band-pass filter circuit is composed of three LC parallel resonators and three LC series resonators, the inductors are zigzag inductors, inductance coils are distributed on the upper surface of the substrate and are connected through through holes to form zigzag vertical spiral zigzag inductors, and the capacitors are MIM capacitors. The filter has the advantages of low insertion loss, high suppression, small size, high stability, suitability for batch processing, multiple harmonic suppression and the like.

Owner:YANGTZE DELTA REGION INST OF UNIV OF ELECTRONICS SCI & TECH OF CHINE HUZHOU

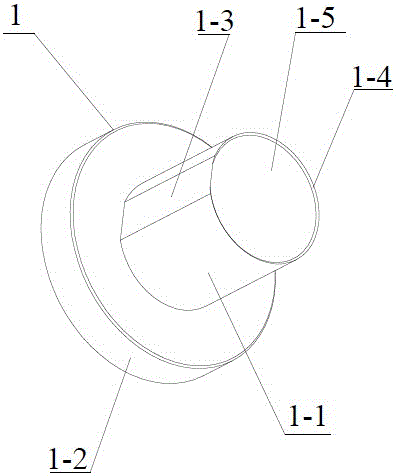

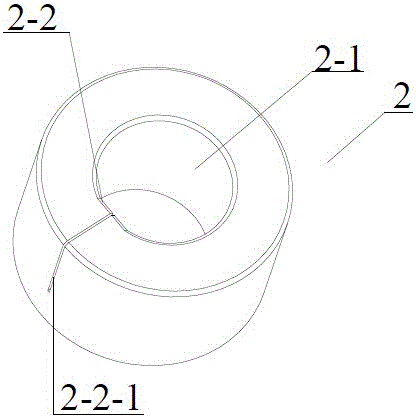

Special forming mold for circular tantalum core of tantalum capacitor and using method thereof

InactiveCN106611655ASimple structureImprove pressing qualityCapacitor manufactureManufacturing technologyTantalum capacitor

The invention discloses a special forming mold for the circular tantalum core of a tantalum capacitor and a using method thereof in order to solve the technical problem that most of the tantalum cores formed by the existing forming mold are of a long and thin cylindrical structure and a circular tantalum core cannot be formed using the existing forming mold is solved. The forming mold comprises an upper convex mold, a concave mold, a lower convex mold, an adjusting cushion block, a tantalum wire limiting block, and adjusting gaskets. The adjusting cushion block matches the lower convex mold. The concave mold matches the lower convex mold. The concave mold and the lower convex mold constitute a semi-closed circular forming cavity. Tantalum powder is poured into the semi-closed circular forming cavity, and a tantalum wire is placed on the tantalum powder. The tantalum wire limiting block is used for limiting the tantalum wire. After the tantalum wire is limited, tantalum powder is poured into the cavity. The upper convex mold matches the concave mold. The upper convex mold, the concave mold and the lower convex mold constitute a closed circular forming cavity to form a circular tantalum core through pressing. Adjusting gaskets of appropriate size can be selected according to the size of a tantalum core to realize layered pressing. The special forming mold for the circular tantalum core of a tantalum capacitor has the advantages of simple structure, good pressing quality, good batch consistency, convenient de-molding, and the like, and has a wide application prospect in the technical field of electronic component production and manufacture.

Owner:长春维鸿东光电子器材有限公司

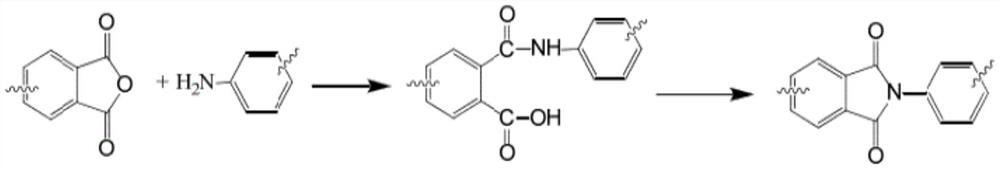

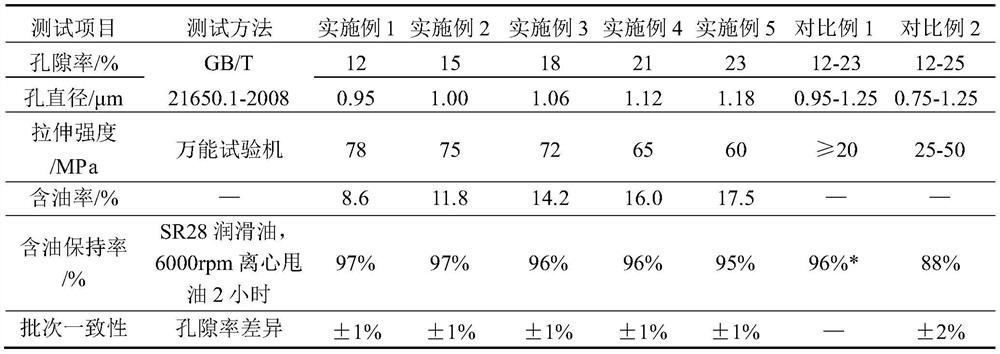

Porous polyimide composite material for bearing retainer, preparation method of porous polyimide composite material and bearing retainer

PendingCN111763429AEasy to use for a long timeExtended service lifeShaftsBearing componentsTetrafluoroethyleneDiphenyl ether

The invention belongs to the technical field of bearing materials, and relates to a porous polyimide composite material for a bearing retainer, a preparation method of the porous polyimide composite material and the bearing retainer. The porous polyimide composite material for the bearing retainer is prepared by limiting, pressing and sintering the following raw materials in percentage by mass: 92-97% of monoether anhydride polyimide and 3-8% of polytetrafluoroethylene, wherein the monoether anhydride polyimide is prepared by polycondensation, dehydration and cyclization of 4, 4 '-oxybisphthalic anhydride and 4, 4'-diaminodiphenyl ether. Under the condition that the porosity of the composite material is equivalent to that of an existing material, the strength of the composite material canbe remarkably improved, so that the strength performance of the composite material is compatible with micropore characteristics, long-term use of the retainer after one-time oiling is facilitated, andthe service life of a bearing is prolonged under the condition that the requirements of harsh bearing working conditions are met.

Owner:LUOYANG BEARING RES INST CO LTD

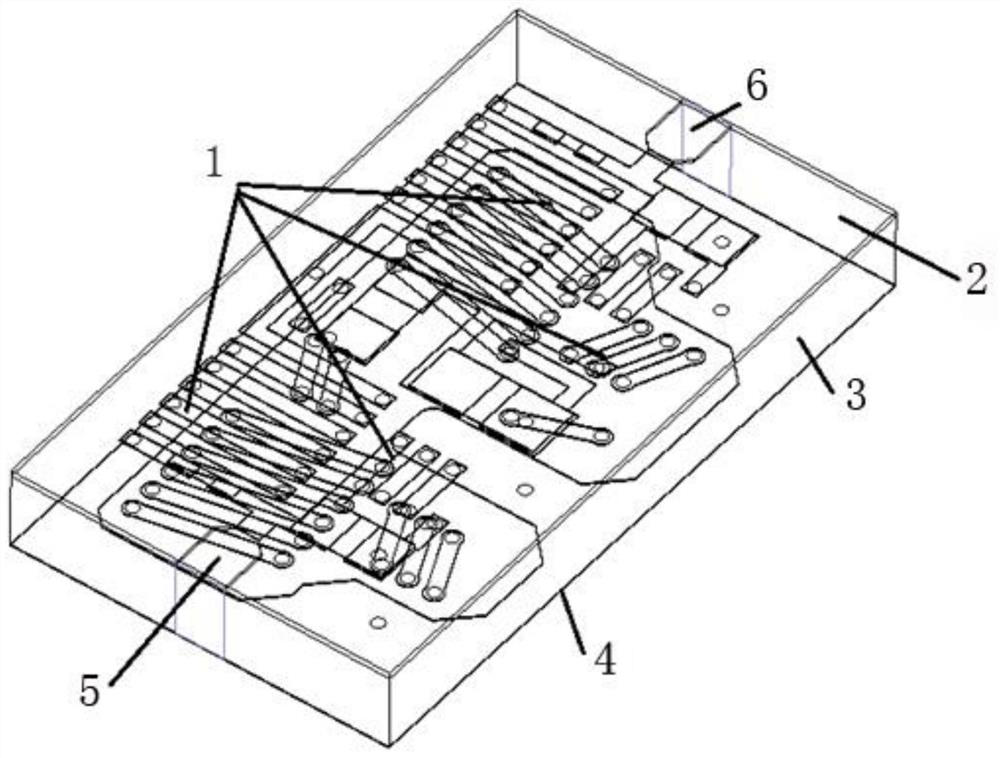

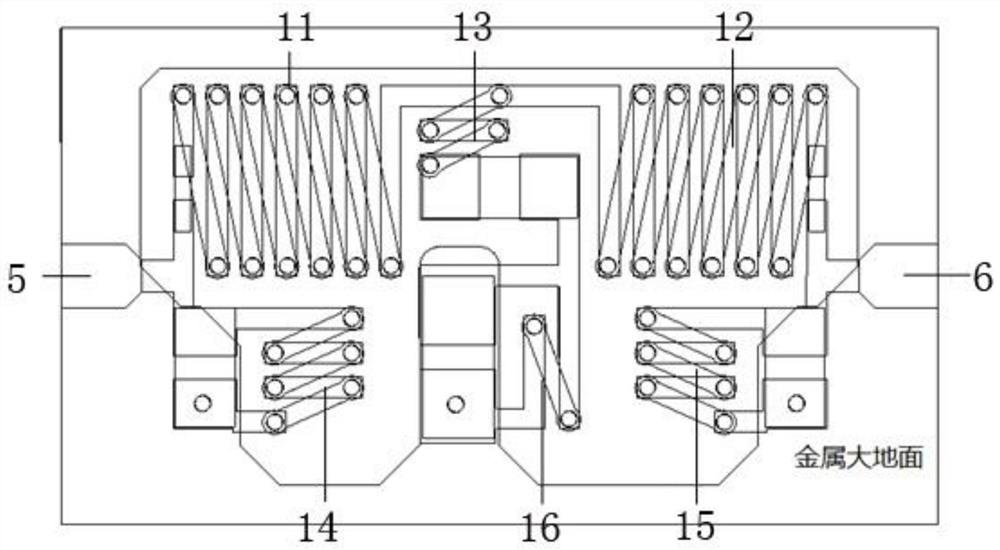

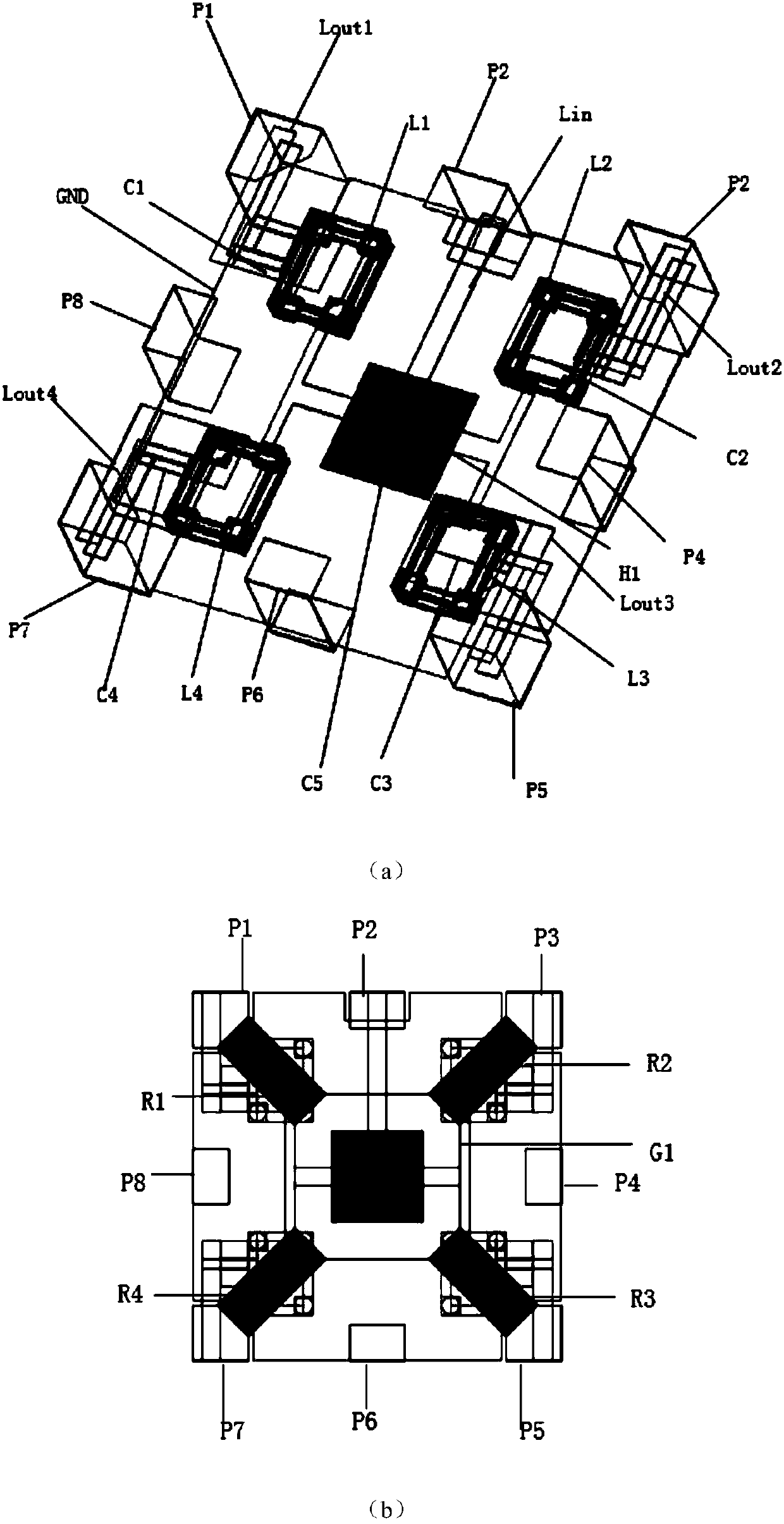

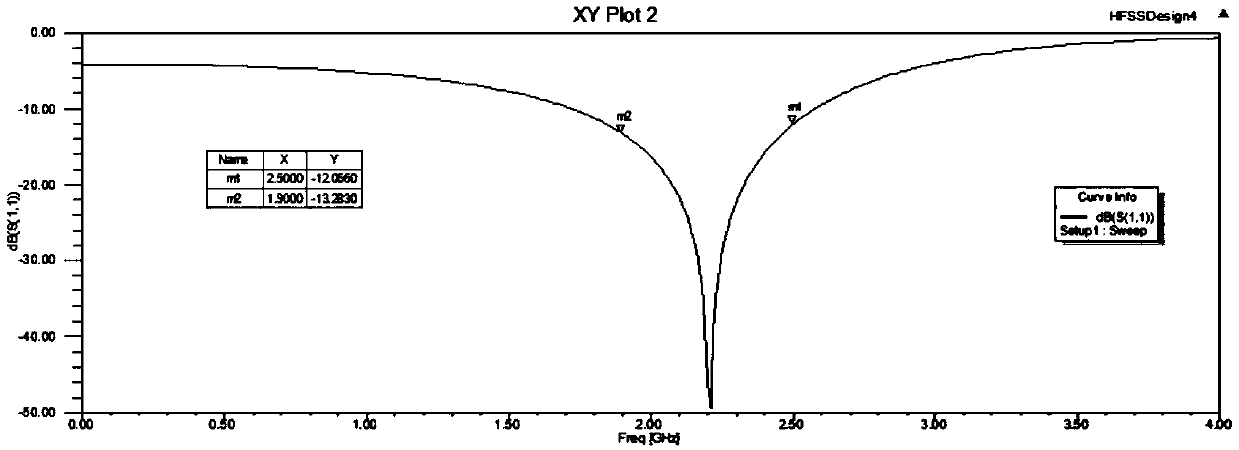

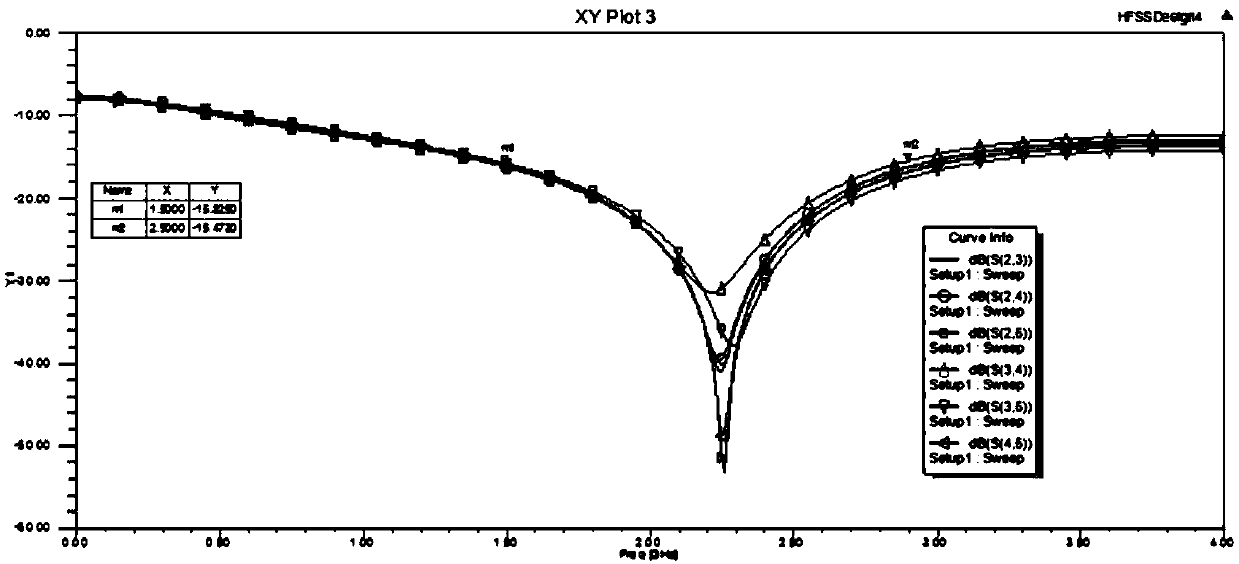

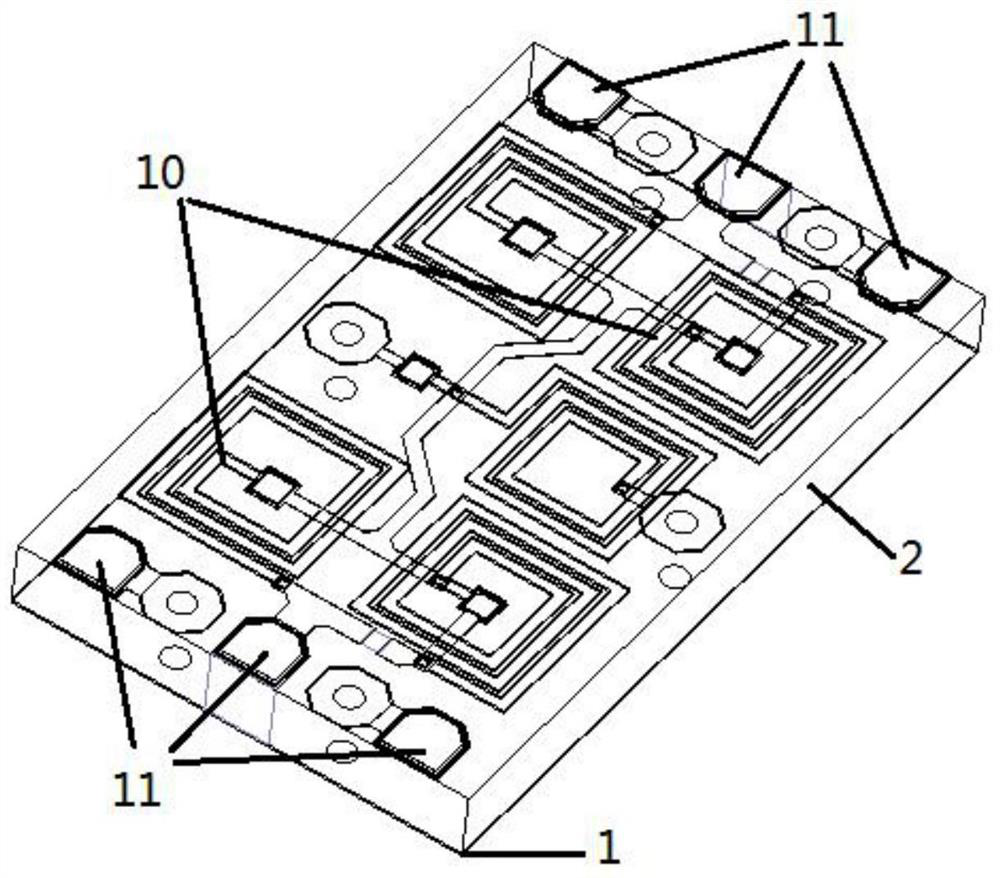

Four-power divider with LTCC-based S-waveband lumped symmetric structure

The invention discloses a four-power divider with an LTCC-based S-waveband lumped symmetric structure. The power divider for a reactance network adopts a specific lumped symmetric structure, is formedby three-dimensional placement of lumped parameter elements through multi-layer low-temperature co-fired ceramic technology, and the size of the device is greatly reduced. The four-power divider divides and distributes input signal power into four output ports, and the advantages of small insertion loss, small size, light weight, good output port phase consistency, high isolation degree, high reliability, good electrical performance and good temperature stability, good electrical performance batch consistency, and low cost and allows mass production. The four-power divider can be used as a single component and is suitable for mobile communication and satellite communication such as Beidou navigation systems, and is also suitable for system and devices with high requirements on electric performance, material consistency, thermal mechanical property, temperature stability, manufacturability and anti-interference performance.

Owner:NANJING UNIV OF SCI & TECH

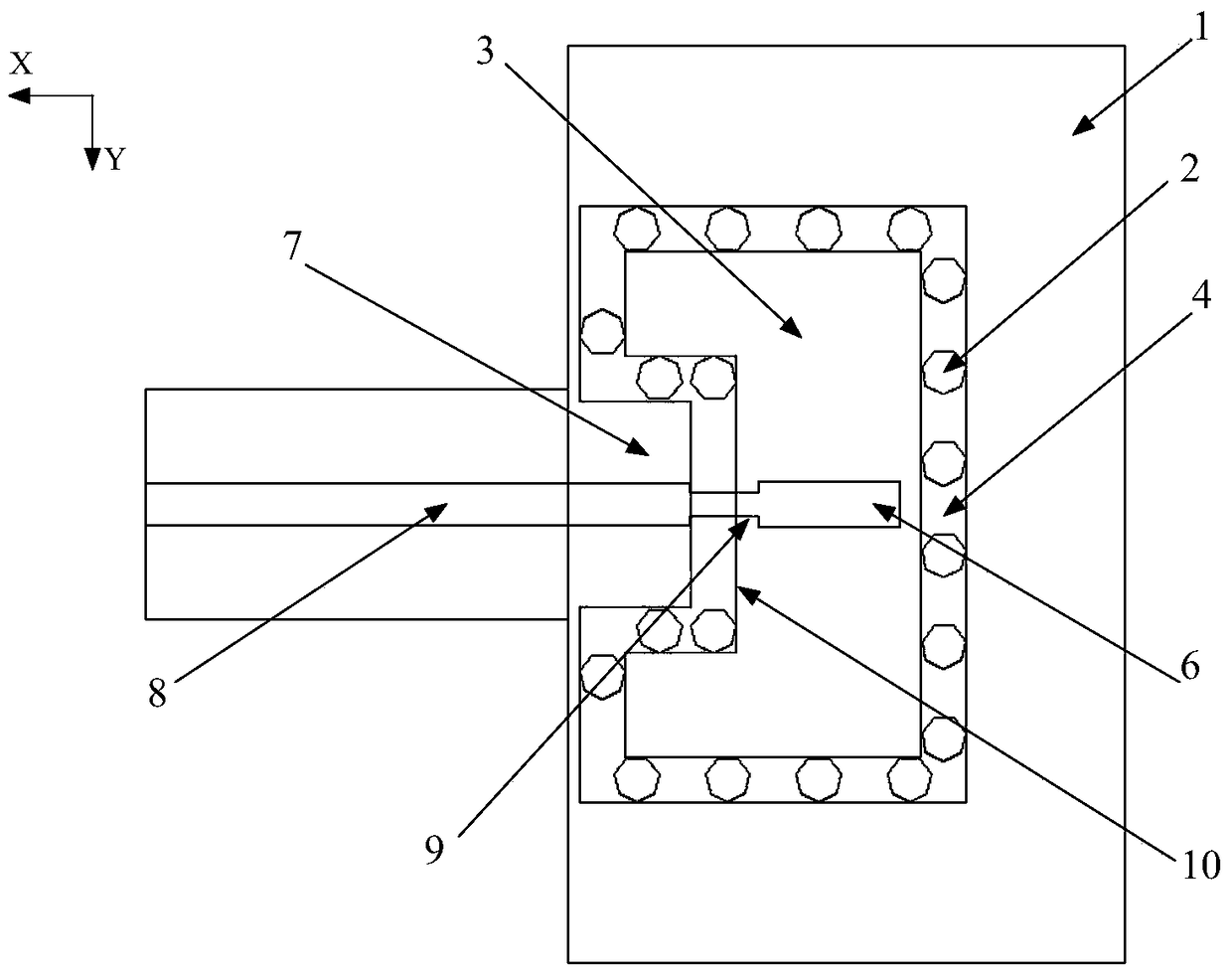

Vertical interconnection circuit structure between substrate-integrated ridge waveguide plates

The invention provides an inter-board perpendicular interconnection circuit structure for a substrate integrated ridge waveguide (SIRW), and aims to provide a millimeter wave inter-board perpendicular interconnection circuit structure with small volume, easy integration, high interconnection property and long-term reliability. The inter-board perpendicular interconnection circuit structure is implemented by the following technical scheme: the SIRW (3) perpendicular to the surface of a base board is integrated on an LTCC multilayered circuit board (1); a substrate integrated ridge waveguide opening is etched in a corresponding outlet in the metal ground on the surface of the LTCC multilayered circuit board (1); Z-direction metalized filling holes (2) are arranged to form a metal hole gate array to equivalently form the waveguide wall and single-side ridges in the waveguide; metallic shield holes and probe restraining cavities (7) on the two sides of a 50-ohm strip line (8) are arranged at the equal spacing; and the alignment pressing and connection of the SIRW interfaces on the opposite sides between two boards is realized through pin hole alignment, so that the perpendicular interconnection transition of the millimeter wave signal between two boards in a way of 50-ohm strip line-SIRW-SIRW-50-ohm strip line is realized consequently.

Owner:10TH RES INST OF CETC

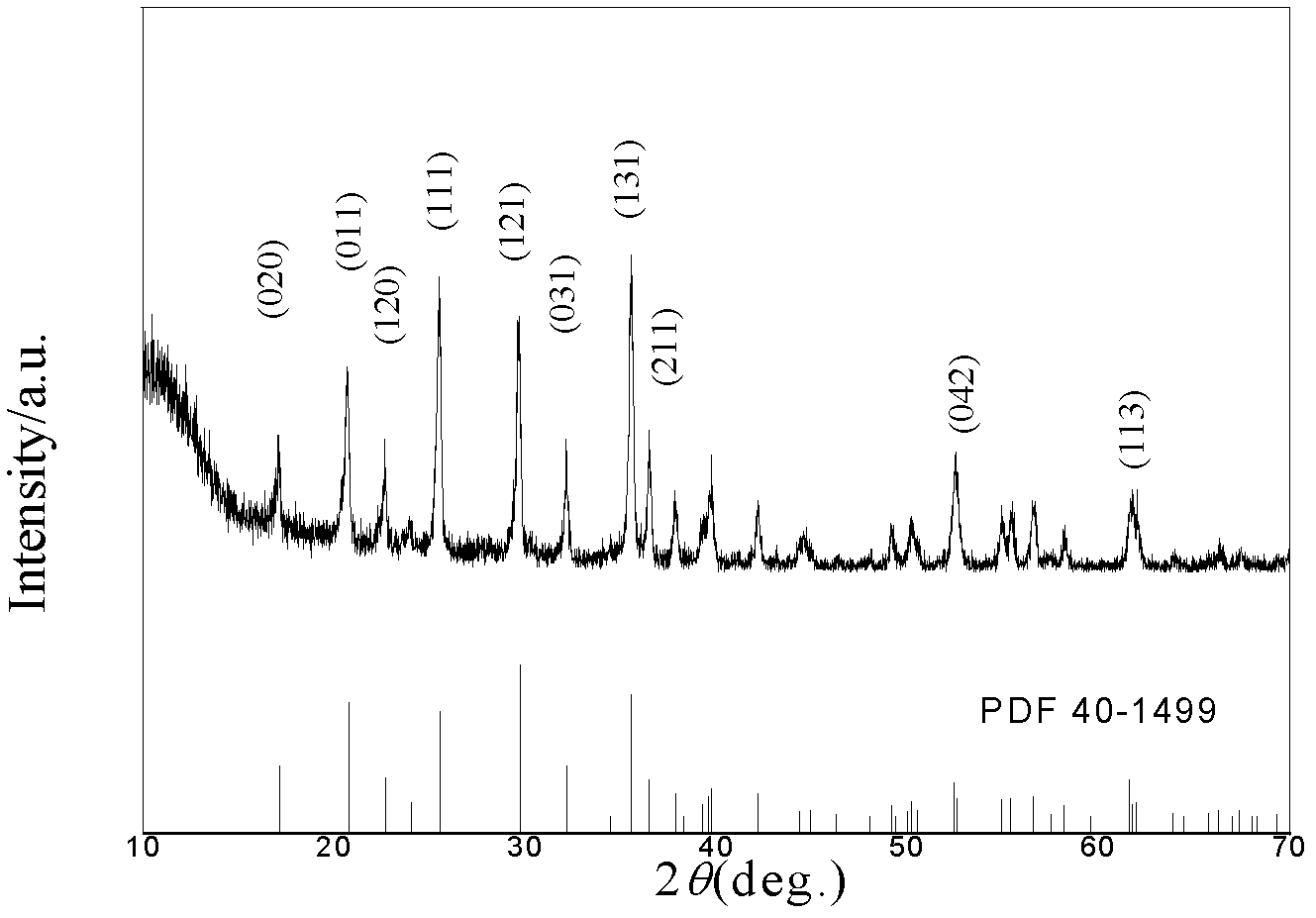

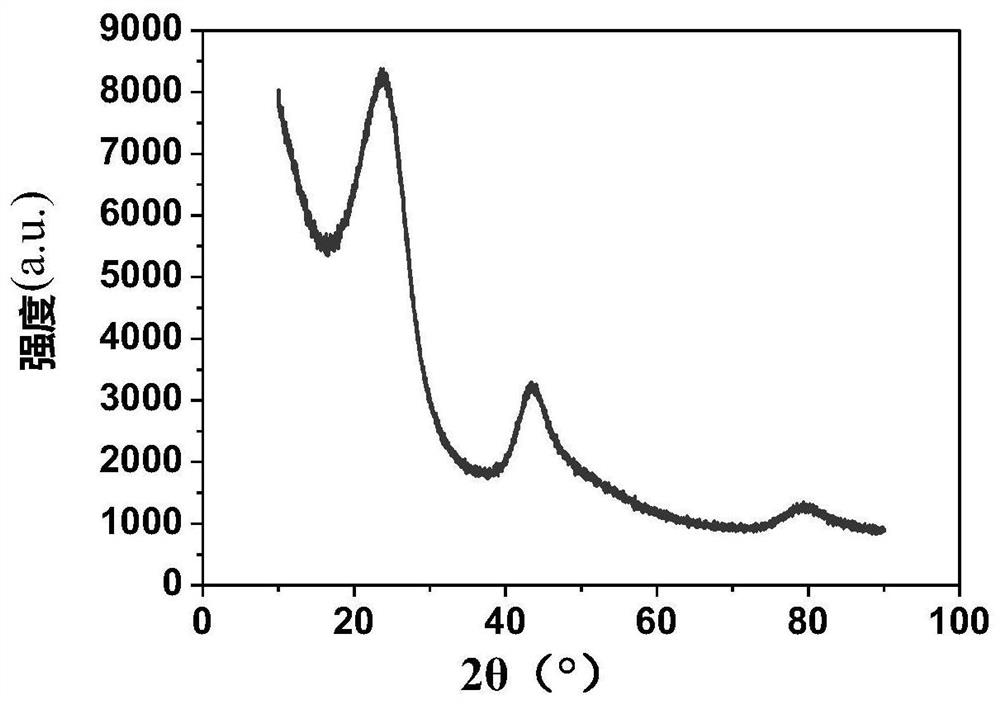

Novel polyanion type positive electrode material preparation process

InactiveCN104701537AImproved magnification performanceHigh specific capacityCell electrodesCyclic stabilityMonoclinic crystal system

The present invention provides a novel polyanion type positive electrode material preparation process. The technical scheme comprises that an organic matter assisted spray drying method is adopted to prepare the novel polyanion type positive electrode material Li3V2(PO4)3, and the prepared Li3V2(PO4)3 has the specific capacity close to the theoretical capacity, and has good rate cycle stability. The preparation process of the present invention has the following characteristics that: the monoclinic crystal base Li3V2(PO4)3 has the NASICON (sodiumsuperionconductor) structure so as to improve the rate performance of the material; and the 3 Li<+> in Li3V2(PO4)3 can be reversibly inserted and deinserted, the theoretical specific capacity achieves 197 mAh / g, and the Li3V2(PO4)3 has the highest specific capacity in the currently found phosphate lithium ion battery electrode material.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

Method for preparing composite material of carbon coated lithium ferrous phosphate through iron phosphate

InactiveCN100389062CImprove completenessSuitable for industrial productionCell electrodesPhosphorus compoundsFerrous ammonium phosphatePhosphoric acid

Owner:SHANGHAI JIAO TONG UNIV

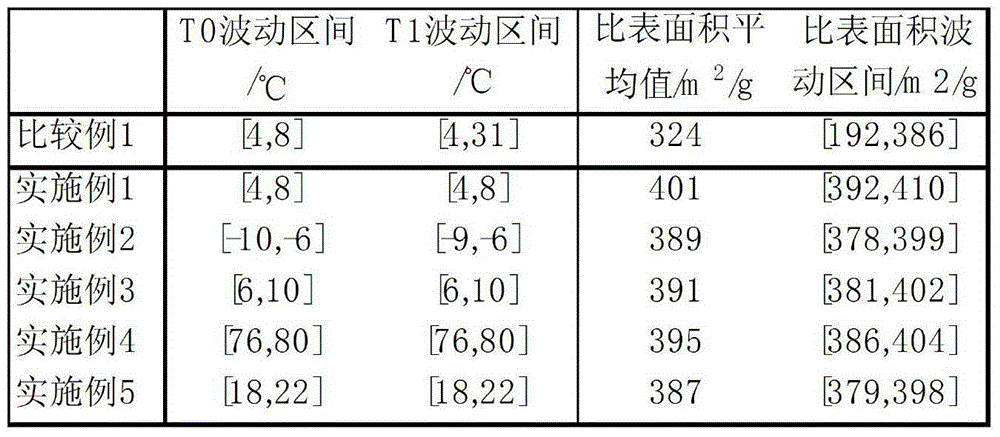

Preparation method of graphene

ActiveCN104787755AStrong temperature controllabilityGood batch consistencyCvd grapheneGraphite oxide

The invention belongs to the technical field of preparation of graphene and in particular relates to a preparation method of graphene. The preparation method of graphene comprises the following steps: firstly mixing oxidants uniformly in a process of preparing graphite oxide, then adding graphite powder, effectively separating the mixing heat from the reaction heat and enabling the temperature of the whole feeding stage to be controllable. Compared with the prior art, the graphene prepared through the method is relatively high in specific surface area and obviously high in batch stability.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

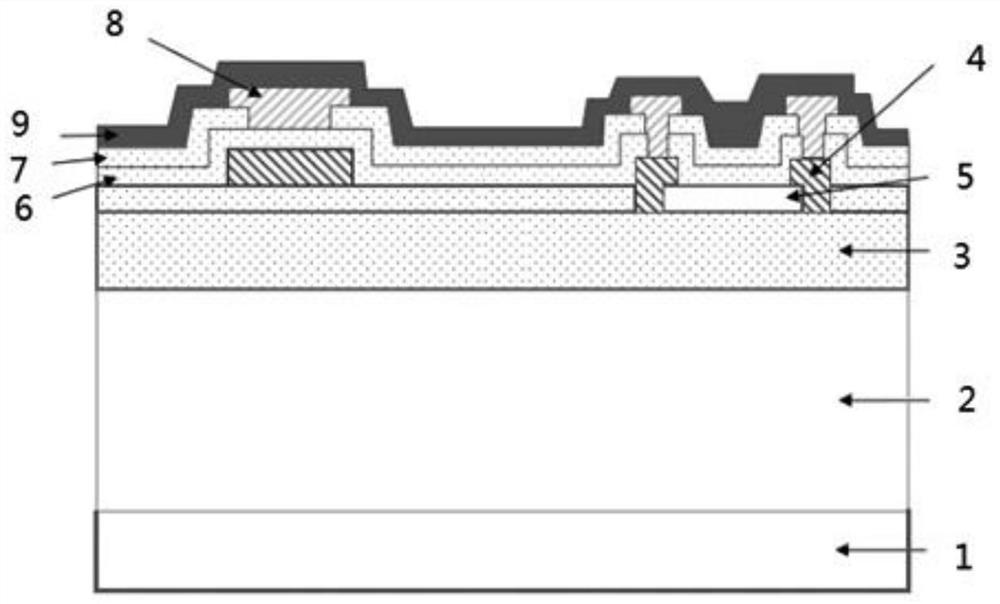

IPD absorption band-pass filter

PendingCN112421195AImproved stop-band rejection performanceImprove yieldWaveguide type devicesFilm resistanceFilter (signal processing)

The invention relates to an IPD absorption band-pass filter and belongs to the technical field of filters. The sensor comprises a substrate layer and a back gold layer on the lower surface of the substrate layer, wherein a first silicon nitride layer grows on the substrate layer, a thin-film resistance layer is sputtered on the first silicon nitride layer, a first metal layer is formed on the first silicon nitride layer, a second silicon nitride layer grows on the first metal layer, and a polyimide layer grows on the second silicon chloride layer; a second metal layer is formed on the polyimide layer, a third silicon nitride layer grows on the second metal layer, and a filter circuit structure is formed on the first metal layer and the second metal layer; the filter circuit structure comprises a first band-pass signal processing unit, a second band-pass signal processing unit and an LC parallel resonance circuit which are connected in series between an input port and an output port, anIPD-GaAs process is adopted, the absorption type filter circuit structure is manufactured on a GaAs substrate through photoetching, sputtering, electroplating, etching and other procedures, and the effect of high stop band suppression is achieved.

Owner:云南雷迅科技有限公司

Preparation method of large-scale flake ultra-high thermal conductivity diamond/copper composite material

Owner:哈尔滨锦威科技有限公司

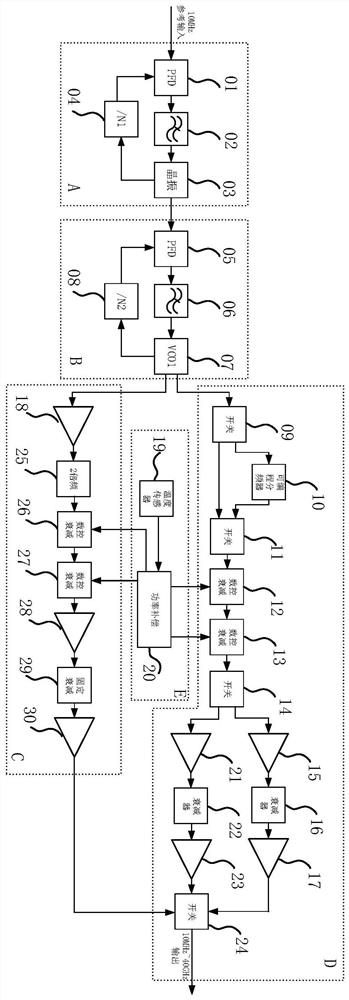

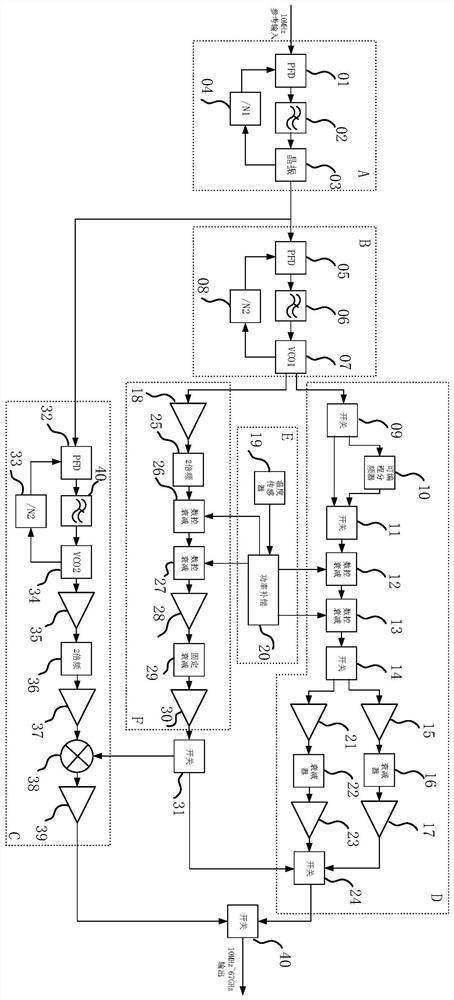

Miniaturized ultra-wideband microwave millimeter wave signal generator

PendingCN112039524ASmall commissioning workloadLow costPulse automatic controlUltra-widebandPower compensation

The invention relates to a miniaturized ultra-wideband microwave millimeter wave signal generator. The signal generator comprises a plurality of phase-locked loops connected in sequence, a frequency mixing circuit, a frequency doubling amplification circuit connected with the phase-locked loops, and a power compensation circuit connected with the frequency mixing circuit and the frequency doublingamplification circuit. Signals output by the phase-locked loops are divided into two paths, one path outputs frequency mixing signals after passing through the frequency mixing circuit, the other path outputs amplification signals through the frequency doubling amplification circuit, and the two paths of output signals output microwave and millimeter wave signals after frequency summation. The power compensation circuit is respectively connected with the frequency mixing circuit and the frequency doubling amplification circuit and is used for compensating the power of signals in the frequencymixing circuit and the frequency doubling amplification circuit. After the technical scheme is adopted, the ultra-wideband microwave millimeter signal generator provided by the invention realizes product miniaturization, low cost and high index through the design of the circuit; and meanwhile, the product is easy to produce and process, good in batch consistency and small in debugging and testingworkload.

Owner:西安豹斐电子科技有限公司

Electronic parking executor applied to motor vehicle brake system

ActiveCN102001334BImprove stabilityReduce noiseBraking action transmissionBraking componentsCalipersParking brake

The invention discloses an electronic parking executor 1 applied to a motor vehicle brake system, which comprises a shell, a cover, a motor, motor accessories, a planetary gear transmission mechanism, parking brake calipers and the like. The electronic parking executor also comprises an integrated transmission mechanism frame, wherein a transmission mechanism and a planetary gear transmission mechanism from a motor shaft and a planetary gear main shaft are installed on a body in the integrated transmission mechanism frame, and the power transmission route of the transmission mechanism is from the motor shaft to the planetary gear main shaft. The technical scheme provided by the invention can effectively solve the problems of inconsistent assembly between rigid spacers and the motor shaft and the main shaft of the planetary gear transmission mechanism, axial nonparallelism and easy deformation of the rigid spacers after stressing in the prior art; meanwhile, the invention also has the characteristics of increasing the stability of internal transmission mechanism and the performance consistency after being connected with braking, reducing assembly cost, increasing assembly quality, benefiting tests, having good batch consistency and the like.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

Dual-frequency dual-polarized dipole antenna unit for 5G

PendingCN112736433AHas heightWith dual frequency characteristicsSimultaneous aerial operationsAntenna supports/mountingsDielectric substrateDipole antenna

The invention discloses a dual-frequency dual-polarized dipole antenna unit for 5G. The dual-frequency dual-polarized dipole antenna unit comprises an antenna oscillator composed of a dielectric substrate and metal radiators, the dielectric substrate is a PCB, and the metal radiators are symmetrically arranged on the two sides of the dielectric substrate through a copper-clad process and are provided with open grooves. The radio frequency cable is connected with the metal radiators through the microstrip line and feeds the metal radiators, the shapes of the metal radiators and the open grooves can be set according to the performance and structural requirements of the antenna unit, the antenna unit has the advantages of wide bandwidth, high gain, good directional diagram consistency and convergence, and the antenna is compact in structure and small in size, has the dual-frequency dual-polarization characteristic, is good in radiation characteristic, and is especially suitable for a 5G base station with higher requirements for the bandwidth and size of the antenna.

Owner:南京中新赛克科技有限责任公司

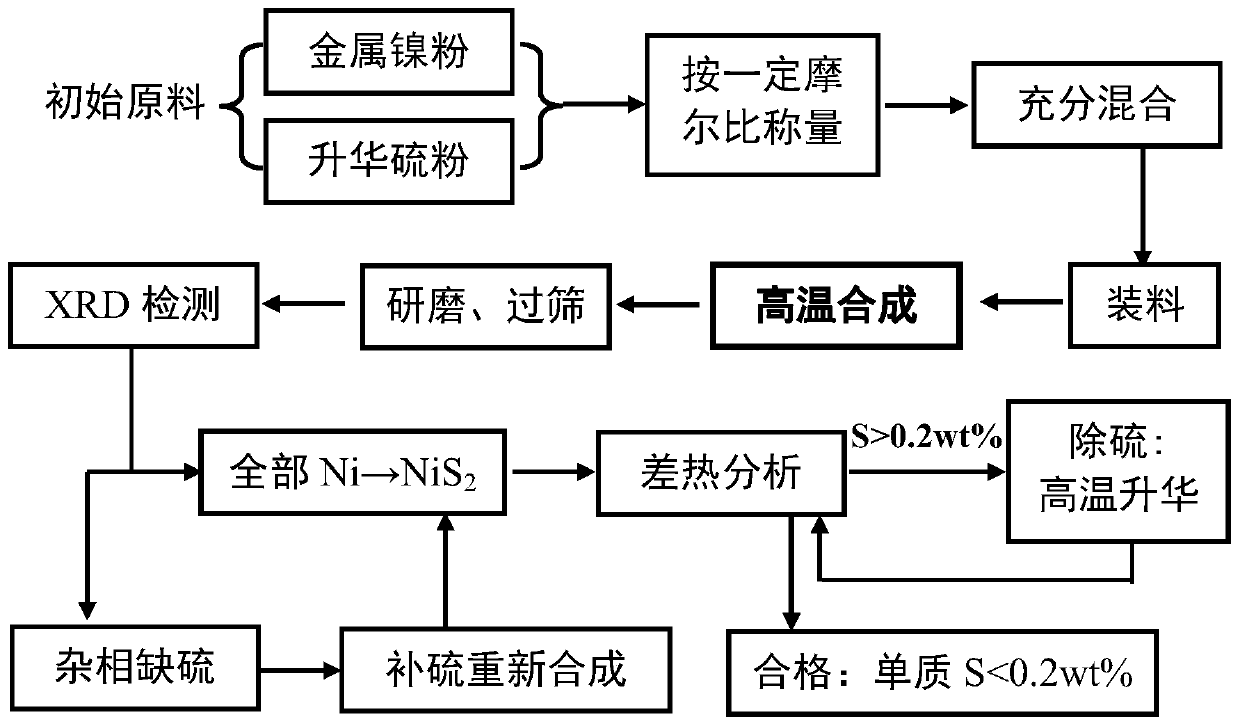

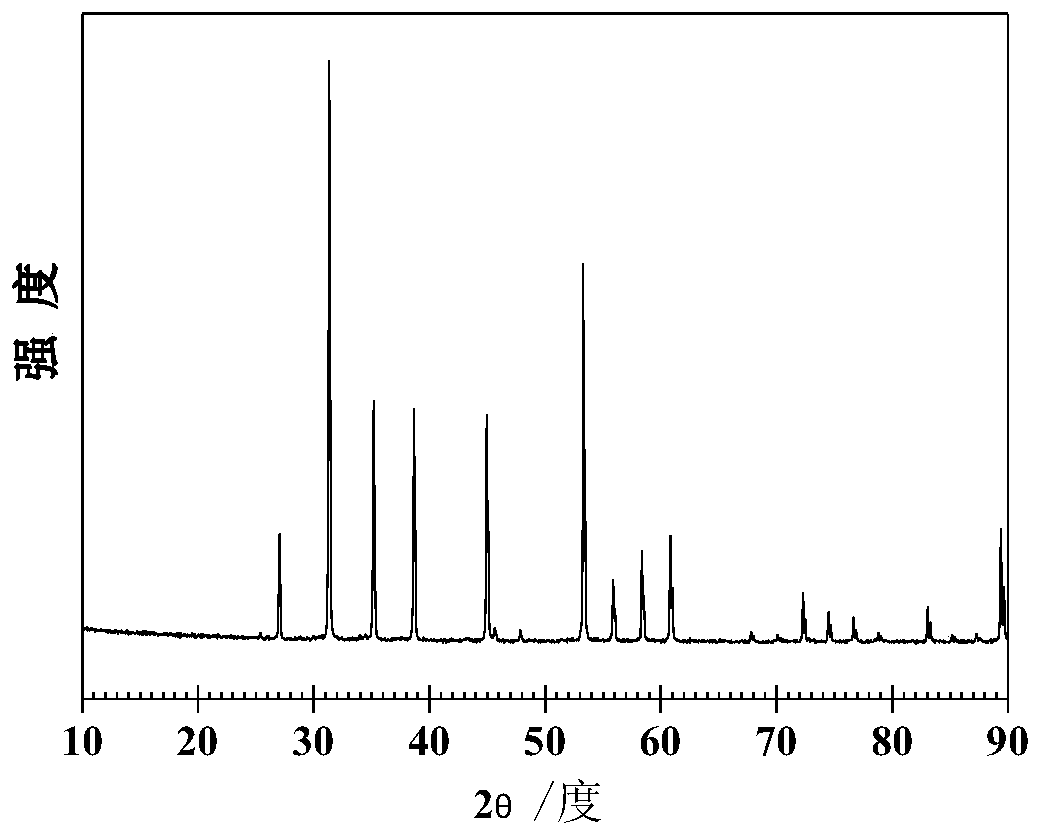

Large-scale preparation method of single-phase NiS2 powder

ActiveCN111129490AHigh purityImprove conductivityCell electrodesSolid electrolyte cellsHeat analysisPhysical chemistry

The invention discloses a large-scale preparation method of single-phase NiS2 powder. The preparation method comprises the steps of 1) mixing metal nickel powder and sublimed sulfur powder in proportion; 2) performing high-temperature solid-phase synthesis heat treatment on the mixed powder in a protective gas atmosphere; 3) carrying out grinding, sieving and phase characterization on the synthesized powder, if a phase characterization result shows that sulfur is insufficient, supplementing sublimed sulfur powder for mixing, and carrying out high-temperature solid-phase synthesis again according to the condition in the step (2) until metal nickel is completely synthesized into a NiS2 phase; and 4) performing differential thermal analysis on the NiS2 powder synthesized in the step 3), if the differential thermal analysis shows that the mass percentage content of elemental sulfur is higher than 0.2%, removing redundant elemental sulfur through high-temperature heat treatment until the mass percentage content of elemental sulfur is lower than 0.2%. The process is simple, large-scale production can be achieved, the obtained NiS2 powder is high in purity, high in conductivity and uniform in particle size, and a foundation is laid for obtaining high-power thermal batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

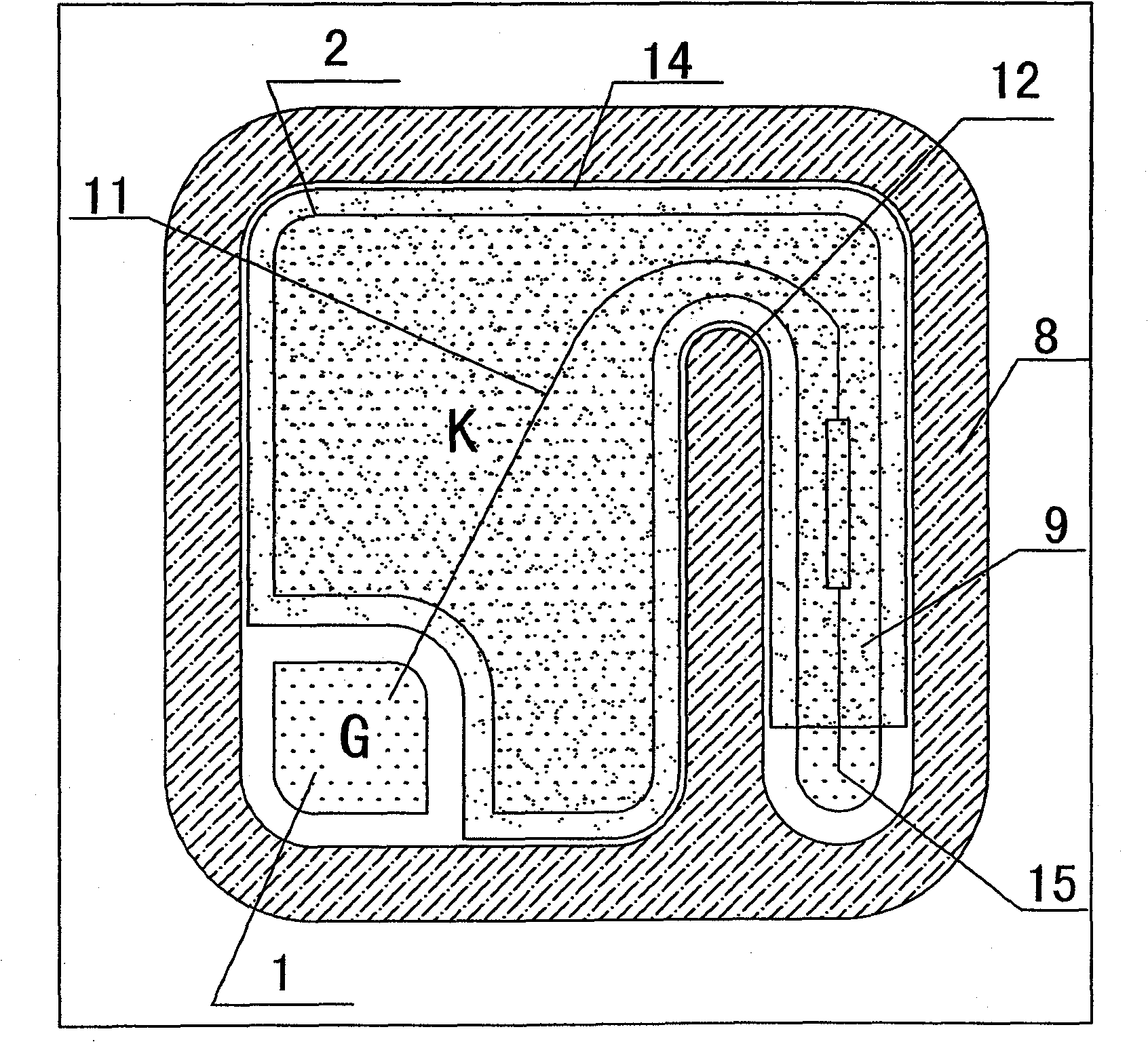

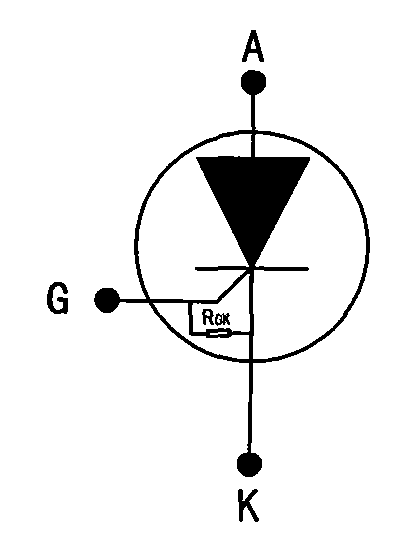

Gate sensitive triggering unidirectional controlled silicon chip and production method thereof

ActiveCN101339955BExtended operating temperature rangeGood temperature characteristicsThyristorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceSilicon-controlled rectifier

The invention discloses a gate sensitive trigger one-way silicon controlled rectifier (SCR) chip which promotes the temperature characteristics of products and improves batch-to-batch consistency of trigger current IGT. The invention also provides a method for producing the gate sensitive trigger one-way SCR chip; and the method has the advantages of simple process, convenient processing and improving performance of products. The gate sensitive trigger one-way SCR chip comprises a gate electrode G, a cathode electrode K, an anode electrode A, an N<+> emitter region, an N-shaped long base region, a P-shaped short base region and a P-shaped anode region; and an external groove is etched around the chip. The SCR chip is characterized in that a section of internal groove is arranged in the chip, the internal groove and the external groove form a strip-shaped resistance arm, the resistance arm forms a diffused resistor RGK with a larger resistance value by utilizing the P-shaped short baseregion of the N<+> emitter region, one end of the diffused resistor RGK is connected with the gate electrode G by an internal lead of the chip, and the other end is connected with the cathode electrode K by the internal lead.

Owner:JIANGSU JIEJIE MICROELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com