Gate sensitive triggering unidirectional controlled silicon chip and production method thereof

A silicon chip and gate technology, applied in the manufacture of electrical components, thyristors, semiconductor/solid-state devices, etc., can solve the problems of poor batch-to-batch repeatability, poor controllability, limitations, etc., to achieve convenient production and processing, improved temperature characteristics, Good batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

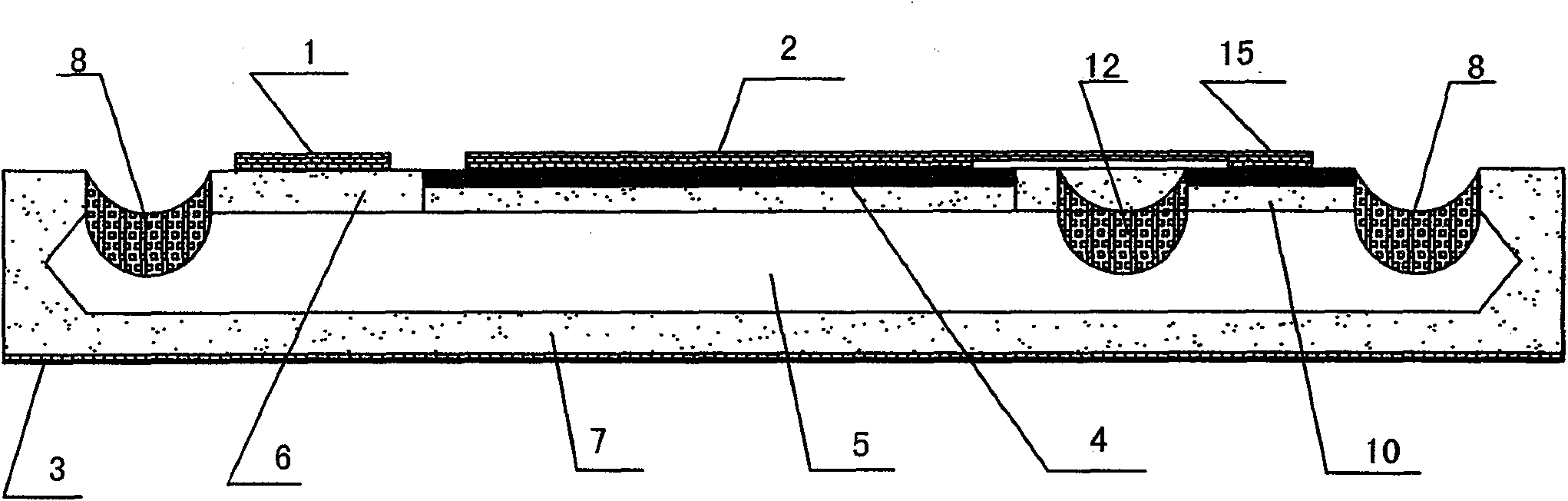

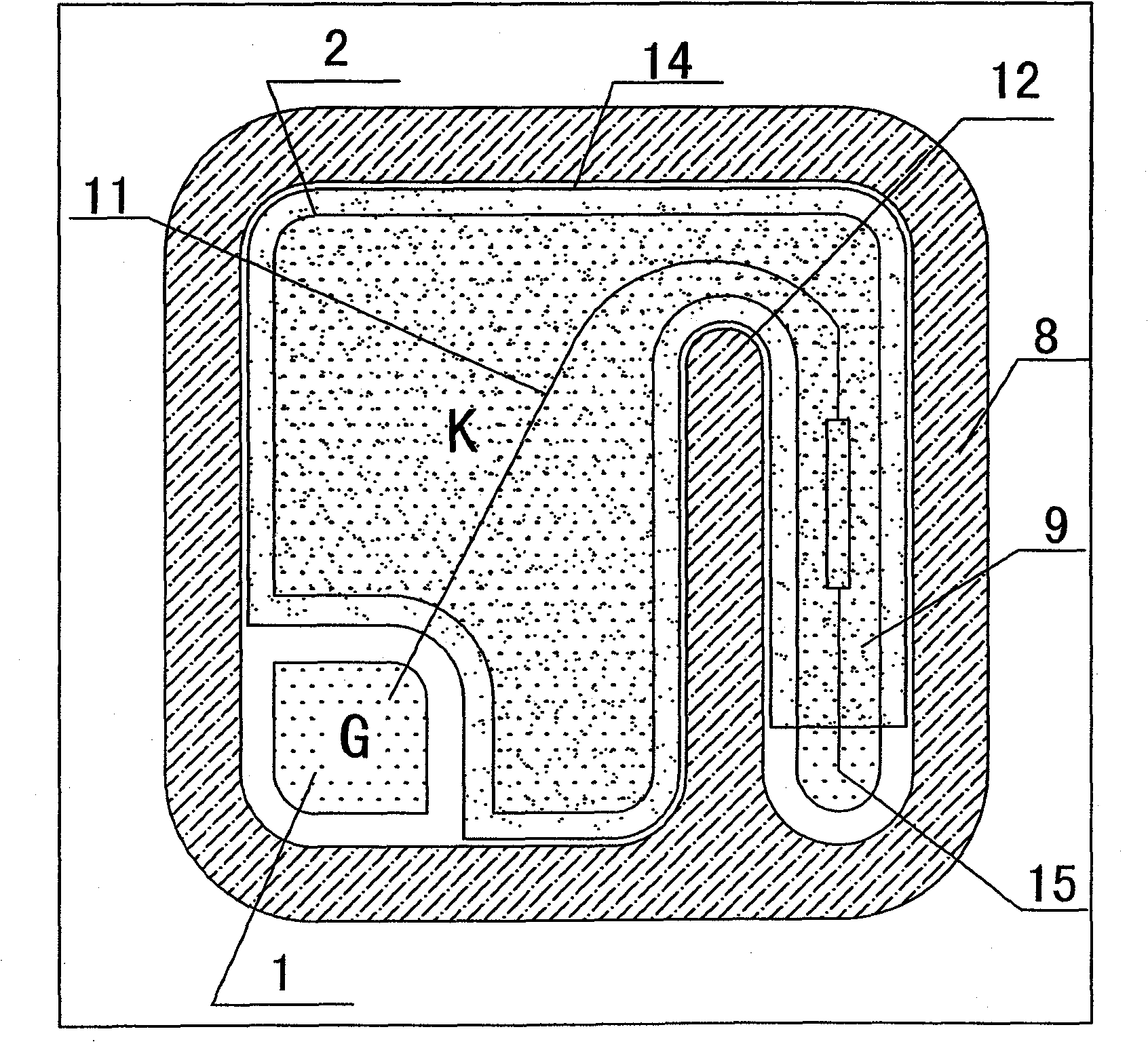

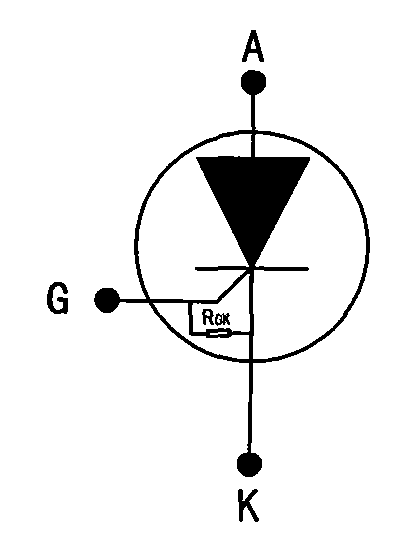

[0039] like Figures 1 to 6 As shown, the gate sensitive trigger one-way thyristor chip of the present invention includes gate electrode G1, cathode electrode K2, anode electrode A3, N + Emitter region 4, N-type long base region 5, P-type short base region 6 and P-type anode region 7, an outer groove 8 is etched around the chip, and a section of inner groove 12 is arranged inside the chip, and the inner groove 12 from N + The upper surface of the emitter region opens, passes through the P-type short base region, and opens into the 5 layers of the N-type long base region. A long strip-shaped resistance arm 9 is formed between the inner trench 12 and the outer trench 8, The resistor arm 9 utilizes N + The P-type short base region 6 under the emitter region 4 forms a diffusion resistor R with a larger resistance value GK 10. The diffusion resistance R GK One end of 10 is connected to the gate electrode G1 through the inner lead 11 of the chip, and the other end is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com