Large-scale preparation method of single-phase NiS2 powder

A powder and single-phase technology, which is applied in the field of large-scale preparation of single-phase NiS2 powder, can solve problems such as powder synthesis difficulties, and achieve the effects of good conductivity, simple process, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

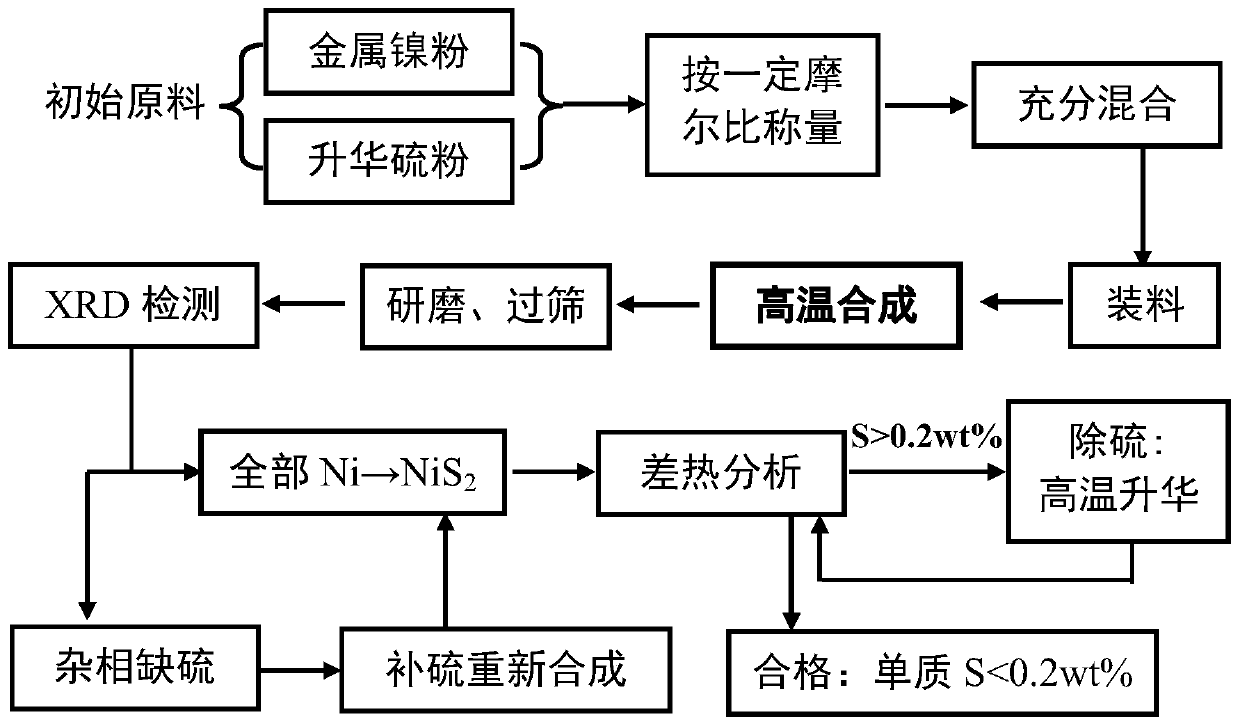

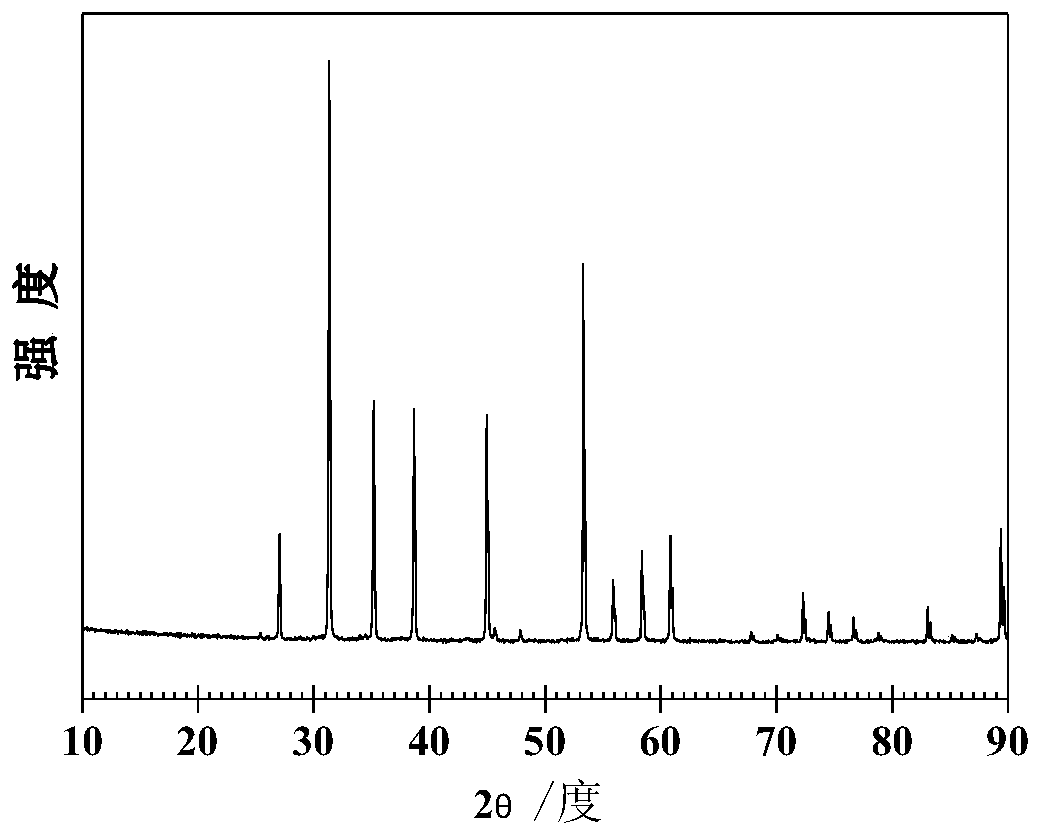

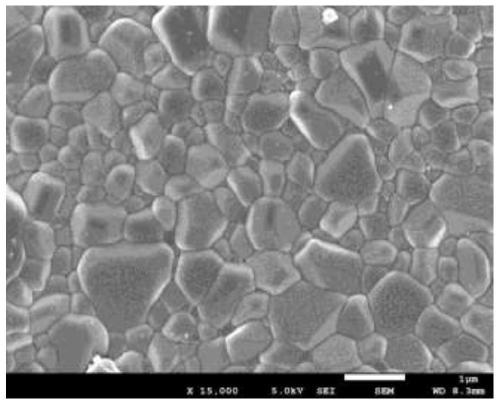

[0028] Such as figure 1 The process flow shown, a single-phase NiS 2 The large-scale preparation method of powder, the preparation method comprises the following steps: commercially available metal nickel powder and sublimation sulfur powder are initial raw materials, first weigh 10Kg metal nickel powder and 25Kg sublimation sulfur powder and fully mix, under Ar atmosphere, The mixed powder was placed in a graphite crucible with a cover, and the crucible was placed in a tubular atmosphere furnace, and the temperature was raised to 680 °C at a heating rate of 5 °C / min, kept for 2 hours, and then cooled to room temperature with the furnace. Collect synthetic materials for grinding and sieving, and conduct XRD and differential thermal tests. The XRD result is NiS 2 phase, without other impurity phases, the result of differential heat is that the elemental sulfur content is 2.1wt%, and then the sulfur removal process is carried out: under the Ar atmosphere, the sieved NiS 2 The ...

Embodiment 2

[0030] Such as figure 1 The process flow shown, a single-phase NiS 2The large-scale preparation method of powder, the preparation method comprises the following steps: commercially available metal nickel powder and sublimated sulfur powder are the initial raw materials, first weigh 10Kg metal nickel powder and 15Kg sublimated sulfur powder to fully mix, under Ar atmosphere, The mixed powder was placed in a graphite crucible with a cover, and the crucible was placed in a tubular atmosphere furnace. The temperature was raised to 650 °C at a heating rate of 5 °C / min, kept for 2 hours, and then cooled to room temperature with the furnace. Collect synthetic materials for grinding and sieving, and conduct XRD test, the result has NiS 2 phase and NiS phase. Weigh 3Kg of sublimated sulfur powder and mix it with the synthetic powder, and then re-synthesize, the synthesis system is the same as above, until all the metallic nickel is synthesized into NiS 2 until. The differential the...

Embodiment 3

[0032] Such as figure 1 The process flow shown, a single-phase NiS 2 The large-scale preparation method of powder, the preparation method comprises the following steps: commercially available metal nickel powder and sublimated sulfur powder are the initial raw materials, first weigh 10Kg metal nickel powder and 35Kg sublimated sulfur powder to fully mix, under Ar atmosphere, The mixed powder was placed in a graphite crucible with a cover, and the crucible was placed in a tubular atmosphere furnace. The temperature was raised to 600 °C at a heating rate of 10 °C / min, kept for 2 hours, and then cooled to room temperature with the furnace. Collect synthetic materials for grinding and sieving, and conduct XRD test, the result is NiS 2 Mutually. The differential thermal analysis of the obtained powder shows that the sulfur content is greater than 0.2wt%. Desulfurization process: under Ar atmosphere, sieved NiS 2 The powder was placed in a graphite crucible, and the crucible was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com