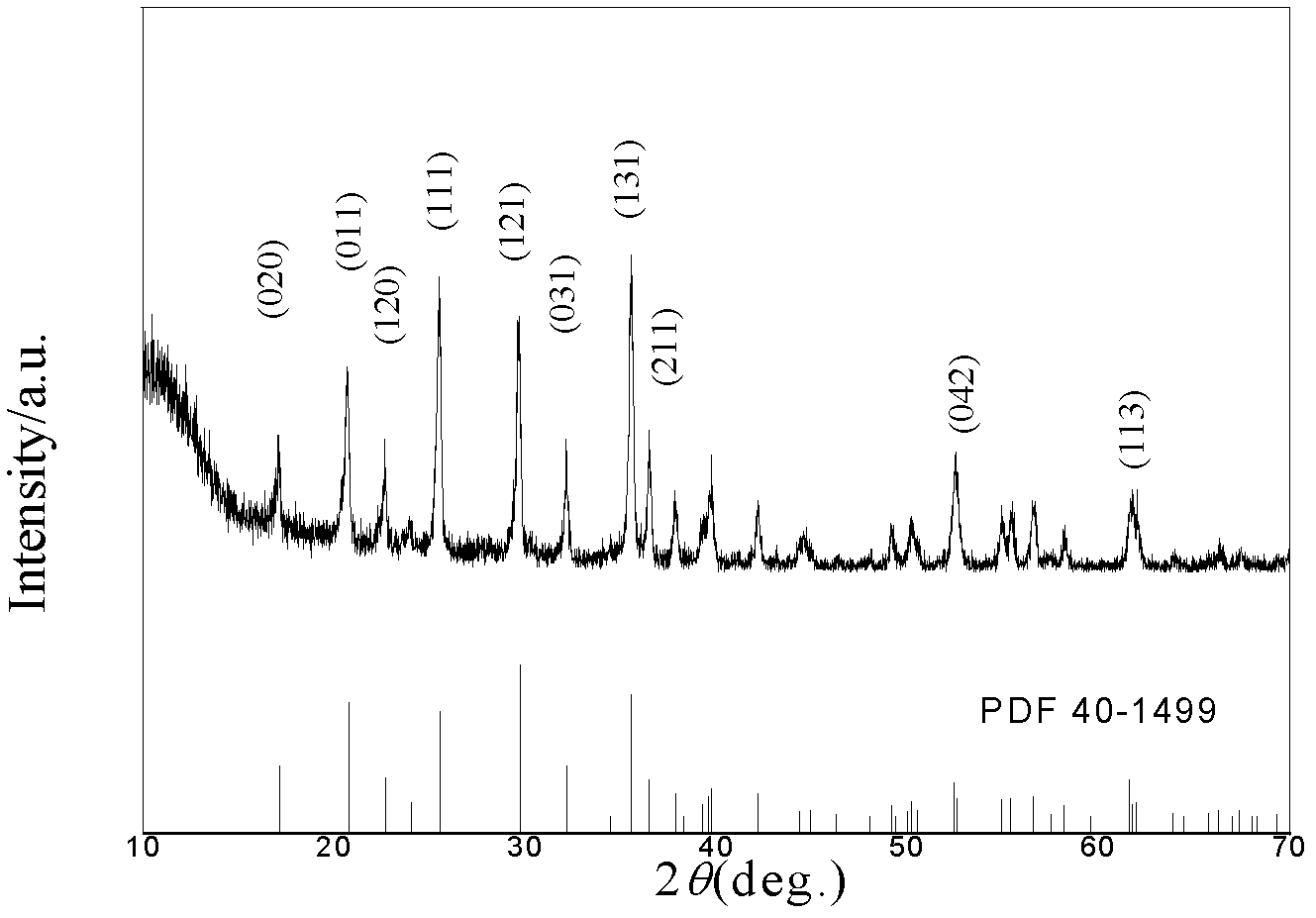

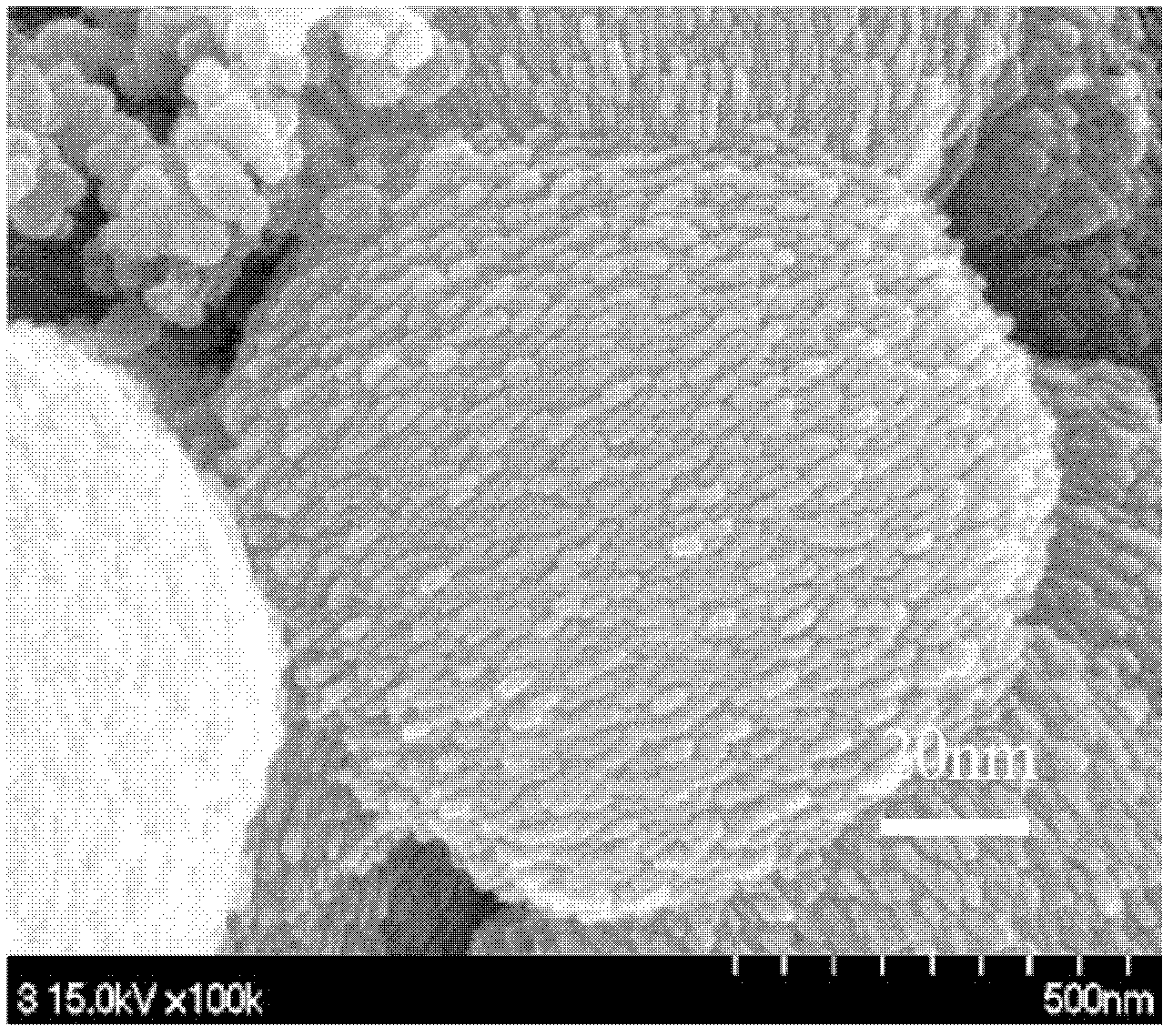

Industrial production method for preparing nanometer lithium iron phosphate by adopting solvent thermal method

A technology of lithium iron phosphate and solvothermal method, which is applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve problems such as uneven and wide particle size distribution, poor product batch consistency, and poor electrochemical performance of products , to achieve the effects of good recovery and purification efficiency, easy control, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Phosphoric acid, ferrous sulfate, lithium hydroxide, glucose, H 2 O and isopropyl alcohol are mixed and stirred evenly in a closed reaction kettle, the molar ratio of phosphoric acid, ferrous sulfate, and lithium hydroxide is 1:1:3, and the mass of the solid accounts for 30% of the total mass of the solution. Water and isopropyl The volume ratio of alcohol is 1: 5, wherein the glucose addition is 13% of the mass of solid powder (excluding carbon source); the airtight reactor is protected by an inert atmosphere, and after stirring for 2 hours, the temperature is raised to 200° C., and the heating time is 3 hours. Make it undergo a crystallization reaction, and the water vapor is condensed and recovered through the condensation system installed on the reactor; after cooling, it is centrifugally settled, and then washed with isopropanol, and this cycle is repeated several times until the impurities on the particle surface are removed; the impurity-removed The slurry is spr...

Embodiment 2

[0033] Mix ammonium phosphate, ferrous chloride, lithium oxalate, salicylic acid, and absolute ethanol in a closed reaction kettle and stir evenly. The molar ratio of ammonium phosphate, ferrous chloride, and lithium oxalate is 1:1:4. Wherein the salicylic acid addition is 18% of solid powder (does not contain carbon source) quality, and the quality of solid accounts for 80% of total solution mass; Airtight reactor inert atmosphere protection, after stirring time 5h, be warming up to 100 ℃, heating The time is 6 hours, so that crystallization reaction occurs; after cooling, it is separated by pressure filtration, and then washed with absolute ethanol, and this cycle is repeated several times until the impurities on the surface of the particles are removed; the slurry from which impurities are removed is spray-dried to obtain two The secondary particles are spherical powders; the waste water and waste organic solvents generated during the synthesis process are recovered and puri...

Embodiment 3

[0038] Ammonium dihydrogen phosphate, ferrous oxalate, lithium carbonate, carbon nanofiber, H 2 O and propanol are mixed and stirred evenly in a closed reaction kettle, the molar ratio of ammonium dihydrogen phosphate, ferrous oxalate, and lithium carbonate is 1:1:2, and the mass of the solid accounts for 55% of the total mass of the solution. The volume ratio of alcohol is 1:1.5, wherein the amount of carbon nanofiber added is 7% of the mass of the solid powder (without carbon source); the closed reaction kettle is protected by an inert atmosphere, and after stirring for 7 hours, the temperature is raised to 300° C., and the heating time is 1 hour , so that crystallization reaction occurs, and the water vapor is condensed and recovered through the condensation system installed on the reactor; after cooling, it is separated by pressure filtration, and then washed with propanol, and this cycle is repeated several times until the impurities on the surface of the particles are rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com