Patents

Literature

60results about How to "Preparation applicable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drug delivery system and preparation method thereof

InactiveCN101485629AHigh feasibilityImprove stabilityLyophilised deliveryEmulsion deliveryOrganic solventSide effect

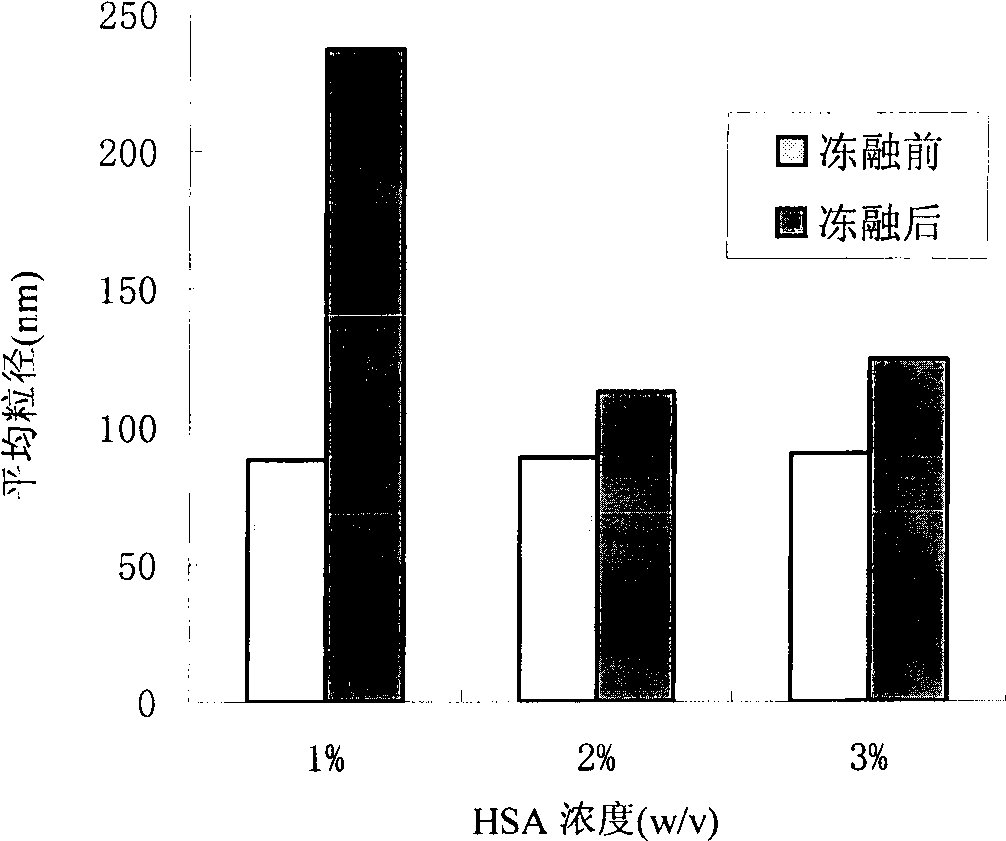

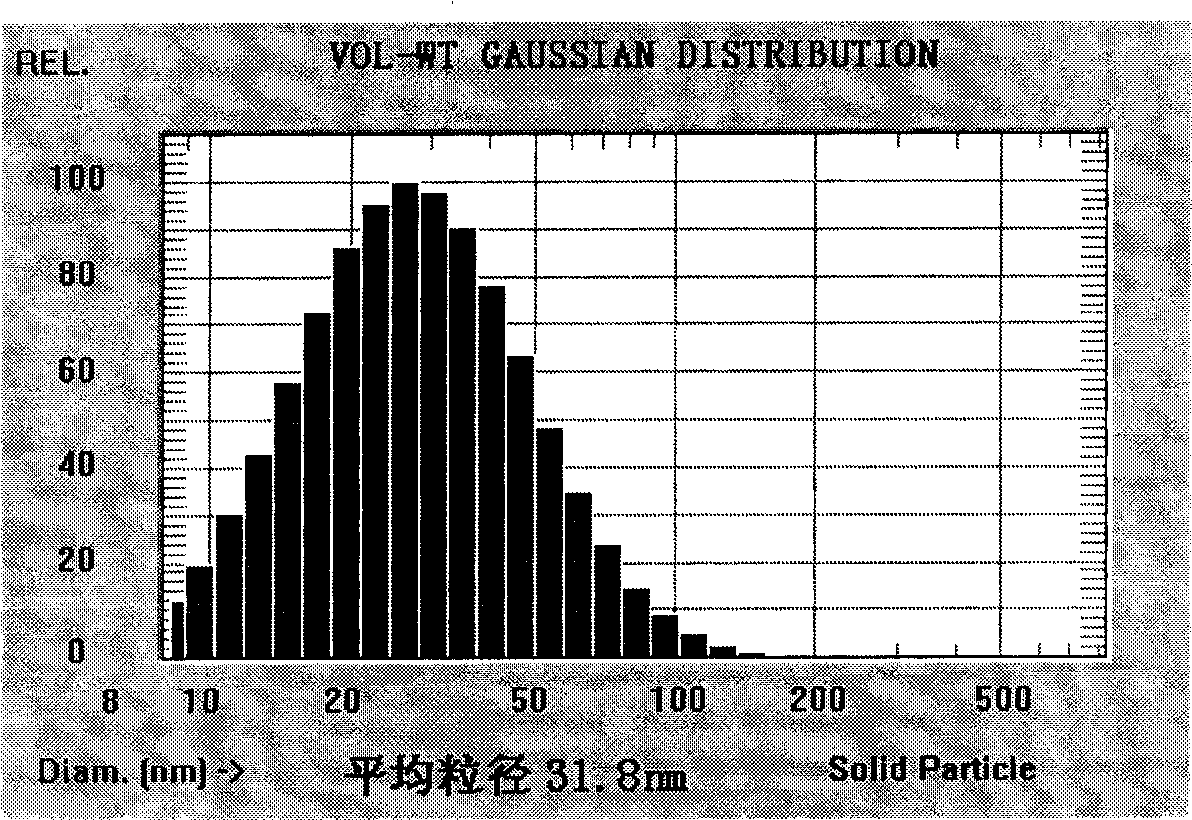

The invention belongs to the technical field of medicines, and discloses a delivery system based on protein-phospholipid. The system comprises a protein-phospholipid dispersion with the weight ratio of between 1:100 and 100:1, wherein the grain size of the protein-phospholipid is between 5 and 1,000nm, and the surface of the phospholipid or the surface and the inside of the phospholipid are coated / covered by a protein layer. The preparation method comprises: preparing a phospholipid containing phase, preparing a protein containing water phase, performing the homogenization treatment on the phospholipid containing phase and the protein containing water phase at a temperature of between 0 and 40 DEG C and under a pressure of between 400 and 40,000psi, and obtaining a dispersion system with the average grain size of less than 1,000nm. The delivery system has the advantages of realizing the delivery in various ways such as injection, oral taking, cavities and canals, skin and the like, and lowering side effects of medicines. The delivery system solves the problems of drug-loading rate and stability of protein nano-grain and liposome, and adopts low-toxicity organic solvent, even no organic solvent; and the preparation method is easy for industrialized application, and can prepare a liquid type protein-phospholipid containing delivery system.

Owner:SHENYANG PHARMA UNIVERSITY

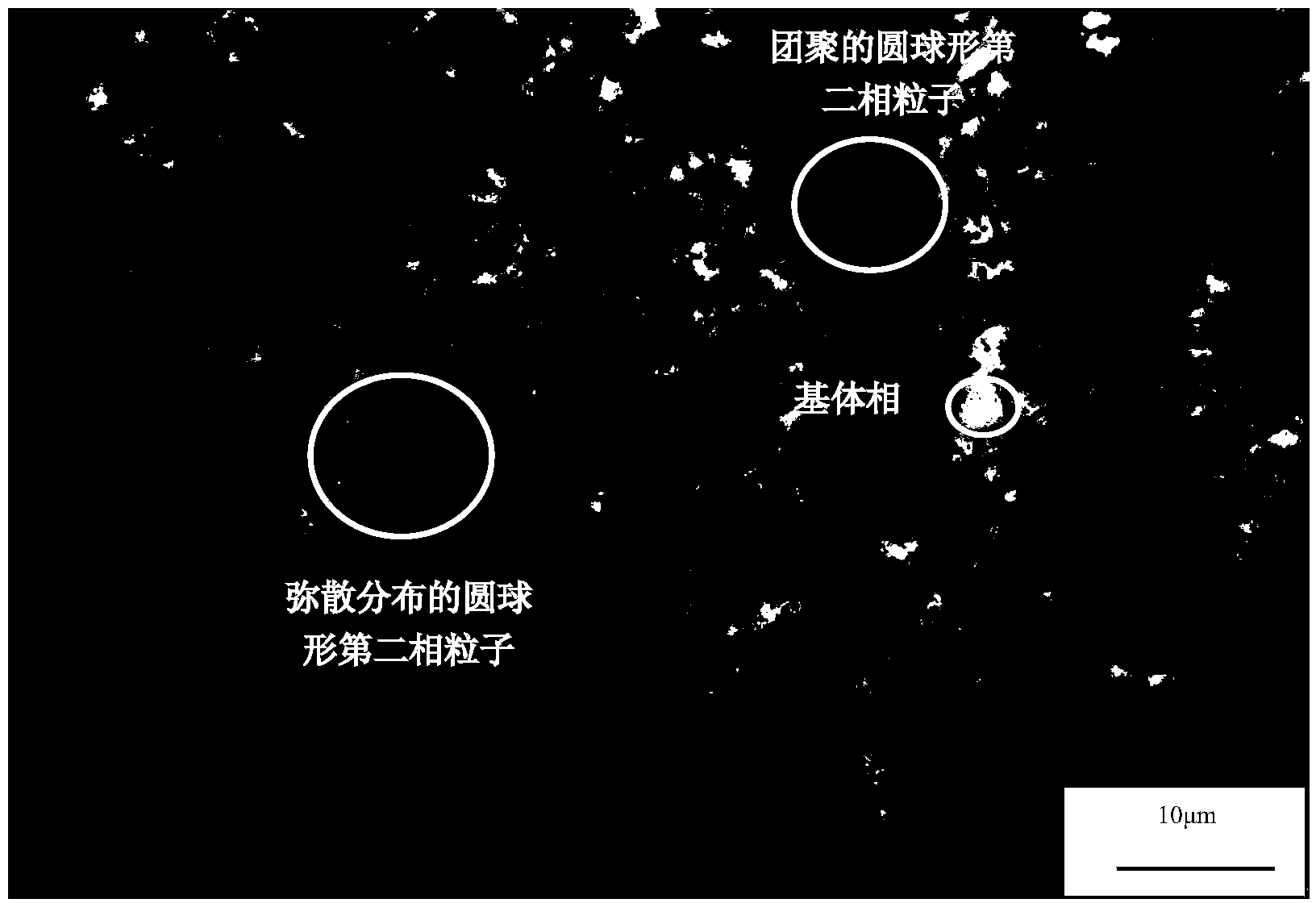

Preparation method of high-performance magnesium alloy plate with double-phase structure

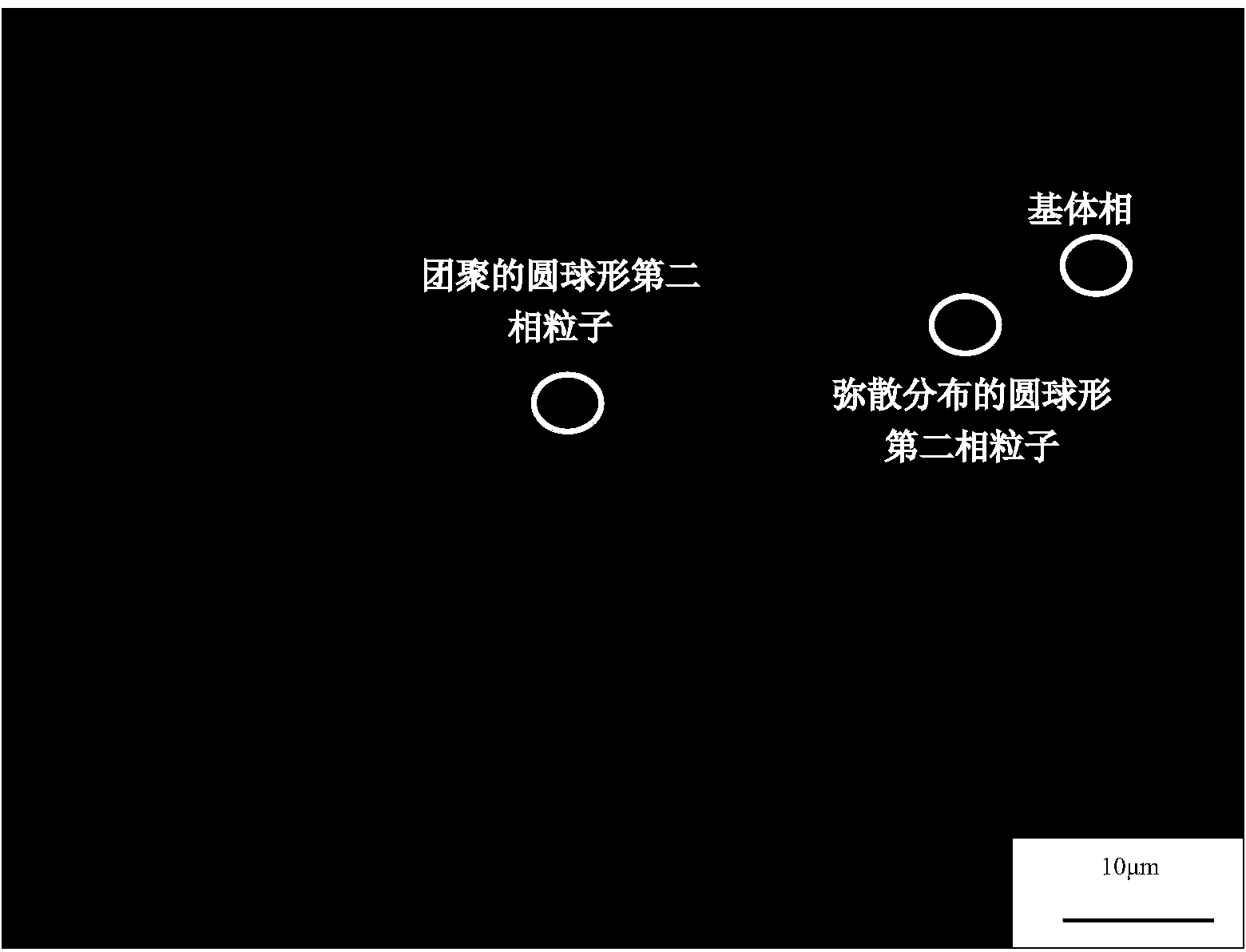

The invention belongs to the technical field of non-ferrous metal magnesium alloy preparation and processing, and particularly relates to a preparation method of a high-performance magnesium alloy plate with a double-phase structure. In the method provided by the invention, a virgin alloy blank of a double-phase microstructure magnesium alloy is prepared by a spray deposition or quick-flow powder preparation or powder metallurgy process; the virgin alloy blank of the double-phase microstructure magnesium alloy is subjected to extrusion, forging, rolling and stamping 'pre-deformation' to form a pre-deformed blank with a 'double-phase texture'; and the pre-deformed blank is subjected to hot rolling or cold rolling to obtain the finished product. The magnesium alloy provided by the invention has the characteristics of 'double-phase structure' (consisting of fine alpha-Mg matrix phase and stable fine second-phase particles) and 'double-phase texture', and a magnesium alloy plate with good comprehensive performance can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

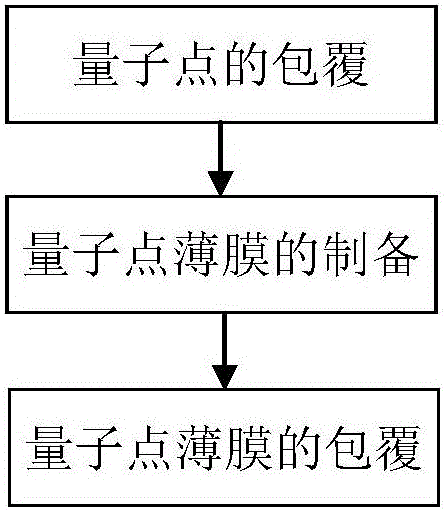

Preparation method of quantum dot film

ActiveCN105779968APlay a protective effectAchieve protectionChemical vapor deposition coatingOrganic filmPolyethylene terephthalate

Disclosed is a preparation method of a quantum dot film. The preparation method of the quantum dot film comprises the following steps that (1) a metal oxide film with the nanometer or sub-micron thickness is formed on the surfaces of quantum dots in a deposition mode through an atomic layer deposition technology so as to cover the quantum dots; (2) the quantum dots with covering metal oxide coat an organic film polyethylene terephthalate substrate, so that the quantum dot film is obtained through preparation; and (3) oxide films with the nanometer or sub-micron thickness are formed on the surface of the quantum dot film and the surfaces of the quantum dots in a deposition mode through a spatial separation atomic layer deposition technology so as to ensure that the quantum dots are not oxidized. According to the preparation method of the quantum dot film, due to the fact that the method with the step that passive films cover the surfaces of the quantum dots step by step is adopted to prepare the quantum dot film, the problem that due to the fact that the quantum dots are prone to being oxidized, the luminescence performance of the quantum dots is lost is solved, and the preparation method has the advantages of being simple in preparation technology, low in preparation cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

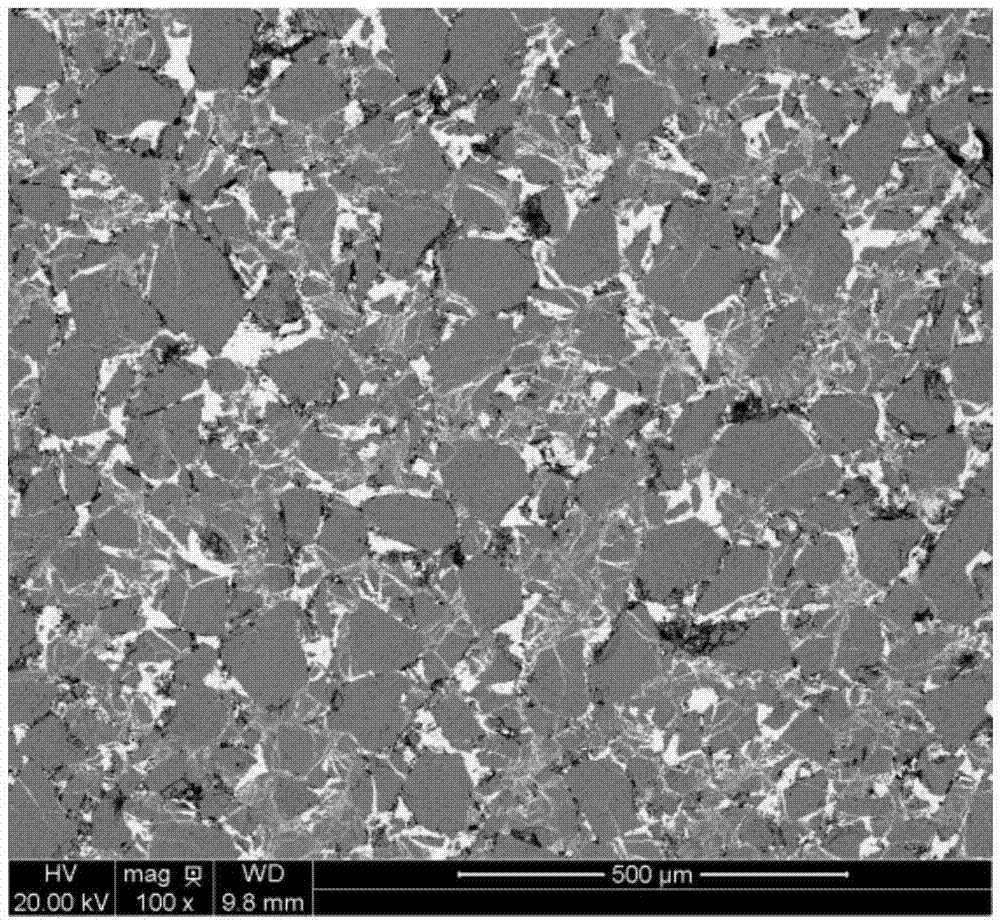

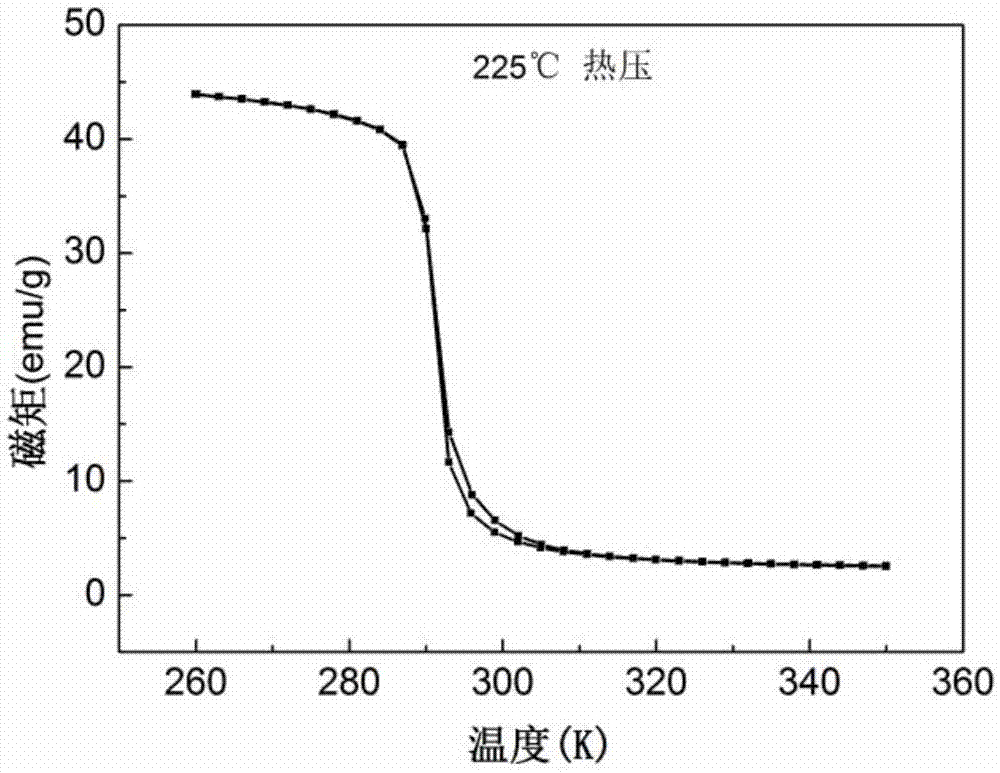

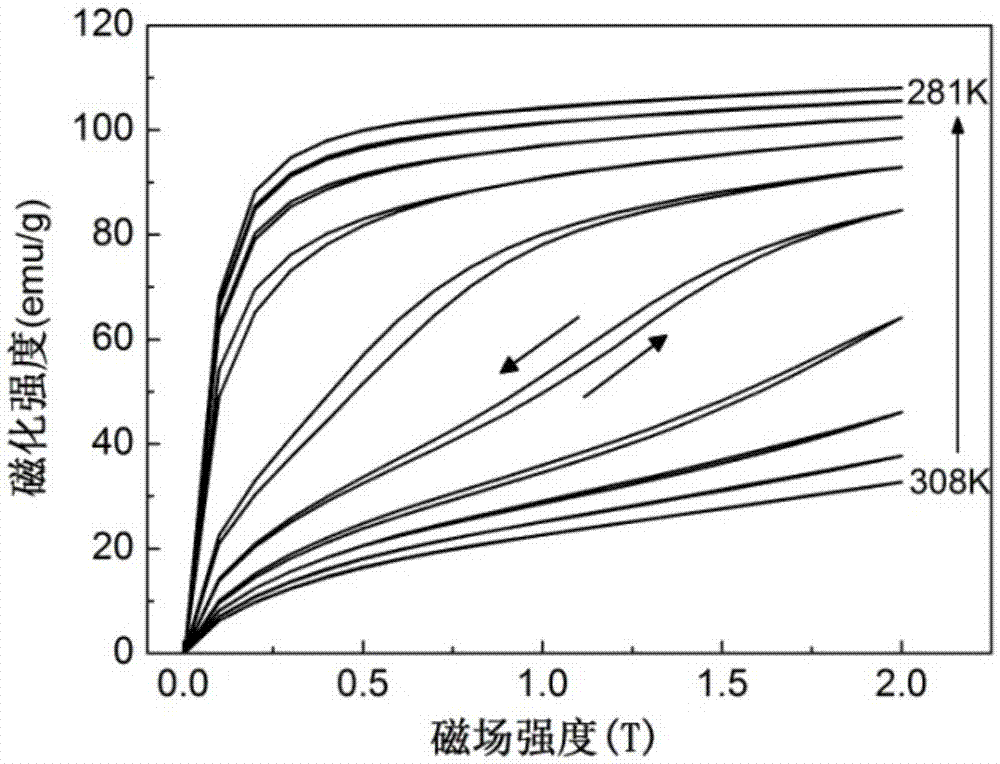

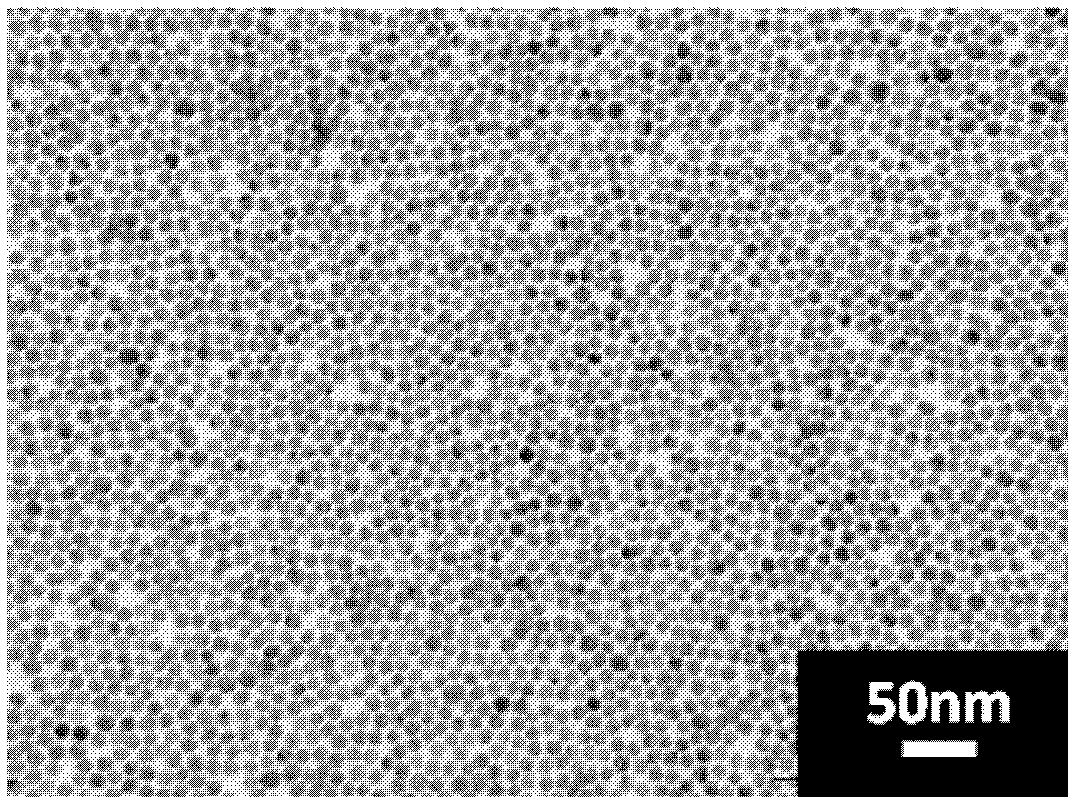

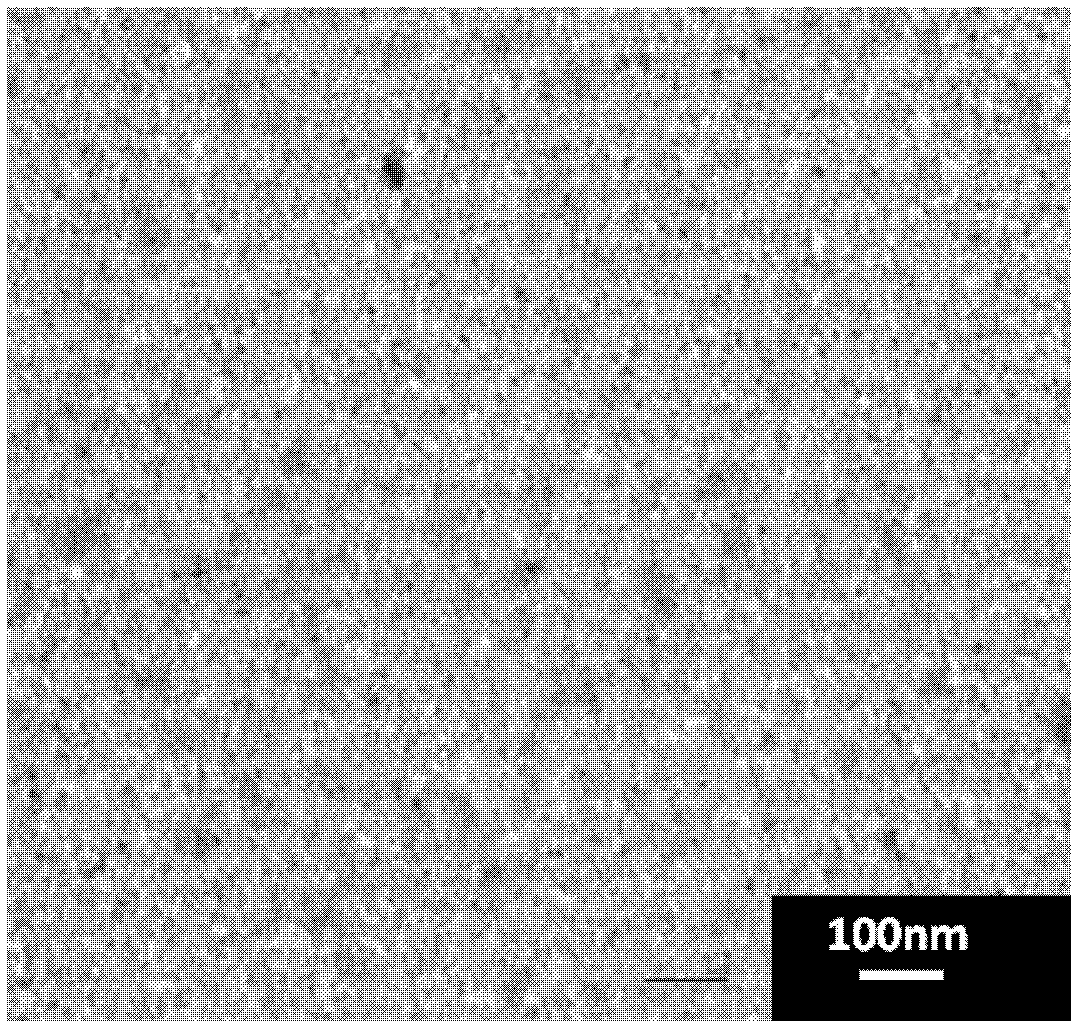

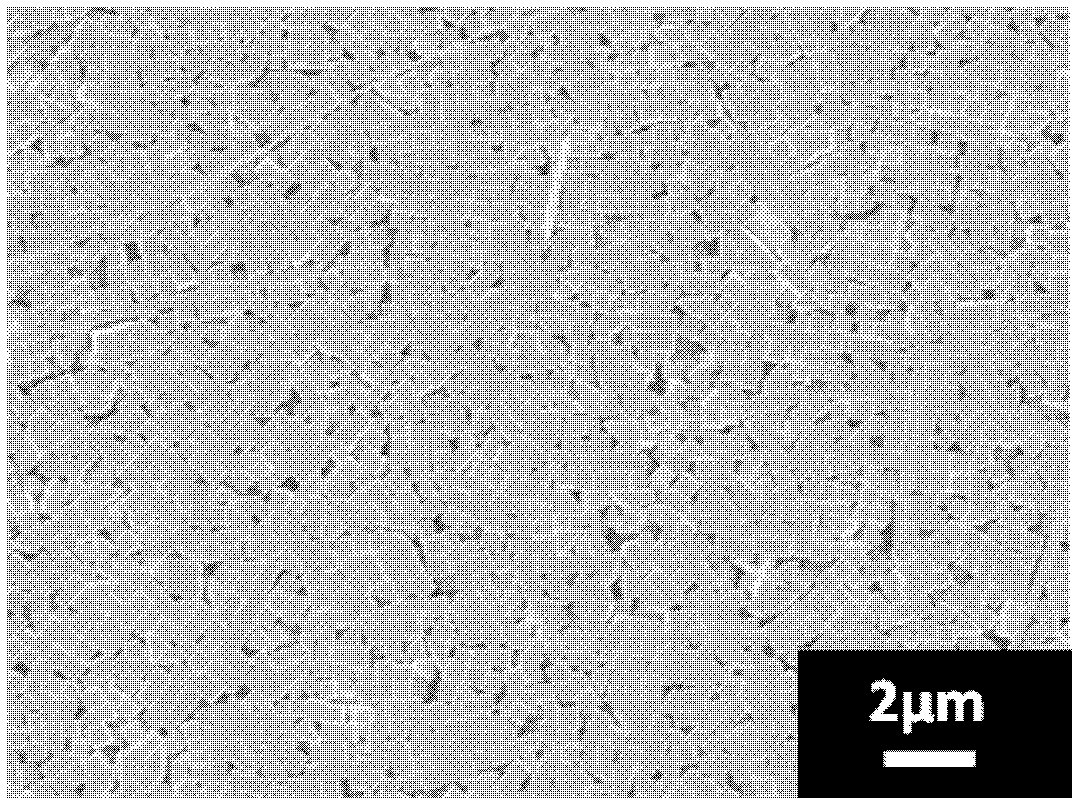

LaFeSi based magnetic refrigeration composite material and preparation method and application thereof

ActiveCN106906408ARaw materials are cheap and easy to getHigh thermal conductivityHeat-exchange elementsAlloyThermal hysteresis

The invention discloses a LaFeSi based magnetic refrigeration composite material and a preparation method and application thereof. The LaFeSi based magnetic refrigeration composite material comprises functional body components such as LaFeSi based alloy particles and matrix components such as low-melting-point metal or alloy, and the LaFeSi based alloy particles are bonded and coated by the matrix components to form a bulk material; and the LaFeSi based alloy particles are of a NaZn13 type structure. According to the LaFeSi based magnetic refrigeration composite material and the preparation method and application thereof, composite hot pressing is conducted between the cheap and easily-obtained low-melting-point metal or alloy and the LaFeSi based alloy particles, the appropriate low-melting-point components are selected, the pressing pressure, the hot pressing temperature, the pressure maintaining time and the like are adjusted, and thus the high-thermal-conductivity LaFeSi based magnetic refrigeration composite material can be obtained; the magnetic entropy change of the LaFeSi based magnetic refrigeration composite material is less reduced compared with that before hot pressing, the magnetic hysteresis loss is low, and thermal hysteresis is avoided; and in addition, the process is simple and easy to operate, the process conditions are relatively mild, energy consumption is little, the cost is low, the repeatability is good, and the preparation method can be widely used in preparation of magnetic refrigeration materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for growth of sulfide crystal containing alkali metal, gallium or indium

InactiveCN1952222AAvoid difficultiesEasy to getPolycrystalline material growthFrom melt solutionsIndiumAlkaline earth metal

Growing method of alkali metals, chalcogene compounds crystal of gallium or indium, involves synthesis and crystal growth of a type alkali metals, chalcogene compounds crystal of gallium or indium ATrQ2(A=Li,Na,K,Rb,Cs;Tr=Ga,In;Q=S,Se,Te)the synthesis and crystal growth. The purpose of this invention is to combine the synthesis of alkali metals, chalcogene compounds crystal of gallium or indium ATrQ2 and growth technology of flux crystal. Choose alkaline earth metal chalcogene compounds, chalcogene compounds of gallium or indium and proper alkaline metal halide flux for raw materials, through reaction flux method to prepare and grow alkali metals, gallium or indium sulfur compounds ATrQ2 crystal.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for preparing nanometer material assembly

InactiveCN102616736APreparation applicableThe method steps are simpleNanostructure manufactureOrganic solventSolvent

The invention discloses a method for preparing a nanometer material assembly. The method comprises the following steps of: mixing a nanometer material aqueous solution and an organic solvent A, adding a solvent B, and oscillating to obtain the nanometer material assembly. In the preparation process of the nanometer material assembly, water in the nanometer material aqueous solution and the solvent A form a liquid-liquid interface, so that an assembly platform is constructed for preparing the nanometer material assembly; and by adding the solvent B, the ambient environment of a nanometer material is changed, the tension of the interface is changed, and the polarity of the aqueous solution and the solvent A can be changed, so that the enrichment and assembly of the nanometer material from the aqueous solution to the interface are promoted, and the nanometer material assembly is prepared. Compared with the prior art, the method is simple, has the characteristics of economy and quickness, and is suitable for preparing various nanometer material assemblies.

Owner:UNIV OF SCI & TECH OF CHINA

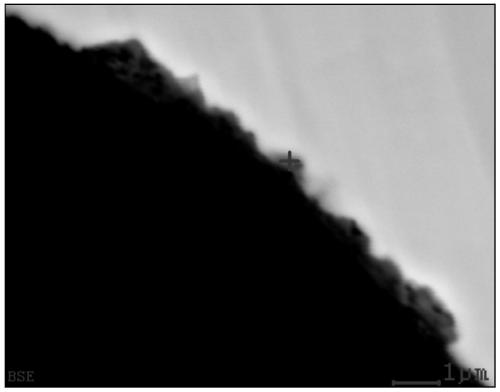

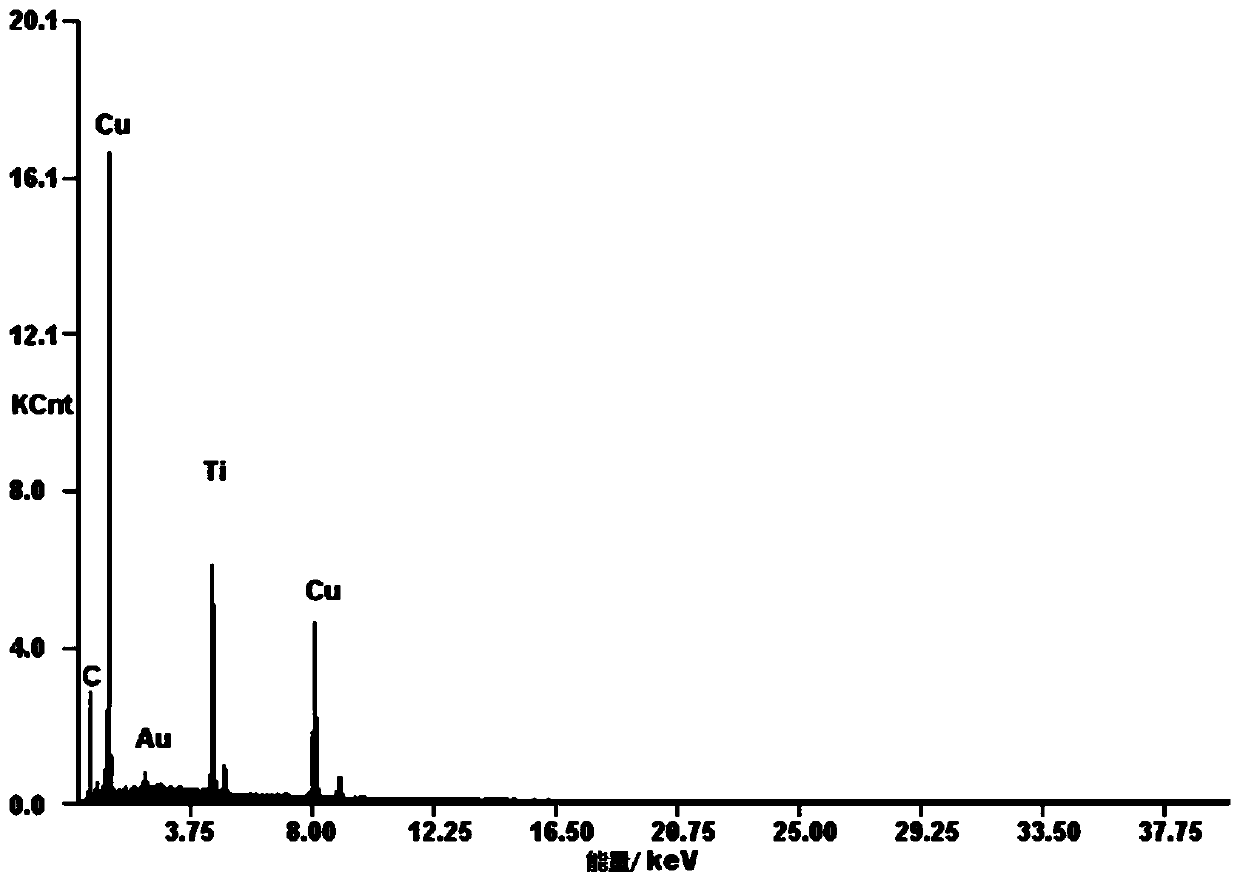

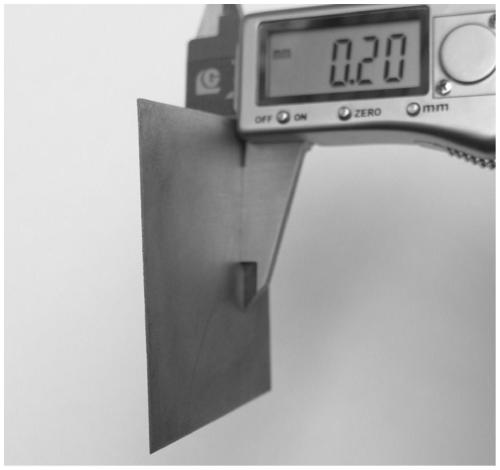

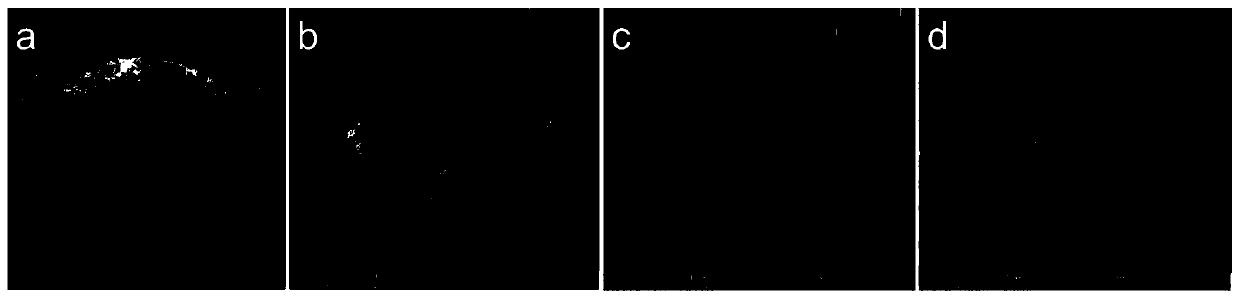

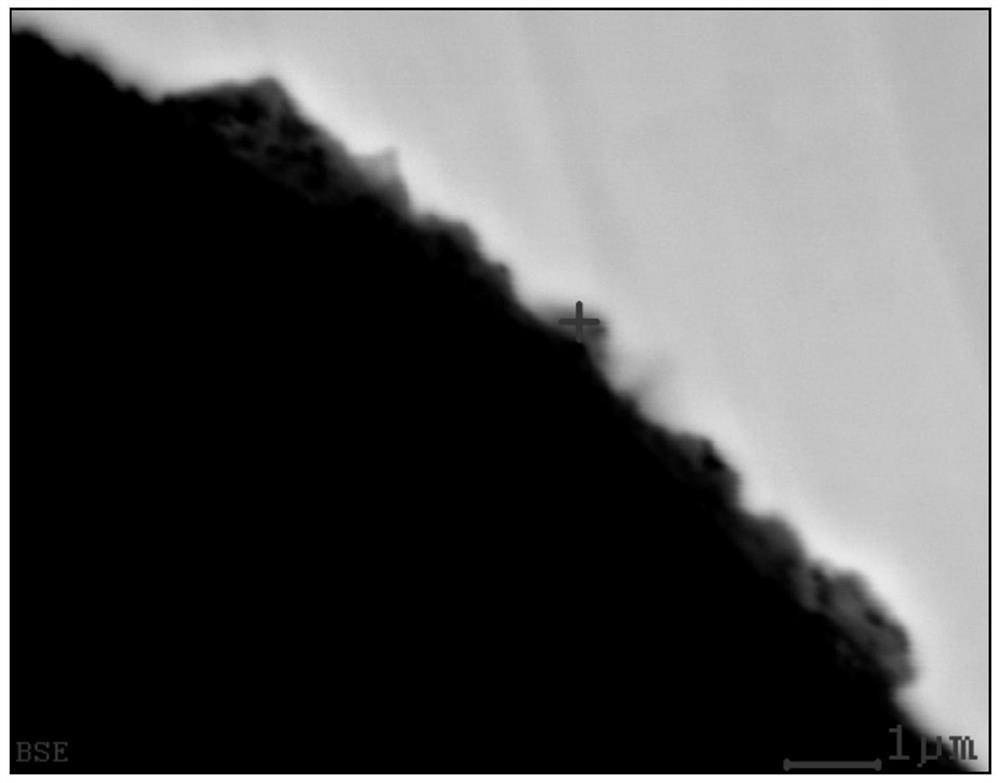

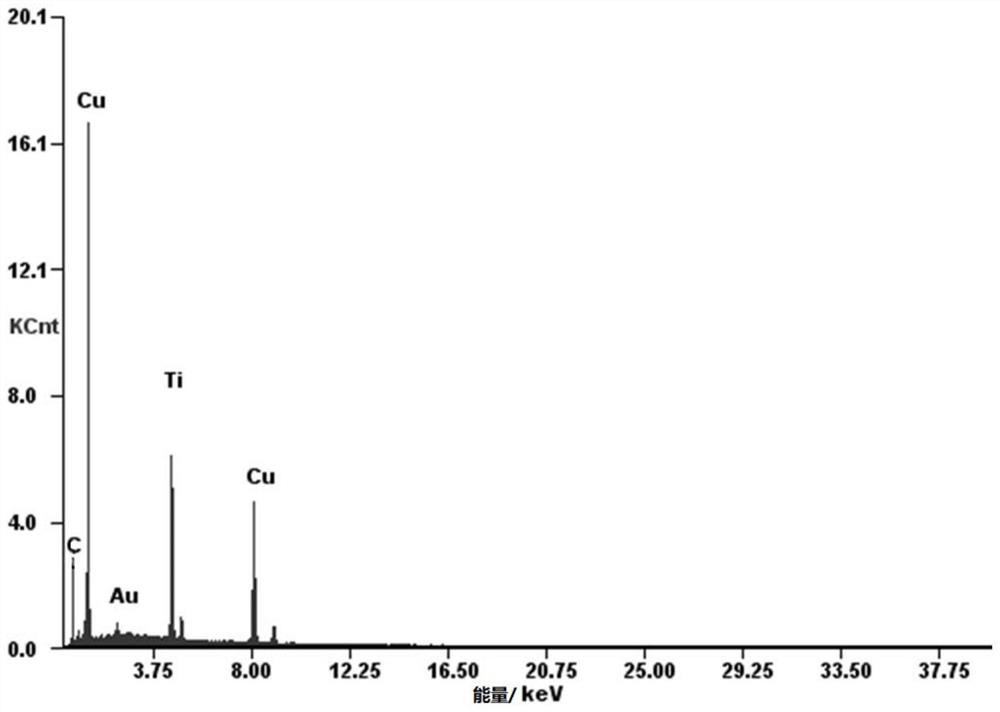

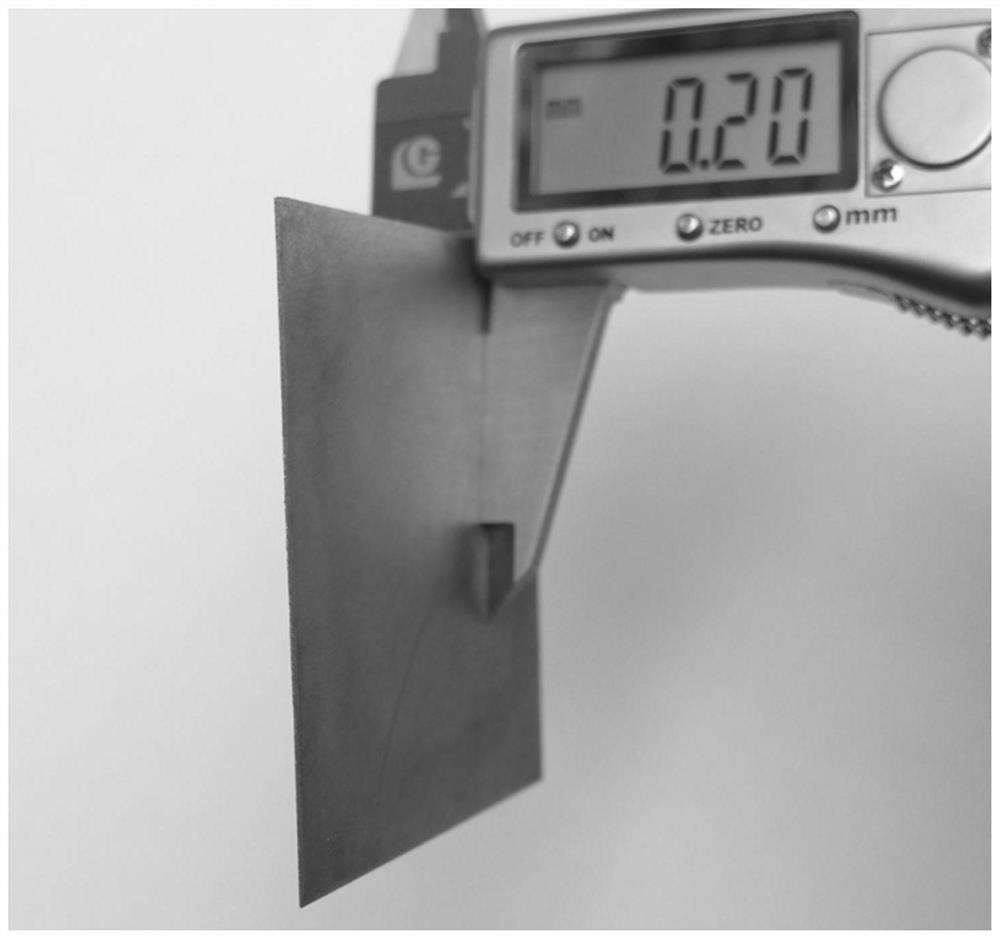

Preparation method for large-size slice-shaped and ultrahigh-heat-conductivity diamond/copper composite material

The invention provides a preparation method for a large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material and relates to the preparation method for the diamond / coppercomposite material. The purpose of the preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is to solve the problems of the low heat conductivity and the poor interfacial bonding strength of the diamond / copper composite material. The preparation method comprises the steps that diamond particles coated with metal films are filled intoa mold cavity of a graphite mold to obtain a prefabricated body; and the prefabricated body is placed into a crucible, block-shaped pure copper and copper alloy are placed at the upper portion of theprefabricated body inside the crucible to be placed into an air pressure leaching furnace, interfacial layer material tissue form adjusting and control are performed under an argon protective atmosphere, warming copper melting, heat preservation and pressure maintaining leaching are performed, and finally, pressure maintaining stepped cooling is performed. In an obtained composite material component, the diamond volume fraction is 60-85%, the heat conductivity reaches 1500 W / mK, the edge length reaches 60-130 mm, and the thickness reaches 0.2-4 mm. The preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is suitable for preparing the high-heat-conductivity diamond / copper composite material.

Owner:哈尔滨锦威科技有限公司

Synthetic polymer and natural extracellular matrix composite material, artificial blood vessel and preparation method thereof

PendingCN110201223AGood biocompatibilityImprove biological activityProsthesisCell-Extracellular MatrixVascular tissue

Owner:NANKAI UNIV

Technique of preparing fiber reinforcement glass based composite material

The invention relates to a process for preparing a fiber reinforced glass-based composite material. The process adopts a common layering design method for preparing a resin base composite material, directly uses glass fiber or fabrics thereof as a glass matrix and heat-resisting fiber as a reinforcing material, adopts processes of layering and hot pressing to prepare the glass-based composite material, and comprises main steps of pretreatment, laying and hot-pressing densification of the material. Compared with the prior slurry impregnation method and the prior sol-gel method, the process remarkably simplifies the preparing technology, effectively improves processing efficiency, reduces energy consumption, does not generate dust pollution during processing, and is particularly suitable for preparing the high fiber content reinforced glass-based composite material. The preparing method endows the glass-based composite material with better design property, and has compact product structure.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

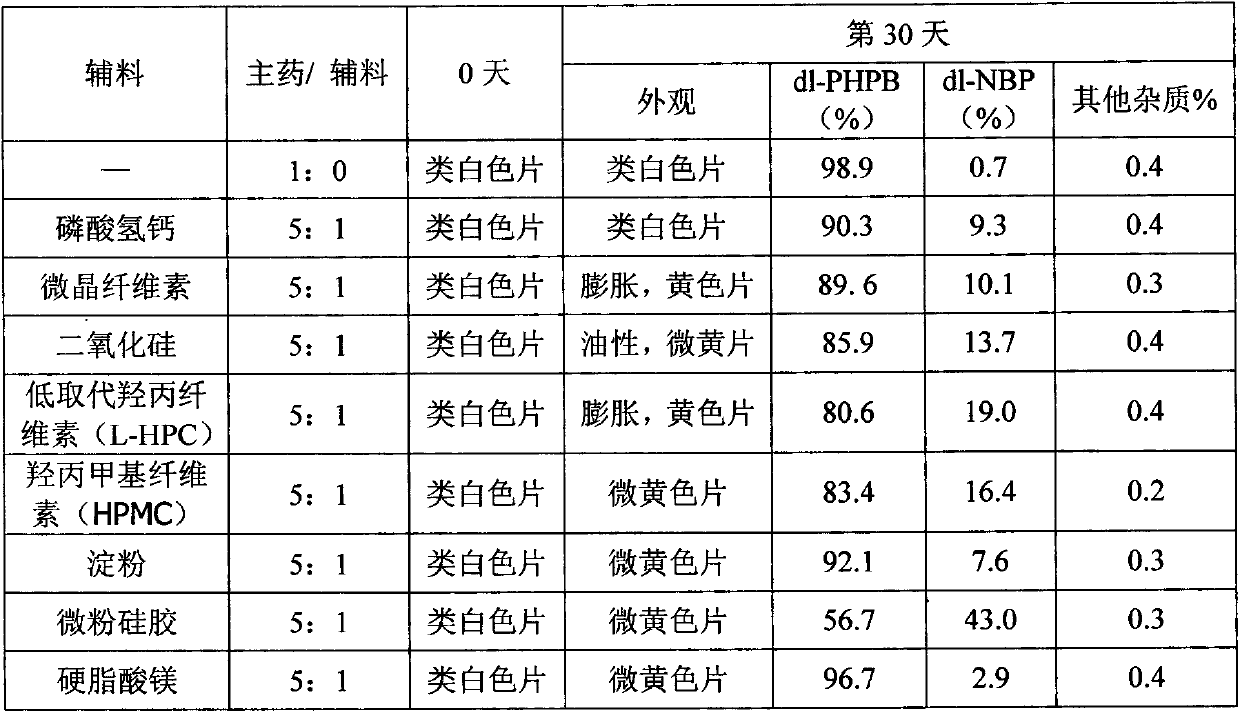

Racemic 2-(alpha-hydroxyl amyl) benzoate tablets and preparation method thereof

ActiveCN103127025AMain drug stability increasedPreparation applicablePharmaceutical non-active ingredientsEster active ingredientsBULK ACTIVE INGREDIENTHydroxyl value

The invention relates to a racemic 2-(alpha-hydroxyl amyl) benzoate tablets and a preparation method thereof, aiming at solving the problem that an active ingredient, namely racemic 2-(alpha-hydroxyl amyl) benzoate is easy to degrade and has low stability in a conventional tablet preparation technology. According to the preparation method of the racemic 2-(alpha-hydroxyl amyl) benzoate tablets, crude drug powder is directly tabletted or an alkalization treatment process is adopted in a preparation technology, so that the stability of the main drug of the racemic 2-(alpha-hydroxyl amyl) benzoate tablets is obviously improved; and the preparation method is suitable for preparation of the tablets.

Owner:山西首智生物科技有限公司

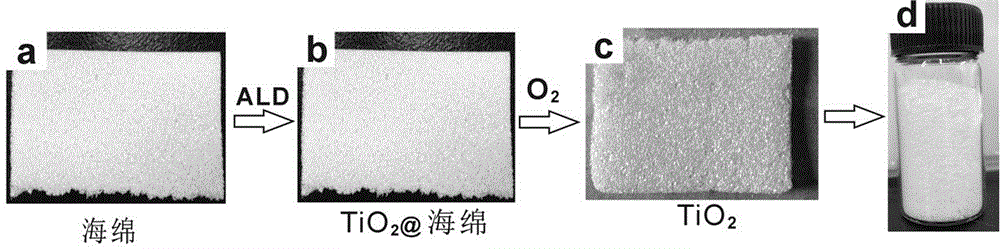

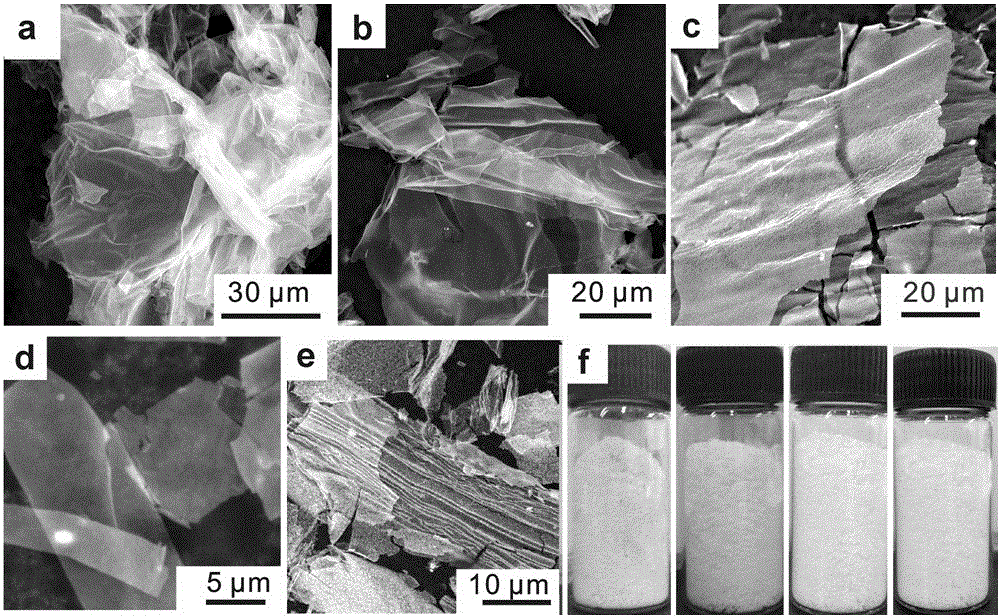

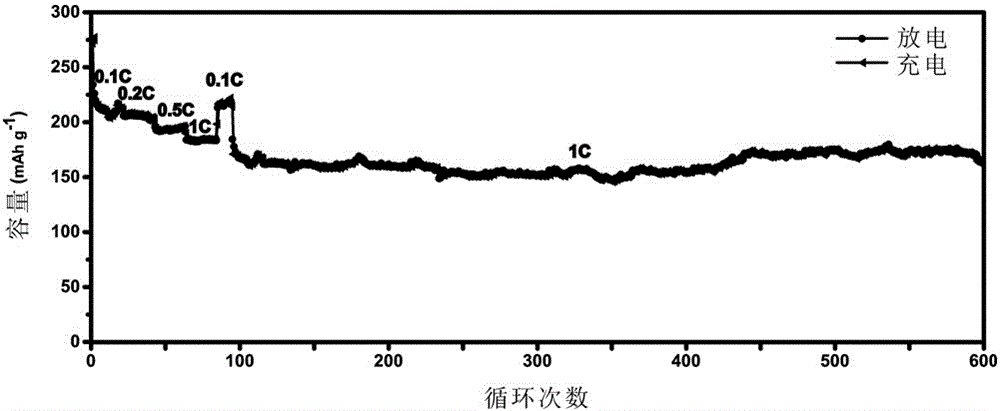

Two-dimensional nanometer thin film negative electrode material of lithium ion battery and preparation method of negative electrode material

InactiveCN106207147AUniform and dense thicknessGood flexibilityCell electrodesSecondary cellsLithium electrodeLithium battery

The invention belongs to the technical field of electrochemistry, and in particular relates to a two-dimensional nanometer thin film negative electrode material of a lithium ion battery and a preparation method of the negative electrode material. The problems of abrupt capacity attenuation and poor stability of a TiO2 negative electrode during large-current charge and discharge are solved by preparing a TiO2 two-dimensional nanometer structure. The preparation method comprises the following steps of growing a TiO2 nanometer thin film on a sponge by an atomic layer deposition method; and performing thermal treatment on the sponge coated with the TiO2 nanometer thin film to remove the sponge so as to obtain a TiO2 two-dimensional nanometer thin film after deposition frequency is reached, wherein the thin film is used for a negative electrode of the lithium ion battery. By simply changing the deposition frequency, the nanometer thin films with different thicknesses can be obtained. The preparation method has the advantages of simplicity in process, high repeatability and high yield. The negative electrode material of the lithium ion battery, prepared according to the method, has the advantages of structural stability and good cycle performance.

Owner:FUDAN UNIV

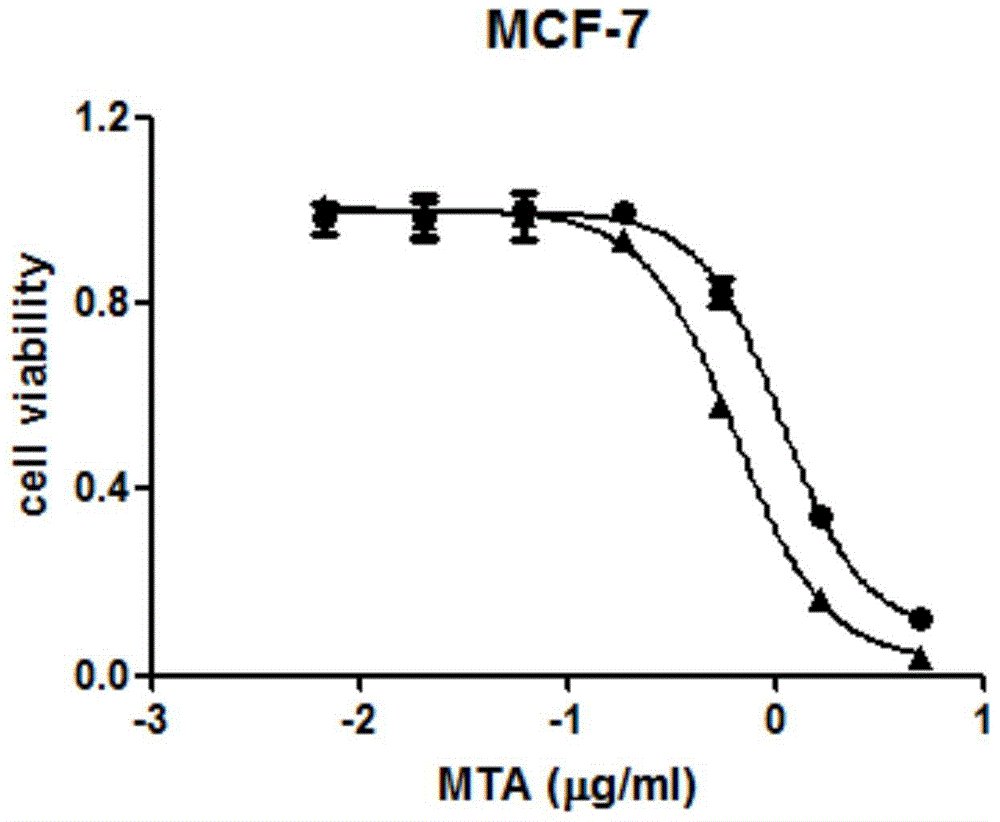

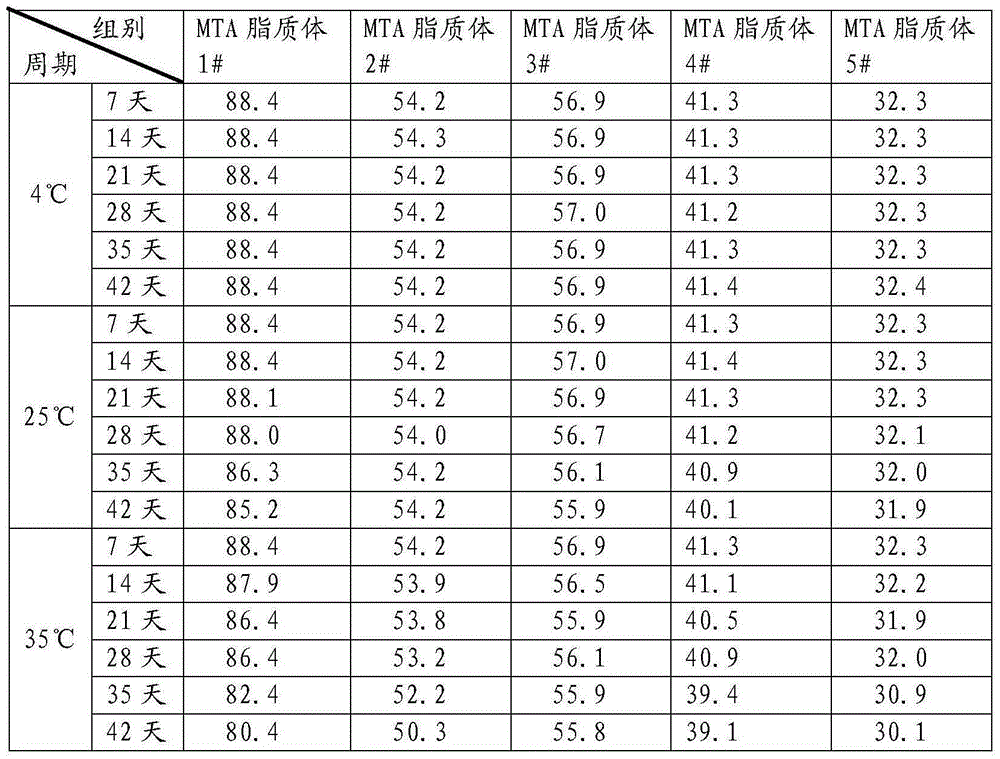

Pemetrexed liposome and preparation method thereof

InactiveCN104546723AImprove stabilitySimple processOrganic active ingredientsPharmaceutical non-active ingredientsMedicineTrial drug

The invention provides a pemetrexed liposome, which is characterized by being prepared from a pemetrexed and a liposome mixture, wherein the mass ratio of the pemetrexed and the liposome mixture is 1:(0.1-10); through the prepared pemetrexed liposome, the drug resistance can be reduced by more than 60% of non-liposome pemetrexed. Known from stability test, the liposome is favorable in stability. Known from clinical trials, the efficacy of the liposome can be improved by more than 80% compared with the common preparation, the in-vivo retention time can be prolonged by more than 65%, and the targeting effect is obvious.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

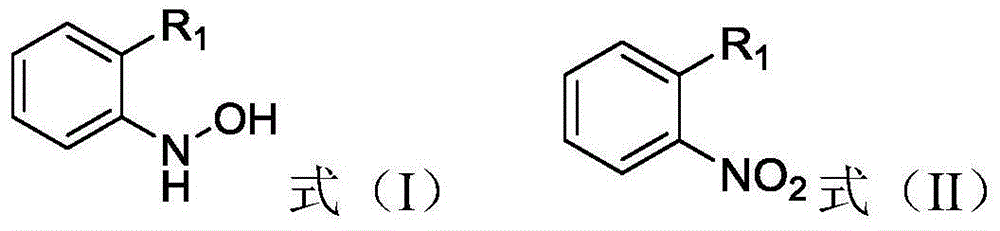

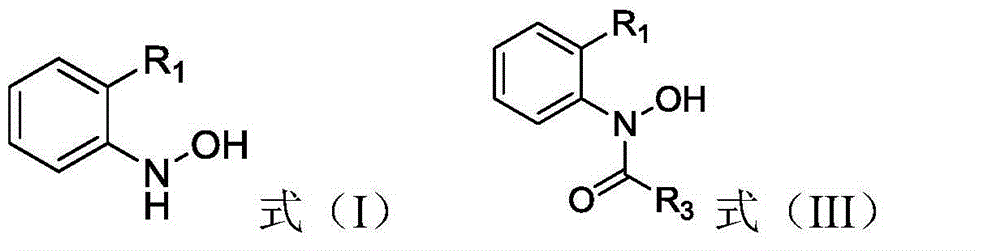

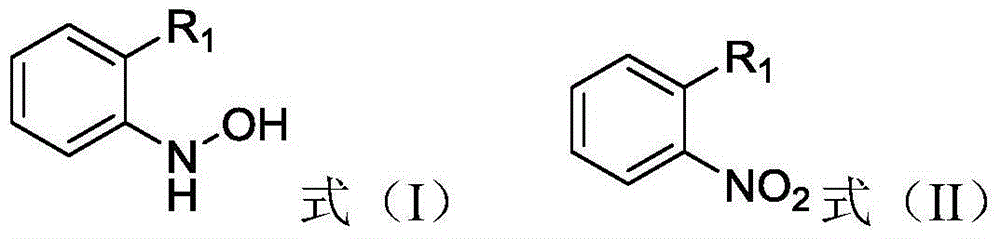

Preparation methods of aromatic hydroxylamine compound and N-aromatic acylated hydroxylamine compound

InactiveCN104557712APreparation applicableAvoid churnCarbamic acid derivatives preparationOrganic compound preparationHydrogenHalogen

The invention discloses a preparation method of aromatic hydroxylamine compound as shown in general formula (I). The preparation method comprises the following steps: performing reduction reaction on a compound as shown in formula (II) and hydrazine hydrate in an organic solvent in the presence of a reduction catalyst, wherein the organic solvent is at least one of aliphatic ether and cyclic ether; R1 is hydrogen, halogen, cyano, C1-C4 alkyl, C1-C4 haloalkyl or -CH2-O-R2, wherein R2 is substituted or unsubstituted phenyl, naphthyl, pyridyl, pyrazinyl, pyrimidinyl, pyridazinyl, pyrazolyl or imidazolyl; in addition, the invention further discloses a preparation method of N-aromatic acylated hydroxylamine compound as shown in formula (III). According to the preparation methods of aromatic hydroxylamine compound and N-aromatic acylated hydroxylamine compound, the reduction reaction has a conversion rate of above 99% and a selectivity of above 99%; the N-acylation reaction has a conversion rate of above 99% and a selectivity of above 98%.

Owner:NUTRICHEM LAB CO LTD

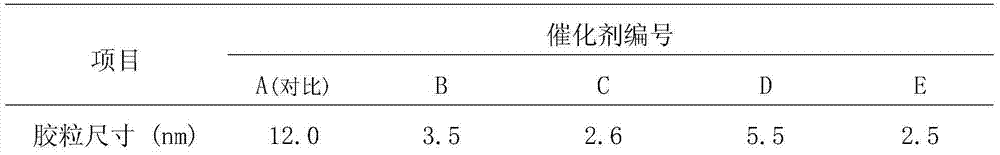

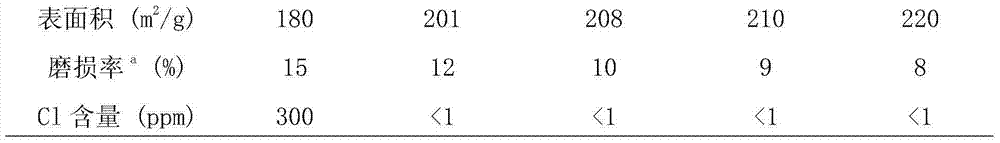

Fischer-Tropsch catalyst, as well as preparation method and application thereof

ActiveCN104707620ANovel production methodSimple processLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSilicic acidIon exchange

The invention provides a Fischer-Tropsch catalyst, as well as a preparation method and application thereof. A silicate solution is used as a raw material, a silicic acid solution is obtained through cation exchange treatment, and Cl and other anionic impurities in the silicic acid solution are then removed through anion exchange treatment, so as to obtain an activated silicic acid solution; the activated silicic acid solution can replace commercial silica gel to serve as a silicon source for Fischer-Tropsch catalyst preparation, so as to effectively solve the difficult problem of non-uniform mixing of iron species and SiO2, further enlarge the surface area of the catalyst, and improve the mechanical strength of the catalyst. The method is simple and convenient to operate, low in cost, and very applicable for the preparation of the commercialized Fischer-Tropsch catalyst.

Owner:SYNFUELS CHINA TECH CO LTD

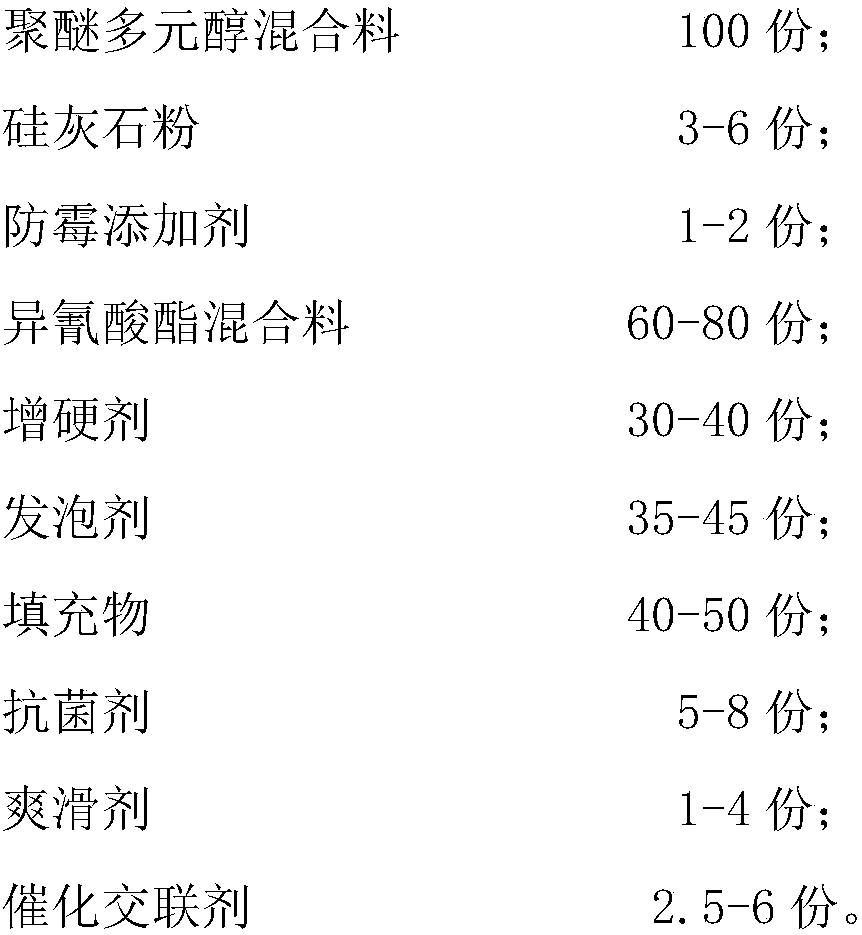

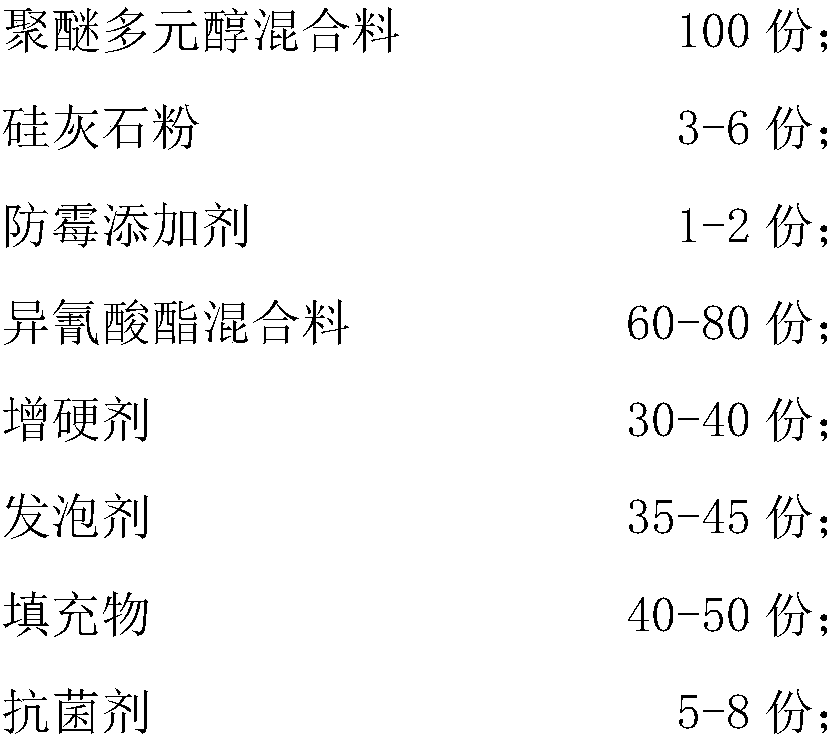

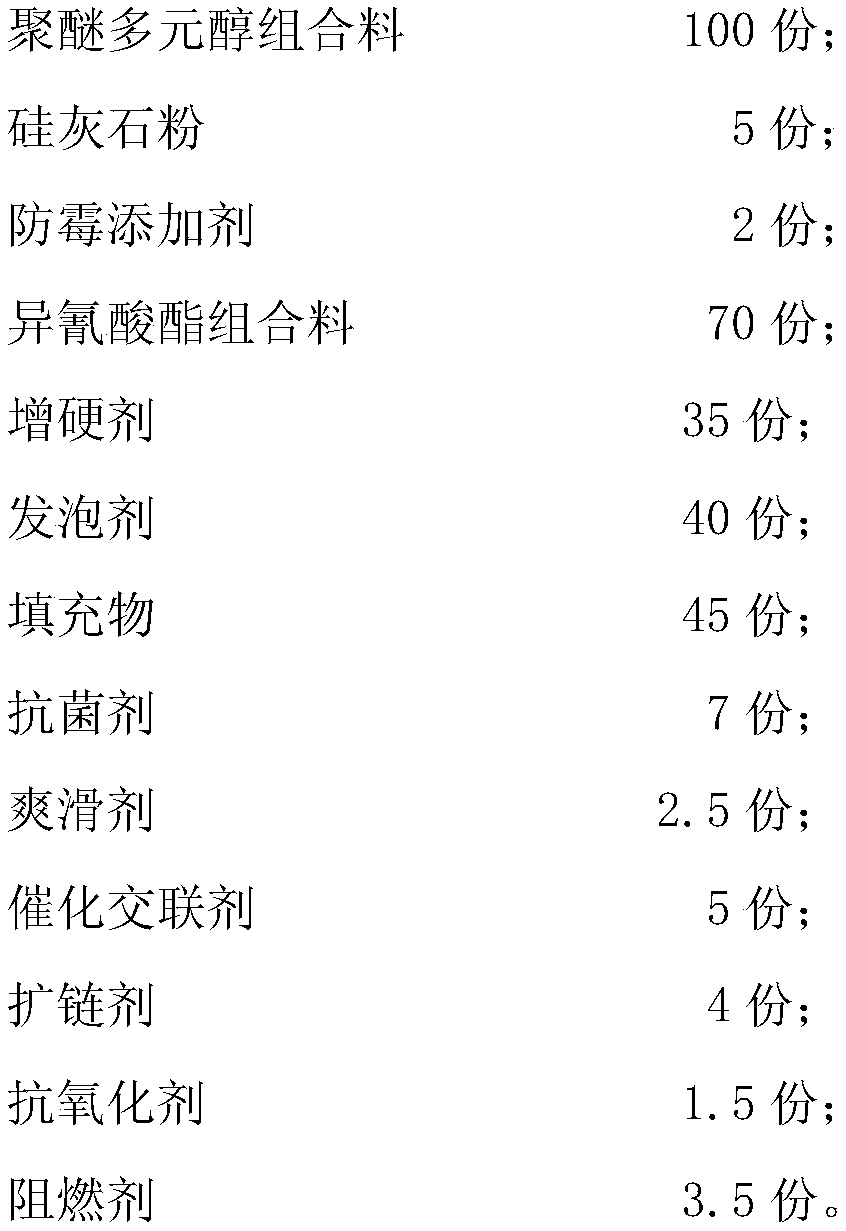

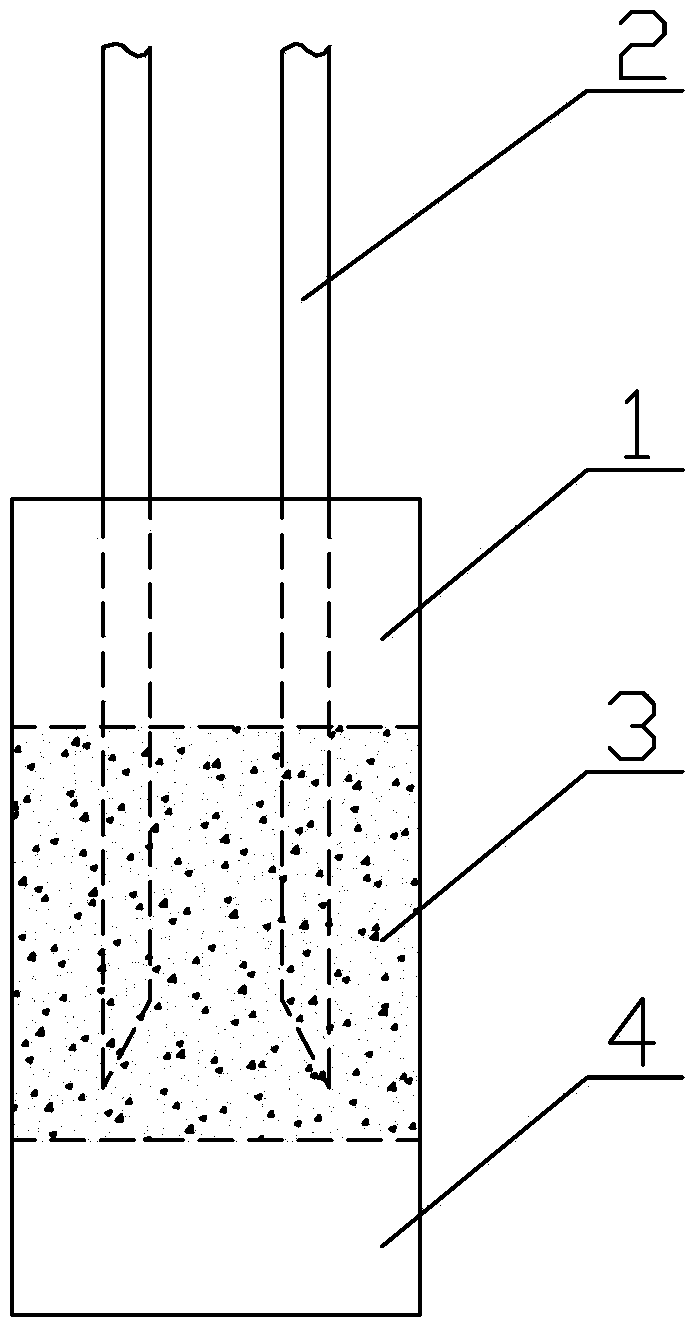

Polyurethane material, high-elasticity antibacterial polyurethane powder puff and preparation method thereof

InactiveCN108484874AIncrease elasticityImprove antibacterial propertiesPackaging toiletriesPackaging cosmeticsFoaming agentSlag

The invention provides a polyurethane material, a high-elasticity antibacterial polyurethane powder puff and a preparation method thereof. The polyurethane material is prepared from the following rawmaterials in parts by weight: 100 parts of a polyether polyol mixture, 3 to 6 parts of a wollastonite powder, 1 to 2 parts of an anti-mildew additive, 60 to 80 parts of an isocyanate mixture, 30 to 40parts of a hardening agent, 35 to 45 parts of a foaming agent, 40 to 50 parts of fillers, 5 to 8 parts of an antibacterial agent, 1 to 4 parts of a refreshing and slipping agent, and 2.5 to 6 parts of a catalytic cross-linking agent. The polyurethane powder puff provided by the invention is researched and developed specifically at the aim of providing good adaptability and compatibility for humanbody skin; compared with the conventional latex and the existing powder puff which is prepared by adopting industrial polyurethane, the polyurethane powder puff has the unique advantages of better skin affinity, no slag drop, odourlessness, bacterial resistance, high elasticity, better oil control capacity, more convenience in cleaning, exquisite hand feeling, environment friendliness and the like, and has a broad popularization and application prospect.

Owner:HUIZHOU YUANAN NEW MATERIALS

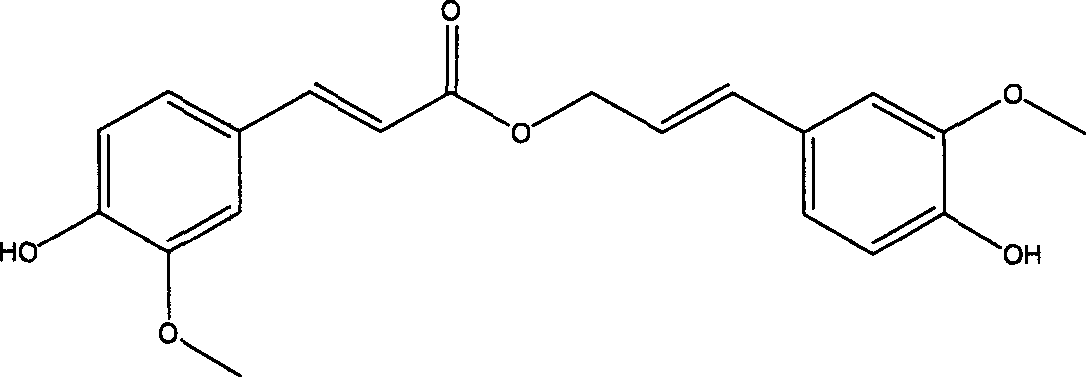

Application of coniferyl ferulate in anticancer medicine

InactiveCN1608616APreparation applicableEasy to operateOrganic active ingredientsAntineoplastic agentsConiferyl ferulateChemical stability

The present invention relates to the development of active anticancer component in Chuanxiong rhizome, and is especially the application of coniferyl ferulate in anticancer medicine. The present invention separates coniferyl ferulate from Chuanxiong rhizome as one traditional Chinese medicine and provides new precursor compound for designing new medicine with effective Chinese medicine component. The present invention establishes the liquid chromatographic purification method of the compound with simple operation, high repeatability and mild condition, and suitable for the preparation of Chinese medicinal components with inferior chemical stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

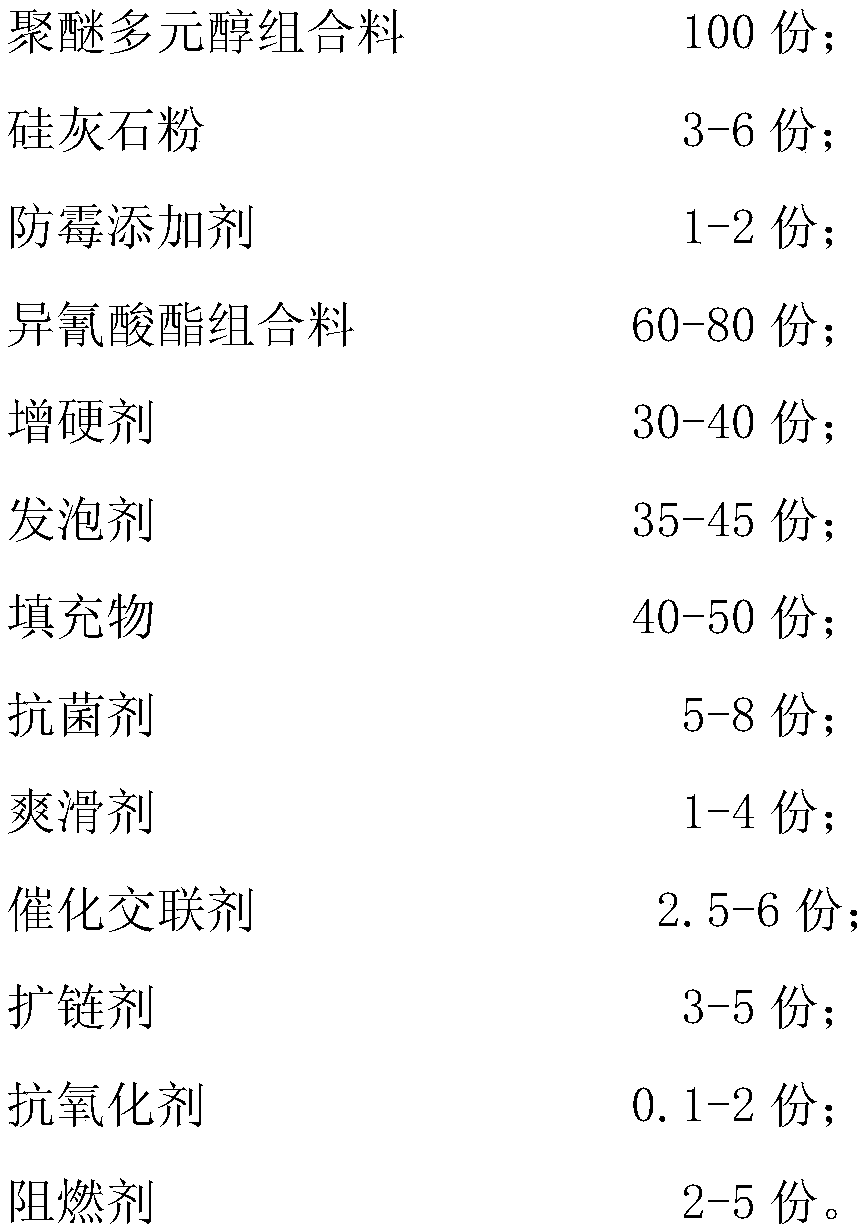

Polyurethane material and preparation method thereof

InactiveCN110358285AGood skin affinityPreparation applicablePackaging toiletriesPackaging cosmeticsPolyolFoaming agent

The invention provides a polyurethane material and a preparation method thereof. The polyurethane material is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol mixed material, 3-6 parts of wollastonite powder, 1-2 parts of mould proof additive, 60-80 parts of isocyanate mixed material, 30-40 parts of a hardening agent, 35-45 parts of a foaming agent, 40-50parts of a filler, 5-8 parts of an antibacterial agent, 1-4 parts of a slipping agent, 2.5-6 parts of a catalytic crosslinking agent, 3-5 parts of a chain extender, 0.1-2 parts of an antioxidant, and2-5 parts of a flame retardant. The polyurethane material is preferentially developed for a powder puff, thus the powder puff prepared based on the material can provide good adaptability and compatibility for the skin of the human body, compared with a powder puff prepared from traditional latex and existing industrial polyurethane, the powder puff prepared based on the material has the unique advantages of being better in skin friendliness, free of chip falling, odourless, antibacterial, high in elasticity, better in oil control property, more convenient to clean, exquisite in hand feeling,environmentally friendly and the like, meanwhile, the invention provides a brand-new polyurethane preparation technology, and the prepared polyurethane material has the wide application prospects.

Owner:焦荣

Method for preparing superconducting joint of Bi-2212 wire rod

ActiveCN103855586ASimple preparation processPreparation applicableLine/current collector detailsWire rodEngineering

The invention discloses a method for preparing a superconducting joint of a Bi-2212 wire rod. The method comprises the following steps: 1. cleaning a to-be-connected end of the Bi-2212 wire rod, and polishing the end; 2. corroding the polished surface of the wire rod subjected to polishing in a corrosive solution; 3. by taking a metal pipe of which one end is closed and the other end is open as a connecting piece, forming two through holes in the closed end of the metal pipe, and assembling two corroded wire rods and the metal pipe to obtained an assembly part; and 4. performing partial molten heat treatment on the assembly part to obtain the superconducting joint of the Bi-2212 wire rod. By adopting a chemical corrosion mode, a silver layer at the end of the Bi-2212 wire rod is effectively corroded, a superconducting core is exposed under the condition that a ceramic core is not damaged, a contact area between the ceramic core and the peripheral original powder is greatly enlarged, the performance of the superconducting joint is improved, and the current-carrying performance of the superconducting joint in the prepared superconducting joint of the Bi-2212 wire rod reaches 83-90 percent of the performance of the wire rod.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

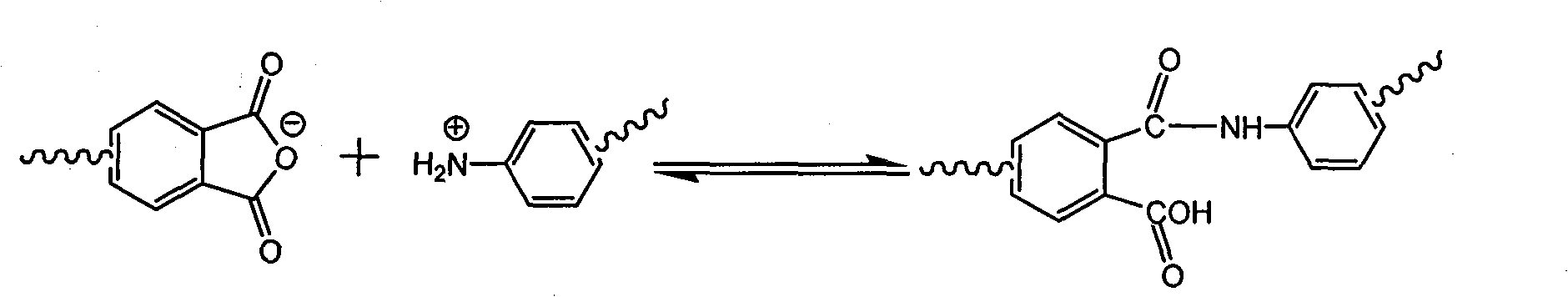

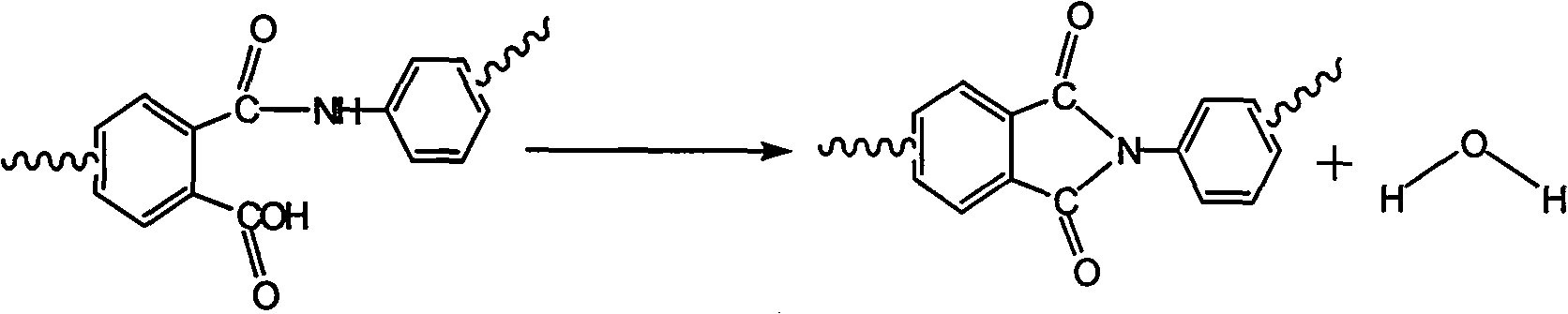

TiO2/PI hybridized film with optic catalytic self-cleaning function and preparation method thereof

The invention provides a TiO2 / PI hybridization film with photocatalysis and self-cleaning function and the process for preparing it, which is characterized in that adding organic monomer in the process of preparing thin films with sol-gel processing, with titanium collosol hydrolytic polymerization happening, forming medlin phase (PAA) in original position polyreaction, finally, forming a nanometer crystal phase TiO2 / PI hybridization film after heat treating. The thickness of hybridization film is not less than 300nm, which higher than anatase nanometer crystal phase obtained from common puretitanium collosol. There isn't crackle and flake for film in the process of heat treating. Chosing a suitable medlin leading body, a Ti-S bond is formed at the same time of forming a hydrogen bond inthe hybridization film, which endowing film with photocatalysis and self-cleansing effect under the visible light. And the photocatalysis and self-cleansing effect of the film are higher than the photocatalysis activity of common titanium oxide nanometer crystal phase film, meanwhile, the film has good radiation resistant and chemical stability.

Owner:TONGJI UNIV

Preparation method of large-scale flake ultra-high thermal conductivity diamond/copper composite material

Owner:哈尔滨锦威科技有限公司

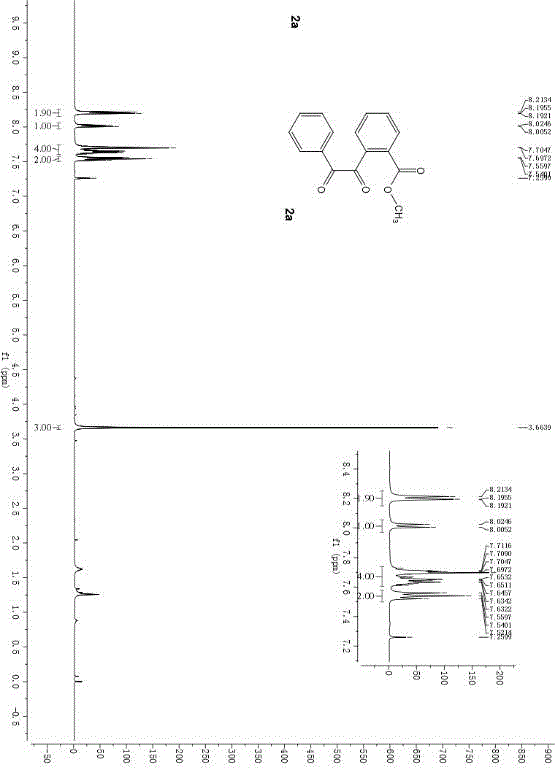

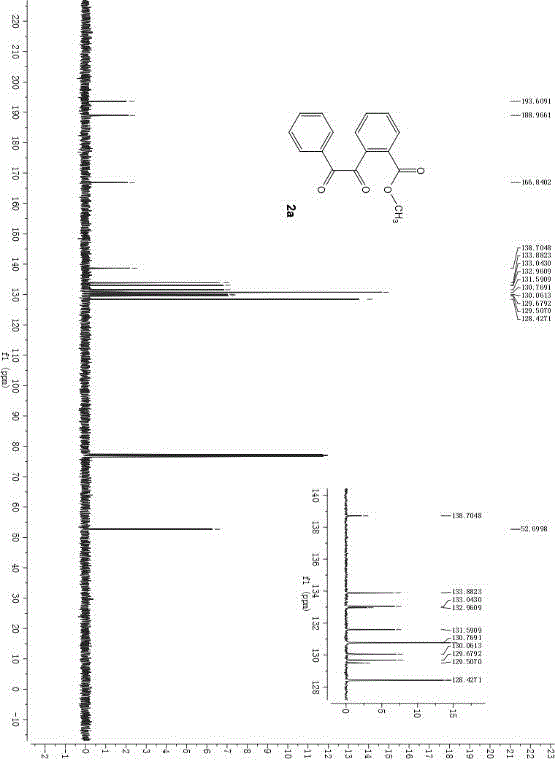

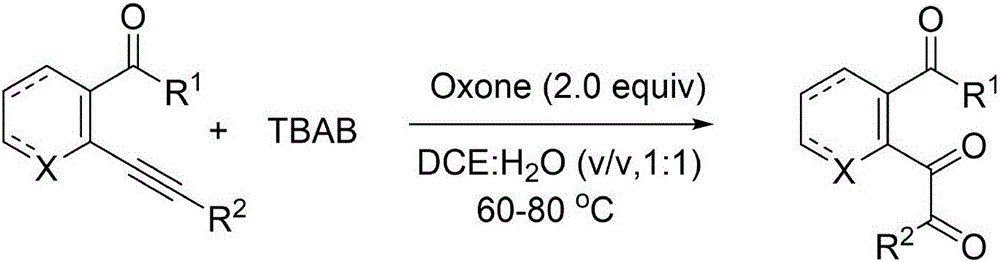

Method for synthesizing ph-dicarbonyl-aryl-formic-ether series compounds based on metal-free participation method

ActiveCN106588525AGood greeningThe reaction is easy to operateOrganic compound preparationCarboxylic acid esters preparationSolventEther

The invention discloses a method for synthesizing ph-dicarbonyl-aryl-formic-ether series compounds based on the metal-free participation method, and belongs to the technical field of organic chemistry. The method includes the steps that phalkynyl benzoic ether is used as a reaction substrate, bromide is added to serve as a bromine source, peroxosulfuric acid inorganic salt serves as an oxidizing agent, a solvent is added, the mixture is reacted for 6 hours to 12 hours at the temperature of 60 DEG C to 80 DEG C, then column chromatography silica gel (SiO2) is added, then the mixture continues to be stirred for 0.5 hour to 1 hour, filtering, extracting and drying are carried out, filtering is carried out again, filtering liquid is subjected to pressure reduction distillation, an organic solvent is removed, then rapid column chromatography is carried out, and the ph-dicarbonyl-aryl-formic-ether series compounds are obtained. By means of a reaction, using of a metal catalyst is avoided, the reaction condition is mild, the substrate is wide in applicability, easy and convenient to operate, low in cost, small in by product, high in product purity, convenient to separate and purify and capable of suiting for large-scale preparing.

Owner:JIAXING UNIV

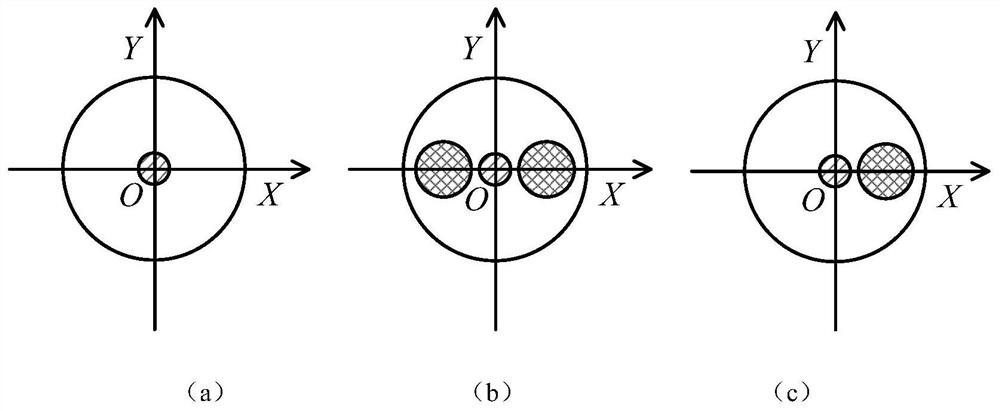

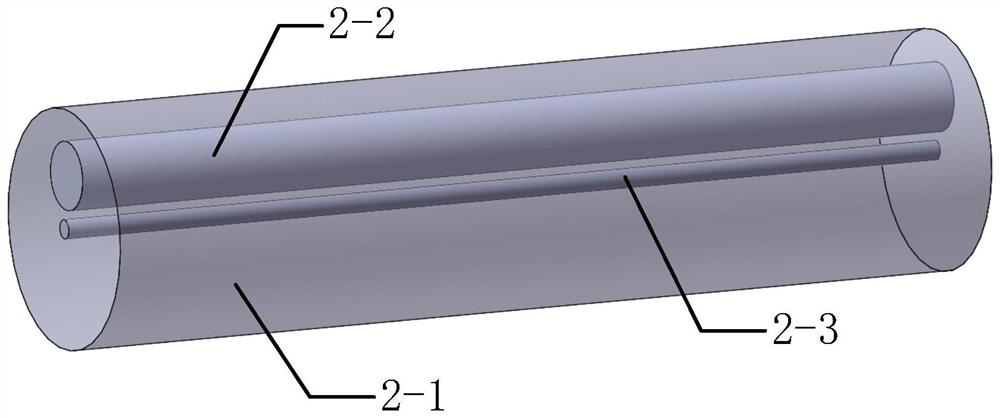

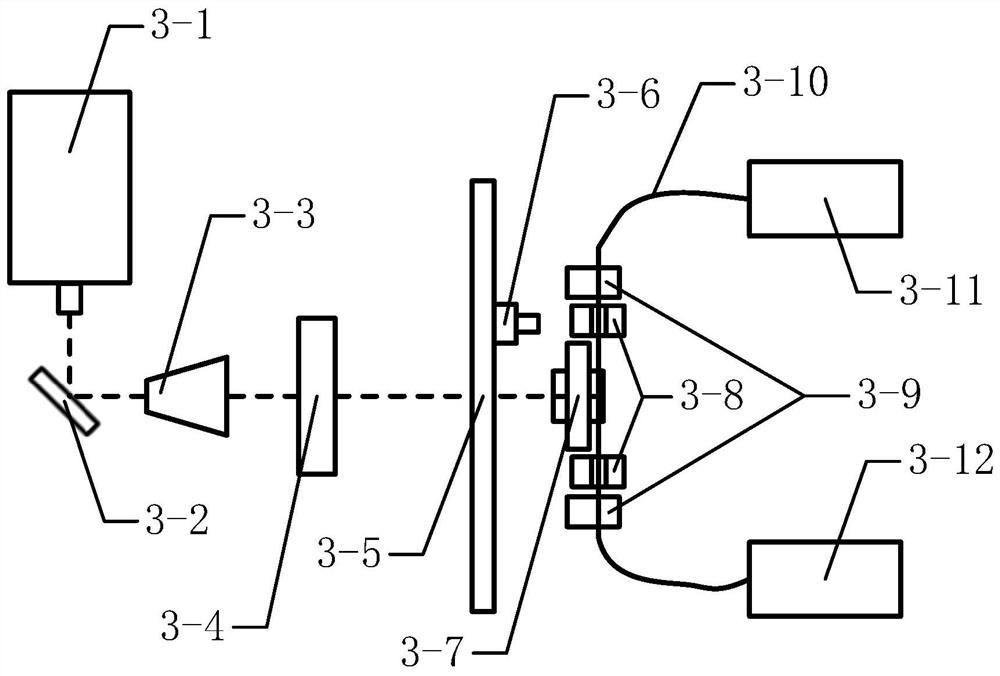

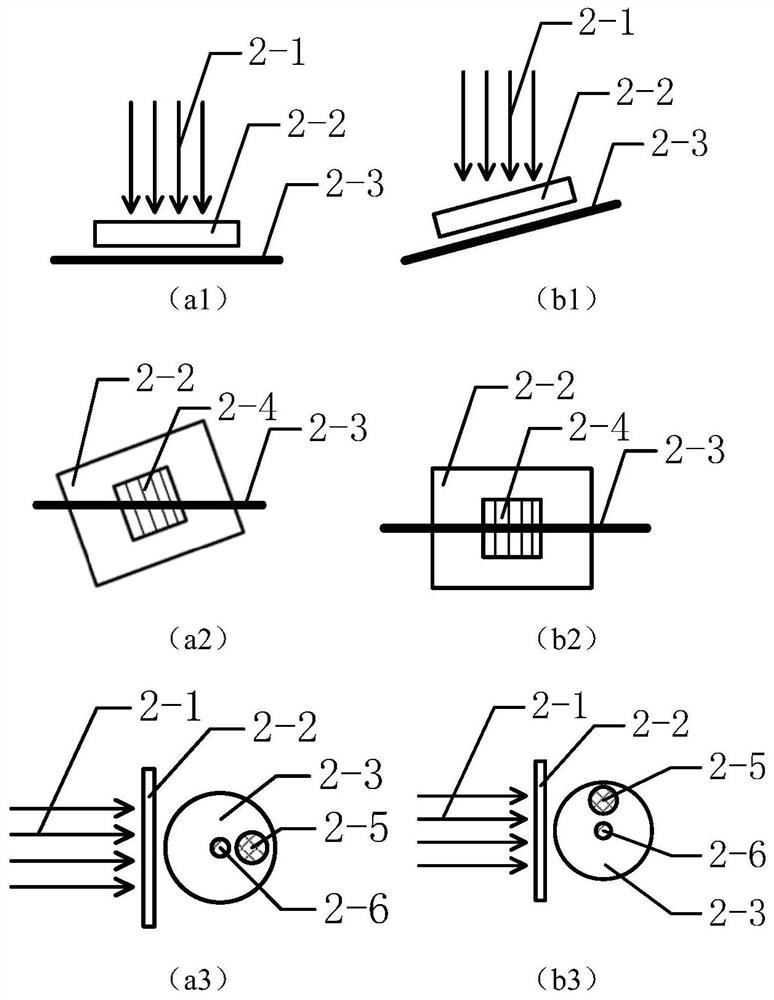

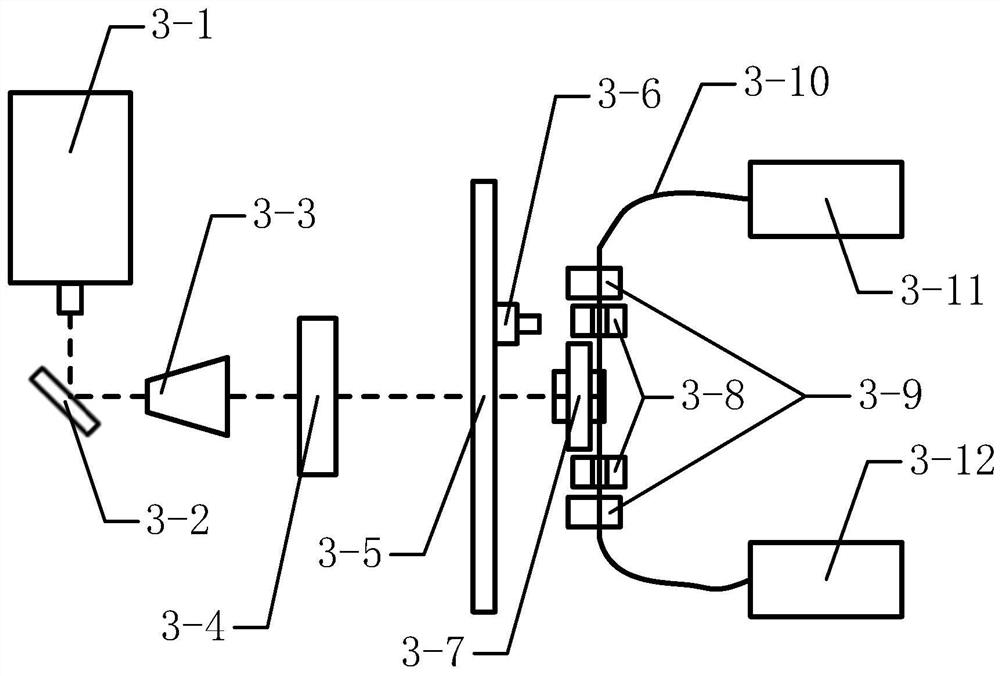

Single-stress-element optical fiber chirped fiber bragg grating and preparation method thereof

InactiveCN112068238APreparation applicableLow costCladded optical fibreOptical waveguide light guideFiberGrating

The invention provides a single-stress-element optical fiber chirped fiber bragg grating and a preparation method thereof. A single-stress-element optical fiber is a special optical fiber with a single stress element in a cladding. The single-stress-element optical fiber chirped fiber bragg grating is characterized by comprising the following steps: sequentially putting an excimer laser, a reflector, a beam expander, a cylindrical lens, a mask plate and a single stress element optical fiber into a writing light path, and adjusting the optical fiber by using a refractive index matching liquid,a microscope and an optical fiber rotating clamp to ensure that the single stress element does not shield ultraviolet laser, wherein the fiber core is parallel to the mask plate and is vertical to thegrid line of the mask plate, so that the chirped fiber bragg grating can be obtained by using a method of inscribing the uniform fiber bragg grating. The single-stress-element optical fiber chirped fiber bragg grating can be used for preparing the single-stress-element optical fiber chirped fiber bragg grating, and can be widely applied to the technical field of optical fiber devices.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for preparing tert-butoxycarbonyl phenylboronic acid

InactiveCN105017301AReduce manufacturing costLow costGroup 3/13 element organic compoundsOrganic synthesisPhenylboronic acid

The present invention discloses a method for preparing tert-butoxycarbonyl phenylboronic acid, and relates to the field of organic synthesis, and the tert-butoxycarbonyl phenylboronic acid is prepared from carbonyl phenylboronic acid as a raw material by one-pot method in the effect of thionyl chloride and tert-butyl alcohol base. The inexpensive and readily available raw material is used, the cost of production is dramatically reduced, the method is suitable for preparation of o-tert-butoxycarbonyl phenylboronic acid, m-tert-butoxycarbonyl phenylboronic acid, and p-tert-butoxycarbonyl phenylboronic acid; and highest product molar yield is 95%, purity reaches 98%, process conditions are stable, operation is easy, and industrial mass production is easy to achieve.

Owner:BENGBU CHINA SYNCHEM TECH CO LTD

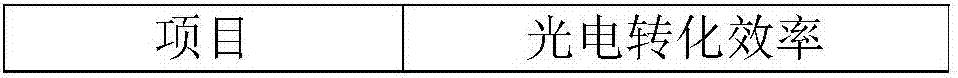

Nanometer particle film used for flexible perovskite solar cell and manufacturing method thereof, and the flexible perovskite solar cell

ActiveCN107331779ALow costSimple processSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellNanoparticle

The invention relates to a manufacturing method of a nanometer particle film used for a flexible perovskite solar cell. The method comprises the following steps of using a precursor solution containing chlorine to soak nanometer particles so as to carry out preprocessing, and acquiring the preprocessed nanometer particles; dispersing the acquired nanometer particles in a solvent and acquiring a nanometer particle dispersion liquid; and depositing the nanometer particle dispersion liquid into a film, drying the solvent and acquiring the nanometer particle film. By using the manufacturing method, under a low temperature, a compacted film can be acquired. And the method is suitable for perovskite solar cell manufacturing on various kinds of flexible substrates. The nanometer particle film is used for the flexible perovskite solar cell and stability of the solar cell can be increased. Simultaneously, the flexible perovskite solar cell possesses excellent photoelectric conversion efficiency.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

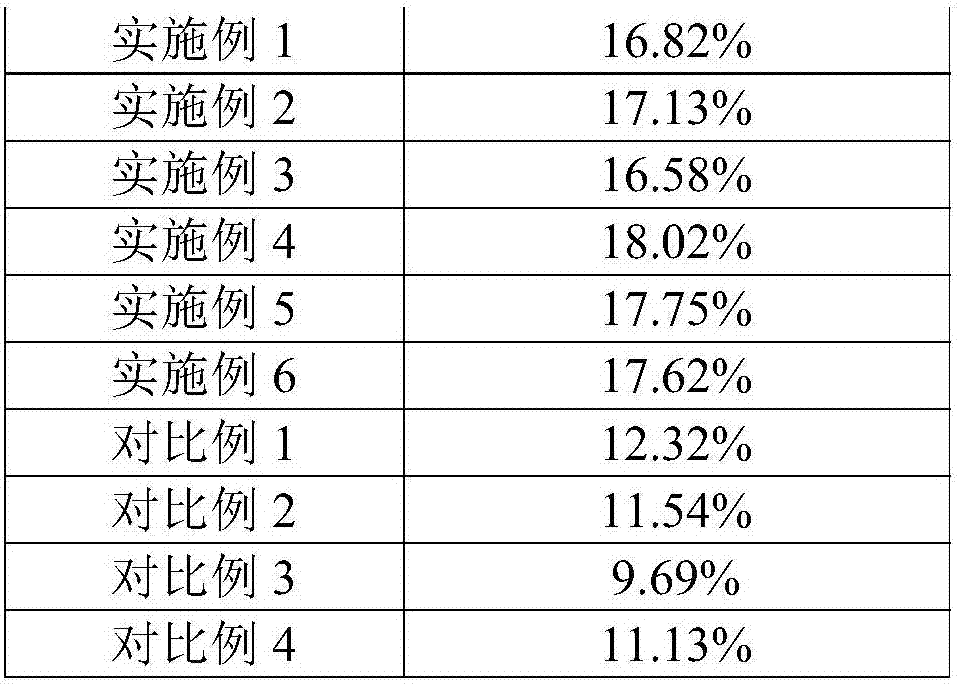

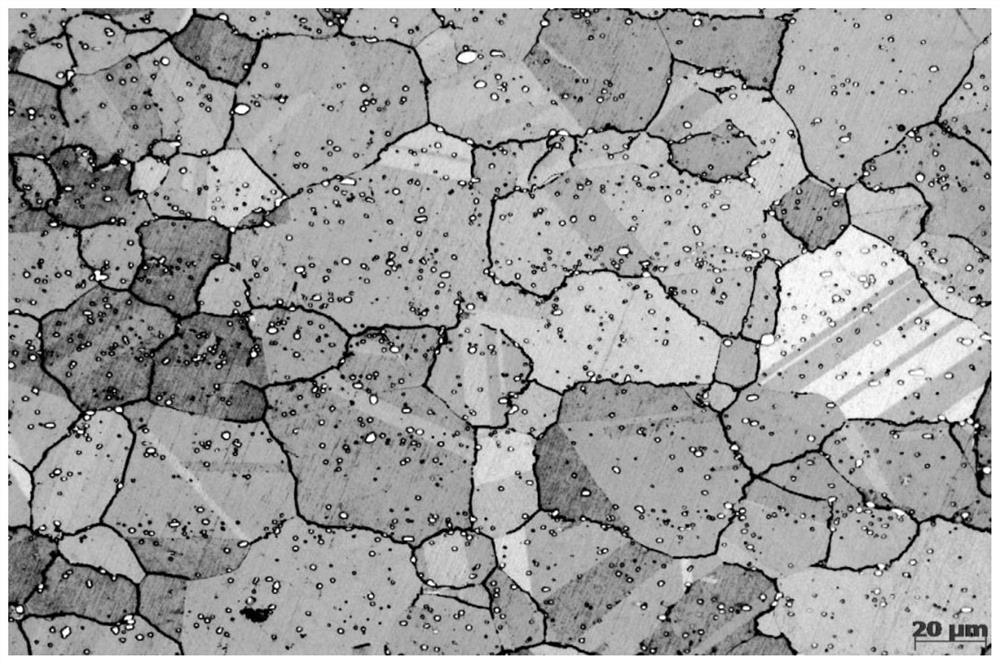

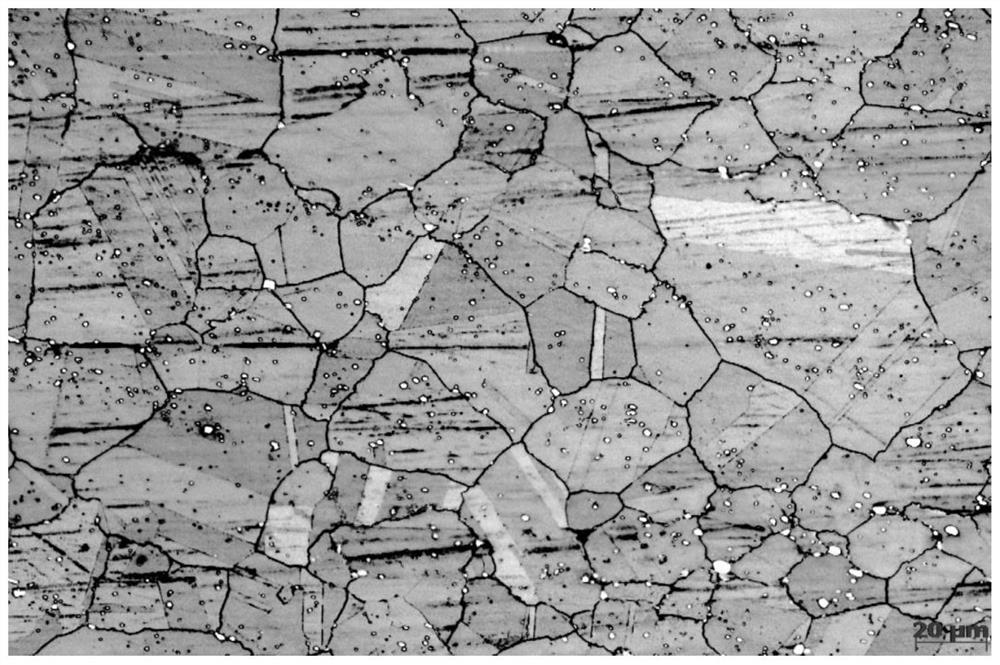

Etchant for displaying austenite structure of heat-resistant steel for air valve and using method

ActiveCN112284860AHigh precisionEasy to makeWeather/light/corrosion resistancePreparing sample for investigationAlcoholPetri dish

The invention discloses an etchant for displaying an austenite structure of heat-resistant steel for an air valve and a using method of the etchant. The etchant is divided into an etchant 1 and an etchant 2, the etchant 1 is prepared from ferric trichloride, hydrochloric acid and water, and the etchant 2 is prepared from anhydrous cupric sulfate, sulfuric acid, hydrochloric acid and glycerol. Theusing method comprises the following steps: (1) preparing the etchant; (2) preparing a sample: (3) etching the sample: immersing a metallographic sample prepared in the step (2) into a culture dish filled with the etchant 1 with the observation surface facing downwards, standing for 10-30 seconds, taking out the sample, washing the sample with tap water, washing the sample with absolute ethyl alcohol with the mass fraction of 99.5%, and blow-drying the sample; then, immersing the sample into a culture dish filled with the etchant 2, standing for 10-20 seconds, taking out the sample, washing with tap water, washing with absolute ethyl alcohol with the mass fraction of 99.5%, and blow-drying; and a clear and complete room-temperature austenite structure can be observed under a microscope. Byadopting the etchant and the using method provided by the invention, the metallographic structure quality of the heat-resistant steel for the air valve can be remarkably improved, and the metallographic quantitative analysis accuracy is improved; and the etchant is simple to prepare and easy to popularize.

Owner:HEBEI IRON AND STEEL

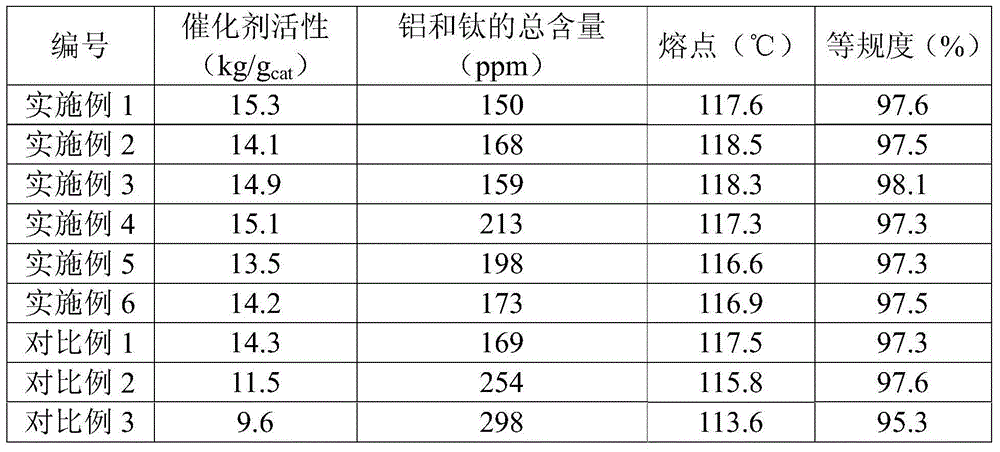

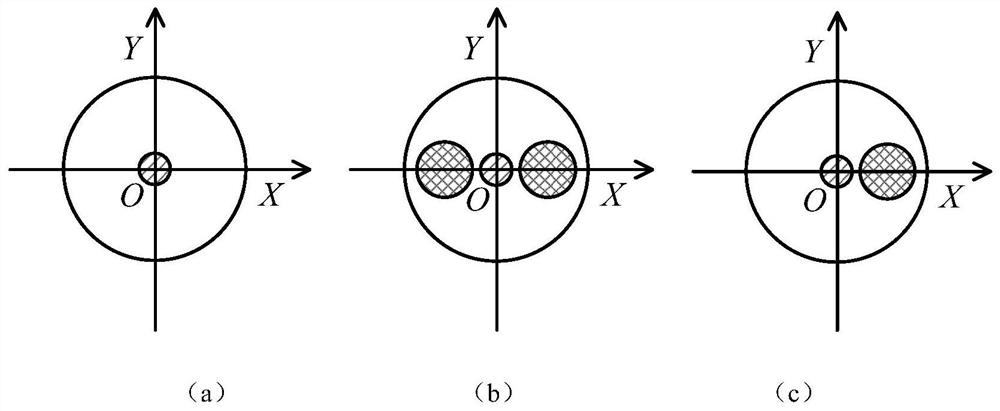

Poly-1-butene and preparation method thereof

The present invention discloses a poly-1-butene and a preparation method thereof. The method comprises that an olefin polymerization catalyst system and a 1-butene-containing monomer are continuously conveyed into a gas phase polymerization reactor under olefin polymerization conditions so as to be subjected to a gas phase continuous polymerization reaction, and the material obtained after the continuous polymerization reaction is discharged out of the gas phase polymerization reactor, wherein the olefin polymerization conditions comprise that the temperature is 60-85 DEG C and the pressure is 0.3-1.5 MPa, the residence time of the 1-butene-containing monomer in the gas phase polymerization reactor is 30-120 min, and the 1-butene-containing monomer contains 60-100 mol% of 1-butene. According to the present invention, the prepared poly-1-butene has high isotacticity (more than or equal to 97%) and low ash content, has a melting point of more than or equal to 110 DEG C, and is suitable for pipe preparation.

Owner:CHINA PETROLEUM & CHEM CORP

Single-stress-element optical fiber tilted fiber bragg grating and preparation method thereof

InactiveCN112068239APreparation applicableEnabling Omni-directional Bend SensingCladded optical fibreOptical waveguide light guideRefractive index matchingFiber

The invention provides a single-stress-element optical fiber tilted fiber bragg grating and a preparation method thereof. A single-stress-element optical fiber is a special optical fiber with a singlestress element in a cladding. The single-stress-element optical fiber tilted fiber bragg grating is characterized by comprising the following steps: sequentially putting an excimer laser, a reflector, a beam expander, a cylindrical lens, a mask plate and a single stress element optical fiber into a writing light path, and adjusting the optical fiber by using a refractive index matching liquid, amicroscope and an optical fiber rotating clamp; and enabling the included angle between the stress element and the grating surface in the fiber core to meet the requirement of the required single-stress-element optical fiber tilted fiber bragg grating. The single-stress-element optical fiber tilted fiber bragg grating can be used for preparing the single-stress-element optical fiber tilted fiber Bragg grating, and can be widely applied to the technical field of optical fiber devices.

Owner:GUILIN UNIV OF ELECTRONIC TECH

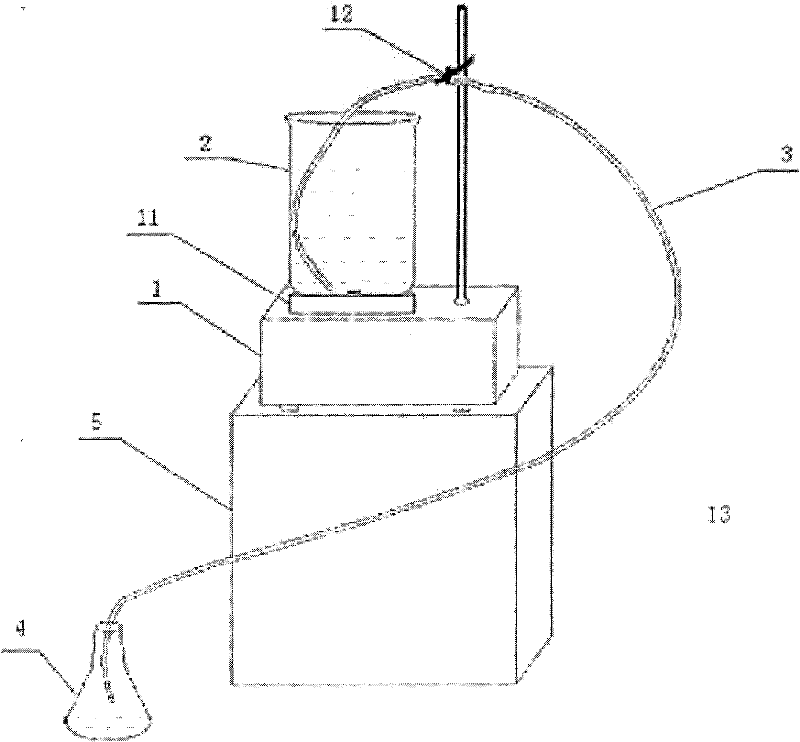

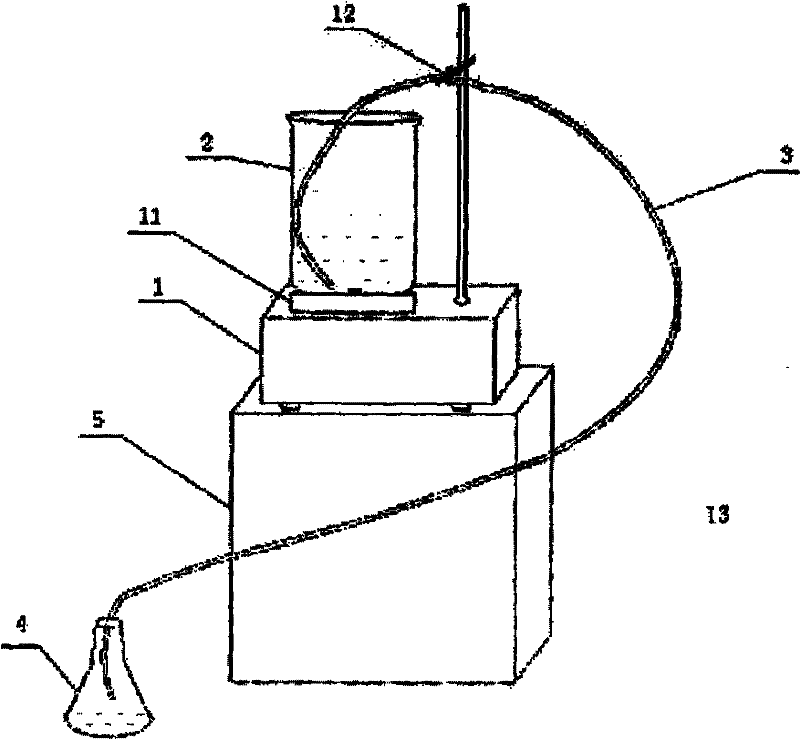

Culture medium preparation device and method

InactiveCN102226145AHigh precisionUniform solidificationBioreactor/fermenter combinationsBiological substance pretreatmentsCulture mediumsChemistry

The invention discloses a culture medium preparation device and method. The culture medium preparation device comprises a preparation container, a stirring device, a bracket and a hollow hose provided with two openings at both ends. The culture medium preparation method is characterized in that all culture medium components are added into the preparation container and are continuously stirred by the stirring device without being decocted previously, so that agar powder components which are unsolvable at normal temperature can be uniformly dispersed and then subpackaged into a culture container through the hollow hose. The culture medium preparation device is simple in structure and easy to manufacture, and can be formed by jointing conventional laboratory equipment. The culture medium preparation method has the advantages of simple operation process and high efficiency. The prepared culture medium has high accuracy and can be solidified uniformly. Thus, the invention can be widely used in colleges and universities, research units, factories and enterprises.

Owner:HENAN INST OF SCI & TECH +2

Preparation method of die-cutting knife edge with gradient function

InactiveCN112899676APreparation applicableEasy to controlMetallic material coating processesErbium lasersComposite material

The invention discloses a preparation method of a die-cutting knife edge with a gradient function, and belongs to the technical field of laser cladding processing. The preparation method is characterized in that three cladding layers are cladded on the surface of a die-cutting knife by using a laser (1200 W-2000W) with stable cladding performance. The first layer is a base layer, the base layer is made of 100.00% of Ni60A powder, the three cladding layers are cladded, and two filling layers are cladded among the three cladding layers to form the base layer; the second layer is a dielectric layer, the dielectric layer is made of 87.20% of Ni60A powder, 6.60% of Co powder and 6.20% of WC powder, two cladding layers are cladded on the basis of the base layer, and a filling layer is cladded between the two cladding layers to form the dielectric layer; and the third layer is a tool nose layer, and the tool nose layer is made of 82.30% of Ni60A powder, 2.50% of Co powder and 15.20% of WC powder. According to the preparation method, and the existing laser cladding technology is controlled and improved, so that the laser cladding technology is suitable for preparing the die-cutting knife with the gradient function.

Owner:张海强

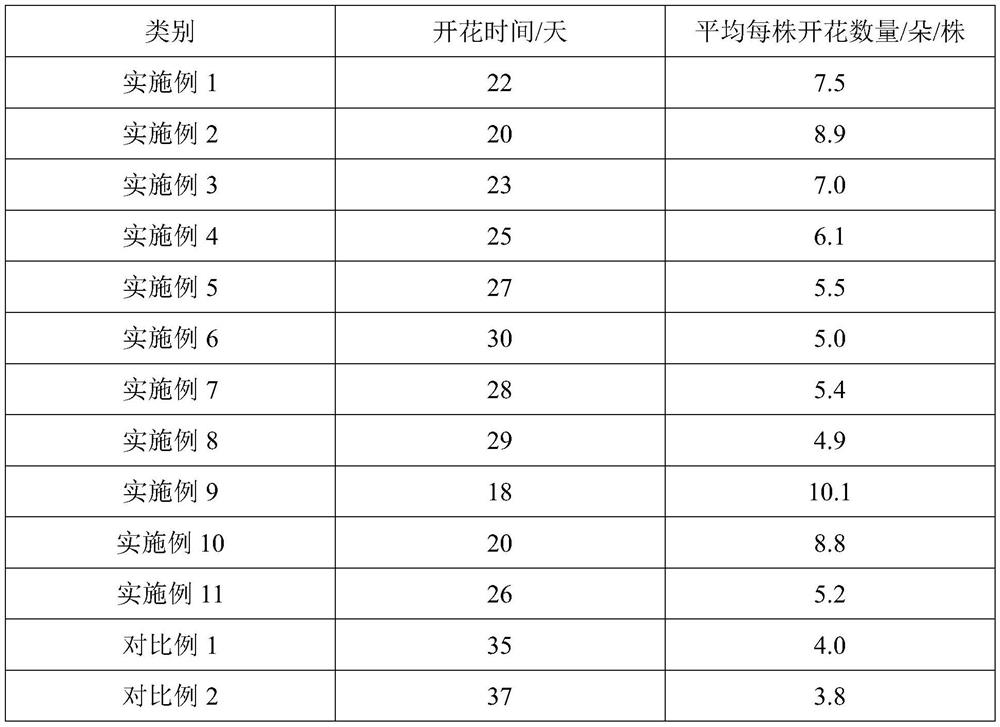

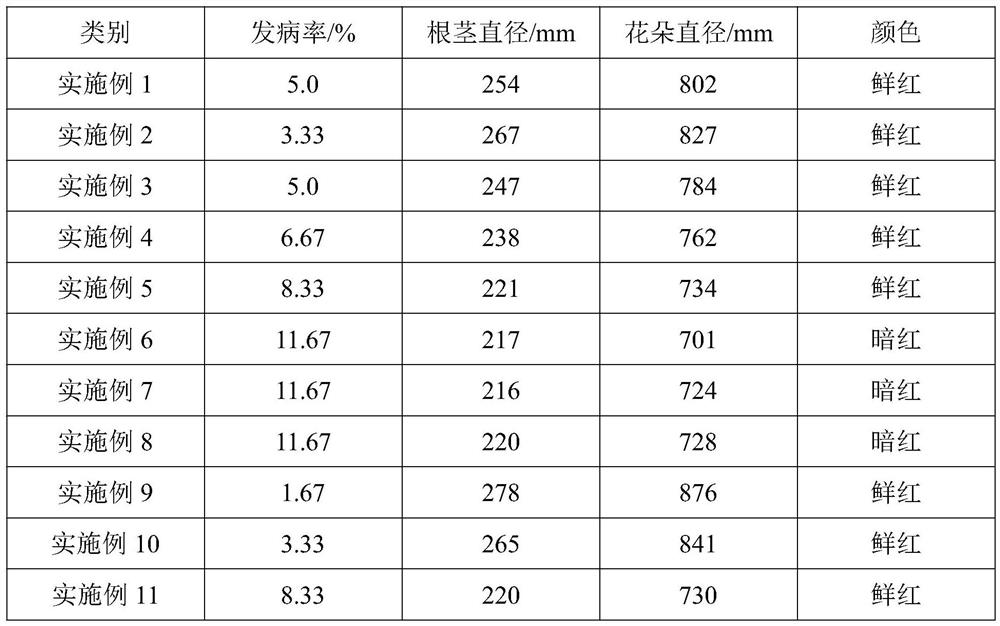

Culture solution for ornamental roses and preparation method of culture solution

InactiveCN113402337AFast growthFoliageCalcareous fertilisersBio-organic fraction processingBiotechnologyNutrition

The invention relates to the technical field of plant culture, and particularly discloses a culture solution for ornamental roses and a preparation method of the culture solution. The culture solution for the ornamental roses is prepared from the following raw materials in parts by weight: 9 to 11 parts of urea, 4 to 6 parts of monopotassium phosphate, 3 to 5 parts of bacillus subtilis, 1 to 1.5 parts of ammonium chloride, 1 to 1.5 parts of calcium chloride, 4 to 6 parts of nutritional leavening, 1 to 2 parts of white vinegar and 600 to 1500 parts of water, wherein the nutritional leavening comprises traditional Chinese medicine residue leavening, rice washing water, tomato leavening and potato leavening. The preparation method of the nutritional leavening comprises the following steps: fermenting traditional Chinese medicine residues, rice washing water, tomatoes and potatoes, and then conducting filtering. According to the invention, the raw materials cooperate with one another, so the ornamental roses grow faster, have enhanced disease resistance, and are luxuriant in branches and leaves and bright in flower color; and in addition, waste raw materials are selected for preparation, so the concept of environmental protection is met. The preparation method disclosed by the invention is simple and convenient to operate and suitable for batch production.

Owner:柒久园艺科技(北京)有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com