Poly-1-butene and preparation method thereof

A butene and olefin polymerization technology, applied in the field of poly-1-butene preparation, can solve the problems of high ash content, difficult to realize poly-1-butene gas phase continuous polymerization, low standard, etc., and achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

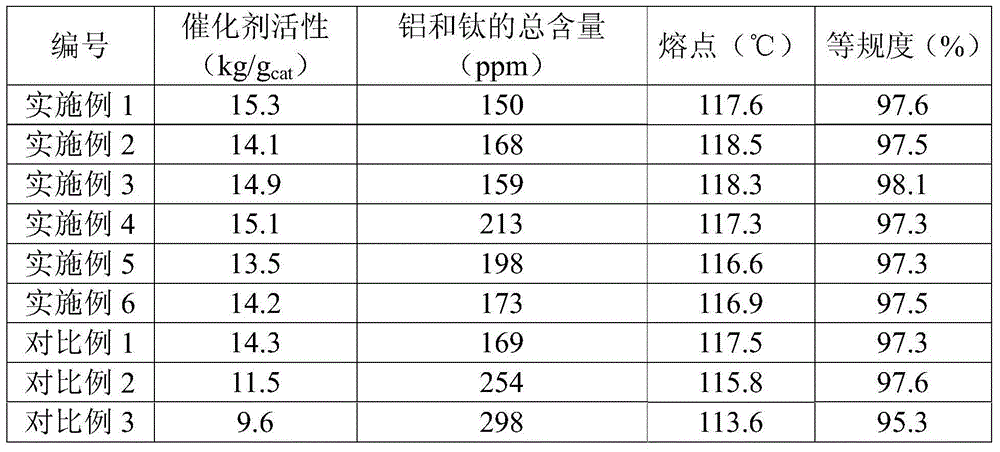

Examples

preparation example Construction

[0014] The invention provides a method for preparing poly-1-butene, wherein the method comprises: continuously feeding an olefin polymerization catalyst system and a monomer containing 1-butene into a gas-phase polymerization reactor under olefin polymerization conditions, and carrying out Gas-phase continuous polymerization reaction, and discharge the material after continuous polymerization reaction from the gas-phase polymerization reactor; the olefin polymerization conditions include: temperature is 60-85°C, pressure is 0.3-1.5MPa; the monomer containing 1-butene The residence time in the gas phase polymerization reactor is 30-120 minutes; the 1-butene-containing monomer contains 60-100 mole % of 1-butene.

[0015] The inventors of the present invention have found in research that when the temperature of the polymerization reaction of the monomer containing 1-butene is 60-85°C and the pressure is 0.3-1.5MPa, the residence time of the monomer in the gas phase polymerization ...

Embodiment 1

[0052] This example is used to illustrate the polybutene-1 and the preparation method according to the present invention.

[0053] Continuously feed the catalyst solid component at 0.61g / h for 50m 3 In the continuous horizontal stirred-bed gas-phase reactor, add triethylaluminum continuously with the pump, its addition makes the molar ratio Al / Ti=50 of the aluminum in the triethylaluminum and the titanium in the catalyst solid component, add continuously Diisopropyldimethoxysilane external electron donor (wherein the molar ratio of external electron donor to titanium in the catalyst solid component is Si / Ti=10). Then, feed 1-butene and hydrogen into the reactor to carry out polymerization reaction, wherein the pressure in the reactor is 1.1MPa, the temperature in the reactor is 65°C, the hydrogen / 1-butene in the reactor Molar ratio (H 2 / C 4 ) is 0.008, the average residence time of 1-butene and hydrogen in the reactor is 60min, and the reactor level is 40%.

[0054] Durin...

Embodiment 2

[0056] This example is used to illustrate the polybutene-1 and the preparation method according to the present invention.

[0057] Continuously feed the catalyst solid component at 0.61g / h for 50m 3 In the continuous horizontal stirred-bed gas-phase reactor, add triethylaluminum continuously with the pump, its addition makes the molar ratio Al / Ti=50 of the aluminum in the triethylaluminum and the titanium in the catalyst solid component, add continuously Diisopropyldimethoxysilane external electron donor (wherein the molar ratio of external electron donor to titanium in the catalyst solid component is Si / Ti=20). Then, feed 1-butene and hydrogen into the reactor to carry out polymerization reaction, wherein the pressure in the reactor is 1.3MPa, the temperature in the reactor is 75°C, the hydrogen / 1-butene in the reactor Molar ratio (H 2 / C 4 ) is 0.008, the average residence time of 1-butene and hydrogen in the reactor is 60min, and the reactor level is 40%.

[0058] Durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com