Method for preparing nanometer material assembly

A nanomaterial and assembly technology, applied in the nano field, can solve the problems of complex steps and the inability to successfully assemble a variety of nanomaterials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

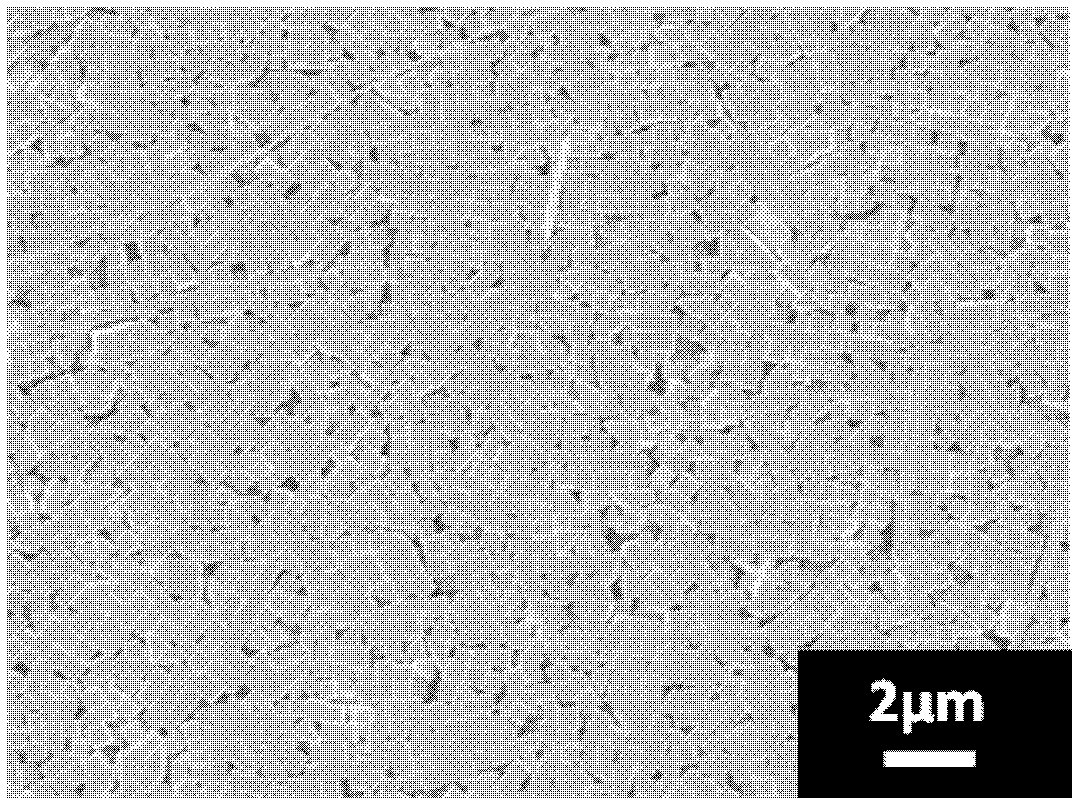

[0029] The present invention has no particular limitation on the preparation method of the nanomaterial aqueous solution, and a method well known to those skilled in the art can be used, specifically: the nanomaterial is centrifuged and cleaned and dispersed in water to obtain the nanomaterial aqueous solution. The nano material used in the present invention may be a nano material well known to those skilled in the art, preferably one or more of gold nano particles, silver nano blocks, silver nano wires and graphene nano sheets. At the same time, the present invention has no special restrictions on the thickness, size, etc. of the aforementioned nanomaterials, and the sizes between the aforementioned nanomaterials may be the same or different. For example, the nanomaterial may be nanoparticles with different particle diameters, nanosquares, nanowires or ultra-thin nanosheets. In addition, the present invention has no special restrictions on the preparation method of the above-m...

Embodiment 1

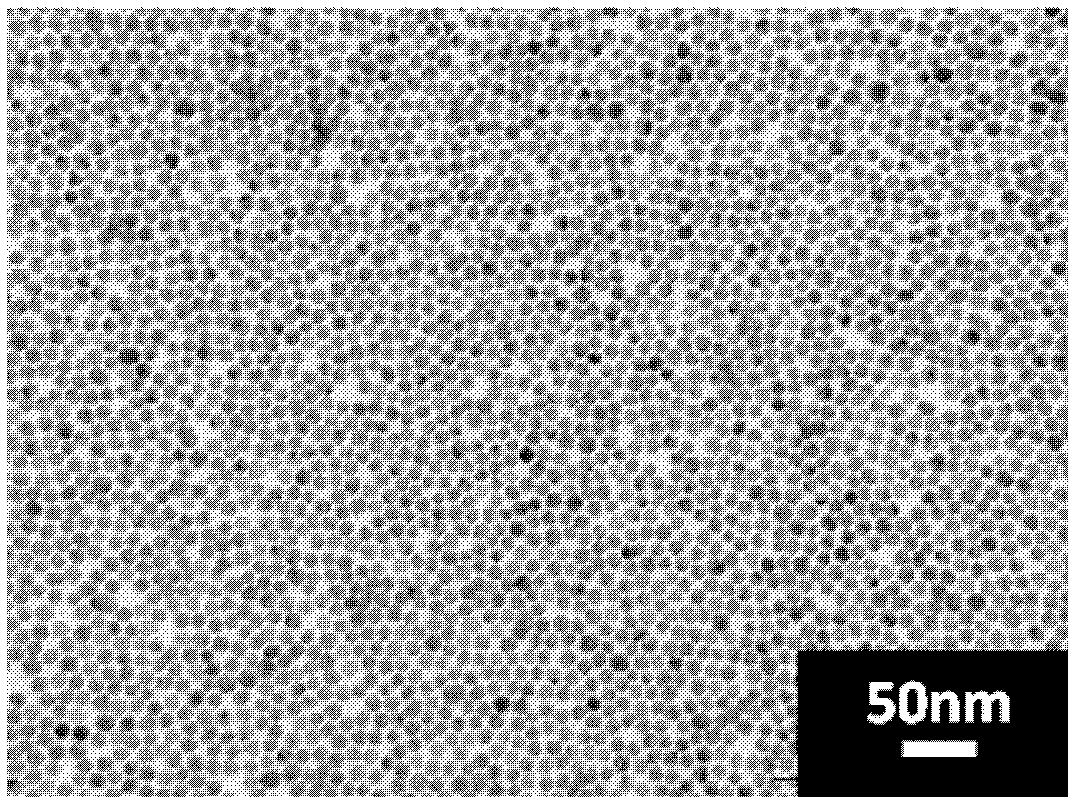

[0038] Example 1: Preparation of gold (Au) nanoparticle assembly

[0039] 1. Synthesis of gold nanoparticles with a diameter of 12nm

[0040] Add 1.0 milliliters (mL) HAuCl 4 Mix the solution (1.0%wt) with 99mL of distilled water, and then heat to boil; in the case of boiling, quickly add 3.0mL of sodium citrate solution (1.0%wt) to generate nanoparticles; heated under reflux for 20min, the color of the solution Change from yellow to wine red, and then cool the solution at room temperature to obtain gold nanoparticles with a diameter of 12 nm.

[0041] 2. Preparation of nanomaterial assembly

[0042] 5mg gold nanoparticles were dispersed in 5mL distilled water, and 5mL of the nanomaterial aqueous solution prepared above was covered in 5mL of carbon tetrachloride (CCl 4 ) Above, a liquid-liquid interface is formed between the two; 1 mL of ethanol is added to the nanomaterial aqueous solution, and after shaking, a self-assembled film, namely, a gold nanomaterial assembly, is quickly for...

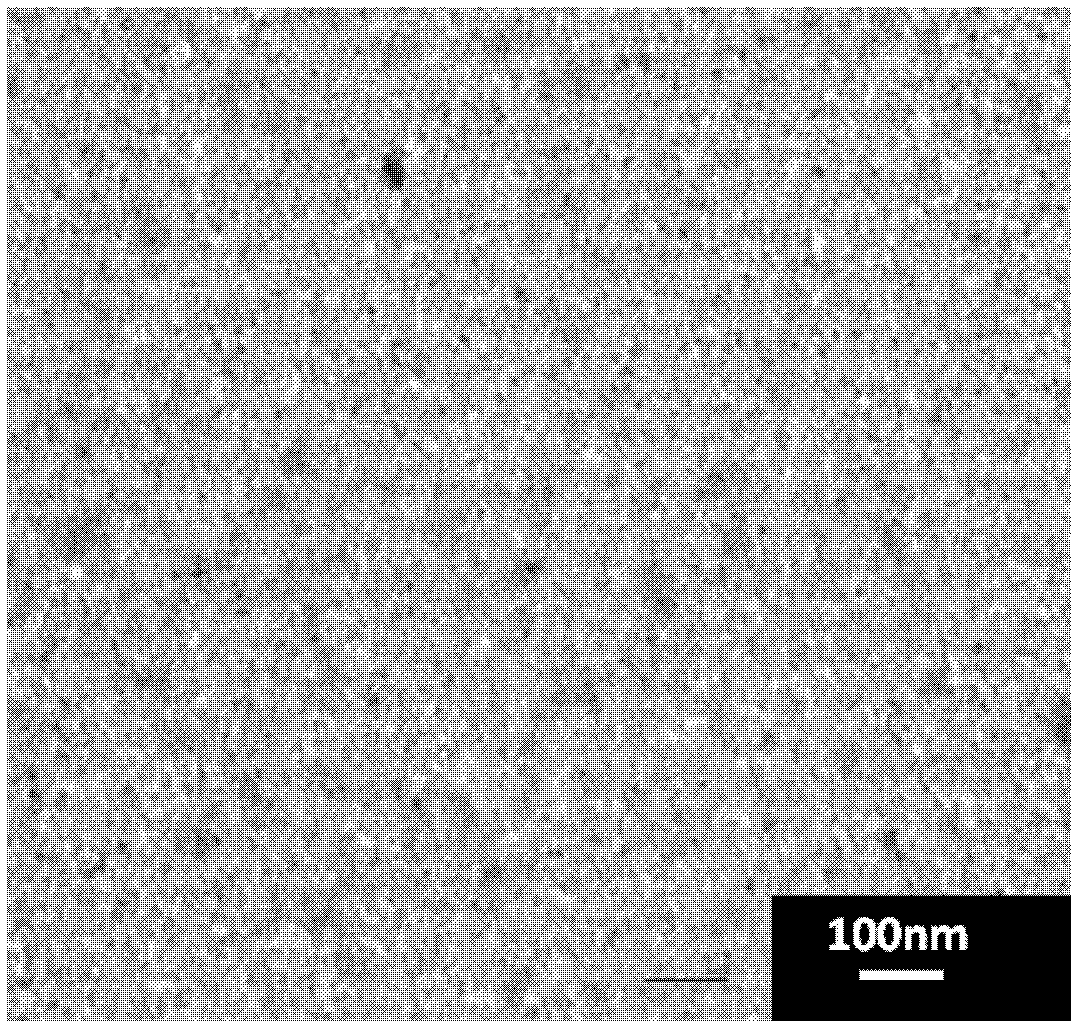

Embodiment 2

[0045] 1. Synthesis of gold nanoparticles with a diameter of 5nm

[0046] Pipette 0.1 mL of HAuCl 4 The solution (0.05M) and 0.1mL of sodium citrate aqueous solution (0.05M) were added to 20mL of distilled water and stirred evenly; then, while stirring, 0.6mL of frozen storage NaBH was added 4 Solution (0.1M); add NaBH 4 Afterwards, the solution immediately turned pink, indicating that gold particles were formed; after stirring for 10 minutes, let it stand at room temperature for 3 hours to obtain gold nanoparticles with a diameter of 5 nm.

[0047] 2. Preparation of nanomaterial assembly

[0048] 5mg gold nanoparticles were dispersed in 5mL distilled water, and 5mL of the nanomaterial aqueous solution prepared above was covered in 5mL of carbon tetrachloride (CCl 4 ) Above, a liquid-liquid interface is formed between the two; 1 mL of ethanol is added to the nanomaterial aqueous solution, and then a layer of self-assembled film, namely, a gold nanomaterial assembly is quickly formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com