Nanometer particle film used for flexible perovskite solar cell and manufacturing method thereof, and the flexible perovskite solar cell

A solar cell and nanoparticle technology, applied in the field of solar cells, can solve the problems of limiting the application of flexible perovskite solar cells, deterioration of cell stability and open circuit voltage, poor stability of organic electron transport layers, etc., and achieve excellent light spot conversion performance, improved stability, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

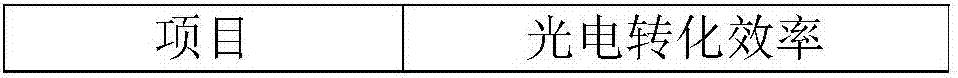

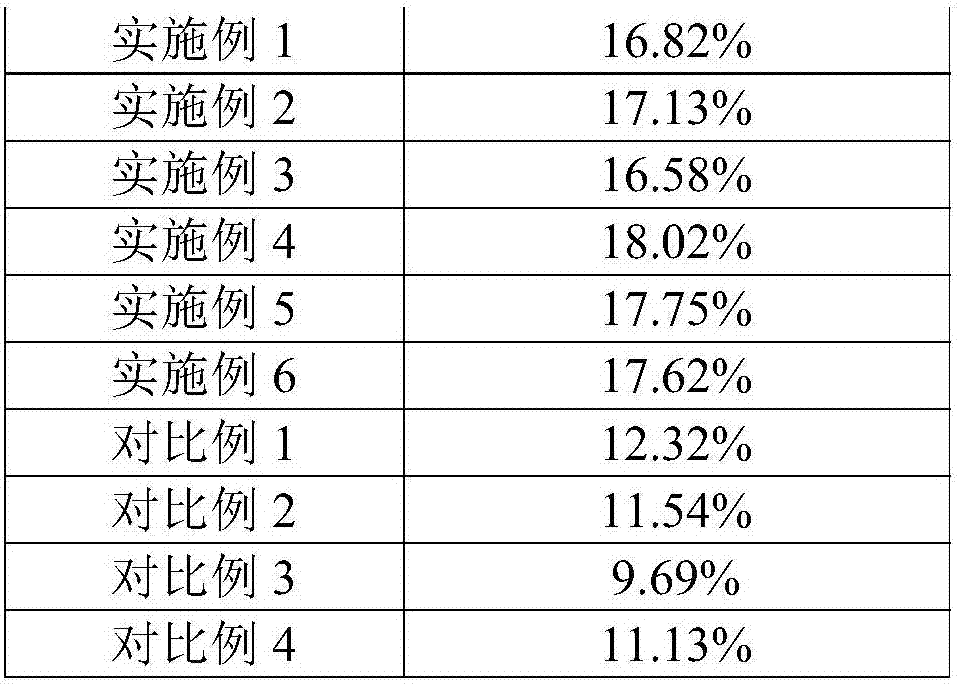

Examples

Embodiment 1

[0035] A method for preparing a nanoparticle film for an electron transport layer of a flexible perovskite solar cell, the method comprising the following steps:

[0036] (1) Using TiCl 4 Solution soaked TiO 2The nanoparticles are pretreated to obtain pretreated nanoparticles;

[0037] (2) ultrasonically dispersing the nanoparticles obtained in step (1) in ethanol to obtain a nanoparticle dispersion;

[0038] (3) The nanoparticle dispersion is spin-coated into a thin film, and the solvent is dried to obtain TiO 2 Nanoparticle films.

[0039] A flexible perovskite solar cell, comprising: a flexible PEN film substrate, and depositing ITO on the substrate as a conductive layer, depositing the TiO prepared above on the above-mentioned ITO conductive layer 2 A thin film made of nanoparticles is used as an electron transport layer, on which a perovskite material is deposited as a light absorbing layer, then Spiro-OMeTAD is deposited as a hole transport layer, and finally metal A...

Embodiment 2

[0041] A method for preparing a nanoparticle film for an electron transport layer of a flexible perovskite solar cell, the method comprising the following steps:

[0042] (1) Using SnCl 4 Solution soaked SnO 2 The nanoparticles are pretreated to obtain pretreated nanoparticles;

[0043] (2) ultrasonically dispersing the nanoparticles obtained in step (1) in isopropanol to obtain a nanoparticle dispersion;

[0044] (3) The nanoparticle dispersion liquid is screen-printed into a thin film, and the solvent is dried to obtain the SnO 2 Nanoparticle films.

[0045] A flexible PEN film substrate, and deposit ITO on the substrate as a conductive layer, and deposit the above-mentioned prepared SnO on the above-mentioned ITO conductive layer 2 A thin film made of nanoparticles is used as an electron transport layer, on which a perovskite material is deposited as a light absorbing layer, then Spiro-OMeTAD is deposited as a hole transport layer, and finally metal Ag is deposited as a...

Embodiment 3

[0047] A method for preparing a nanoparticle film for an electron transport layer of a flexible perovskite solar cell, the method comprising the following steps:

[0048] (1) Use ZnCl 2 Soaking the ZnO nanoparticles in the solution for pretreatment to obtain pretreated nanoparticles;

[0049] (2) ultrasonically dispersing the nanoparticles obtained in step (1) in methylene chloride to obtain a nanoparticle dispersion;

[0050] (3) Ink-jet printing the nanoparticle dispersion into a thin film, and drying the solvent to obtain a ZnO nanoparticle film.

[0051] A flexible PEN film substrate, and deposit ITO on the substrate as a conductive layer, deposit a thin film made of ZnO nanoparticles prepared above on the above-mentioned ITO conductive layer as an electron transport layer, and deposit a perovskite material on this basis as a light-absorbing layer. layer, then deposited Spiro-OMeTAD as a hole transport layer, and finally deposited metal Ag as a counter electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com