LaFeSi based magnetic refrigeration composite material and preparation method and application thereof

A composite material and magnetic refrigeration technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of affecting materials, low thermal conductivity of materials, affecting magnetic working medium and fluid heat exchange, etc., and achieves easy operation in the preparation process , raw materials are cheap and easy to obtain, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In some embodiments, the preparation method includes:

[0059] Prepare raw materials other than H according to the chemical formula of the LaFeSi-based alloy particles;

[0060] Melting the raw materials under the protection of high-purity inert gas to form alloy ingots or quick-setting tablets;

[0061] The alloy ingot or quick-setting sheet is annealed in a vacuum environment or an inert atmosphere, and then rapidly quenched in an environment such as liquid nitrogen or ice water to form a NaZn 13 Type structure LaFeSi-based alloy;

[0062] Breaking the LaFeSi-based alloy into particles with a particle size ≤ 250 μm, and mixing it with a low melting point metal or alloy to form a mixed powder;

[0063] Put the mixed powder under pressure at 8×10 -2 Hot press molding in a high vacuum environment below Pa or in an inert atmosphere, the pressing pressure is 50MPa-1GPa, the hot-pressing temperature is 180-300°C, and the holding time is 0.5min-10min.

[0064] In the pre...

Embodiment 1

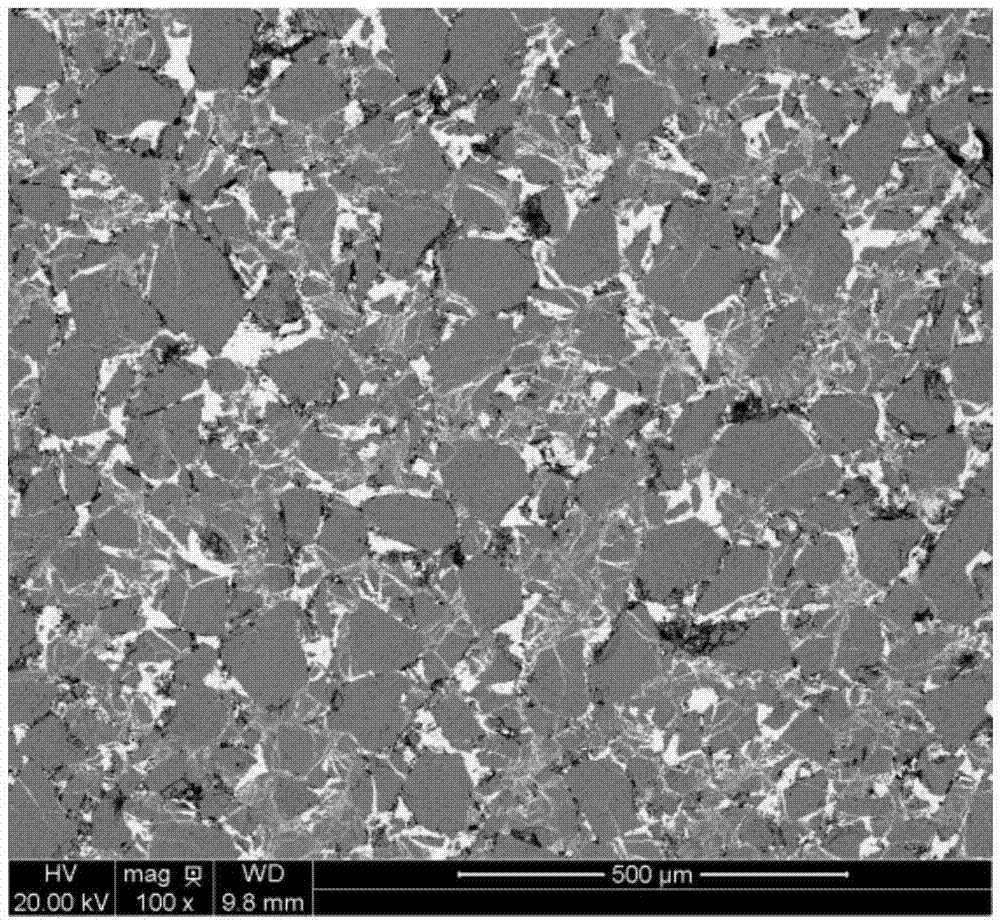

[0081] Embodiment 1 This embodiment involves LaFe 11.6 Si 1.4 h x Preparation and Properties of Sn / Sn Magnetic Refrigeration Composite

[0082] (1) Press LaFe 11.6 Si 1.4 The chemical formula ingredients are put into the crucible of the vacuum induction quick-setting furnace, and then filled with high-purity argon gas after vacuuming. When the temperature reaches 1600°C, the raw materials are completely melted, and the alloy liquid is poured on the rotating copper roller with a speed of 1.7m / s. Preparation LaFe 11.6 Si 1.4 quick-setting tablets;

[0083] (2) Put the prepared quick-setting sheet into the quartz tube and vacuumize to 2×10 -3 After Pa, fill with 0.05MPa argon, and seal the tube;

[0084] (3) Put the sealed quartz tube into a muffle furnace, heat it to 1050°C, keep it warm for 24 hours, and quench it with a mixture of ice and water;

[0085] (4) LaFe 11.6 Si 1.4 Put the quick-setting sheet into the quartz tube, then put it in the hydrogen heat treatment...

Embodiment 2

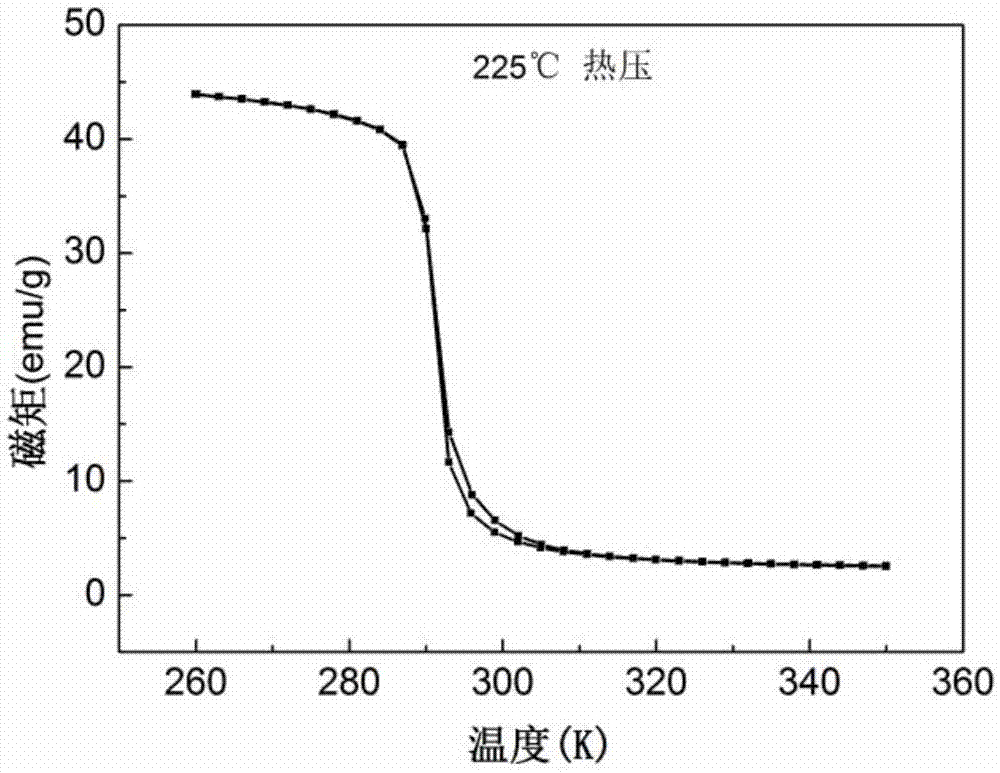

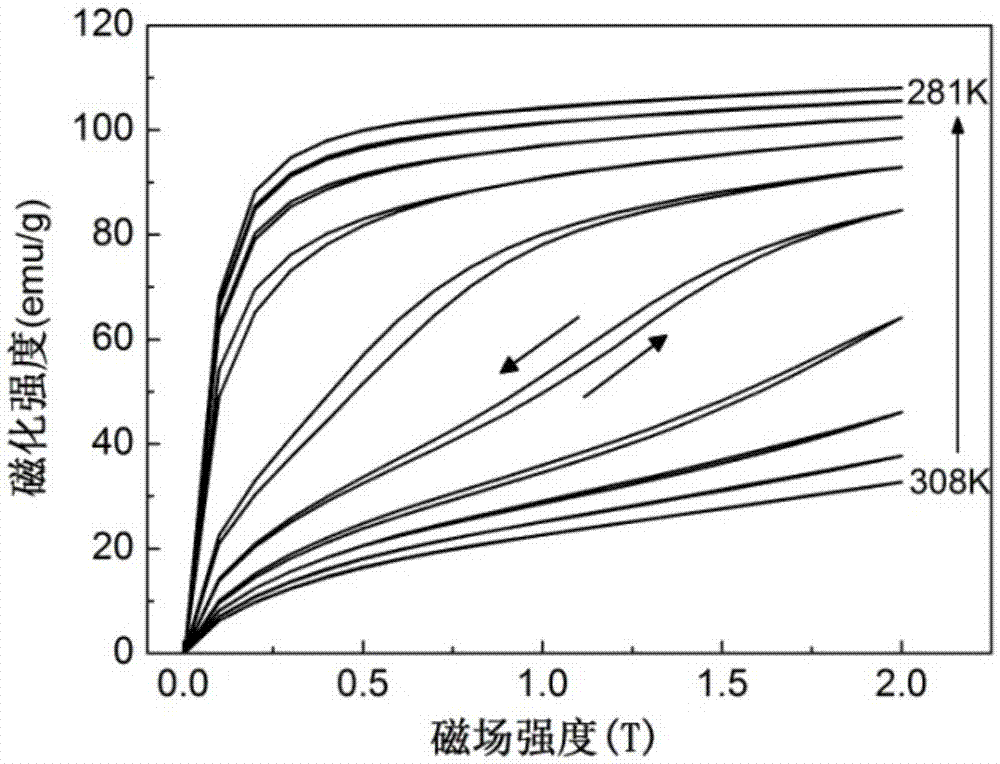

[0089] Embodiment 2 This embodiment involves LaFe 11.6 Si 1.4 h x Preparation and Properties of Sn / Sn Magnetic Refrigeration Composite

[0090] LaFe is prepared in the same way as in Example 1 11.6 Si 1.4 h x / Sn magnetic refrigeration composites, except that the hot-pressing temperature was changed to 233°C.

[0091] The LaFe obtained in this embodiment 11.6 Si 1.4 h x The Curie temperature of the / Sn magnetic refrigeration composite material is 281K, and the calculated maximum magnetic entropy becomes 10.2J / kgK (such as image 3 shown), the thermal conductivity at room temperature measured by the laser thermal conductivity meter is 6.6W / mk (such as Image 6 shown), the compressive strength measured by the universal testing machine is 173MPa (such as Figure 8a shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com