Etchant for displaying austenite structure of heat-resistant steel for air valve and using method

A technology of steel austenite and etchant, which is applied in the field of etchant for displaying heat-resistant steel austenite structure for air valves, can solve the problems of inability to obtain clear and complete microstructure, achieve low cost, improve quality, and prepare simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

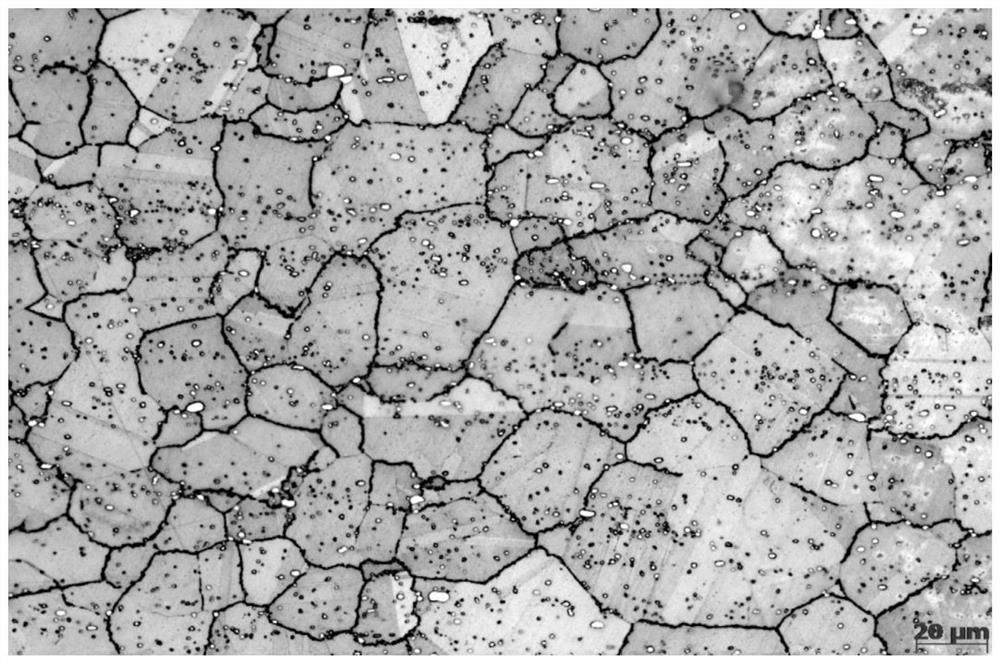

Embodiment 1

[0033] In this embodiment, the heat-resistant steel for air valves is taken as an example. The sample is hot-rolled at a temperature of 1150° C. for 15 minutes, air-cooled, and the method for displaying the austenite structure at room temperature includes the following steps:

[0034] 1) Etching agent preparation: Add 5g of ferric chloride and 35ml of hydrochloric acid with a mass fraction of 37% to 100ml of water in sequence, stir evenly, and prepare etchant 1; respectively add 10g of anhydrous copper sulfate, 10ml of sulfuric acid, and 5ml of Slowly add triol into 100ml of hydrochloric acid with a mass fraction of 37%, stir evenly, and prepare etching agent 2;

[0035] 2) Sample preparation: cut out the heat-resistant steel sample for the gas valve, grind and polish the surface of the sample to be inspected, the polished surface is mirror-like, and has no scratches, rinse it with tap water, and then use a mass fraction of 99.5% Rinse with absolute ethanol and blow dry;

[0...

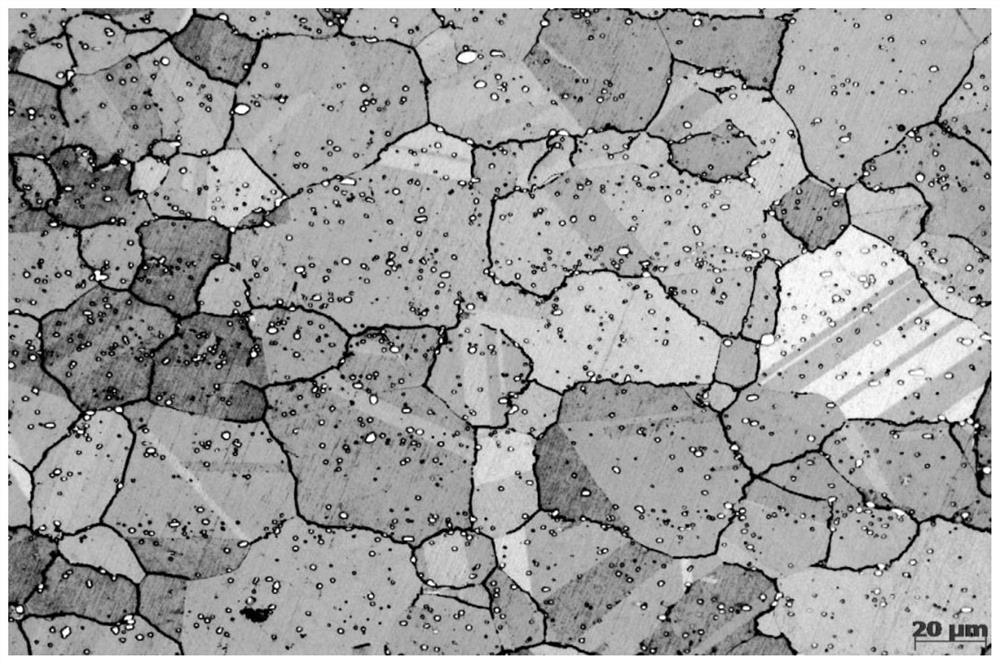

Embodiment 2

[0039] In this embodiment, the heat-resistant steel for air valves is taken as an example. The sample is hot-rolled at a temperature of 1150° C. for 30 minutes, air-cooled, and the method for displaying the austenite structure at room temperature includes the following steps:

[0040] 1) Etching agent preparation: Add 5g of ferric chloride and 35ml of hydrochloric acid with a mass fraction of 37% to 100ml of water in sequence, stir evenly, and prepare etchant 1; respectively add 10g of anhydrous copper sulfate, 10ml of sulfuric acid, and 5ml of Slowly add triol into 100ml of hydrochloric acid with a mass fraction of 37%, stir evenly, and prepare etching agent 2;

[0041] 2) Sample preparation: cut out the heat-resistant steel sample for the gas valve, grind and polish the surface of the sample to be tested. Rinse with water and ethanol and dry;

[0042] 3) Sample erosion: Immerse the metallographic sample prepared in step (2) face down into a petri dish containing etchant 1, ...

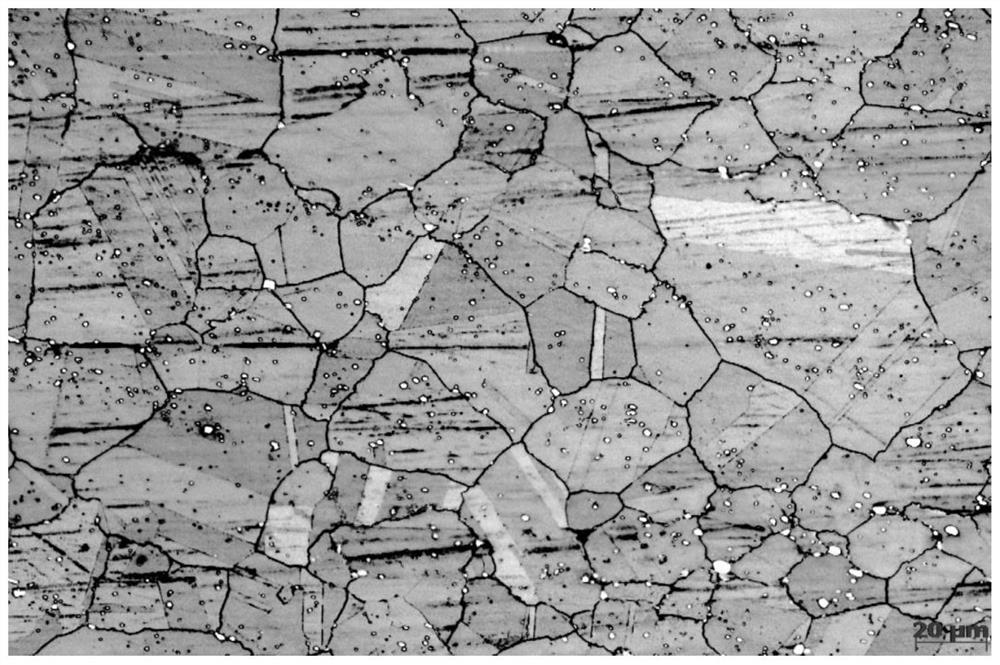

Embodiment 3

[0045] In this embodiment, the heat-resistant steel for air valves is taken as an example. The sample is hot-rolled at a temperature of 1150° C. for 45 minutes, air-cooled, and the method for displaying the austenite structure at room temperature includes the following steps:

[0046] 1) Etching agent preparation: Add 5g of ferric chloride and 40ml of hydrochloric acid with a mass fraction of 37% to 100ml of water in turn, stir well, and prepare etchant 1; respectively add 10g of anhydrous copper sulfate, 15ml of sulfuric acid, and 5ml of Slowly add triol into 100ml of hydrochloric acid with a mass fraction of 37%, stir evenly, and prepare etching agent 2;

[0047]2) Sample preparation: cut out the heat-resistant steel sample for the gas valve, grind and polish the surface of the sample to be tested. Rinse with water and ethanol and dry;

[0048] 3) Sample erosion: Immerse the metallographic sample prepared in step (2) face down into a petri dish containing etchant 1, stay fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com