TiO2/PI hybridized film with optic catalytic self-cleaning function and preparation method thereof

A hybrid film and self-cleaning technology, applied in the field of films with photocatalytic degradation and self-cleaning function

Inactive Publication Date: 2010-12-01

TONGJI UNIV

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the high thickness of the film prepared by sol spraying, it cannot be used for the preparation of titanium oxide nanocrystalline film. Therefore, improving the properties of the sol and increasing the thickness of the primary coating have become the key to improving the sol-gel coating process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

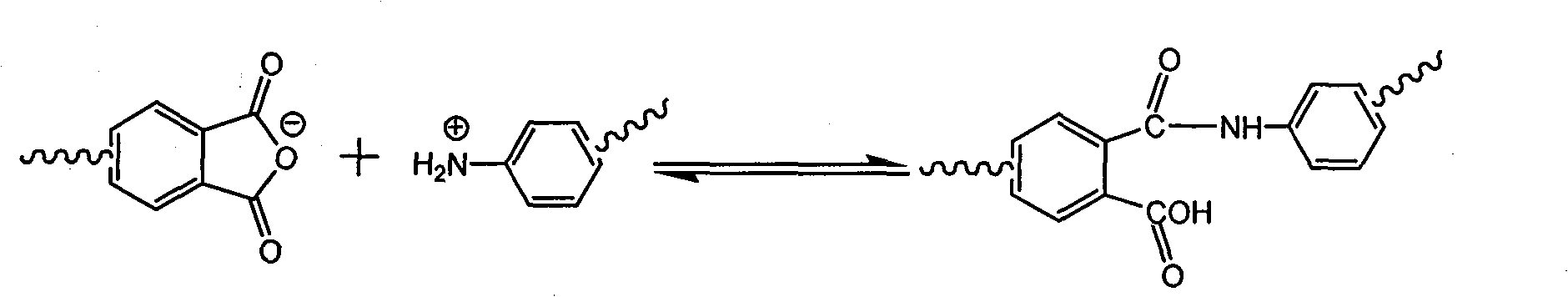

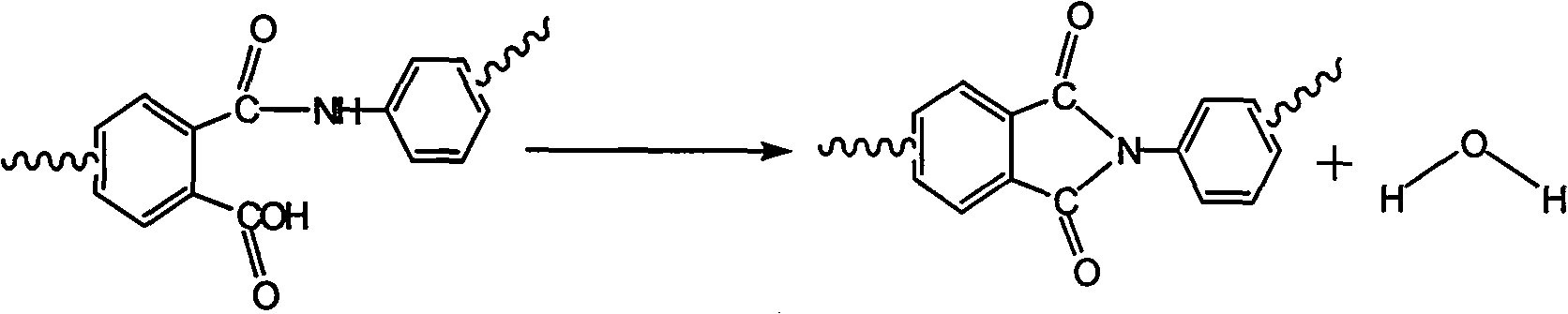

The invention provides a TiO2 / PI hybridization film with photocatalysis and self-cleaning function and the process for preparing it, which is characterized in that adding organic monomer in the process of preparing thin films with sol-gel processing, with titanium collosol hydrolytic polymerization happening, forming medlin phase (PAA) in original position polyreaction, finally, forming a nanometer crystal phase TiO2 / PI hybridization film after heat treating. The thickness of hybridization film is not less than 300nm, which higher than anatase nanometer crystal phase obtained from common puretitanium collosol. There isn't crackle and flake for film in the process of heat treating. Chosing a suitable medlin leading body, a Ti-S bond is formed at the same time of forming a hydrogen bond inthe hybridization film, which endowing film with photocatalysis and self-cleansing effect under the visible light. And the photocatalysis and self-cleansing effect of the film are higher than the photocatalysis activity of common titanium oxide nanometer crystal phase film, meanwhile, the film has good radiation resistant and chemical stability.

Description

TiO2 / PI hybrid film with photocatalytic self-cleaning function and preparation method thereof Technical field The invention relates to an in-situ synthesized titanium oxide nanocrystal and polyimide (TiO2 / PI) hybrid film, in particular to a kind of glass coated on architectural glass, automobile glass, optical glass, etc., and architectural glass Films with photocatalytic degradation and self-cleaning functions on the surface of various inorganic materials such as ceramics and sanitary ceramics. The hybrid film of the present invention has significant photocatalytic degradation function under ultraviolet-visible light wave irradiation. Background technique Nano-scale titanium oxide powder and titanium oxide nanocrystalline film have the characteristics of photocatalytic degradation of organic and inorganic pollutants under ultraviolet light. Various materials coated with titanium oxide nanocrystalline film on the surface are regarded as having a self-cleaning function. Method...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C03C17/34C04B41/81

Inventor 贺蕴秋张伟进

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com