Preparation method of large-scale flake ultra-high thermal conductivity diamond/copper composite material

A technology for composite materials and composite material components, which is applied in the field of preparation of large-scale thin sheet ultra-high thermal conductivity diamond/copper composite materials, which can solve the problems of poor interface bonding strength and low thermal conductivity of diamond/copper, and achieve production cycle Short, good thermal expansion coefficient, and the effect of reducing interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

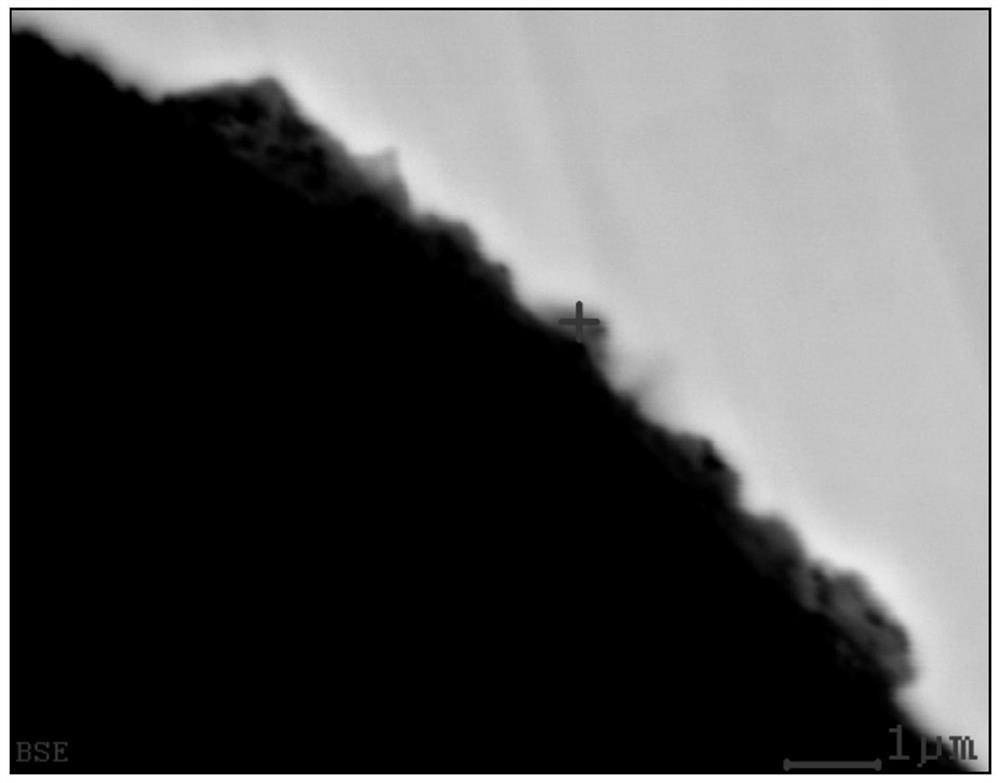

[0033] Specific Embodiment 1: The preparation method of the large-size flake-shaped ultra-high thermal conductivity diamond / copper composite material in this embodiment is carried out according to the following steps:

[0034] 1. Filling the diamond particles coated with the metal film into the cavity of the graphite mold to obtain a preform; the filling amount of the diamond particles coated with the metal film is 60% to 85% of the volume of the graphite mold cavity;

[0035] 2. Place the prefabricated body in the crucible, place the block of pure copper on the upper part of the prefabricated body in the crucible, and place the crucible in the air pressure infiltration furnace;

[0036] 3. Preheat the prefabricated body to 1000-1050°C in an argon protective atmosphere and keep it warm for 1-5 hours to complete the microstructure control of the interface layer material;

[0037] 4. Under the protective atmosphere, raise the temperature of the pressure infiltration furnace to 1...

specific Embodiment approach 2

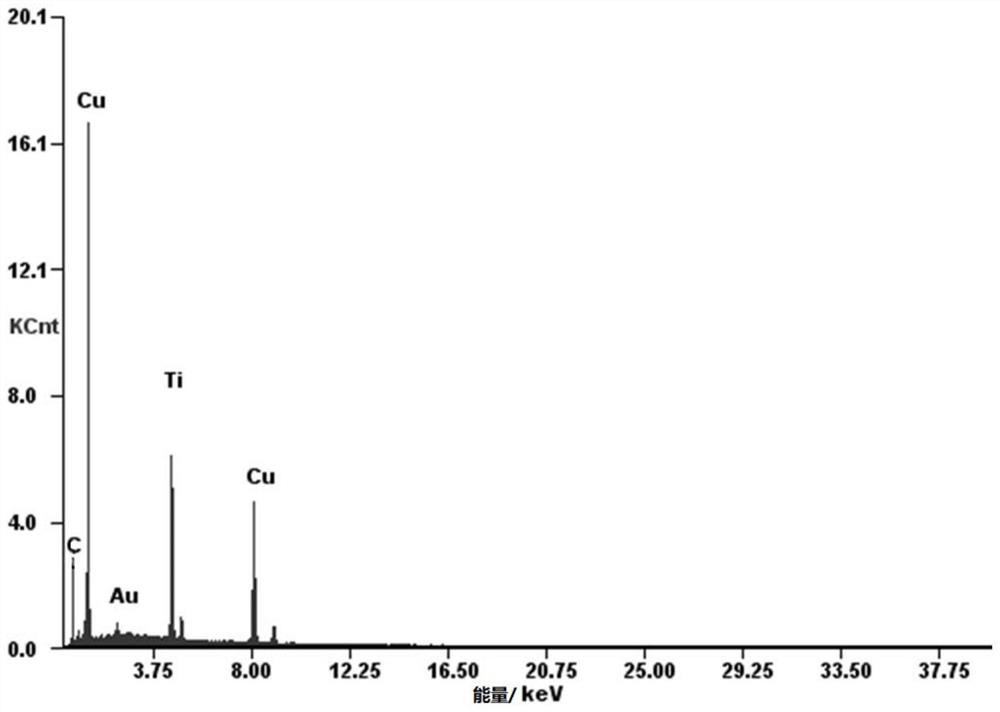

[0046] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the diamond particles coated with a metal film are described in step 1, and the metal film on the diamond particles coated with a metal film is prepared by a magnetron sputtering method. Before magnetron sputtering, pickling and alkali washing are carried out on the diamond particles in sequence until the surface roughness is 50nm-200nm;

[0047] The magnetron sputtering temperature is 100-400°C;

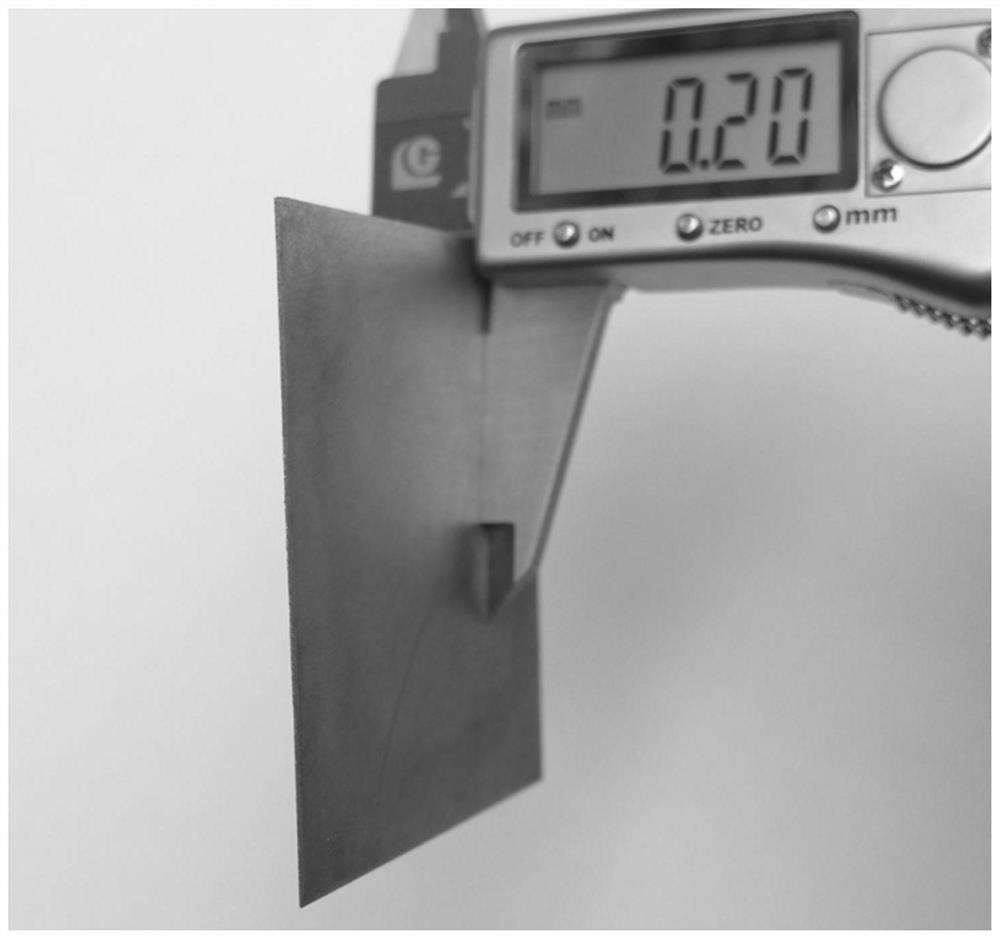

[0048] The particle size of the diamond particles is one of 90-110 μm, 110-400 μm, or a mixture of two in any proportion, wherein the diamond particles are single crystal diamond particles; the diamond-copper composite prepared by using 90-110 μm diamond particles The thermal conductivity of the material component is 750-1000W / mK, and the thermal conductivity of the diamond-copper composite material component prepared by using 110-400μm diamond particles is 800-1300W / mK. The thermal c...

specific Embodiment approach 3

[0050] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the specific process of pickling is: soaking in aqua regia at room temperature for 3 to 5 hours; the specific process of alkali cleaning is: at a concentration of 0.05- Soak in 5g / mL sodium hydroxide solution at room temperature for 3-5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com