Preparation method of graphene

A graphene and graphite technology, applied in the field of graphene, can solve the problems of uncontrolled heating of reactants, failure of oxidation reaction, etc., and achieve the effects of strong temperature controllability and good batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

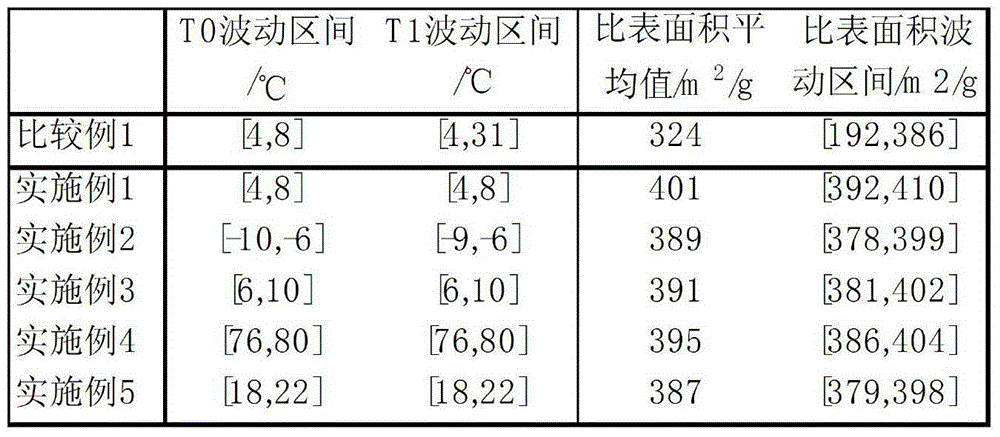

Examples

Embodiment 1

[0029] Embodiment 1, different from Comparative Example 1, this embodiment comprises the following steps:

[0030] Oxidation solution configuration: according to the quality relationship of potassium permanganate: concentrated sulfuric acid (concentration is 98%): sodium nitrate=5:60:1, first add concentrated sulfuric acid (concentration is 98%) and sodium nitrate to the temperature at 6 ℃ Stir in the reactor, then add potassium permanganate to it to obtain the oxidation solution, test and record the temperature T of the oxidation solution 0 .

[0031] Pre-reaction slurry configuration: according to the quality relationship of graphite:potassium permanganate=2:5, slowly add graphite powder to the above-mentioned oxidation solution to obtain the pre-reaction slurry, monitor and record the pre-reactant temperature T during the whole feeding process 1 The change.

[0032] Others are the same as those of Comparative Example 1 and will not be repeated here.

Embodiment 2

[0033] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0034] Oxidation solution configuration: According to the mass relationship of potassium permanganate:concentrated sulfuric acid (98%):sodium nitrate=5:6:1, first add concentrated sulfuric acid (98%) and sodium nitrate at -10°C Stir in the reactor, then add potassium permanganate to it to obtain the oxidation solution, test and record the temperature T of the oxidation solution 0 .

[0035]Pre-reaction slurry configuration: when the temperature of the oxidation solution is at -10°C, according to the mass relationship of graphite: concentrated sulfuric acid (concentration: 98%) = 0.0005:1, slowly add graphite powder to the above oxidation solution to obtain a pre-reaction slurry , monitor and record the pre-reactant temperature T during the whole feeding process 1 The change.

[0036] Oxidation reaction: place the above-mentioned reactants in an environment of -10°C for 6 hours;...

Embodiment 3

[0039] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0040] Oxidation solution configuration: according to the mass relationship of potassium permanganate: nitric acid: sodium sulfate = 1:2:1, first add nitric acid and sodium sulfate to a reactor with a temperature of 10°C and stir, then add potassium permanganate to it to obtain Oxidation solution, test and record the temperature T of the oxidation solution 0 .

[0041] Pre-reaction slurry configuration: when the temperature of the oxidation solution is at 10°C, according to the mass relationship of graphite: nitric acid = 2:1, slowly add graphite powder to the above oxidation solution to obtain a pre-reaction slurry, monitor and record the entire feeding process , pre-reactant temperature T 1 The change.

[0042] Oxidation reaction: place the above reactants in an environment of 10°C for 3 hours; then place them in an environment of 85°C for 30 minutes to complete the oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com