Novel method for synthesizing polyethoxy acrylate with fluorenyl structure by using immobilized catalyst

A technology of ethoxylated acrylic acid and immobilized catalyst, which is applied in the direction of preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of non-conformity with sustainable green and environmental protection chemical industry development, increase of solid waste and liquid Waste, unable to recycle and reuse problems, etc., to achieve the effect of easy separation, pollution reduction and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

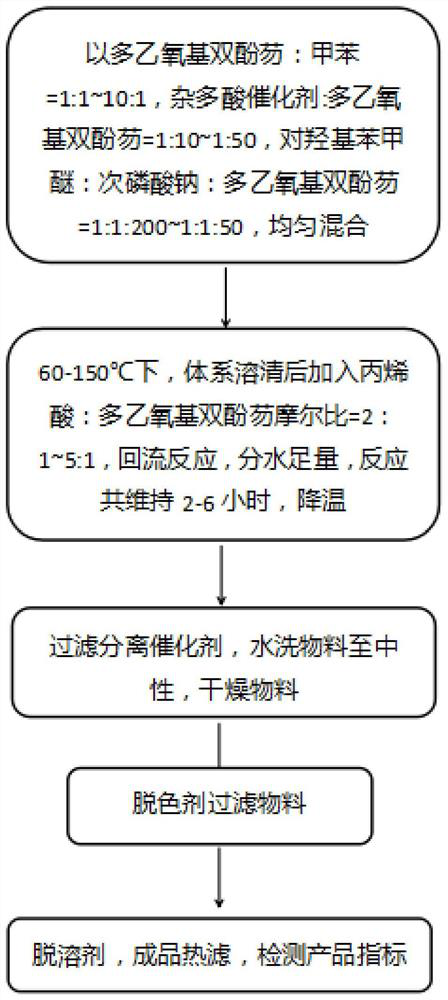

Method used

Image

Examples

Embodiment 1

[0034] Prepare a solid-supported catalyst: use diatomaceous earth as a carrier, load phosphotungstic acid, and the mass percentage of phosphotungstic acid is 20%;

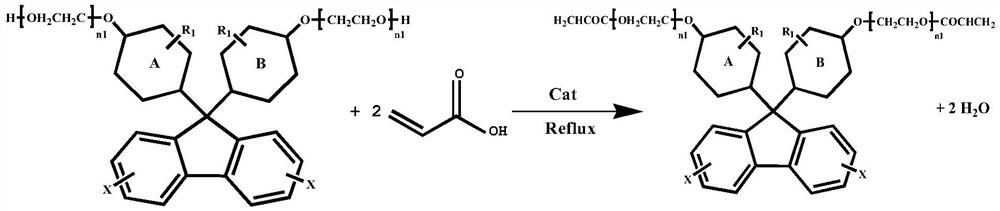

[0035] 100.0g 10-ethoxy bisphenol fluorene, 25.0g immobilized phosphotungstic acid catalyst, 0.15g p-hydroxyanisole and 0.15g sodium hypophosphite were added to a 500ml four-necked round bottom flask with magnetic stirring, and then Add 225g of toluene solvent and 75g of cyclohexane solvent, start stirring, heating and dissolving, after slowly adding 25.5g of acrylic acid dropwise, raise the temperature to 95-105°C for reflux and water separation, react for 4 hours, cool down to 55°C and filter, collect The solid-supported phosphotungstic acid catalyst is reserved for the next use, add 60ml deionized water and wash 5 times until neutral, add 10g anhydrous sodium sulfate, stir and dry for 2 hours, then membrane filter, add 0.02g p-hydroxybenzoic acid to the filtrate Distillation under reduced pressure after the ethe...

Embodiment 2

[0037] Preparation of immobilized catalyst: use white clay as a carrier, load silicotungstic acid, and the mass percentage of silicotungstic acid is 25%;

[0038] Add 240g of 10-ethoxy bisphenol fluorene, 54g of solid-supported silicotungstic acid catalyst, 0.3g of p-hydroxyanisole and 0.3g of sodium hypophosphite into a 1000ml three-neck round bottom flask with magnetic stirring, and then add 450g of toluene Solvent, 150g cyclohexane solvent, start stirring and heating, raise the temperature to 80°C and stir for 20 minutes, after slowly adding 63g of acrylic acid dropwise, quickly raise the temperature to reflux and water separation, react for 4.5 hours, cool down to about 60°C, filter, collect Immobilized silicotungstic acid catalyst for reuse next time, add 300ml of deionized water to wash 7 times until neutral, add 15g of anhydrous sodium sulfate, stir for 15 minutes, let stand for 5 hours, membrane filter, filter the filtered reaction solution Add 0.06g of p-hydroxyanisol...

Embodiment 3

[0040] Prepare the immobilized catalyst: use white clay as the carrier, load silicomomolybdic acid, and the mass percentage of silicomomolybdic acid is 30%;

[0041]Add 350g of 10-ethoxy bisphenol fluorene, 80g of immobilized silicomolybdic acid catalyst, 0.25g of p-hydroxyanisole and 0.35g of sodium hypophosphite into a 2000ml glass bottle with stirring, then add 1050g of toluene solvent, and open Stir and heat, slowly add 93g of acrylic acid, after the addition, quickly raise the temperature to 110°C and reflux, divide the water, react for 6 hours, cool down to about 55°C, filter, collect the immobilized silicon molybdenum acid for next use, add 350ml to remove Ionized water, stirred for 5 minutes, separated after standing for 25 minutes, washed with water for 6 times until neutral, added 20g of anhydrous sodium sulfate, stirred for 3 hours, then membrane filtered, and added 0.1g of p-hydroxyanisole to the filtrate to reduce Pressure distillation, steamed toluene to obtain 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com