Method for preparing composite material of carbon coated lithium ferrous phosphate through iron phosphate

A carbon-coated ferrous phosphate and lithium ferrous phosphate technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the deterioration of the electrochemical performance of lithium ferrous phosphate materials, can not ensure complete reaction, consistent materials It can solve problems such as poor performance, and achieve the effect of good electrochemical performance, good batch consistency of materials, and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh iron phosphate 4 hydrate (FePO 4 4H 2 (2) 0.2mol is 44.578g, ammonium sulfite 0.4mol, add distilled water, the concentration of ammonium sulfite is 1mol / L, then stir for 6 hours, the temperature of stirring is 50 ℃, then filter and clean to obtain amorphous ferrous phosphate Ammonium;

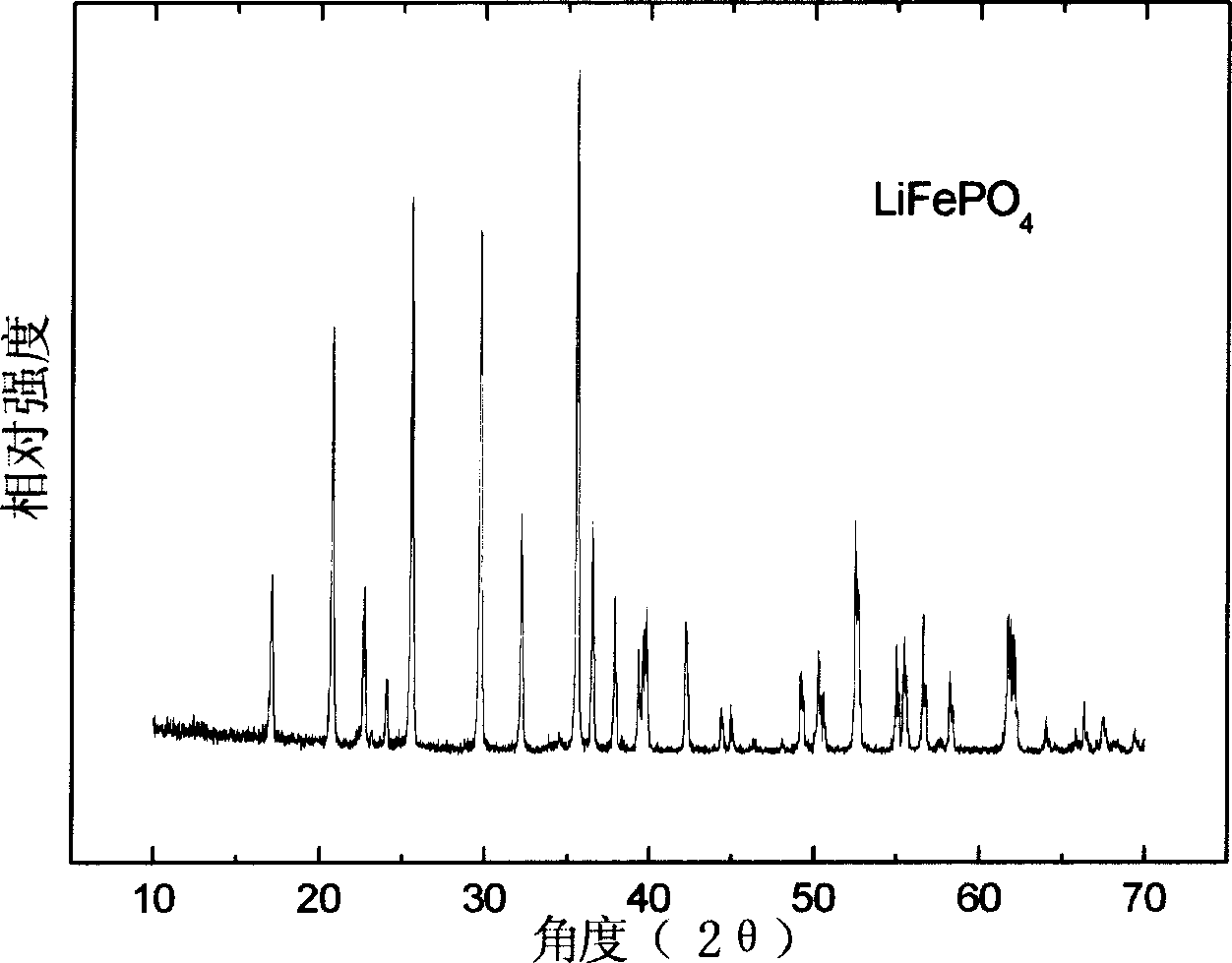

[0024] (2) The obtained amorphous ferrous ammonium phosphate is mixed with 8.392g lithium hydroxide, and under the protection of argon and 5% hydrogen mixed gas, it is treated at 500°C for 2 hours to obtain lithium ferrous phosphate, and 2.375g is weighed Sucrose, sucrose is dissolved in distilled water and mixed with lithium iron phosphate, heated and stirred until evaporated to dryness, and then treated at 650°C for 2 hours under the protection of argon to obtain carbon-coated lithium iron phosphate. figure 1 It is the XRD spectrum pattern of the carbon-coated lithium ferrous phosphate obtained in Example 1, which shows that lithium ferrous phosphate has a good crystal stru...

Embodiment 2

[0026] (1) Weigh ferric phosphate, ammonium sulfite and ammonia water, wherein 4 hydrated ferric phosphate (FePO 4 4H 2 O) 0.2mol is 44.578g, 0.4mol of ammonium sulfite, 0.2mol of ammonia water, add distilled water, the concentration of ammonium sulfite is 1mol / L, then stir for 4 hours, the temperature of stirring is 70°C, then filter and wash to obtain an amorphous state Ferrous ammonium phosphate;

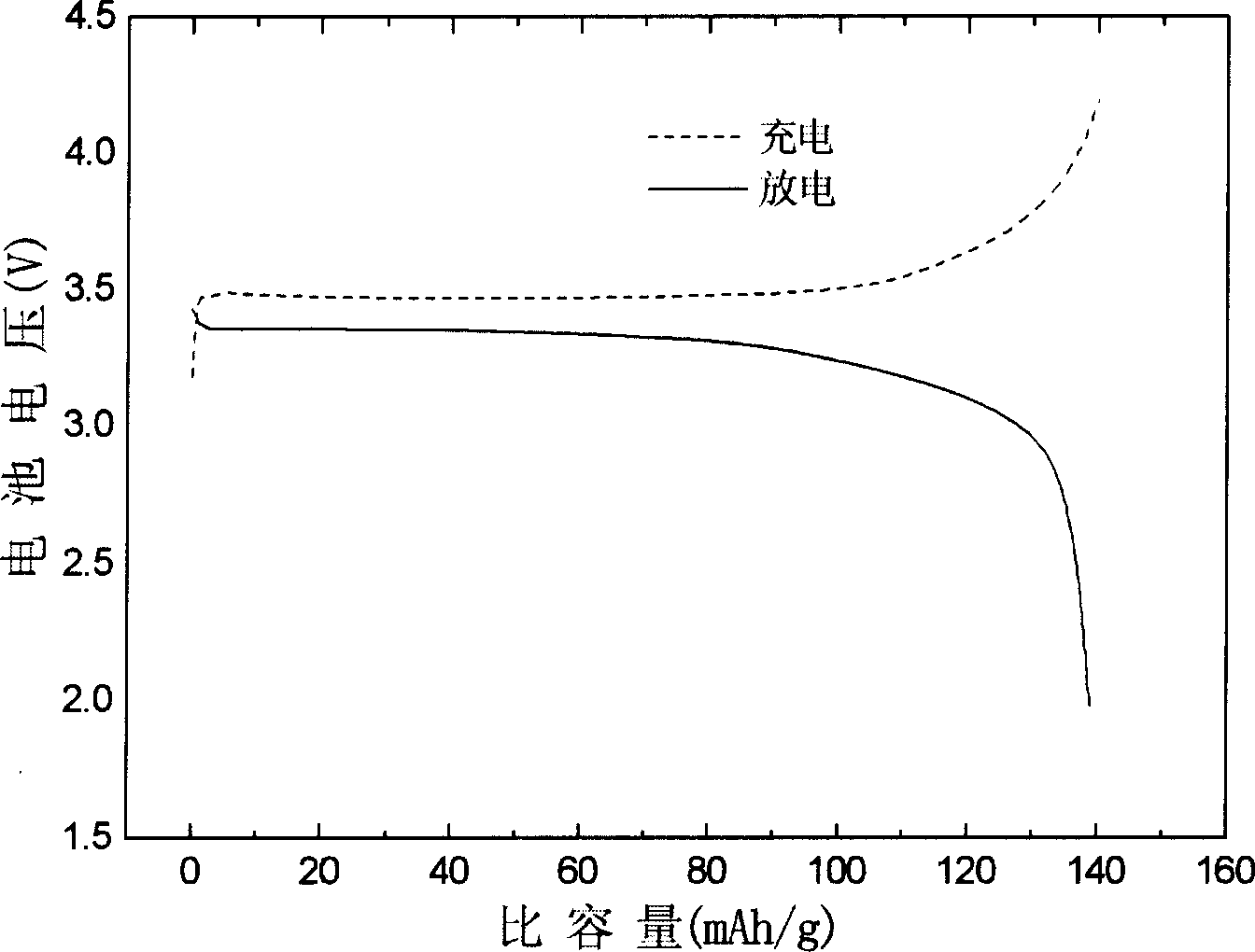

[0027] (2) The obtained amorphous ferrous ammonium phosphate is mixed with 7.389g lithium carbonate and 3.506g sucrose, and distilled water is added to dissolve the sucrose and heat and stir to make the suspension evaporate to dryness, then in argon and 5% hydrogen mixed gas Under protection, it was treated at 700° C. for 1 hour to obtain carbon-coated lithium iron phosphate. figure 2 It is the charge-discharge curve of the carbon-coated lithium ferrous phosphate obtained in Example 2, and the discharge capacity reaches 139mAh / g at 1C.

Embodiment 3

[0029] (1) Weigh iron phosphate, ammonium thiosulfate and ammonia water, in which iron phosphate 2 hydrate (FePO 4 2H 2 (2) 0.2mol i.e. 37.364g, ammonium thiosulfate 0.2mol, ammoniacal liquor 0.1mol, add distilled water, the concentration of ammonium thiosulfate is 0.5mol / L, then stir for 8 hours, the temperature of stirring is room temperature, then filter and clean to obtain non- Crystalline ammonium ferrous phosphate;

[0030] (2) The obtained amorphous ferrous ammonium phosphate was mixed with 20.404g lithium acetate, and under the protection of nitrogen and 5% hydrogen mixed gas, it was treated at 400°C for 3 hours to obtain lithium ferrous phosphate, and 3.506g glucose was weighed, Glucose was dissolved in distilled water and mixed with lithium iron phosphate, heated and stirred until evaporated to dryness, and then treated at 700° C. for 1 hour under nitrogen protection to obtain carbon-coated lithium iron phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com