Stratified anode material of O3-type sodium-ion battery and preparation method and application thereof

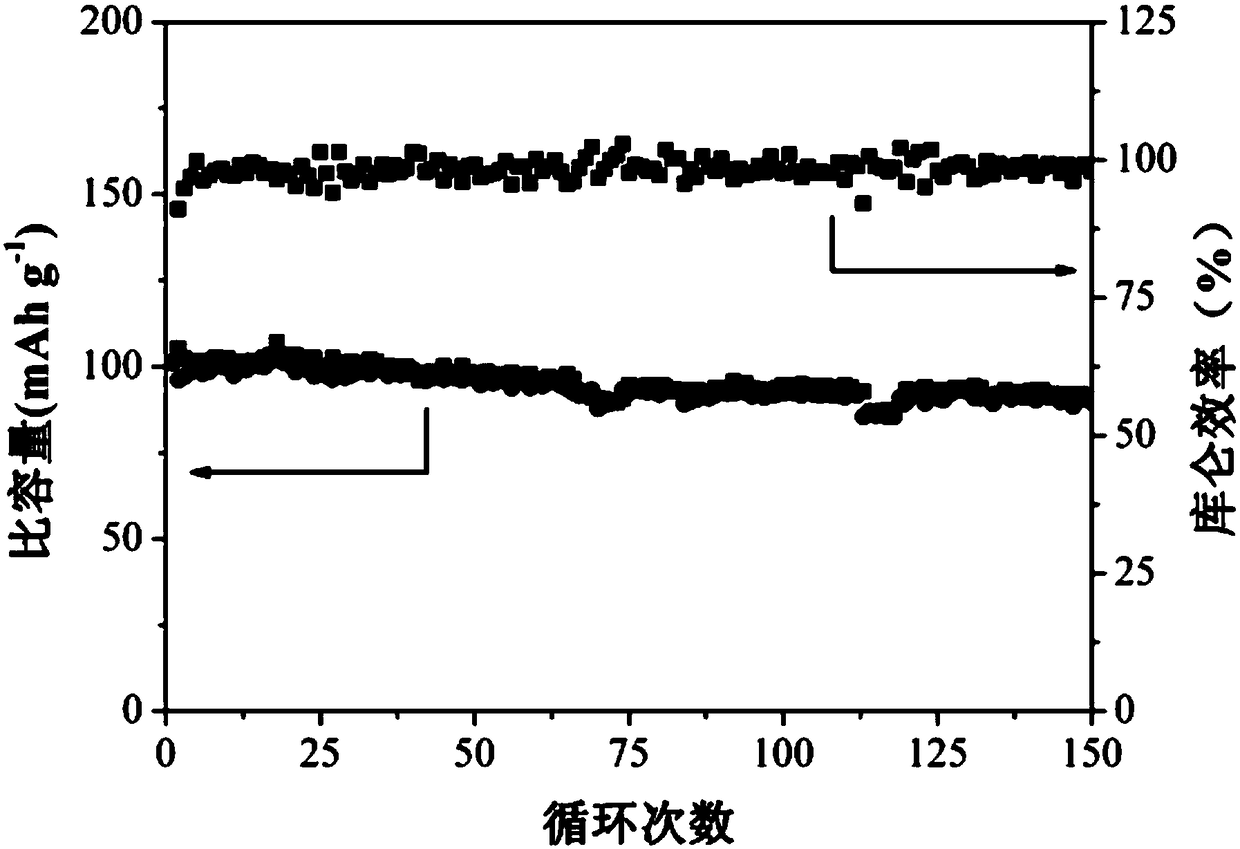

A sodium-ion battery and cathode material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as poor cycle performance, and achieve the effect of small specific capacity test deviation, large cost advantage, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Sodium-ion battery cathode material NaNi 1 / 2 co 1 / 6 mn 3 / 8 o 2 preparation method

[0026] Weigh sodium carbonate, NiO, Co 2 o 3 , MnO 2 and TiO 2 , so that the molar ratio of Na, Ni, Co, and Mn atoms is 1.05:1 / 2:1 / 6:3 / 8.

[0027] Pour the weighed powder into a ball mill jar, add ethanol with a mass of 40% of the total powder mass, mix briefly, cover the ball mill jar tightly, seal it with a parafilm ® film, clamp it on a planetary ball mill, and ball mill at 350r / min for 12 hours Use 250r / min ball mill for 2 hours.

[0028] The slurry after ball milling is directly dried at 80°C, and then simply ground to disperse the large particles. figure 1 It is the SEM picture of the mixed precursor, the material is evenly distributed, and the average particle size is about 1-3um. A stainless steel mold is used to compact the powder into discs with a diameter of 14 mm and a thickness of 5 mm with a hydraulic pump at a compaction pressure of 15 mbar.

[0029] The compact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com