Secondary sintering synthesis method for lithium iron phosphate

A lithium iron phosphate, secondary sintering technology, applied in the interdisciplinary fields of electrochemistry, materials science, and physics, can solve the problems of poor storage performance, lithium intercalation, poor consistency, etc., to improve storage performance and cycle performance, process The effect of simple method and good storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

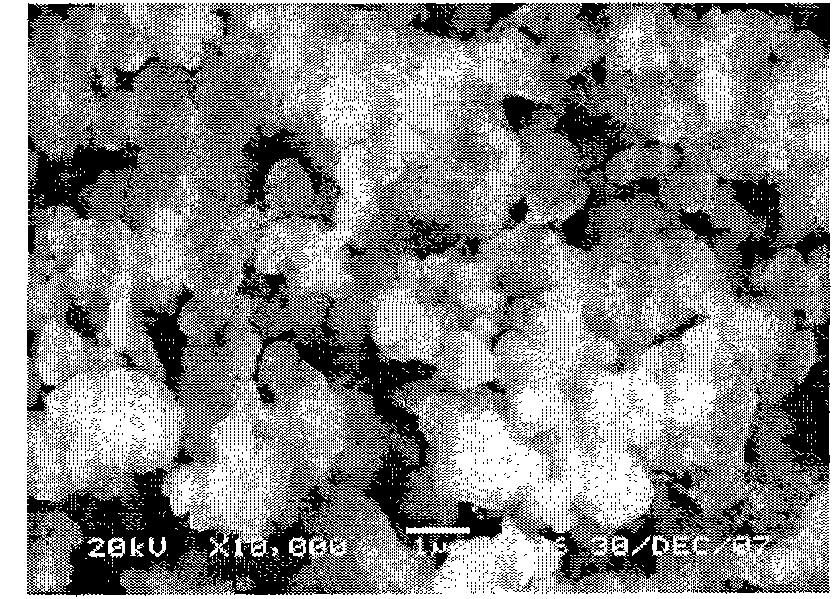

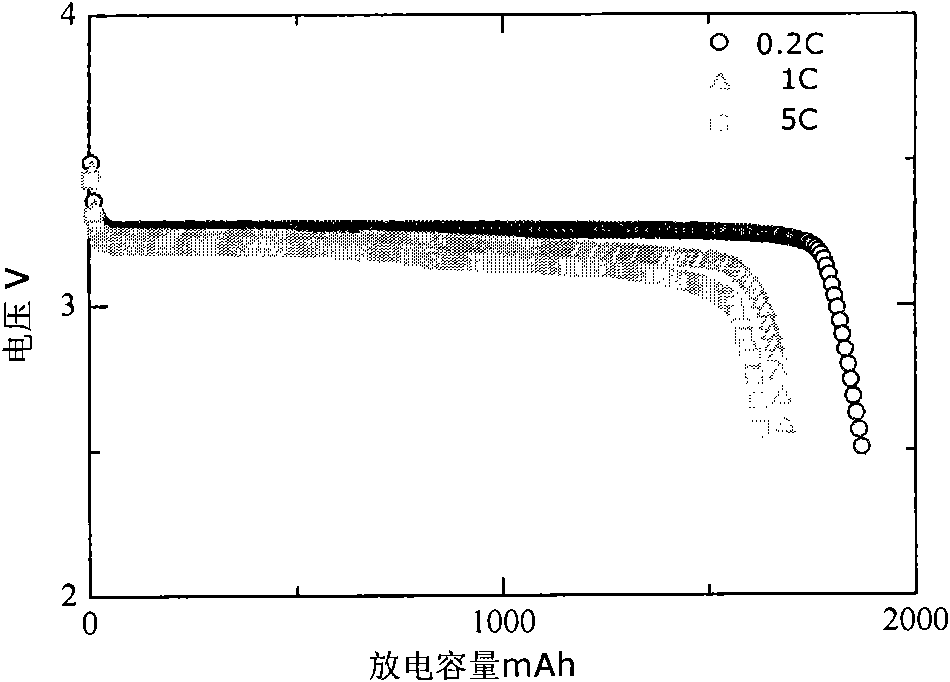

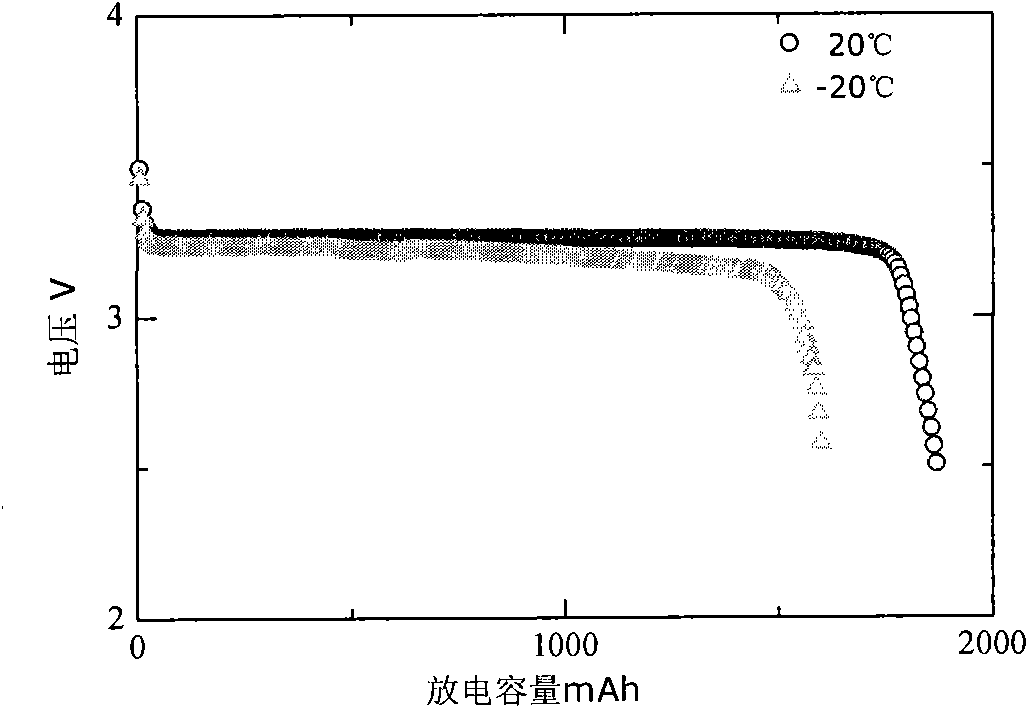

[0032] Embodiment 1: take the lithium carbonate with particle size of 4.5 microns, the ferrous oxalate of 10.2 microns and the ammonium dihydrogen phosphate powder of 15.5 microns. Ferrous oxalate and ammonium dihydrogen phosphate are mixed uniformly, heated to 450°C at a heating rate of 3°C / min, kept for 10h, cooled, crushed and classified to obtain laser particle size D 50 It is 2.1μm lithium iron phosphate; the first sintered 2.1μm lithium iron phosphate is added to the ball mill together with glucose and industrial alcohol for ball milling, and the secondary sintering is carried out after drying. The temperature was raised to 750°C, kept for 15h, cooled, crushed and classified to obtain laser particle size D. 50 2.8μm lithium iron phosphate. from the attached figure 2 It can be seen that the prepared lithium iron phosphate has outstanding discharge rate performance, and the discharge rate of 1C / 5C is 96.2%; image 3 It can be seen that the synthesized lithium iron phos...

Embodiment 2

[0034] Take lithium hydroxide with a particle size of 6.8 microns, ferric oxide with a particle size of 1.1 microns and ammonium dihydrogen phosphate powder with a particle size of 19.2 microns. Iron and ammonium dihydrogen phosphate are mixed uniformly, heated to 550°C at a heating rate of 5°C / min, kept for 5 hours, cooled, crushed and classified to obtain laser particle size D 50 It is 2.9μm lithium iron phosphate; the first sintered 2.9μm lithium iron phosphate is added to the ball mill together with carbon source (sucrose) and industrial alcohol for ball milling, and after drying, secondary sintering is performed. The secondary sintering system is: 8 ℃ The heating rate of / min was heated to 650 °C, kept for 10 h, cooled, crushed and classified to obtain the laser particle size D. 50 3.5μm lithium iron phosphate. from the attached Figure 5 It can be seen that the rate performance of the prepared lithium iron phosphate, the material discharge rate performance is outstandi...

Embodiment 3

[0036] Take lithium dihydrogen phosphate and 3.9 micron iron phosphate powder with a particle size of 5.5 microns, mix lithium carbonate and iron phosphate in a ratio of Li:Fe molar ratio of 1:1, and heat up to 350 at a heating rate of 1 °C / min ℃, heat preservation for 15h, cooling, crushing and classification to obtain laser particle size D 50 It is 3.7μm lithium iron phosphate; the 3.7μm lithium iron phosphate sintered once is added to the ball mill together with carbon source (sucrose) and pure water for ball milling, and the secondary sintering is performed after drying. The secondary sintering system is: 2 ℃ The heating rate of / min was heated to 850°C, kept for 20h, cooled, crushed and classified to obtain the laser particle size D. 50 3.9μm lithium iron phosphate. from the attached Figure 8 It can be seen that the rate performance of the prepared lithium iron phosphate, the material discharge rate performance is outstanding, the discharge rate 1C / 5C is 95.2%; image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| laser granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com