Center hole positioning wheel set press machine

A positioning wheel and center hole technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of imperfection and imperfection, and achieve the effect of simplifying the structure, simplifying the control part, and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

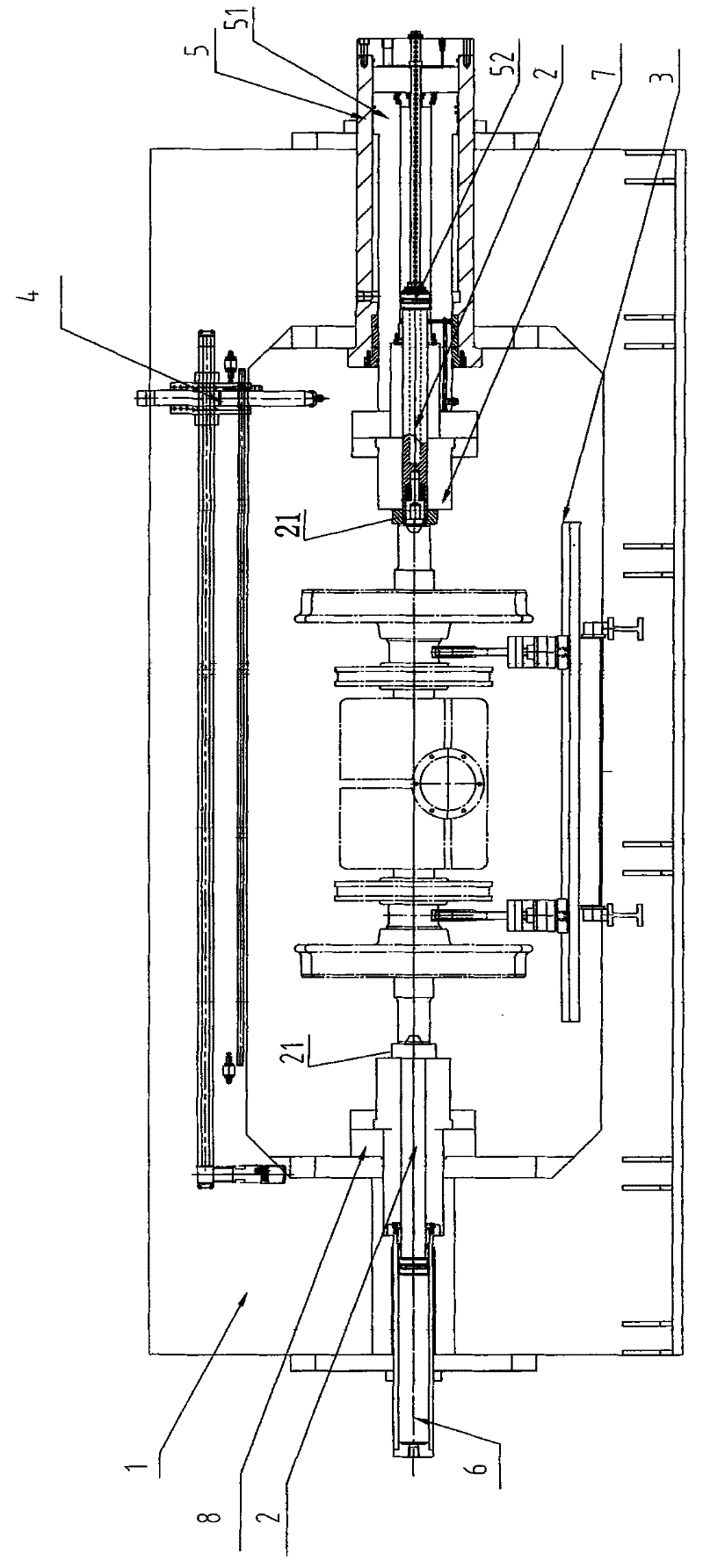

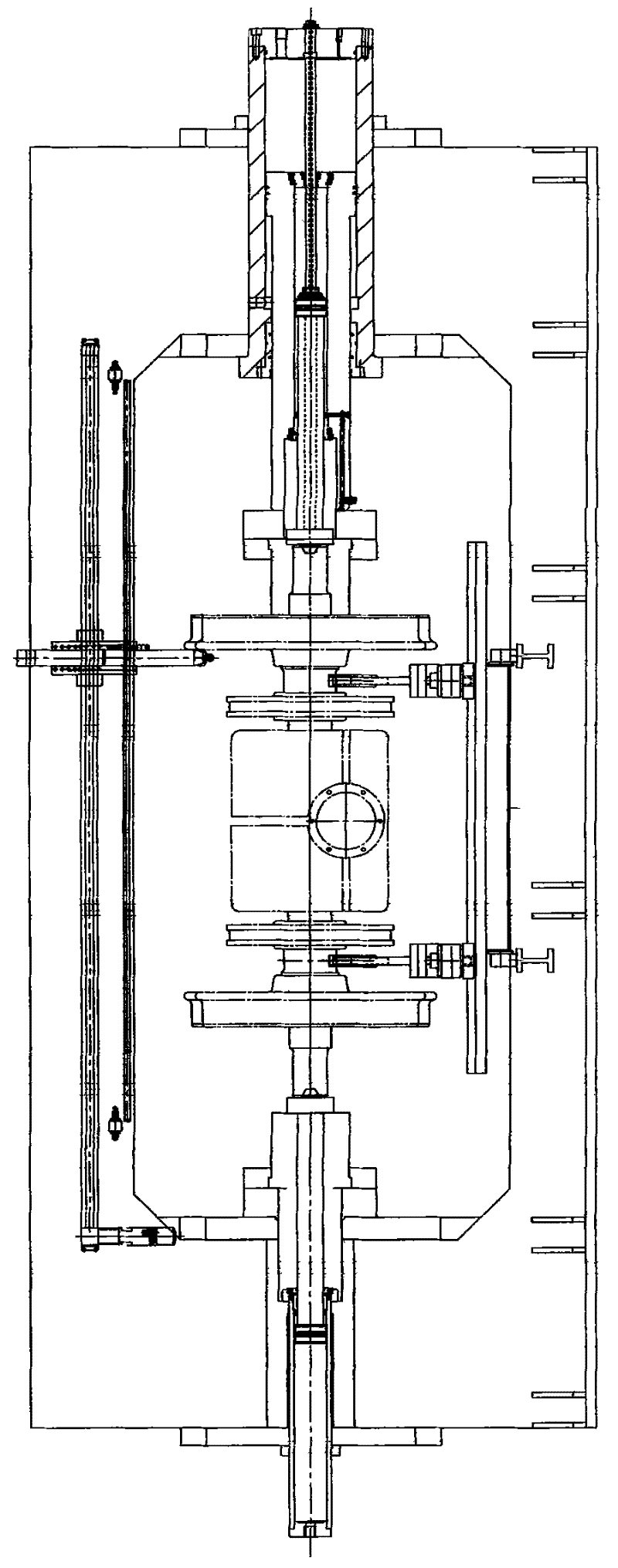

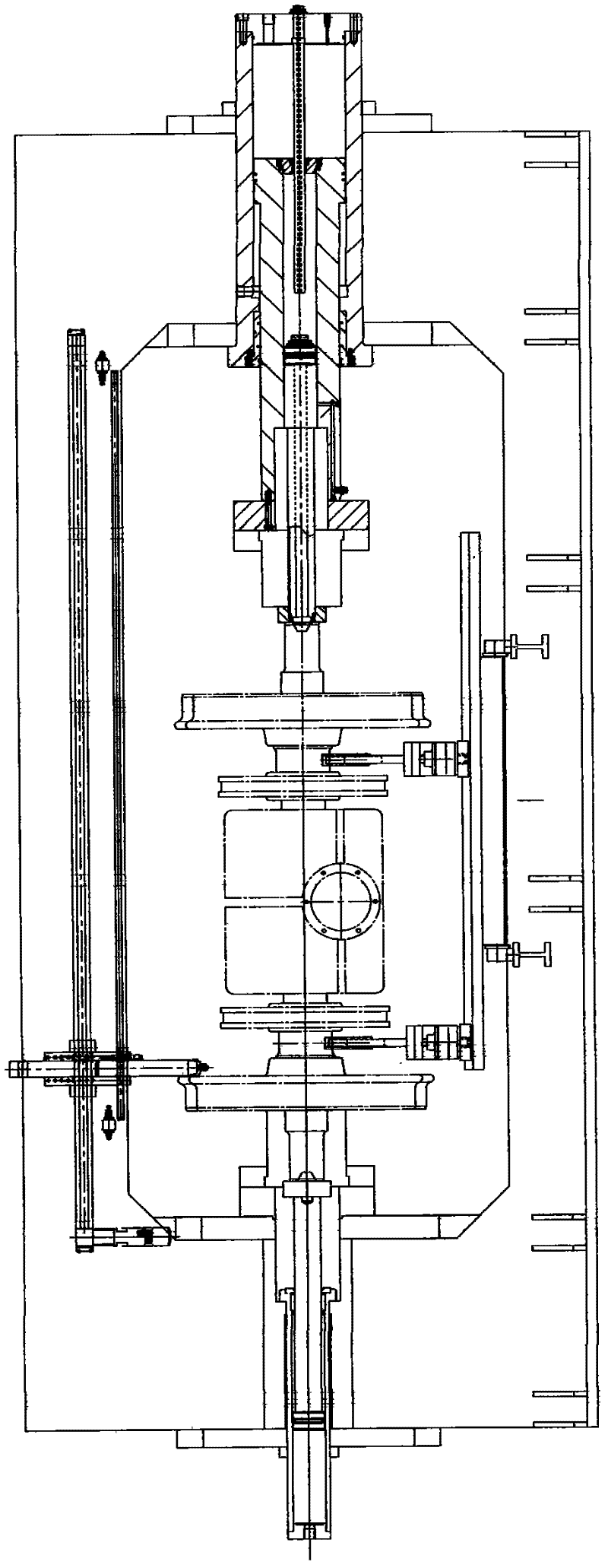

[0015] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1 to Figure 7 As shown, the present invention discloses a center hole positioning wheel set press-fitting machine, which includes a frame 1 and an oil cylinder device arranged axially symmetrically inside it, a thimble device 2, a trolley 3, a detection device 4, a hydraulic system, and an electric control system. It is characterized in that: one end of the oil cylinder device is the main pressure oil cylinder 5, and the other end is the auxiliary oil cylinder 6, a large piston rod 51 is arranged in the main pressure oil cylinder, a small piston rod 52 is arranged in the large piston rod, and the end of the large piston rod is The right indenter seat 7 is installed at the top, the thimble device 2 is installed at the end of the small piston rod, and the thimble device 2 is installed at the end of the piston rod of the auxiliary oil cylinder, and the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com