Firework grain automatic pressing and shaping device

An automatic pressing and forming device technology, which is applied in pyrotechnics, weapon types, offensive equipment, etc., can solve the problems of high degree of danger, adverse effects of corrosion resistance of equipment safety parts, production efficiency needs to be improved, etc., and achieve a high degree of safety , reduce direct contact and pressure, and streamline the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

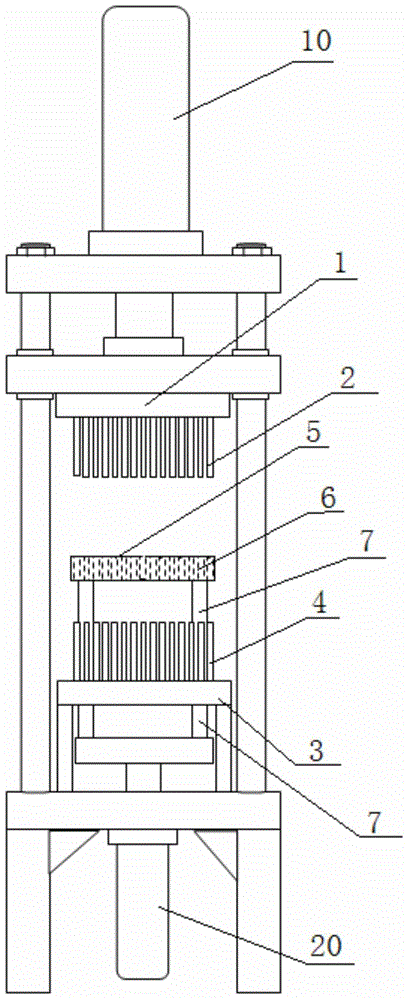

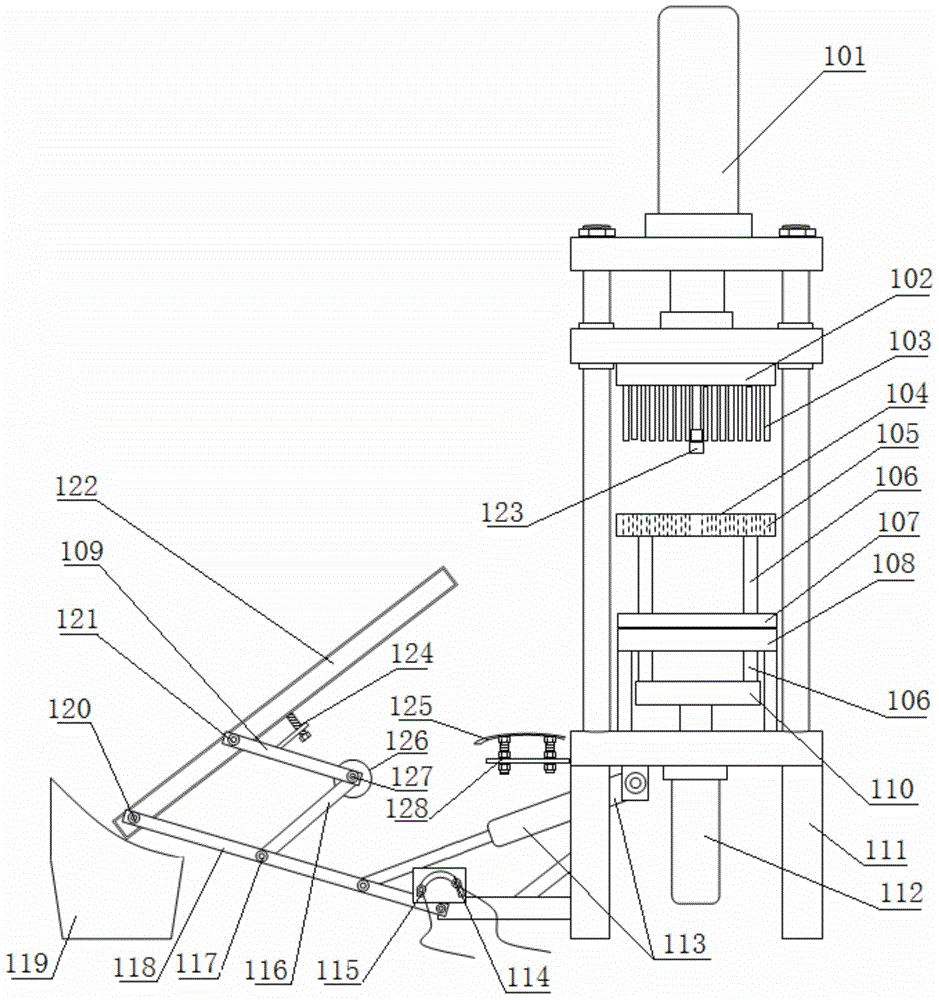

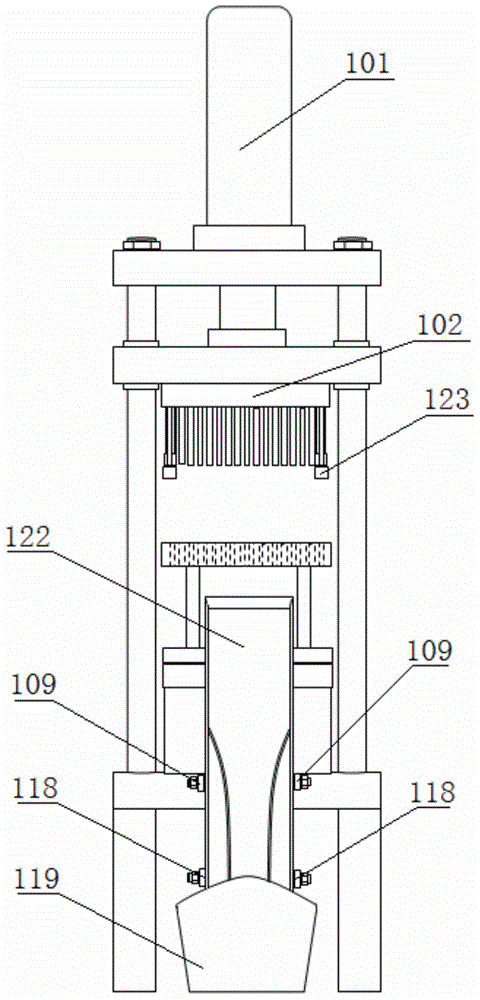

[0029] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the fireworks medicine press includes an upper base plate 102 connected to a driving mechanism such as an upper oil press 101, and a plurality of lower pressing columns 103 are arranged in a matrix on the upper base plate 102. It also includes a lower substrate 108 fixed on the frame 111 , and a plastic isolation buffer layer 107 is provided on the lower substrate 108 . A charging plate 104 is installed between the upper base plate 102 and the lower base plate 108 , and a number of charging holes 105 are arranged in a matrix on the charging plate 104 , and the lower pressing columns 103 and the charging holes 105 are arranged correspondingly. The charge plate 104 is connected to the lower hydraulic press 112 through the connecting rod 106 and the thrust plate 110 . The upper base plate 102 is also provided with a positioning post 123 , and the drug loading plate 104 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com