Press fitting equipment for rubber bushing

A rubber bushing and equipment technology, applied in the field of rubber bushing press-fitting equipment, can solve problems such as installation errors of upper and lower fixtures, deviation of pressing rods, missing bushings, etc., to prevent deviation and wrong installation , the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

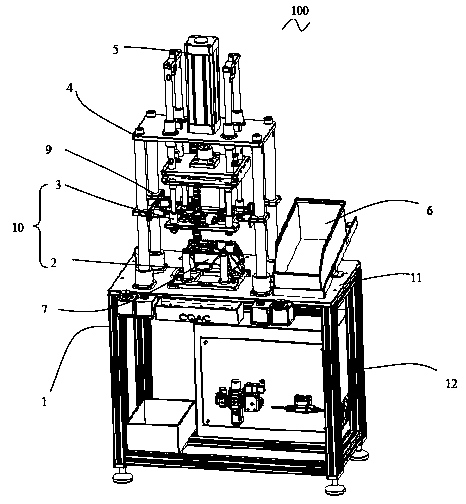

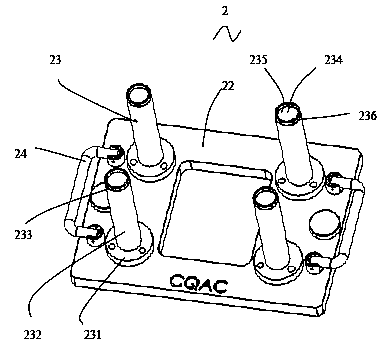

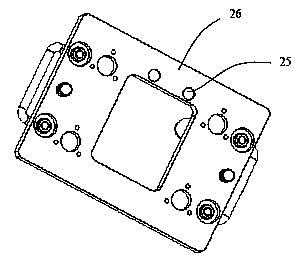

[0024] See Figure 1 to Figure 12 , the rubber bushing press-fitting machine 100 in an embodiment of the present invention is used to press-fit a bushing (not shown) into the workpiece 7 . The rubber bushing press equipment 100 includes a frame 1, a lower clamp 2 fixed on the frame 1, an upper clamp 3 that cooperates with the lower clamp 2 and is arranged above the lower clamp 2, a travel frame 4 that fixes the upper clamp 3, and is used to push The driving device 5 for moving the upper clamp 3 up and down, and the bush receiving device 6 fixed on the frame 1 and located beside the lower clamp 2 for storing the bush. The above-mentioned lower clamp 2 and upper clamp 3 are combined to form a clamp set 10 . The rubber bushing press equipment 100 can complete the tooling of three different types of workpieces 7 , corresponding to the three different types of workpieces 7 , corresponding to three different types of fixture sets 10 . The frame 1 includes a workbench 11 and a fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com