Patents

Literature

131results about How to "Avoid wrong loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

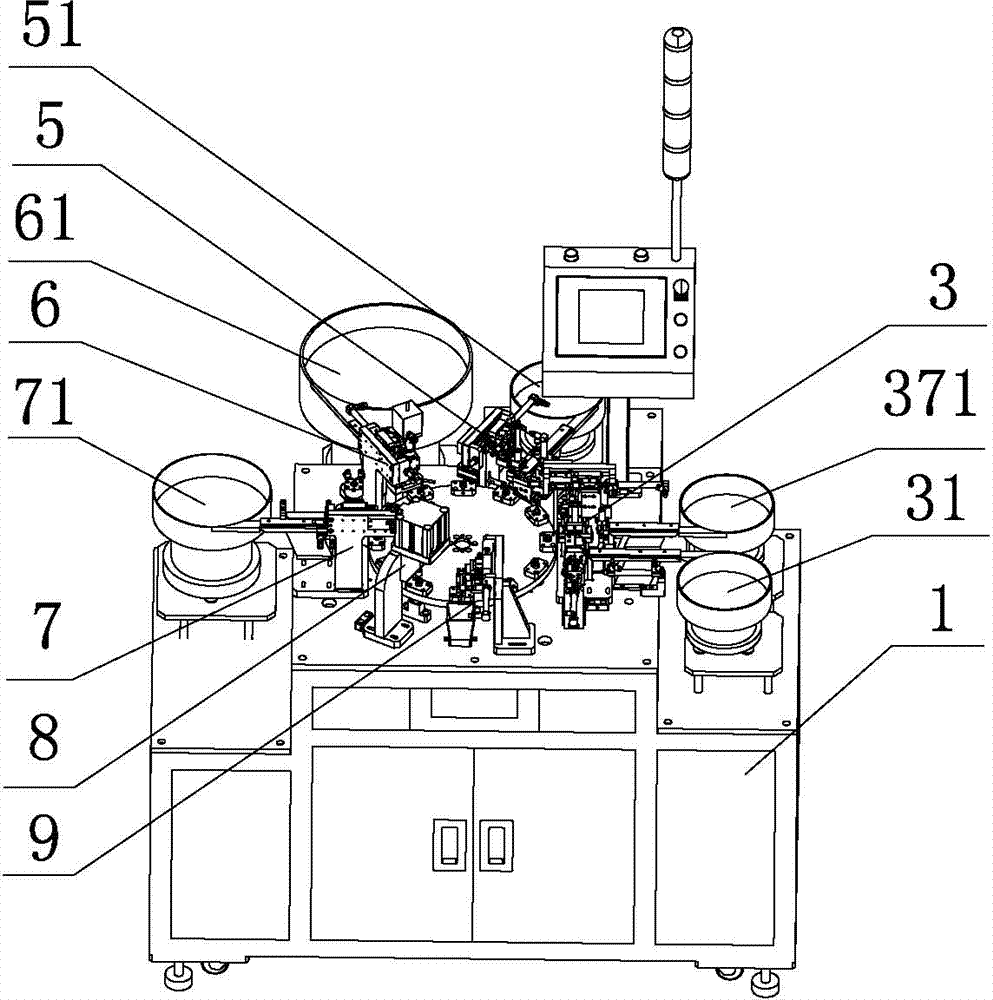

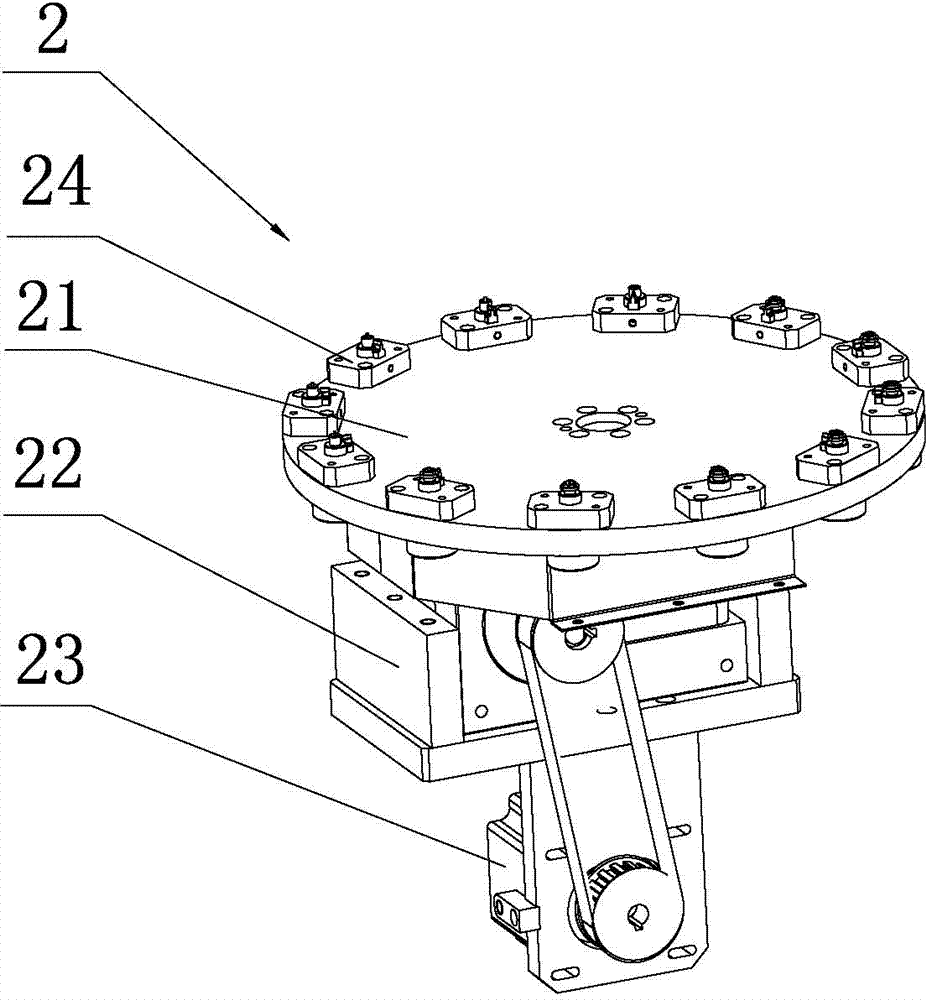

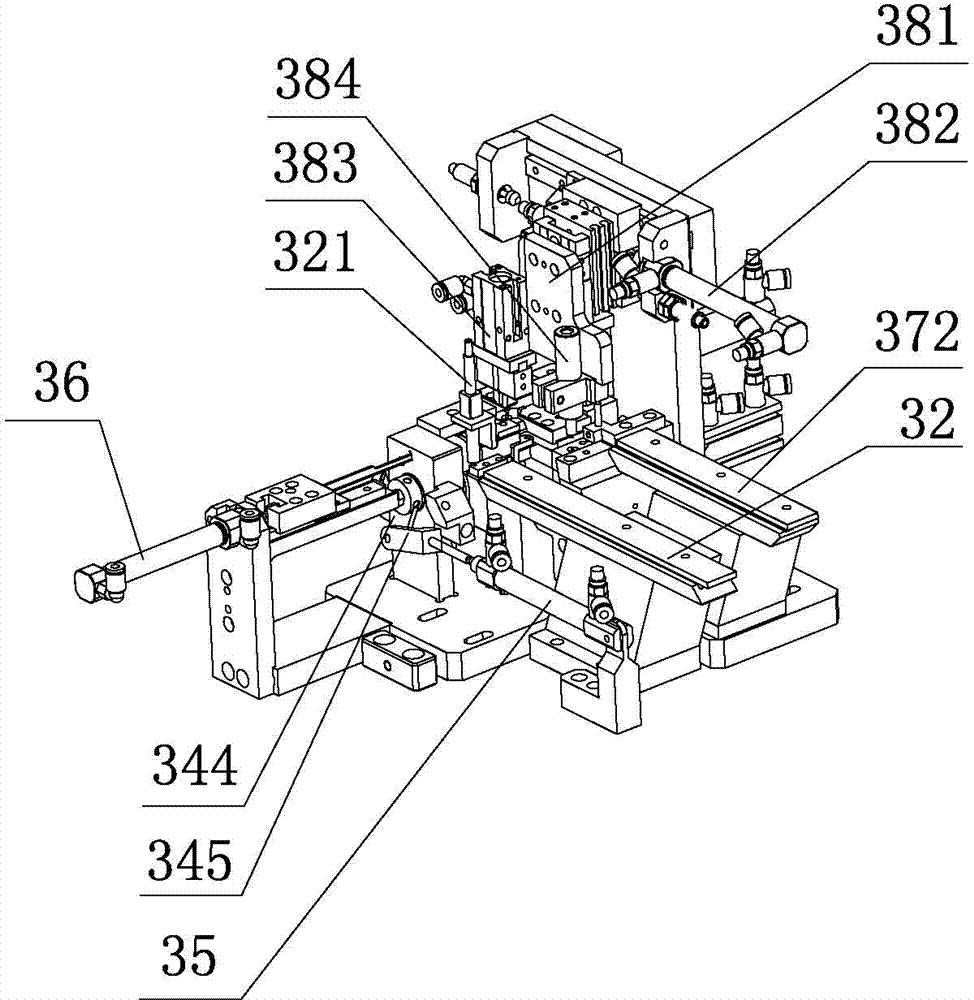

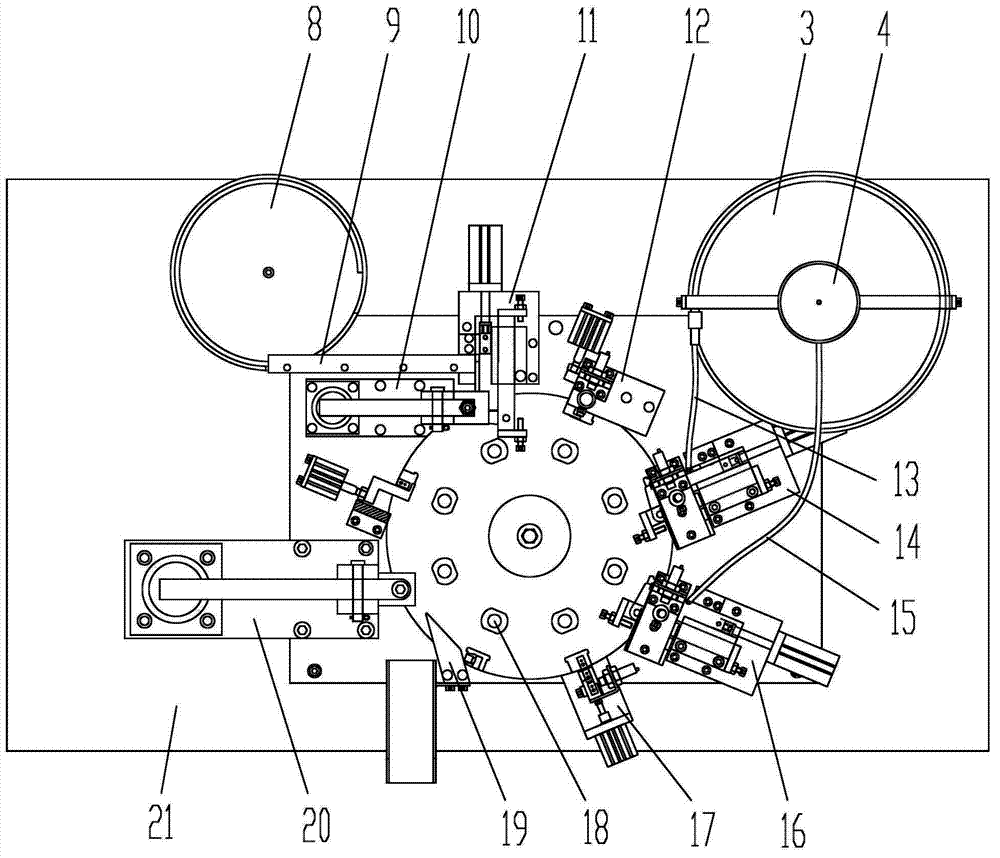

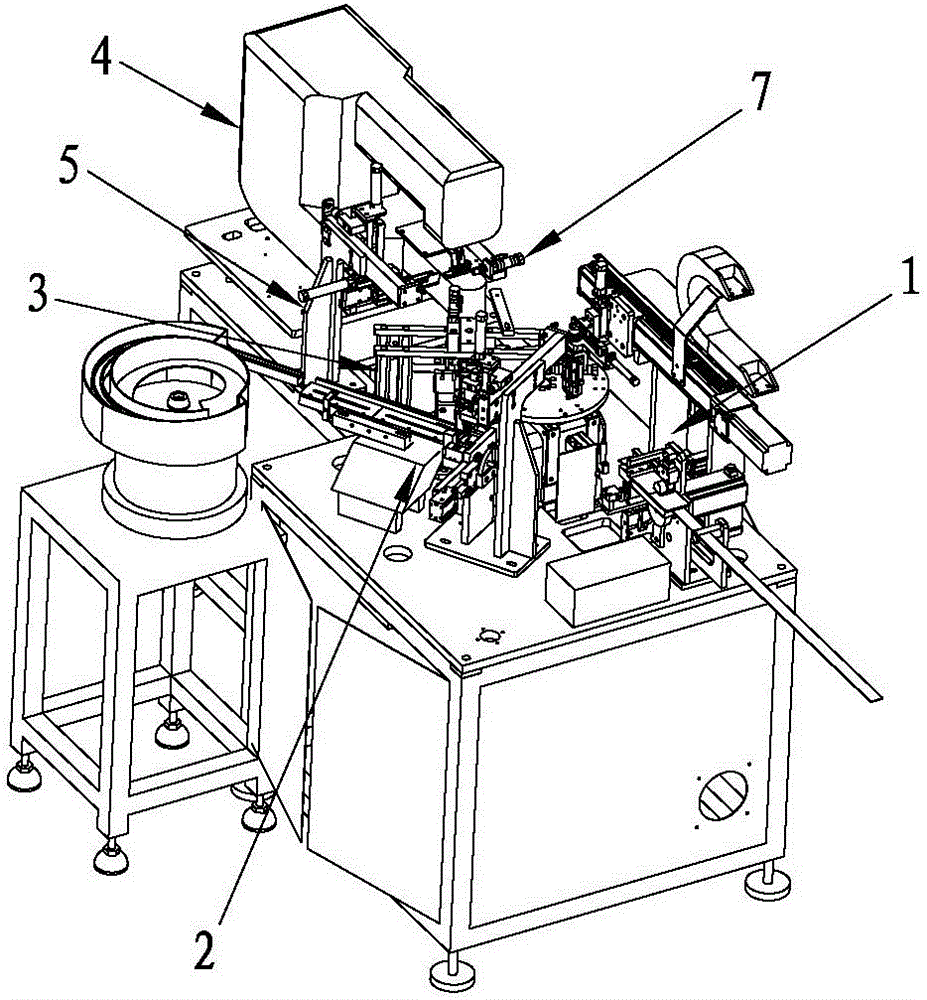

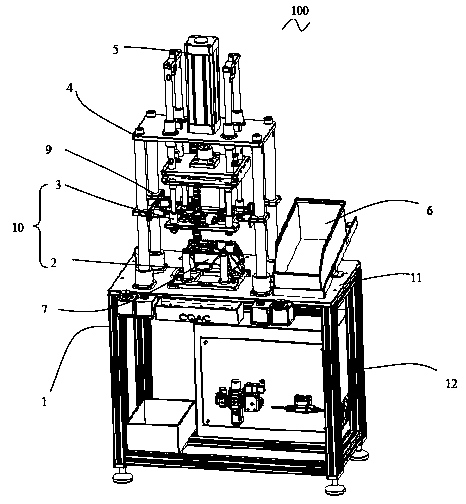

Fully-automatic rivet magnetic circuit assembly machine

ActiveCN103707055AAvoid wrong loadingAvoid leakage and other phenomenaAssembly machinesAutomatic test equipmentEngineering

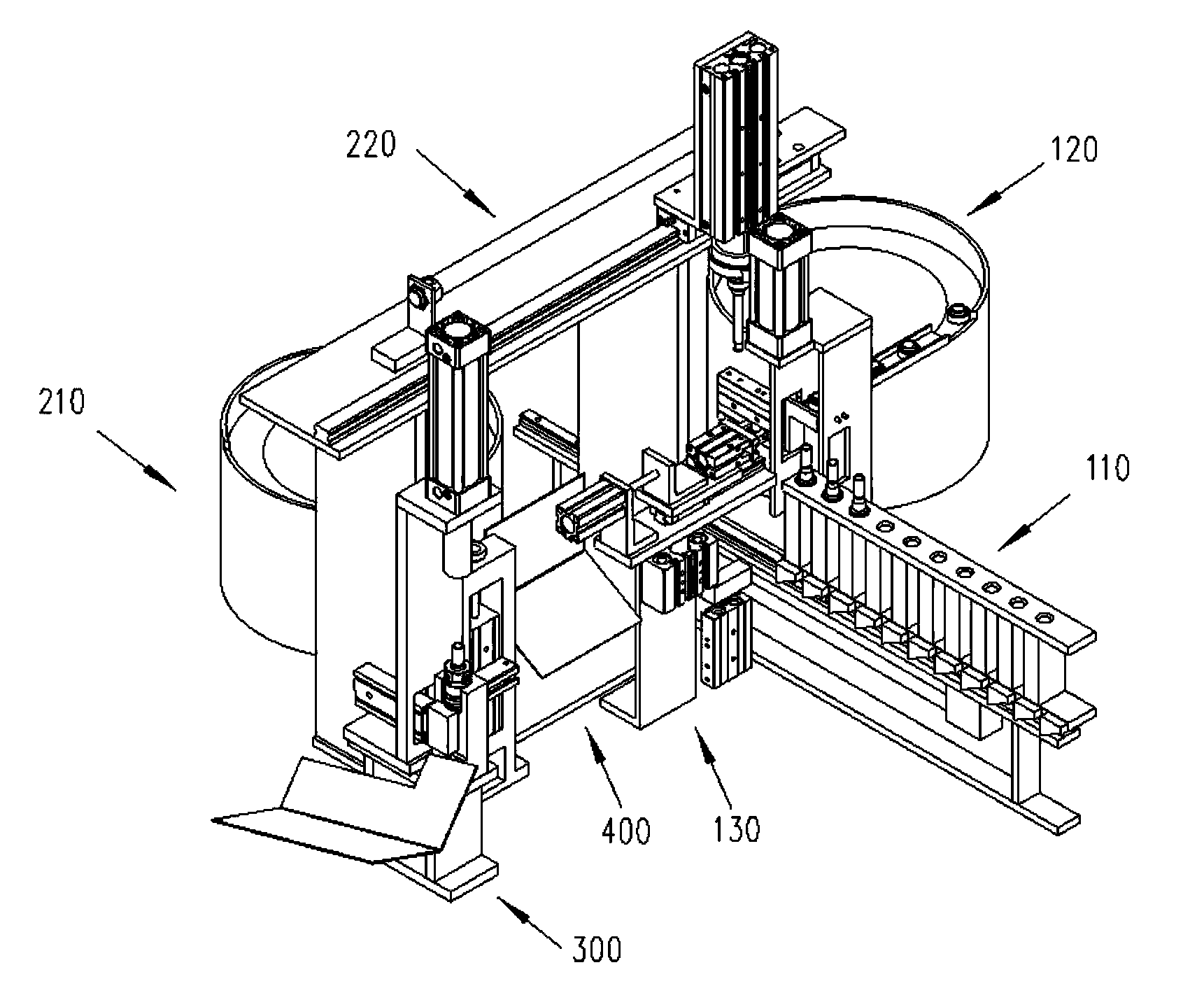

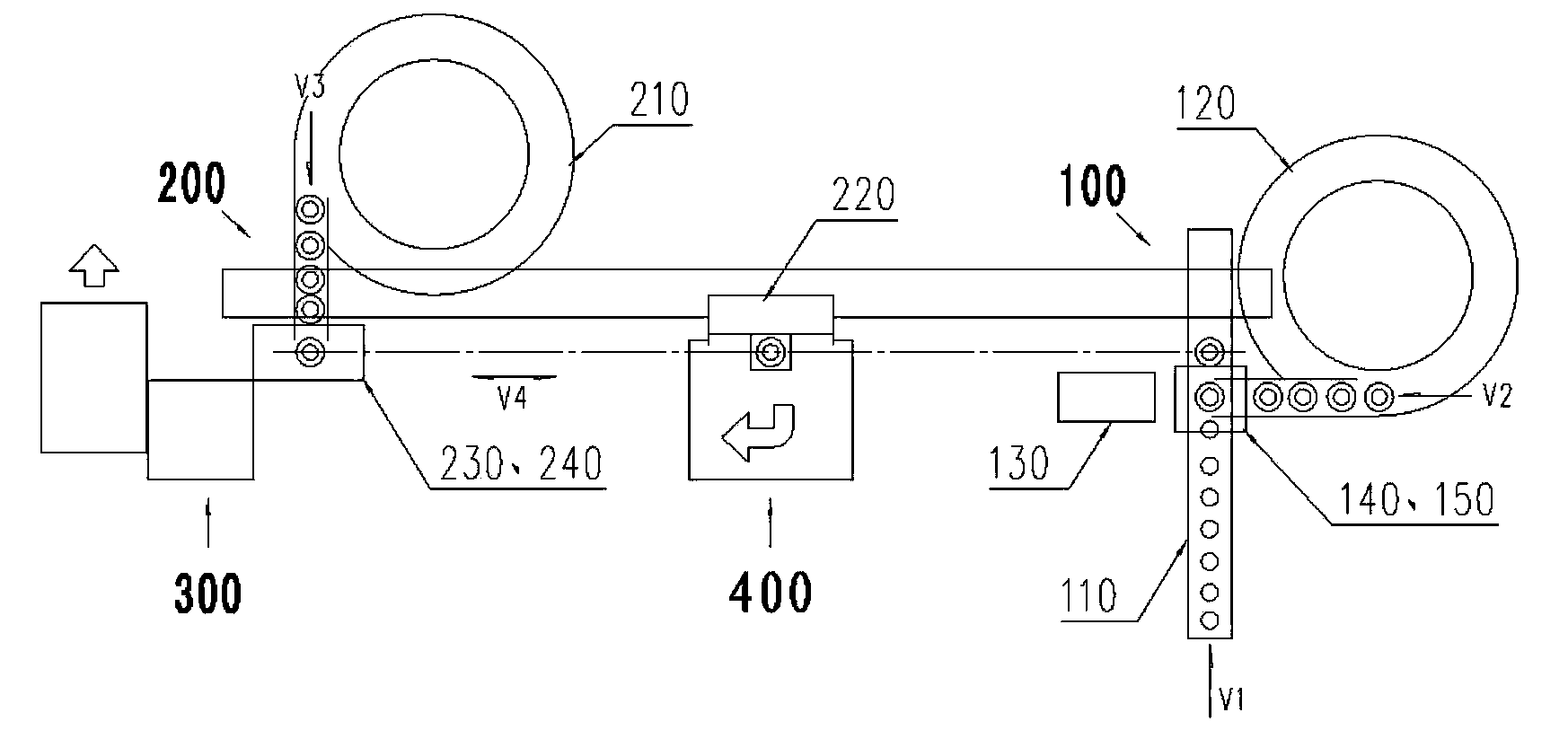

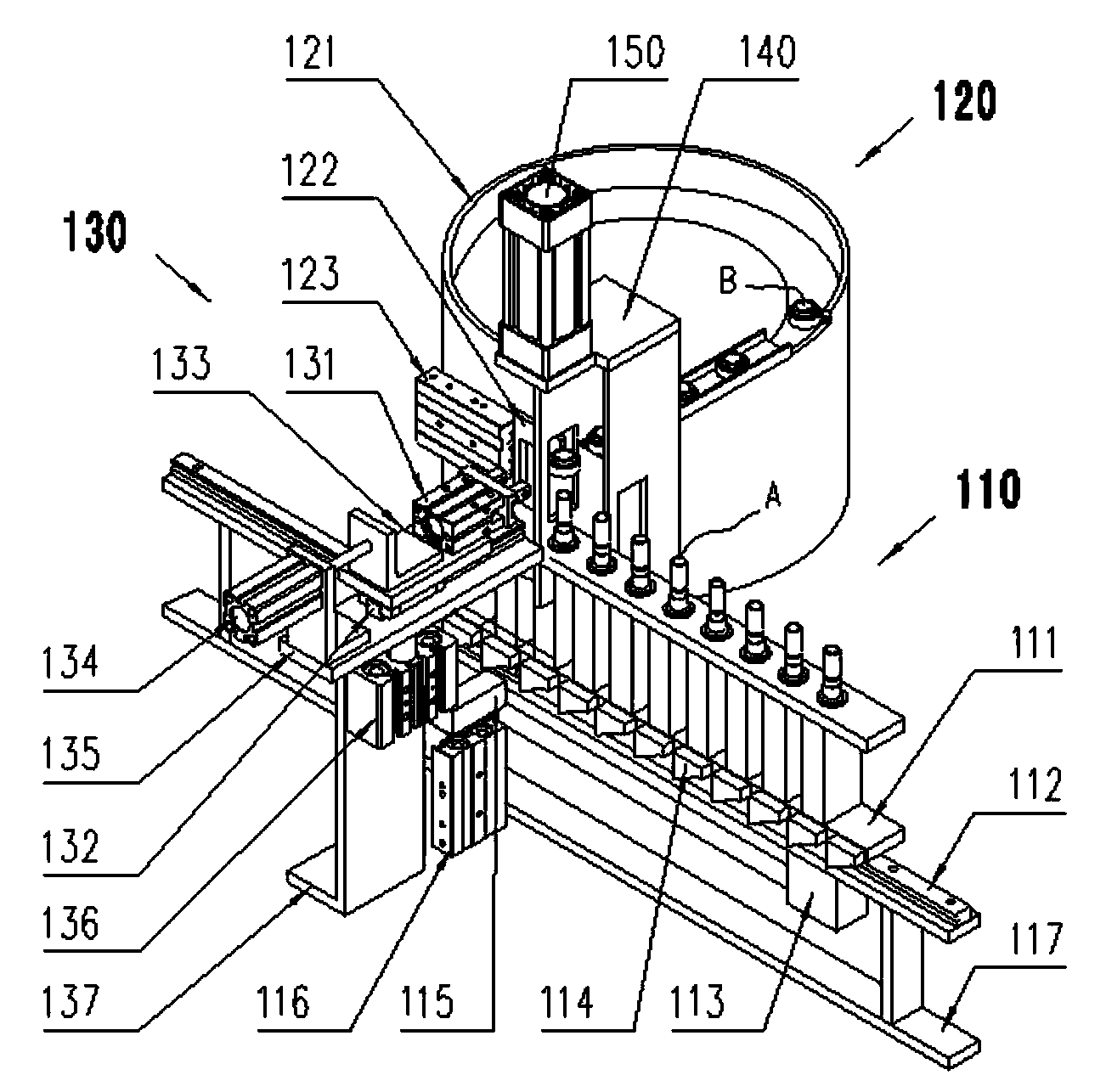

The invention relates to the technical field of automatic assembly equipment, in particular to a fully-automatic rivet magnetic circuit assembly machine comprising a table and a turntable device. The turntable device is arranged at the upper end of the table. According to rivet receiver assembly procedures, the table is sequentially provided with a rivet feeding device, a rivet correcting device, a magnet assembling device, an iron box assembling device, a PCB assembling device, a riveting machine and a discharging device in an annular form. The fully-automatic rivet magnetic assembly machine is available for assembly and processing in a fully-automatic manner, situations of wrong assembly and missing assembly are avoided, one worker can be in charge of a plurality of machines, labor investment is reduced, and labor cost is reduced; and the fully-automatic rivet magnetic assembly machine is small in size, occupation space is saved, and a limit of the size of plant space can be avoided.

Owner:东莞市昱华智创科技有限公司

Automatic dispensable lock assembling machine

The invention discloses an automatic dispensable lock assembling machine, which relates to the field of dispensable lock production equipment. The automatic dispensable lock assembling machine comprises a rack, wherein a rotary workpiece positioning disc is arranged in the middle of a working table at the upper end of the rack; a feeding mechanism, a ball loading mechanism, a spring loading mechanism, a spring detection mechanism, a rivet feeding mechanism, a rivet pre-pressing mechanism, a pressing formation mechanism and an automatic discharging stop block are sequentially and annularly arranged on the outer edge of the rotary workpiece positioning disc; the ball loading mechanism is connected with a steel ball storage bin by a steel ball feeding pipe; the spring loading mechanism is connected with a spring feeding vibration disc by a spring feeding pipe; and the rivet feeding mechanism is connected with a rivet feeding vibration disc by a rivet passing channel. The automatic dispensable lock assembling machine is reasonable in structural design and easy and convenient to use, and can automatically finish feeding and assembling procedures; and the automatic dispensable lock assembling machine is provided with a loading omission preventing detection mechanism, so that the assembling efficiency is high, the phenomena of loading mistakes and omission can be avoided, and the defective percentage of products is low.

Owner:BENGBU SECURITY SEALS

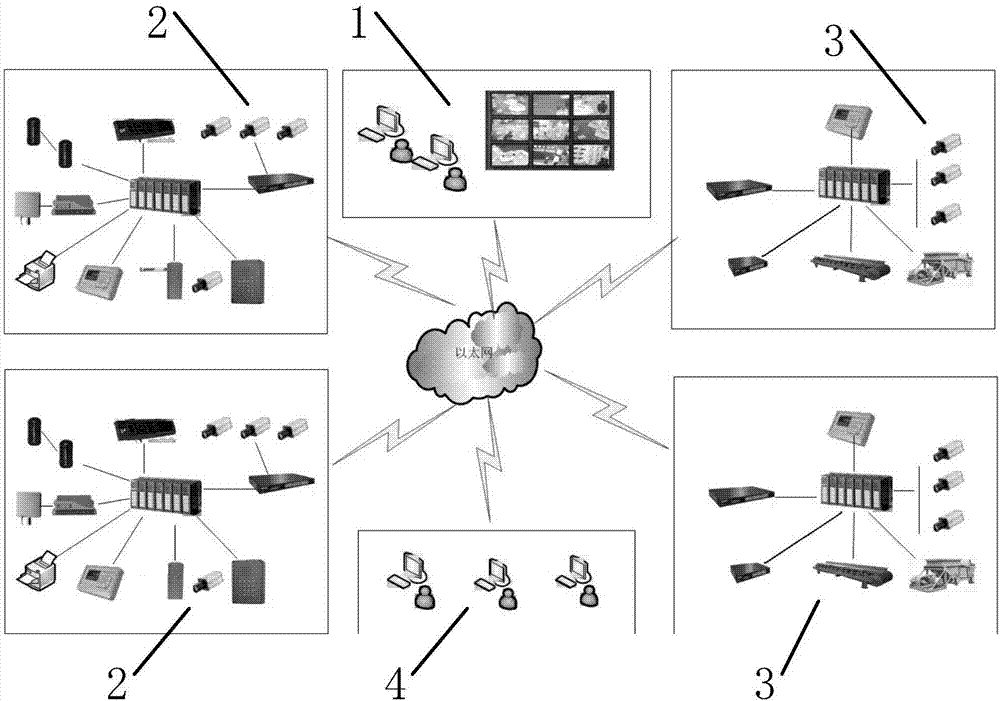

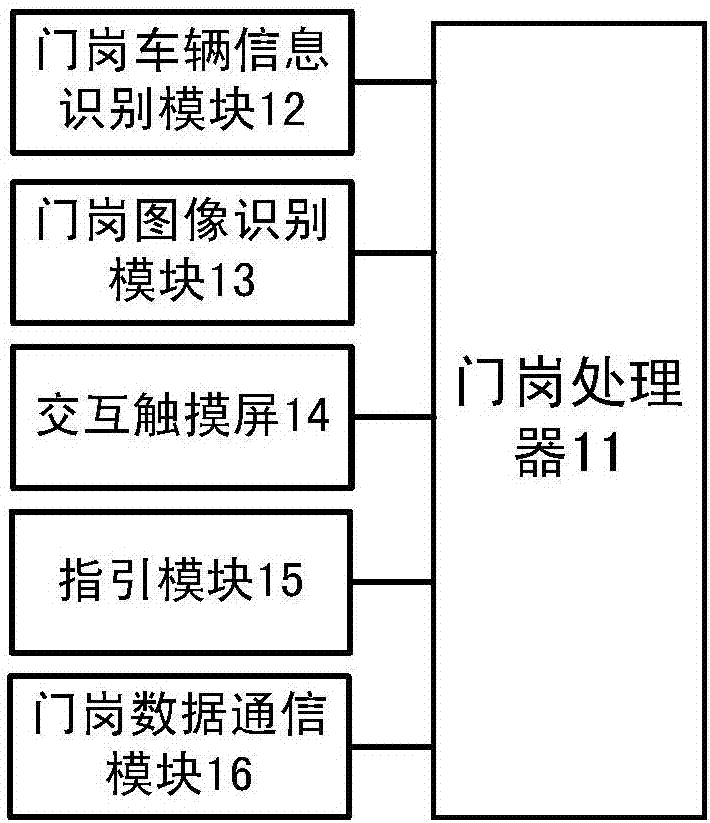

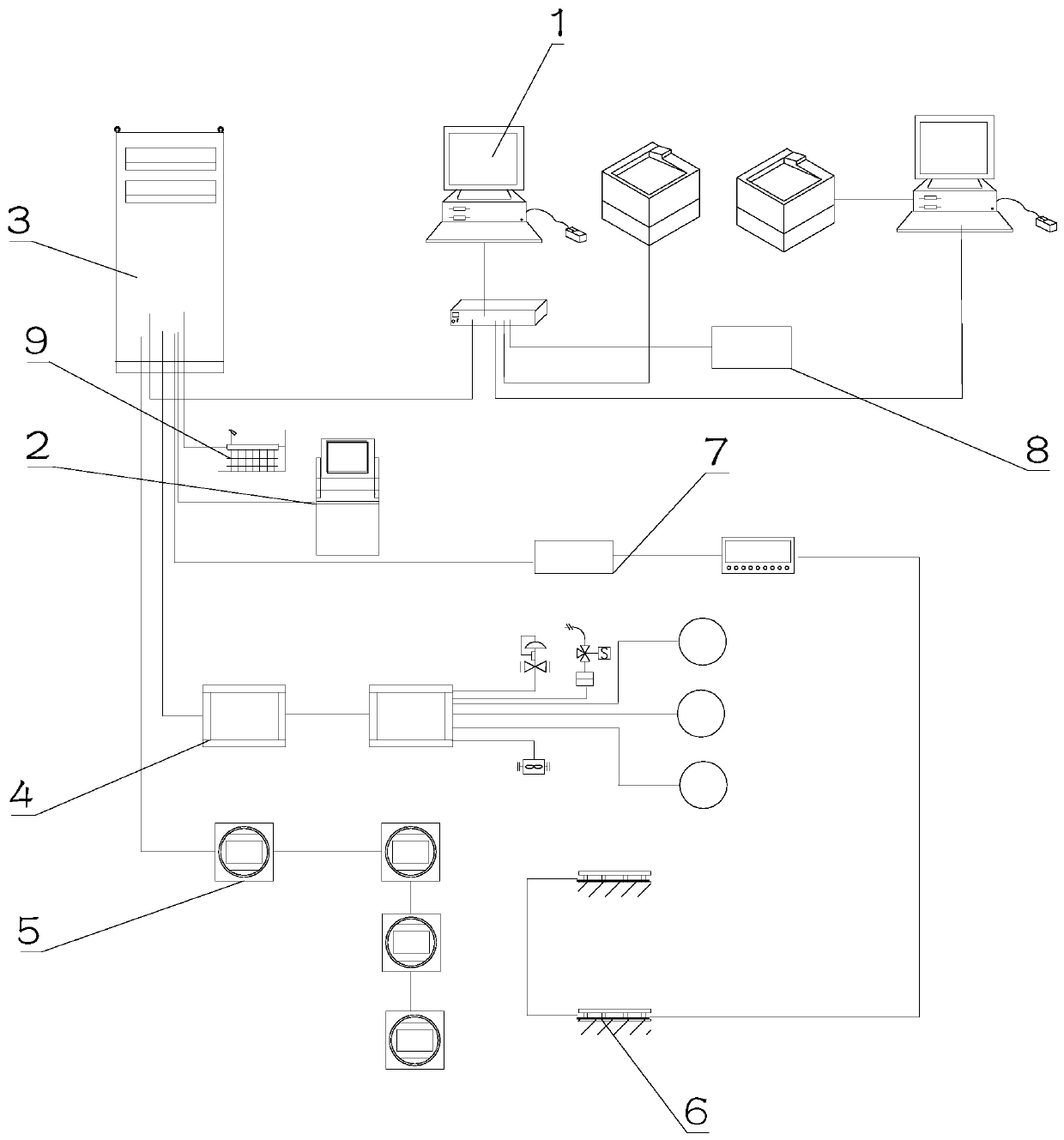

Intelligent mine transportation and sale system

ActiveCN107330802AAvoid wrong loadingPrevent wrong installation warningData processing applicationsRoad vehicles traffic controlData informationEngineering

An intelligent mine transportation and sale system provided by the present invention comprises a monitoring center, a mining area gate sentry sub-system and a weighing sub-system. A gate sentry processor receives the license plate information sent by a gate sentry vehicle information identification module and the vehicle in and out time, sends out a vehicle image information obtaining control instruction to a gate sentry image identification module to control the gate sentry image identification module to shoot the image information of the vehicles, and transmits the license plate information, the vehicle in and out time, the image information of the vehicles and the types of the transported materials to the monitoring center via a gate sentry data communication module, the weighing sub-system weighs the materials loaded by the vehicles, uploads the weights of the materials loaded by the vehicles to the monitoring center, and the monitoring center obtains the data information transmitted by the mining area gate sentry sub-system and the weight information of the materials loaded by the vehicles transmitted by the weighing sub-system, and displays the obtained data information on a monitoring screen of the monitoring center to enable the monitoring personnel to query.

Owner:SHANDONG DONGSHAN WANGLOU COAL MINE +1

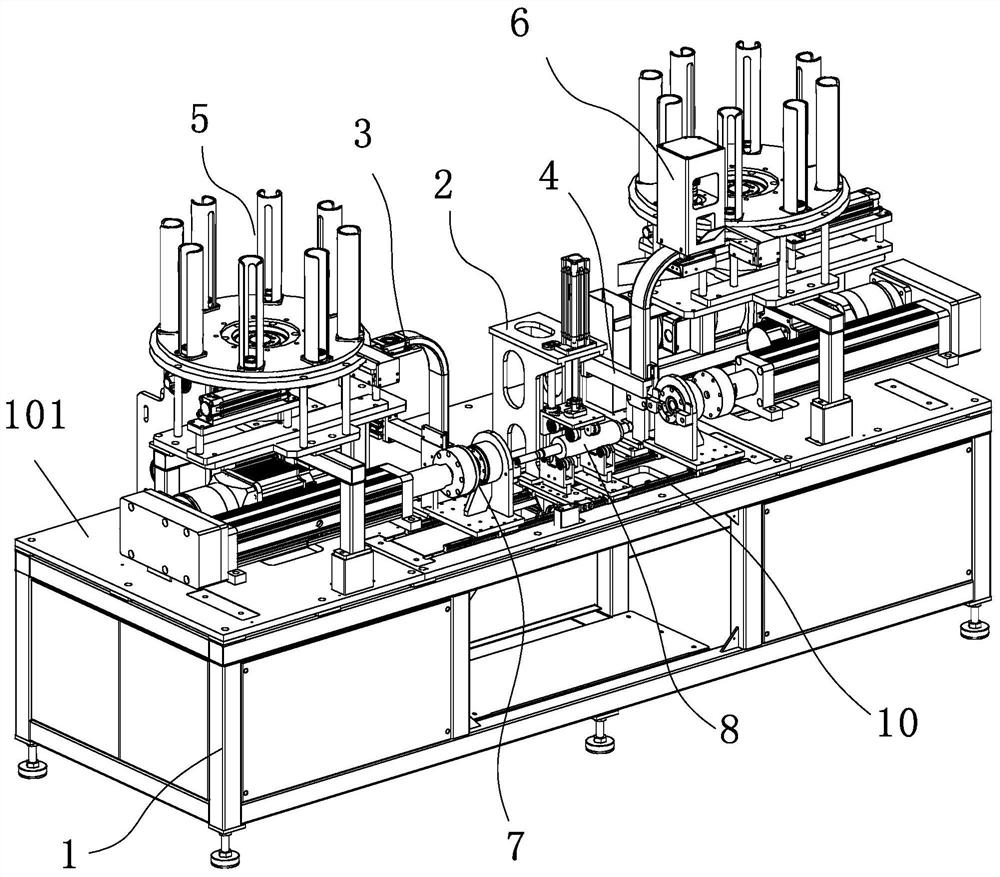

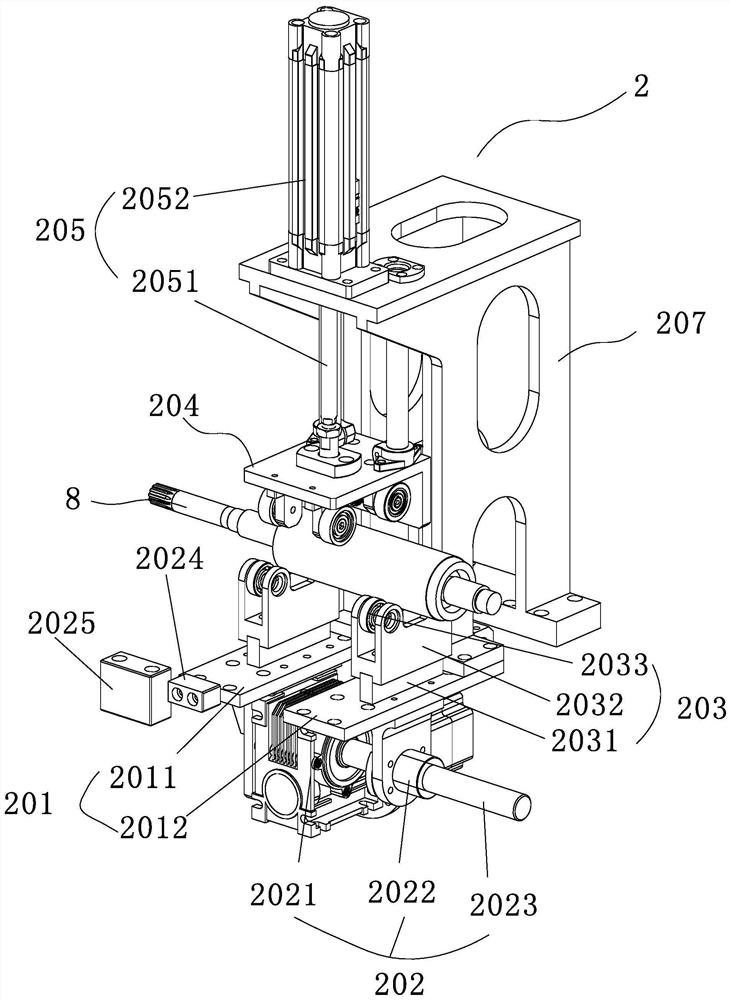

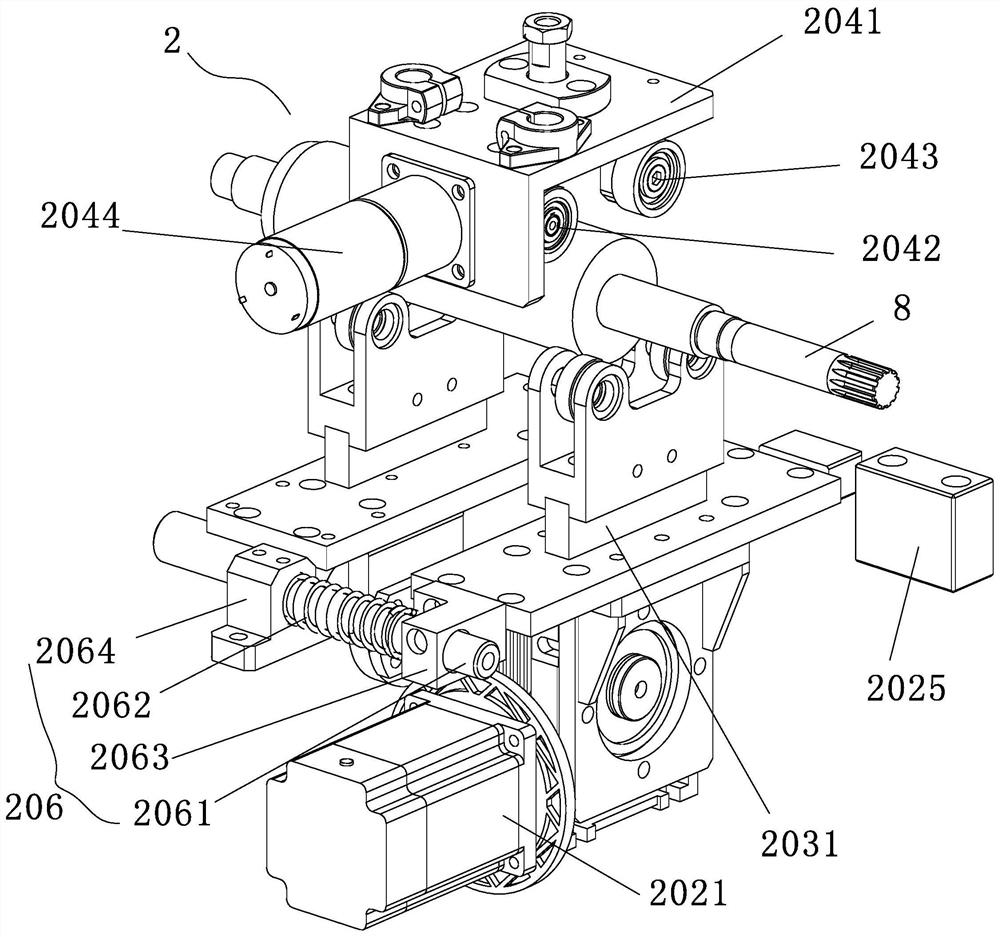

Automatic assembly line capable of continuously assembling automobile guy cable casing fittings

The invention relates to an automatic assembly production line, in particular to an automatic assembly line capable of continuously assembling automobile guy cable casing fittings. The automatic assembly line comprises a first feeding system, a second feeding system, a third feeding system, first mechanical hands, second mechanical hands and a locking mechanism, wherein three automatic assembly sections and an auxiliary assembly section are formed through sequential combination of various equipment; workpieces are transferred by a clamping mechanical arm between the first feeding system and the second feeding system, and are transferred by chuck mechanical hands between the first assembly section and the second assembly section as well as the auxiliary assembly section; each combined equipment is provided with an anti-mistake and anti-leakage device. The automatic assembly line has the beneficial effects that the traditional multiple working procedures of manual assembly are integrally combined, and mechanical equipment is used for automatic assembly, so that the manpower resource is saved, the labor intensity is reduced, the working efficiency is improved, misloading and neglected loading of spare parts because of manual assembly are prevented, the product yield is improved, and the product quality is effectively controlled.

Owner:SHANGHAI WR CONTROLS CO LTD

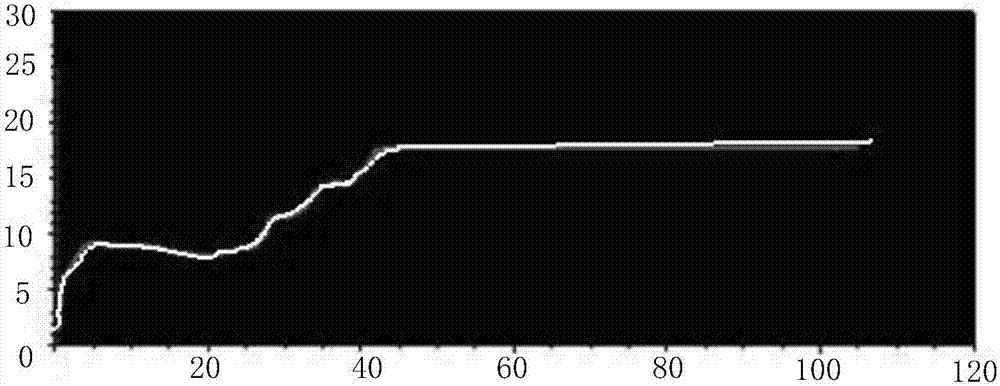

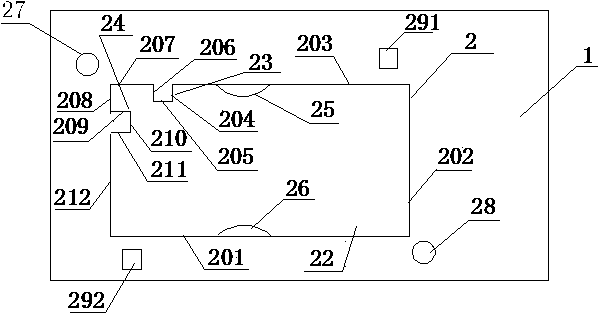

Intelligent temperature-control cooling module for automobile and control method thereof

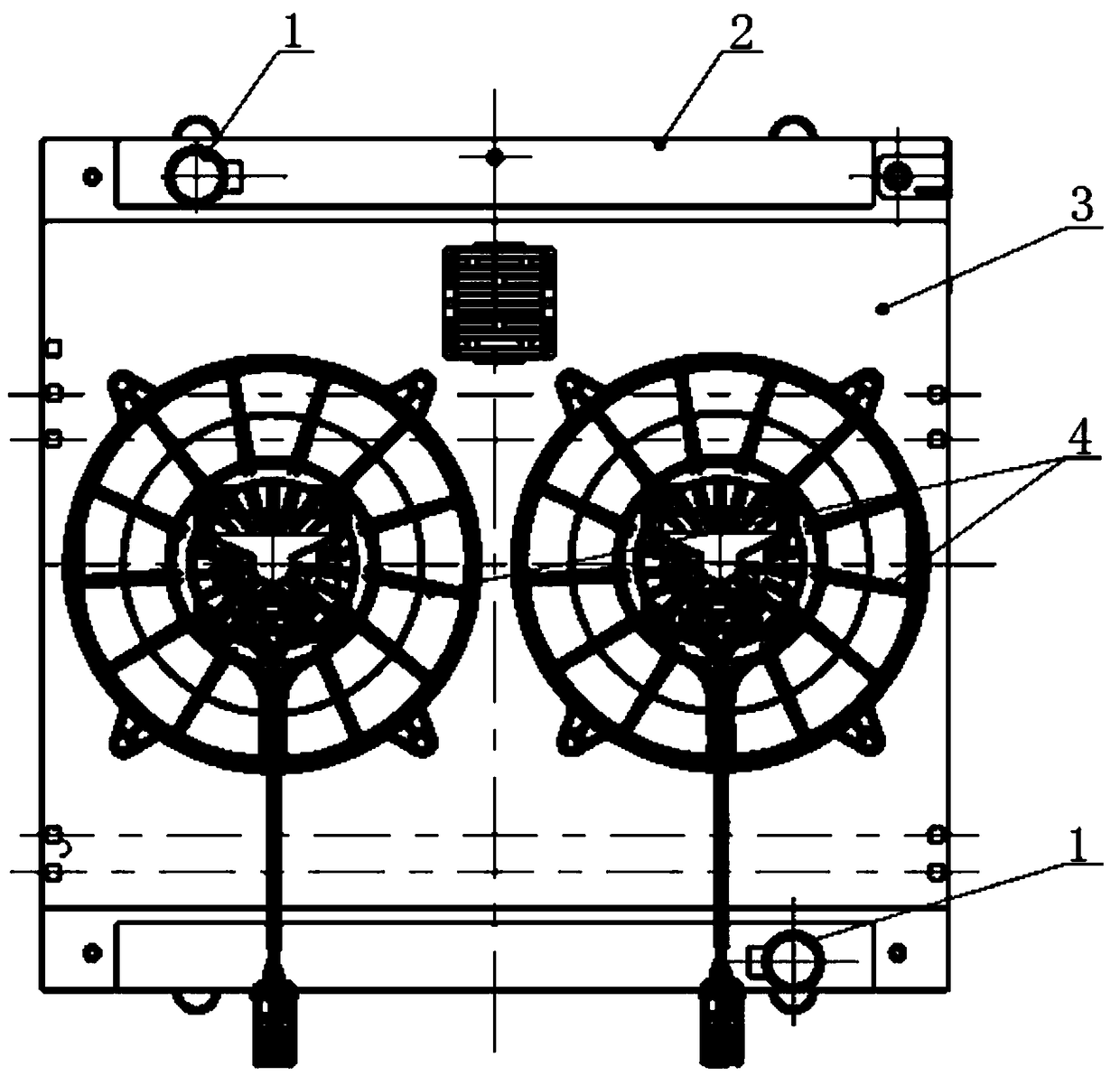

PendingCN109367386AImprove the wind effectImproved thermal performanceComponent optimizationPropulsion coolingCooling water temperatureEngineering

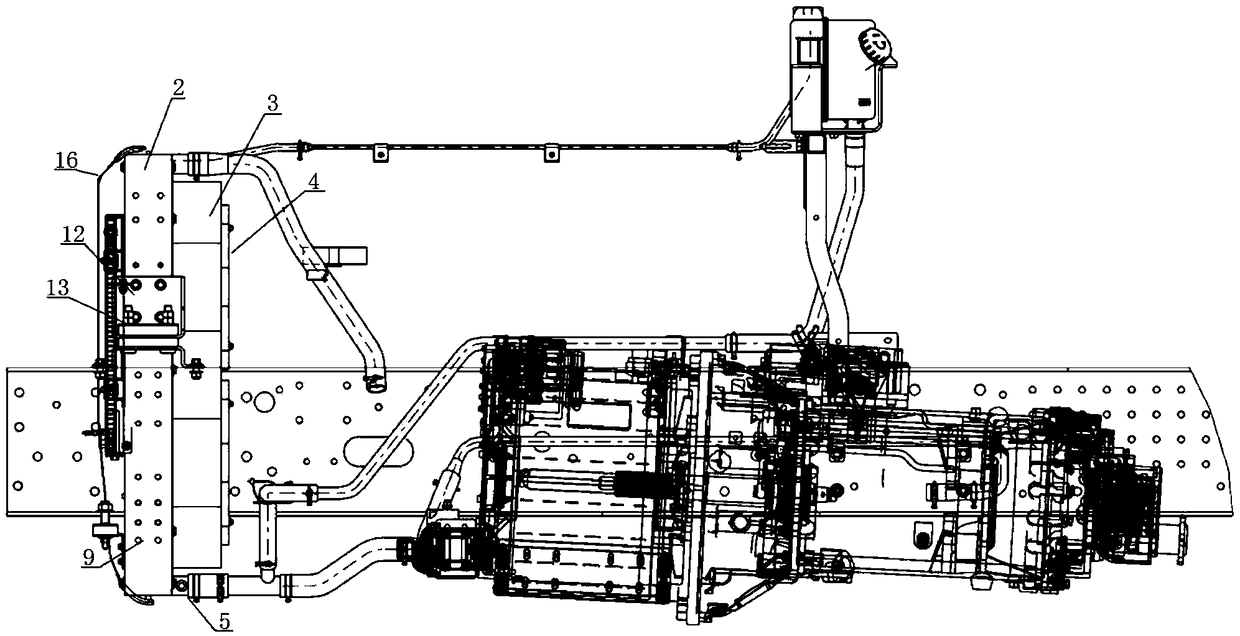

The invention relates to an intelligent temperature-control cooling module for an automobile and a control method thereof. The module comprises a heat radiator (2), an air protection cover (3), an electrical fan (4) and a control unit (6), wherein the electrical fan (4) with an inwards concave air suction type structure is arranged in an electrical fan installation ort seat (16) on the air protection cover (3); the heat radiator (2) and the electrical fan (4) are connected with the control unit (6); the control unit (6) is connected with a vesical control unit and a vehicle dashboard; and a coolant temperature sensor (8) at a water inlet / outlet of the heat radiator (2) is connected with the control unit (6). According to the method, the real-time changes of cooling water temperature and the rotary speed of the electrical fan (4) are controlled accurately by adopting pulse-width modulation (PWM), and the rotary speed and the cooling intensity of the electrical fan (4) are adjusted and stabilized in real time according to the temperature of the coolant temperature sensor (8) and the feedback of the electrical fan (4), so that accurate temperature control and demand-based cooling arearealized, the aims of saving energy and reducing consumption are achieved, and the comfort in riding is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

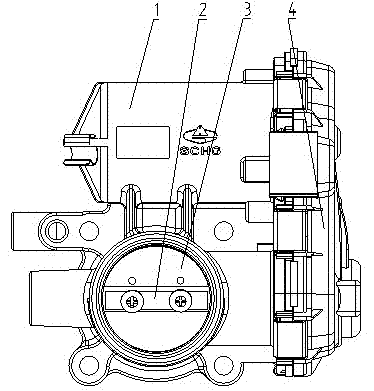

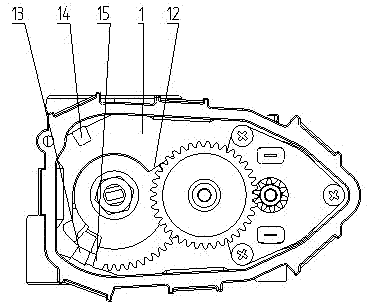

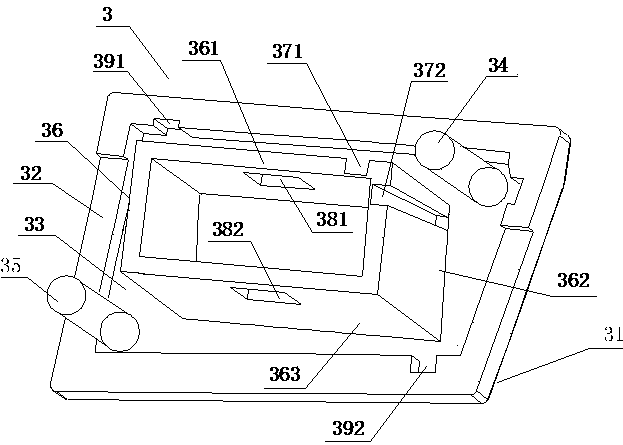

Electronic throttle body

InactiveCN102392742AExtend your lifeImprove securityEngine controllersMachines/enginesElectric machineGear wheel

The invention discloses an electronic throttle body which comprises a throttle body (1), a throttle shaft (2), a throttle plate (3), a position sensor (4) and a DC (direct current) motor, wherein a motor gear arranged on the DC motor is meshed with a middle gear arranged on the throttle body (1), the middle gear is meshed with a sector gear arranged on the throttle shaft (2), a limiting mechanism is arranged on the throttle body (1) and the sector gear, and a torsional spring is connected with the throttle body and the sector gear; when the DC motor does not output power, the throttle plate (3) is located at a high-idling position under the torsional action of the torsional spring; and the torsional spring is composed of a left torsional spring and a right torsional spring which are connected by a middle end. The electronic throttle body disclosed by the invention has the advantages that when one of the two torsional springs fails, the other torsional spring still can control the throttle plate to reset to the high-idling position, thereby improving the security.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

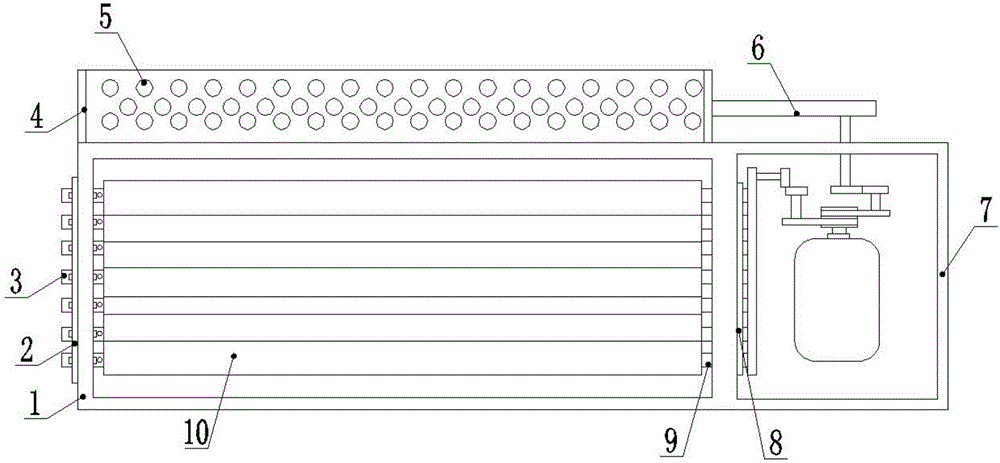

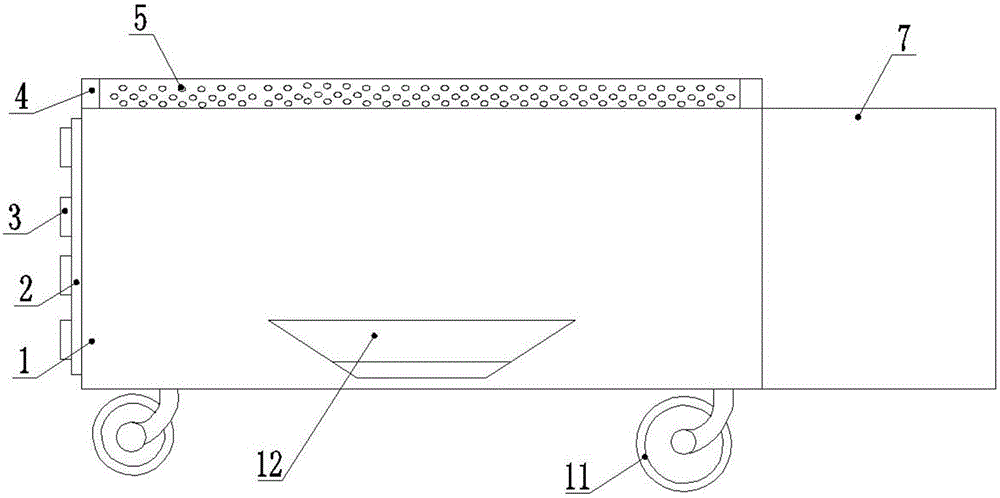

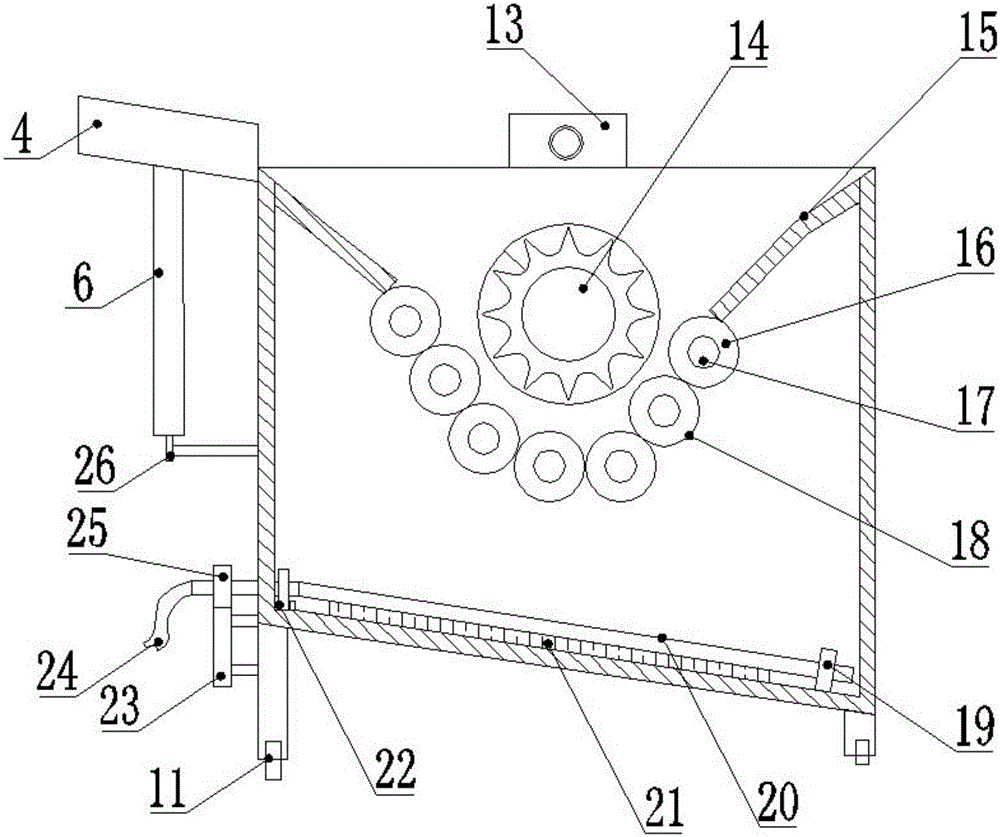

Walnut cleaning machine

The invention relates to a walnut cleaning machine. The walnut cleaning machine comprises a cleaning box and a transmission box, a fixation device is arranged on the opposite side walls of the cleaning box, the fixation device comprises first bearing seats and second bearing seats, a first bearing is installed in each first bearing seat, a sliding key is fixed on the inner wall of each first bearing, a key groove is formed in each first rotating shaft in the axial direction, and the sliding keys are installed in the corresponding key grooves in a sliding mode; a first core hole is formed in one end of each first rotating shaft, a second rotating shaft is rotatably installed in each second bearing seat, a second core hole is formed in one end of each second rotating shaft, and the first core holes and the second core holes are all regular polygon holes; a brush roller is installed in each first core hole and the corresponding second core hole; a cleaning device is arranged on the lower sides of the brush rollers, a locking device is arranged between each first rotating shaft and the corresponding roller body, and a screening device is arranged in the cleaning box. According to the walnut cleaning machine, replacing of brush rollers is easy, the assembling precision of a machine is not affected, and the cleaning effect on walnuts is good.

Owner:李志雄

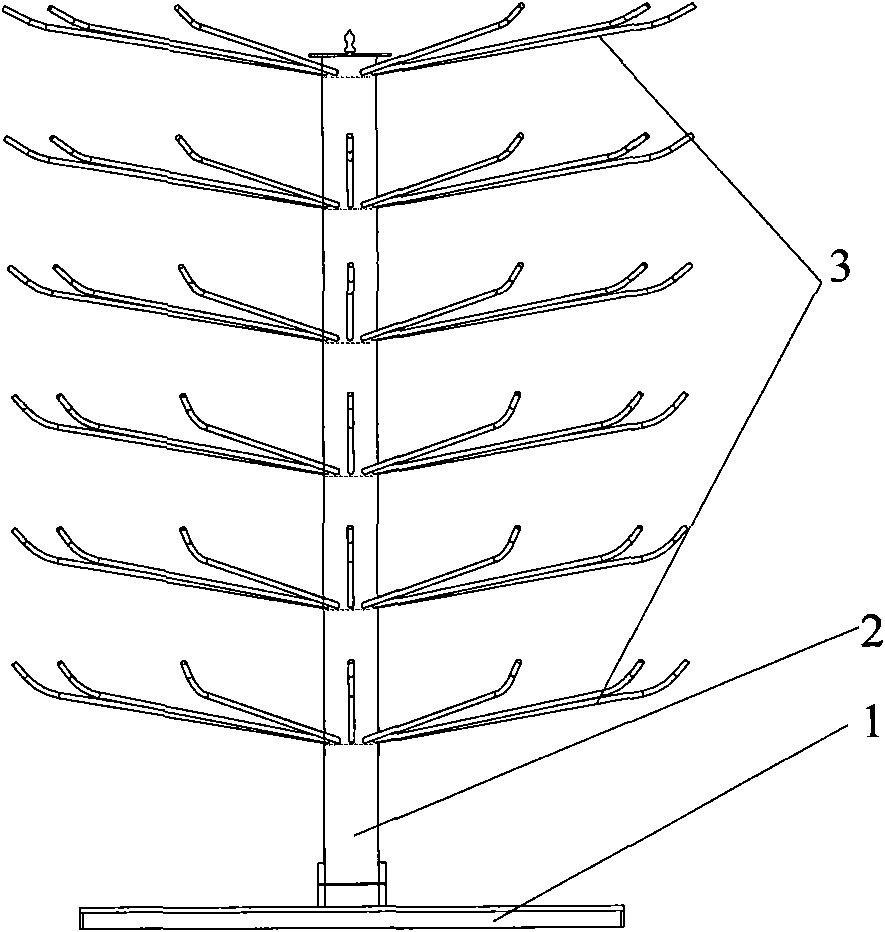

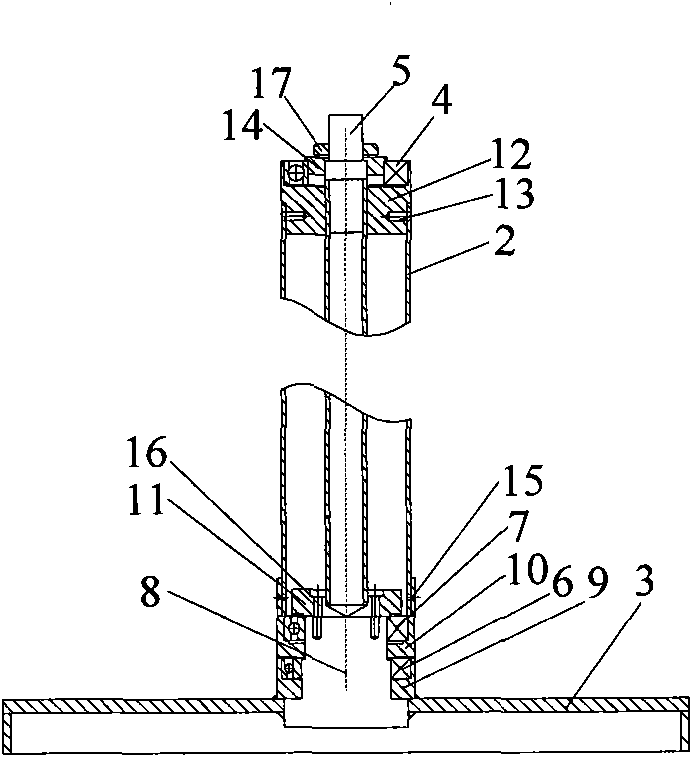

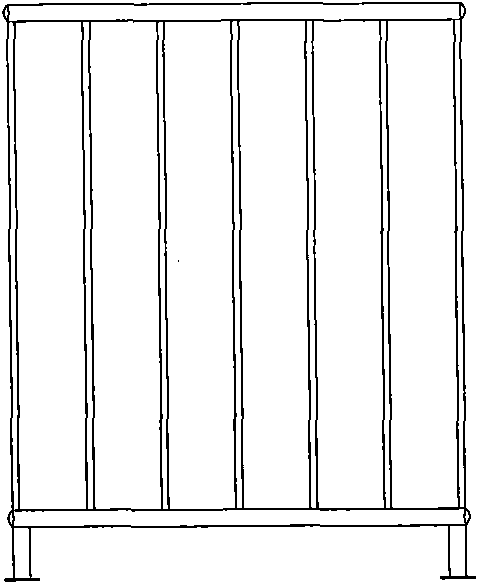

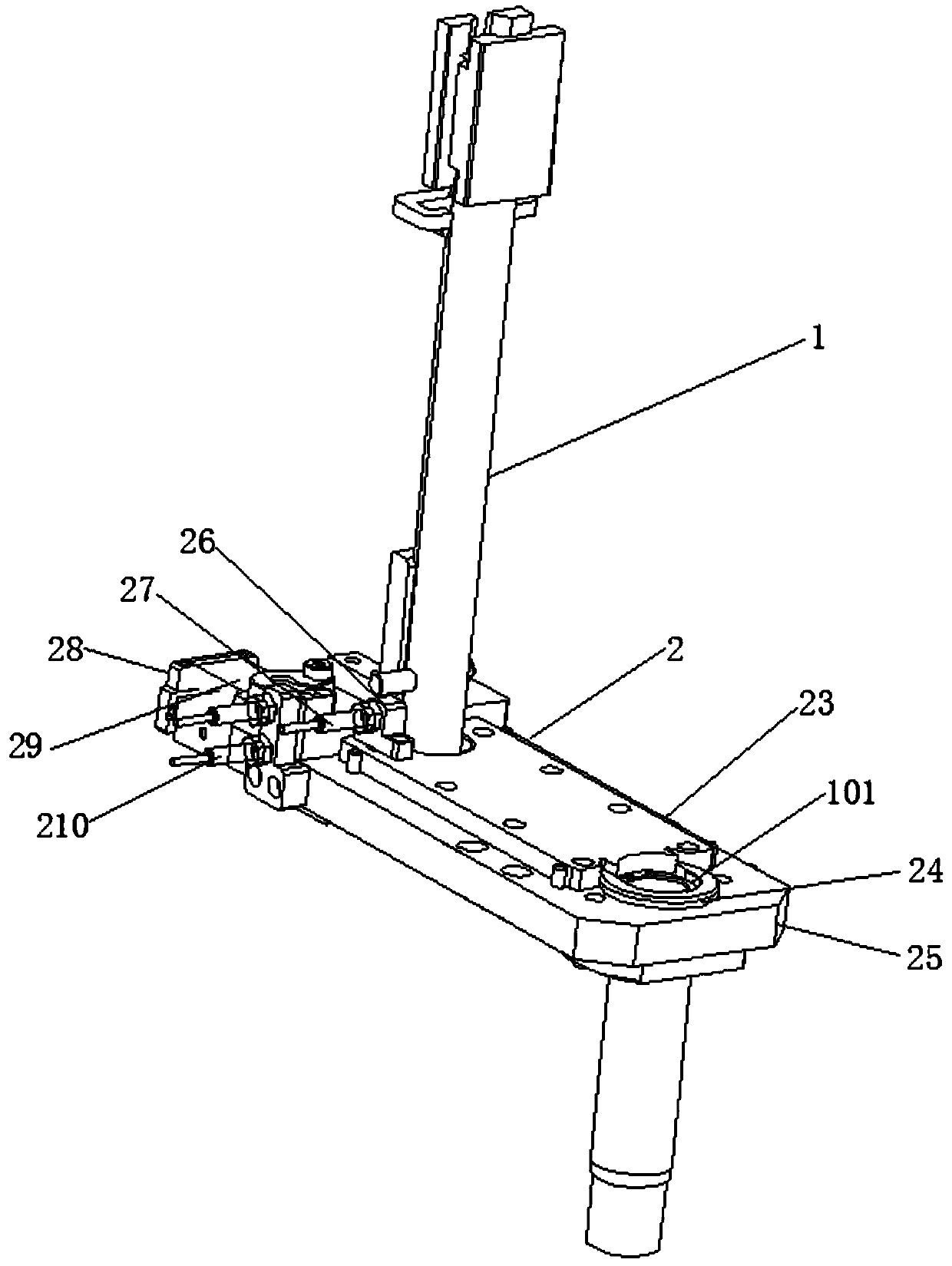

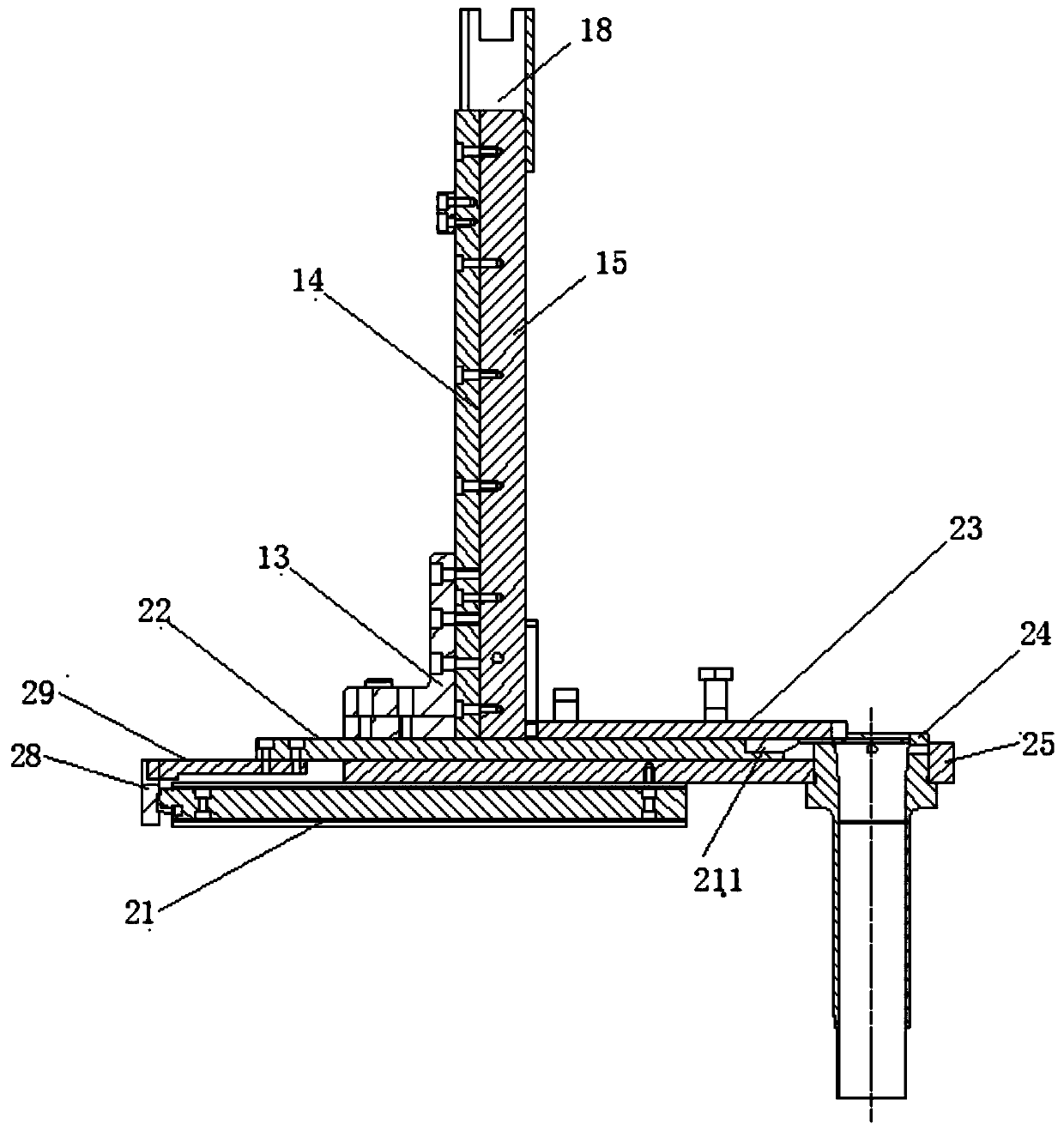

Assistive device tool for placing working tools

The invention discloses an assistive device for placing working tools, comprising a base and a column spinner, wherein the column spinner is provided with a plurality of hanging arms for hanging the working tools. The assistive device is characterized in that the base is fixedly provided with a mandrel movably sheathed in the column spinner, and the column spinner can rotate relative to the base. The six layer of hanging arms for hanging the working tools are formed, wherein drilled holes on each layer are welded with twelve hanging arms. Because of the adoption of the design of the annular tree structure, more working tools are contained in a limited space. A movable swiveling mechanism is adopted, and employees easily classify the working tools and conveniently fetch the working tools when various types of vehicle are produced in a paint production line, thereby avoiding false and neglected assembly for employees. In addition, a safety guard rail is adopted, so that no potential safety hazard exists in the use process and enough safety is ensured. The assistive device is made of common materials and has the advantages of simple manufacture process, good durability and lower cost.

Owner:CHERY AUTOMOBILE CO LTD

Petrochemical engineering intelligent loading and unloading vehicle system and using method

InactiveCN110288748AExact searchReduce waiting timeLiquid transferring devicesIndividual entry/exit registersElectricityManagement unit

The invention discloses a petrochemical engineering intelligent loading and unloading vehicle system, and relates to the technical field of petrochemical engineering equipment. The system comprises a control unit, an information input end, an access control unit, an information identification terminal, a vehicle queuing management unit, a weighing unit and a goods transfer unit; and the access control unit, the information identification terminal, the vehicle queuing management unit, the weighing unit and the goods transfer unit are all electrically connected with the control unit. By using the system, the goods transfer efficiency is improved, and the waiting time of a truck is shortened; IC card data and order data are in one-to-one correspondence, wrong loading, mixed loading, excessive loading and insufficient loading are avoided, and the accuracy of loading and unloading operation is improved.

Owner:上海贵晋新能源科技有限公司

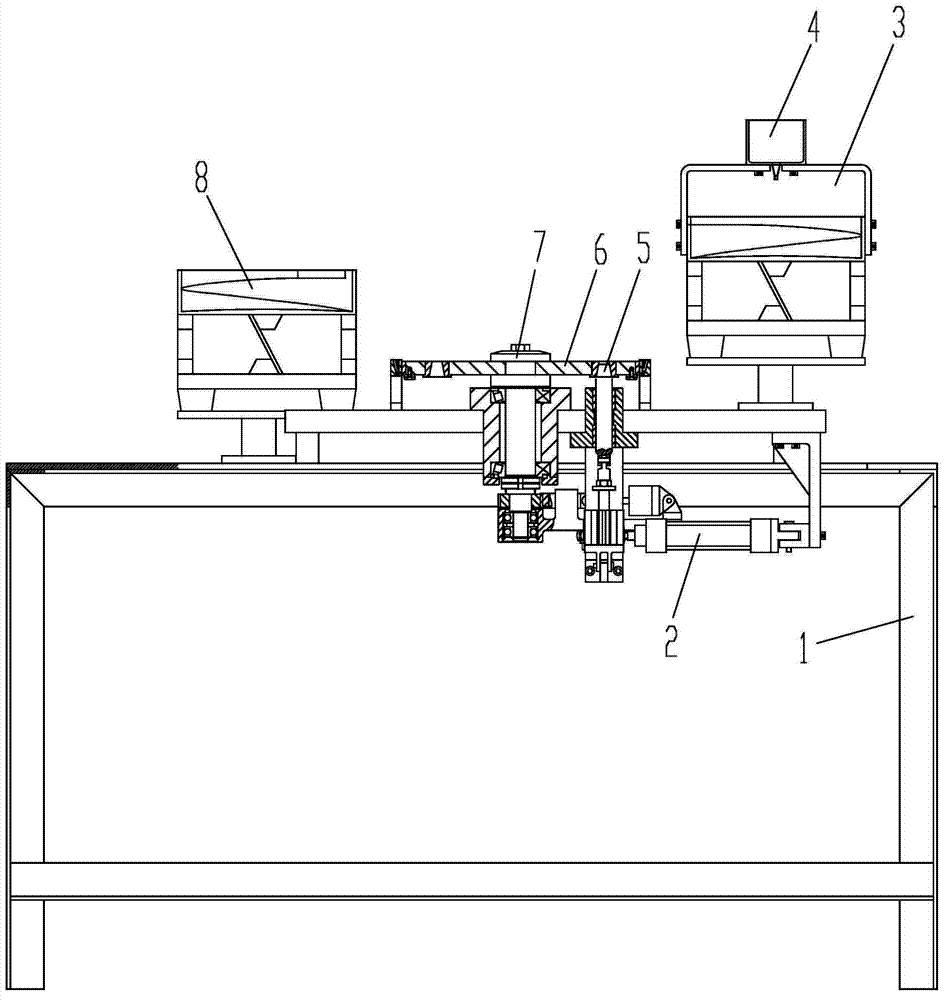

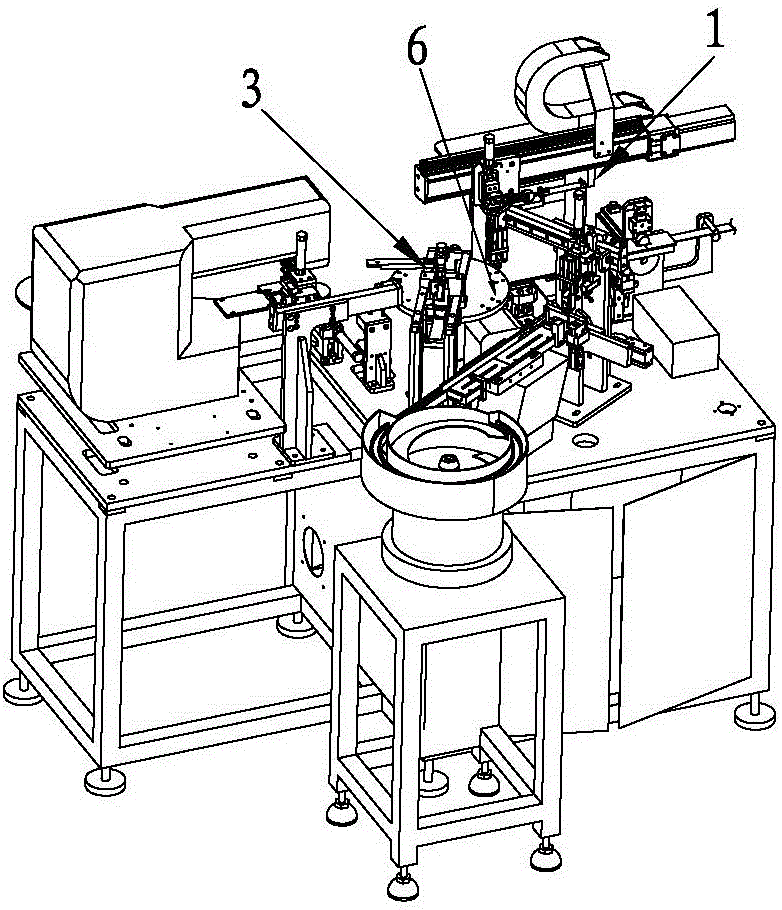

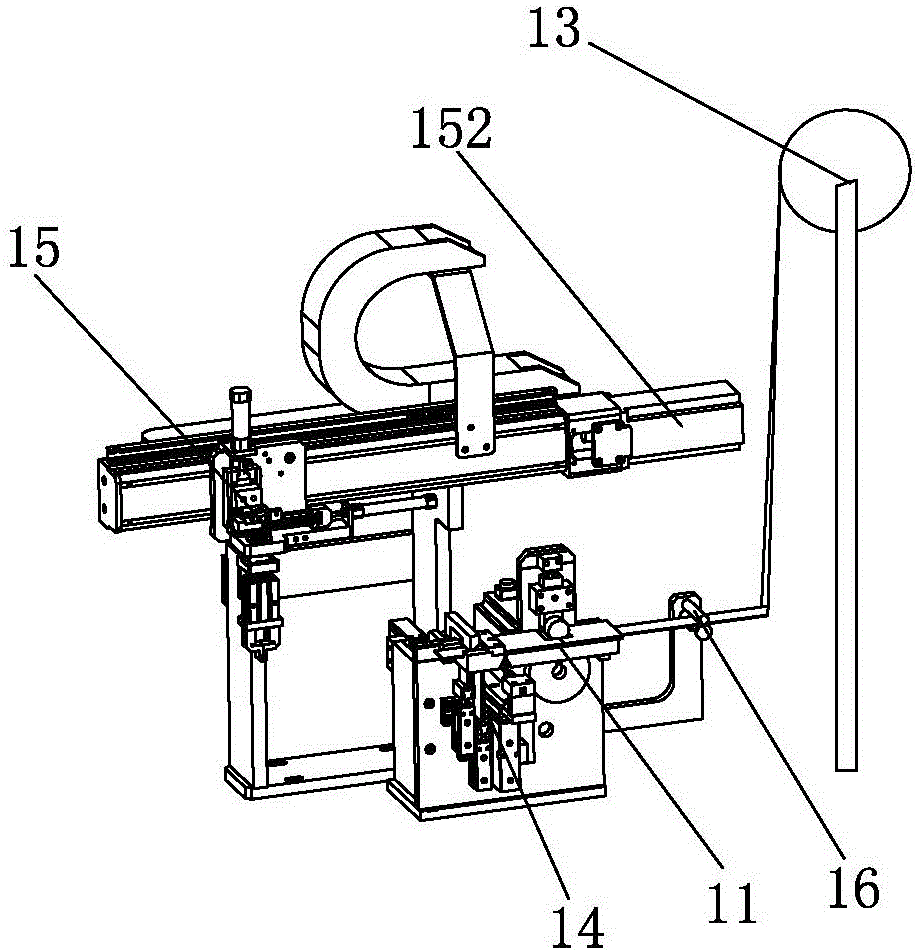

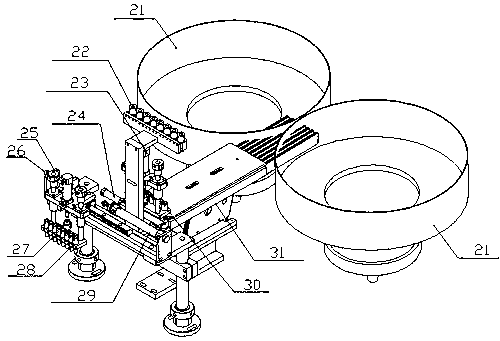

Fastener tape threading automatic assembly machine

ActiveCN106307927AAvoid wrong loadingAvoid leakage and other phenomenaOther accessoriesEngineeringAssembly machine

The invention relates to the technical field of automatic equipment, particularly a fastener tape threading automatic assembly machine which comprises a machine table and a rotary table device, wherein the rotary table device is arranged on the upper end of the machine table; and the periphery of the rotary table device is sequentially provided with a fabric tape charging device, a fastener charging device, a fastener binding device, a knotting vehicle and a feeder for loading and unloading the material for the knotting vehicle. The fastener tape threading automatic assembly machine performs assembly processing automatically, thereby avoiding the phenomena of mistaken assembly, omitted assembly and the like; and thus, one worker can take charge of multiple facilities, thereby reducing the labor investment and lowering the labor cost. The fastener tape threading automatic assembly machine has the advantages of small facility size and arrangement space saving.

Owner:广东省春藤实业有限公司

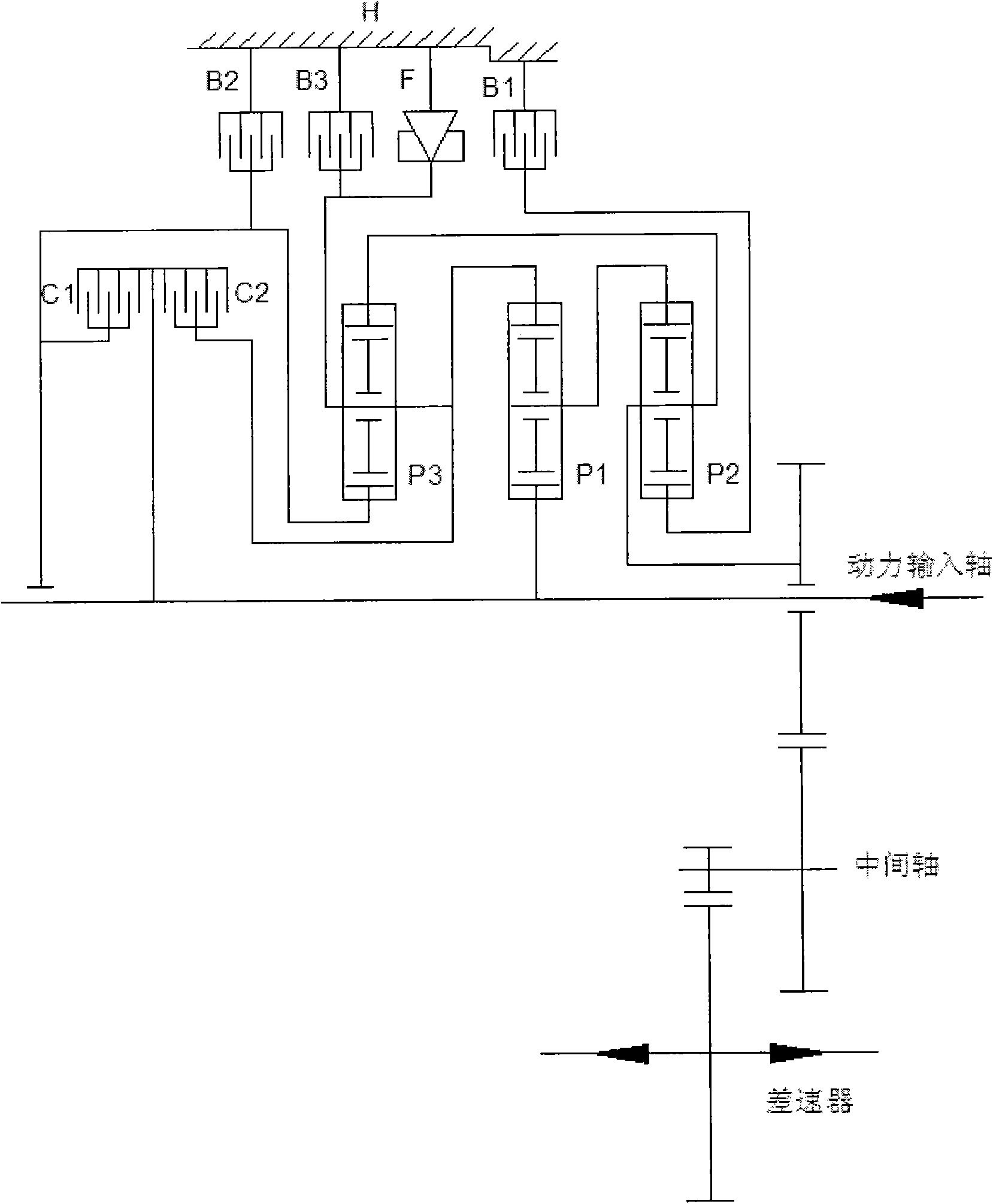

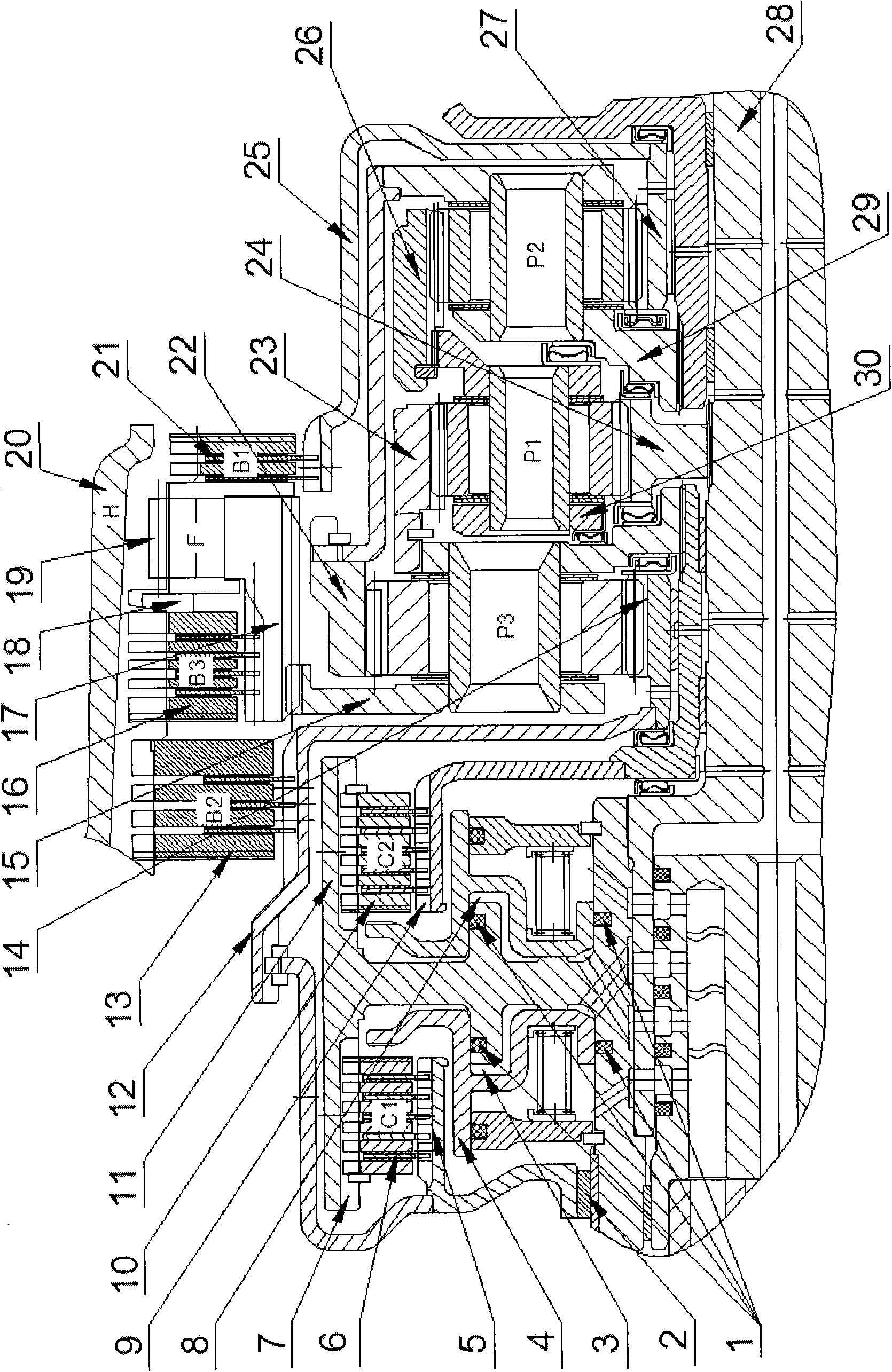

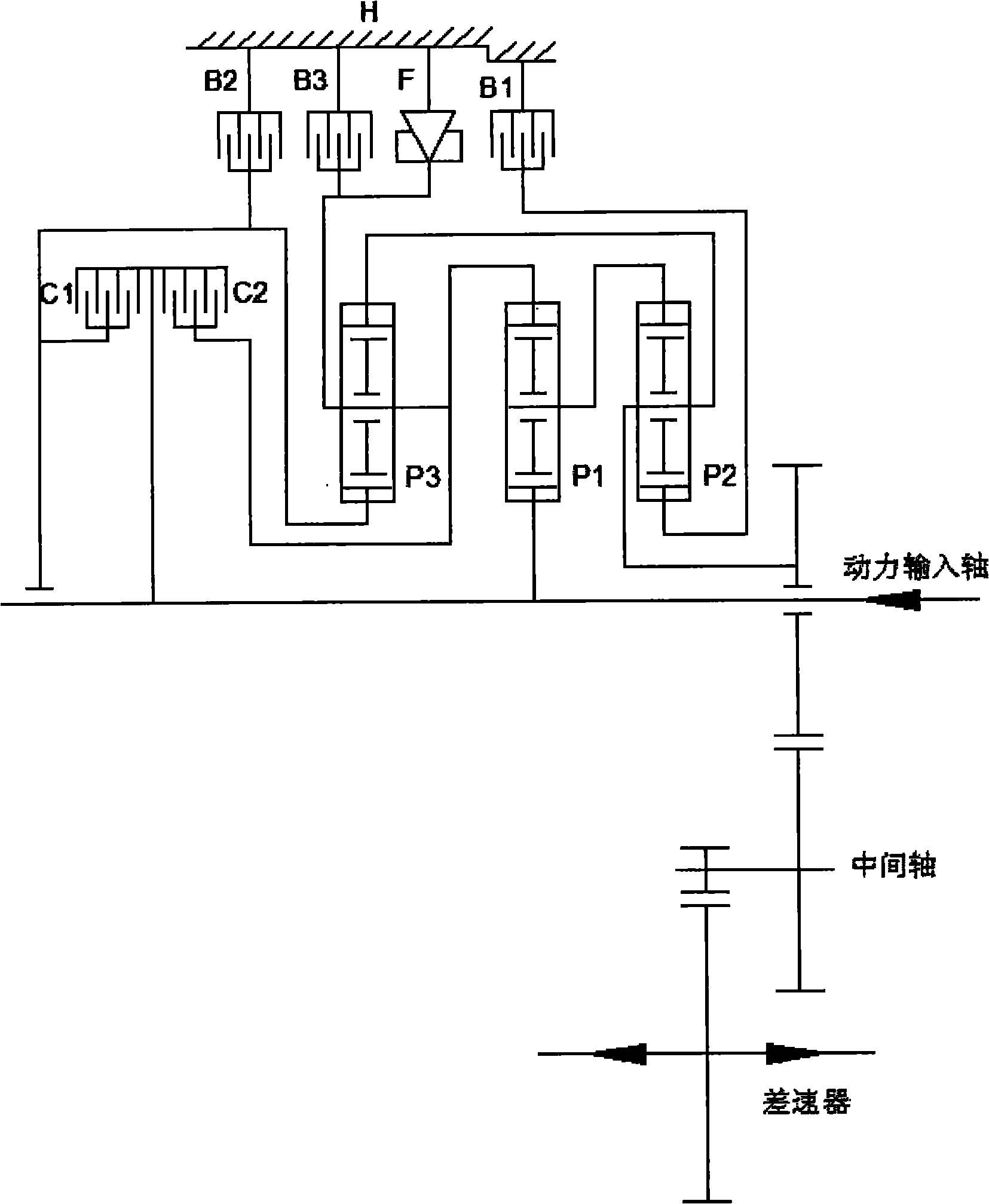

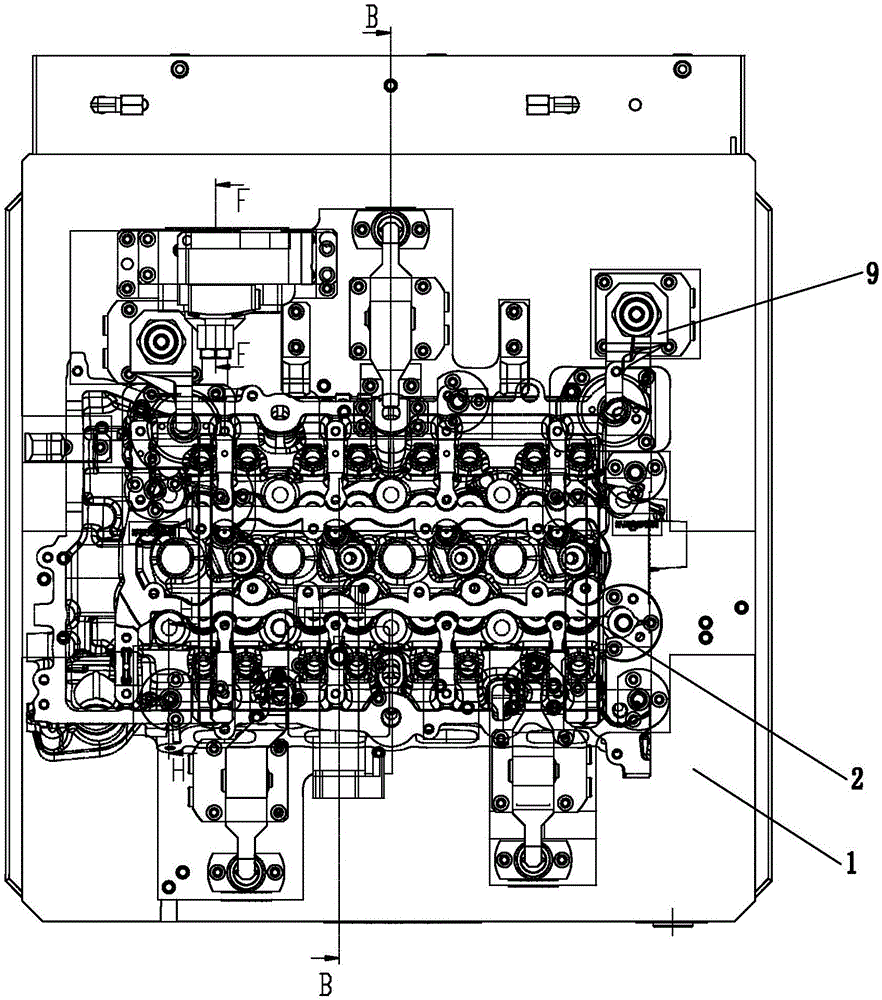

Arrangement of 6AT power drive system

InactiveCN101832371ACompact structureShort axial distanceToothed gearingsGear wheelCar manufacturing

The invention discloses arrangement of a 6AT power drive system, belonging to the field of vehicle manufacture. A shell, a power input shaft, a speed shifting mechanism and a gear shifting part are provided, wherein the speed shifting mechanism comprises an input planetary gear set, an output planetary gear set and a counteraction planetary gear set; the gear shifting part comprises a first clutch, a second clutch, a one-way clutch, a first brake, a second brake and a third brake; the first clutch and the second clutch are axially and symmetrically arranged at the rear end of the speed shifting mechanism in parallel; and the one-way clutch, the first brake, the second brake and the third brake are compactly arranged outside the speed shifting mechanism. The technical scheme has the advantages of ensuring compact structure and short axial distance of the speed shifting mechanism by compactly arranging the gear shifting part around the speed shifting mechanism, reducing the varieties of parts by symmetrically arranging the first clutch and the second clutch, lowering the design cost and effectively preventing the error installation when in assembly.

Owner:CHERY AUTOMOBILE CO LTD

Automatic feeding and pressing equipment for elastic retainer ring for holes

PendingCN110371619AAchieving correct press fitRealize automatic interval feedingConveyorsDe-stacking articlesEngineeringCalipers

The invention discloses automatic feeding and pressing equipment for an elastic retainer ring for holes. The automatic feeding and pressing equipment comprises a material tower assembly, an air cylinder feeding assembly and a floating pressure head assembly, wherein the material tower assembly comprises a material tower which is vertically arranged and is connected with a positioning key strip onthe side surface, the elastic retainer ring is nested in the material tower in a sliding mode and is matched with the positioning key strip, the air cylinder feeding assembly comprises a base with a material channel, a guide sleeve connected with the tail end of the material channel and a material pushing plate for pushing the elastic retainer ring falling from the material tower to the guide sleeve along the material channel, the material pushing plate is driven by an air cylinder, the floating pressure head assembly comprises a pressing rod sleeve with an inner hole, a connecting rod is connected to the upper part of the pressing rod sleeve, a self-adjusting spring and a sliding sleeve are arranged in the pressing rod sleeve, a connecting screw is connected between the connecting rod andthe sliding sleeve, the self-adjusting spring sleeves the connecting screw and the upper end of the self-adjusting spring is connected with the connecting rod, and the lower end of the self-adjustingspring is connected with the sliding sleeve. According to the automatic feeding and pressing equipment, automatic interval feeding can be realized and correct press fitting of the elastic retainer rings for caliper holes can be realized.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

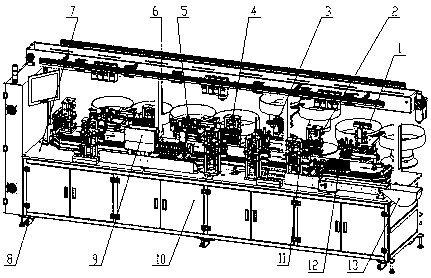

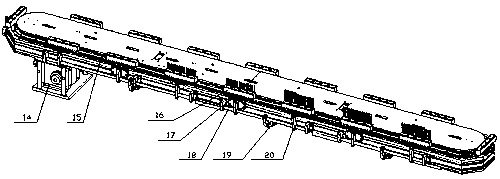

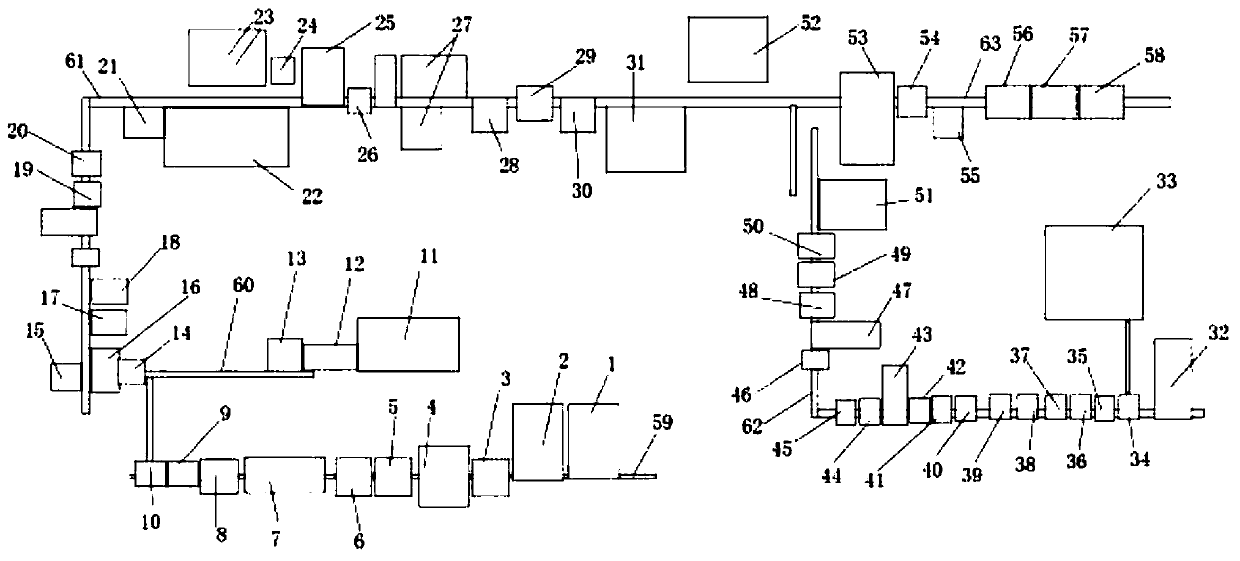

Mechanical pencil machine core assembly production line

ActiveCN110978863ARealize automatic feeding processRealize the assemblyPropelling pencilsProduction lineEngineering

The invention provides a mechanical pencil machine core assembly production line, and belongs to the technical field of mechanical pencil machine core assembly. The mechanical pencil machine core assembly production line comprises a bottom box and a support seat arranged at the bottom of the bottom box, wherein an arc-shaped rail conveying mechanism is arranged at the upper portion of the bottom box, the arc-shaped rail conveying mechanism comprises a chain driven through a divider to operate and a plurality of assembling dies installed on the chain, positioning buckles used for being matchedwith the assembling dies are arranged on the outer side of the chain, and locking shafts and locking air cylinders driving the locking shafts to rotate are arranged at the bottom of the chain. In theembodiment of the mechanical pencil machine core assembly production line, through the arrangement of a movable head feeding mechanism, a spring feeding mechanism, a thread head feeding mechanism anda machine core tube feeding mechanism, automatic feeding and assembling of movable heads, springs, thread heads and machine core tubes can be realized, a detection mechanism is arranged for cooperation in each assembling link so that the assembling precision can be improved, the situations of wrong assembling and neglected assembling are avoided, and the advantages of high assembling efficiency and high automation degree are achieved.

Owner:广东欧尔塔自动化设备有限公司

Press fitting equipment for rubber bushing

InactiveCN103831623APrevent deviationAvoid wrong loadingOptical detectionMetal working apparatusIdentification deviceEngineering

The invention relates to press fitting equipment for a rubber bushing. The press fitting equipment comprises a lower clamp used for fixing a work-piece, an upper clamp matched with the lower clamp, arranged above the lower clamp and used for pressing the bushing into the work-piece, a driving device pushing the upper clamp to move vertically, a neglected-installation-preventing detection device arranged on one side of the upper clamp and used for detecting the bushing inside the upper clamp, and an automatic identification device arranged on one side of the lower clamp and used for identifying the type of the lower clamp. The lower clamp comprises a supporting column fixing the work-piece. The upper clamp comprises a second base plate and a pressing rod towards the second base plate. The second base plate is provided with a locating clamp matched with the supporting column and used for arranging the bushing. A containing cavity which penetrates through the locating clamp and is used for containing the bushing is formed in the locating clamp. The pressing rod can extend into the containing cavity and press the bushing in the containing cavity into the work-piece. According to the press fitting equipment, deflection of the bushing in the press fitting process is prevented, mistaken installation and neglected installation are prevented, and the overall work efficiency and the press fitting quality can be improved.

Owner:SIP GOLDWAY TECH

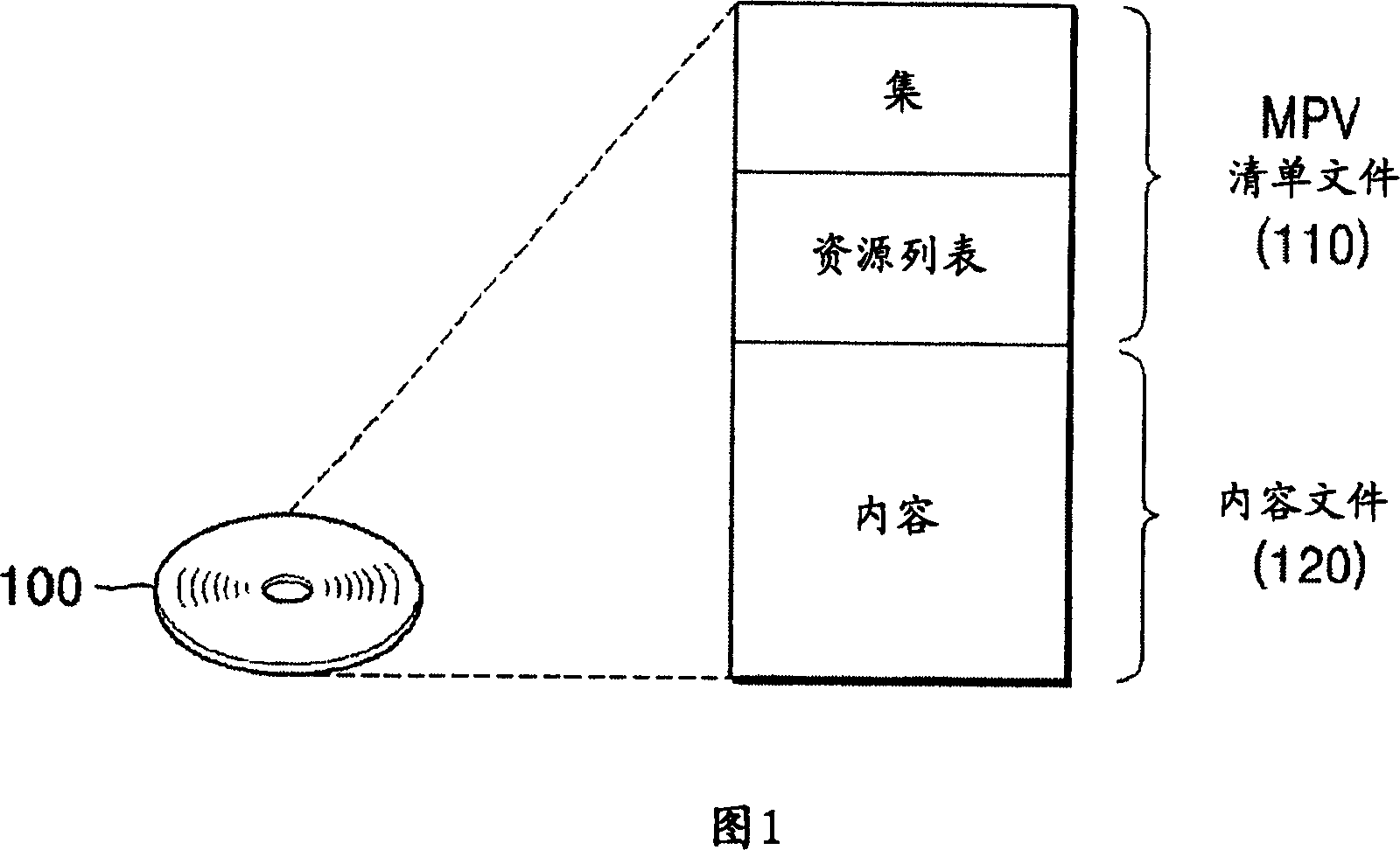

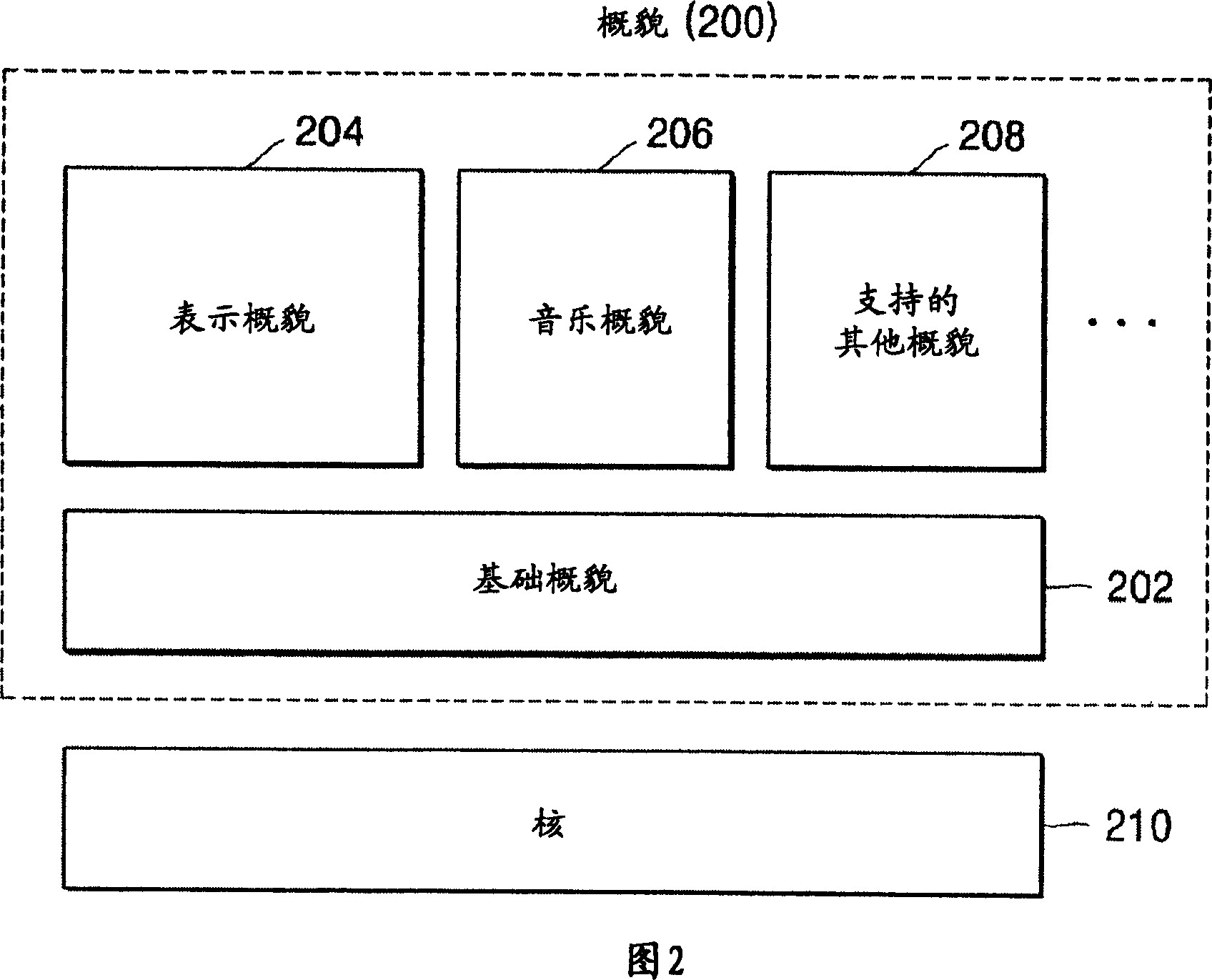

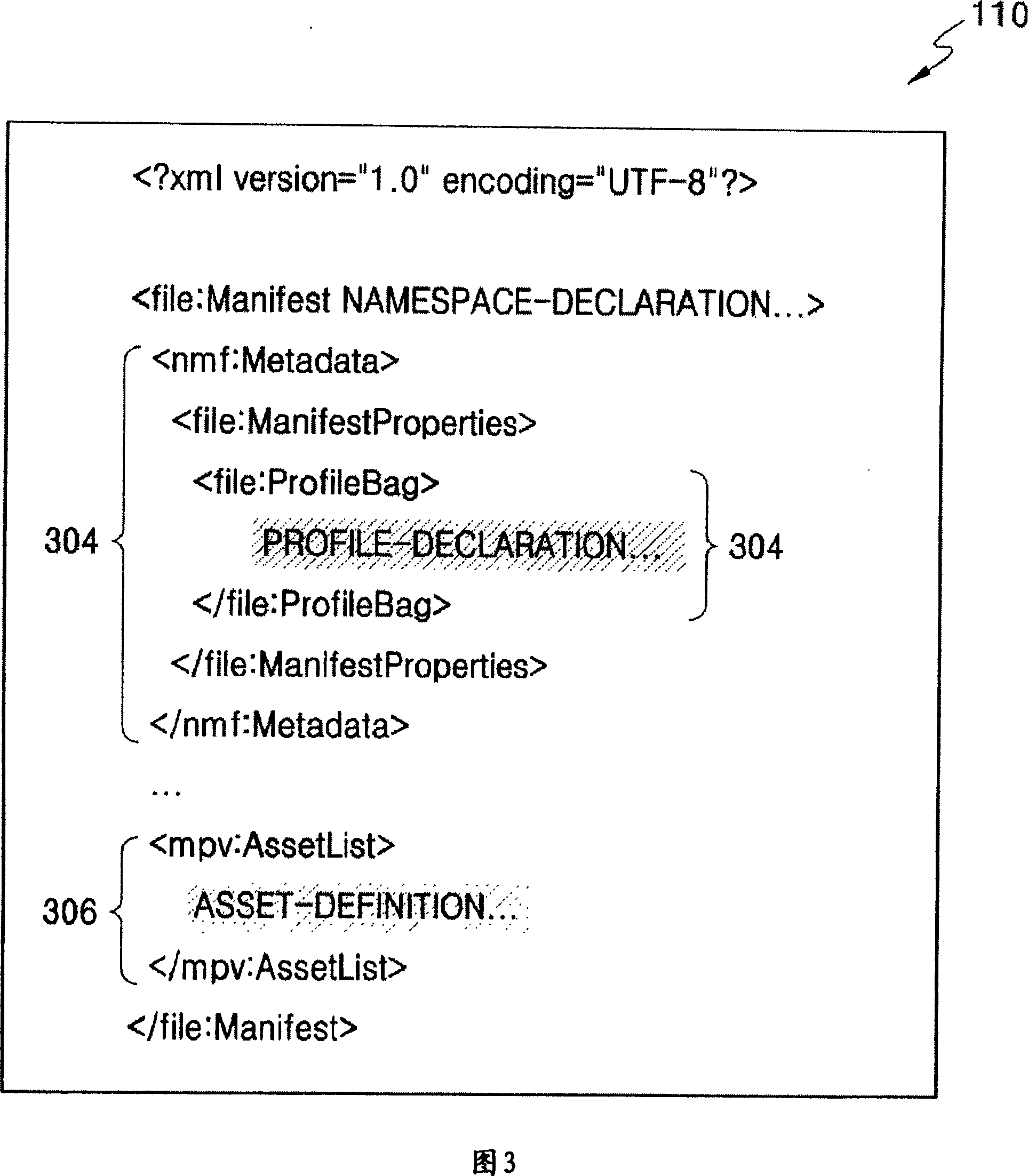

Method of reproducing multimedia data using musicphotovideo profiles and reproducing apparatus using the method

InactiveCN1957349AHigh speedAvoid wrong loadingMultimedia data retrievalRecord information storageComputer hardwareDocumentation

A method and apparatus for reproducing multimedia data using a MusicPhotoVideo (MPV) profile. The method for reproducing multimedia data using a profile complying with the MPV standard, includes: detecting a reference element indicating that a predetermined profile among a plurality of supported profiles is used, in an MPV document; updating the MPV document using information on a profile corresponding to the detected reference element; and reproducing multimedia data by parsing the updated MPV document. Accordingly, by using the MPV standard profile, multimedia data can be reproduced more efficiently.

Owner:SAMSUNG ELECTRONICS CO LTD

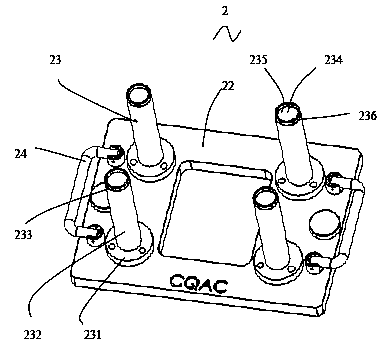

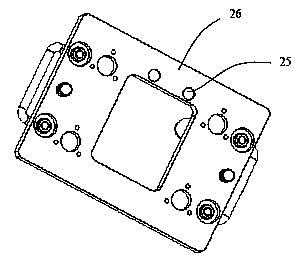

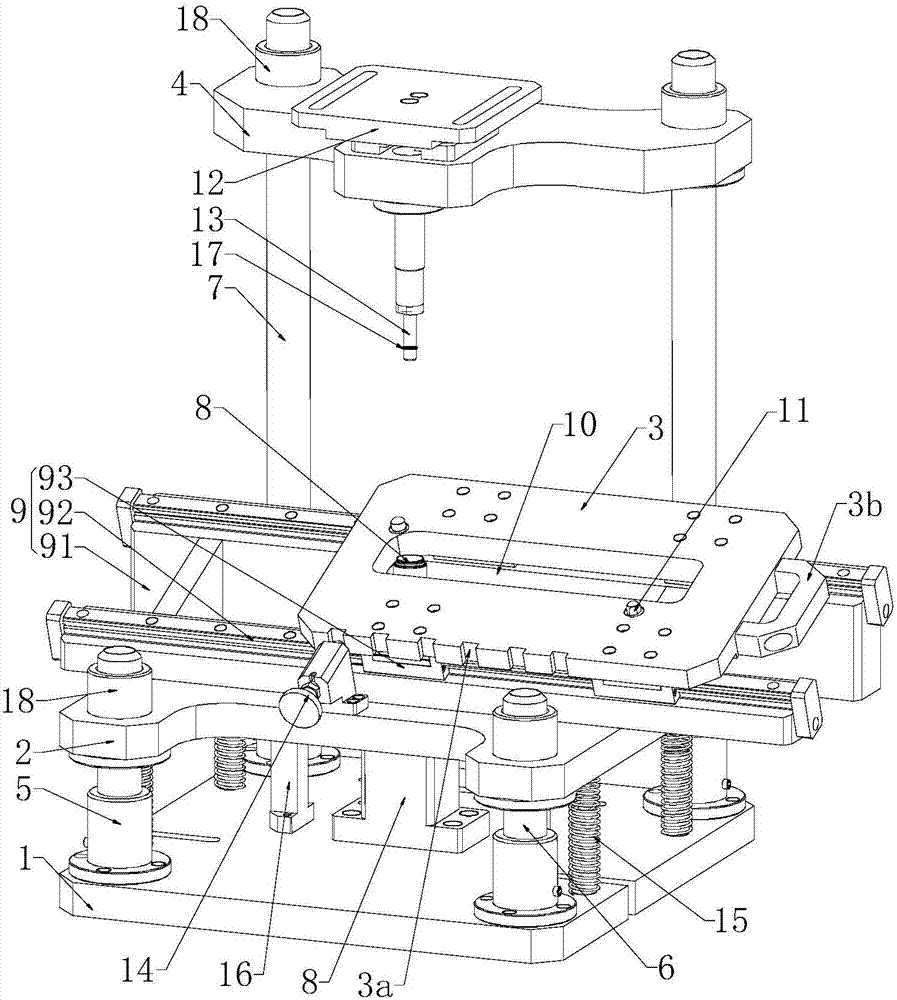

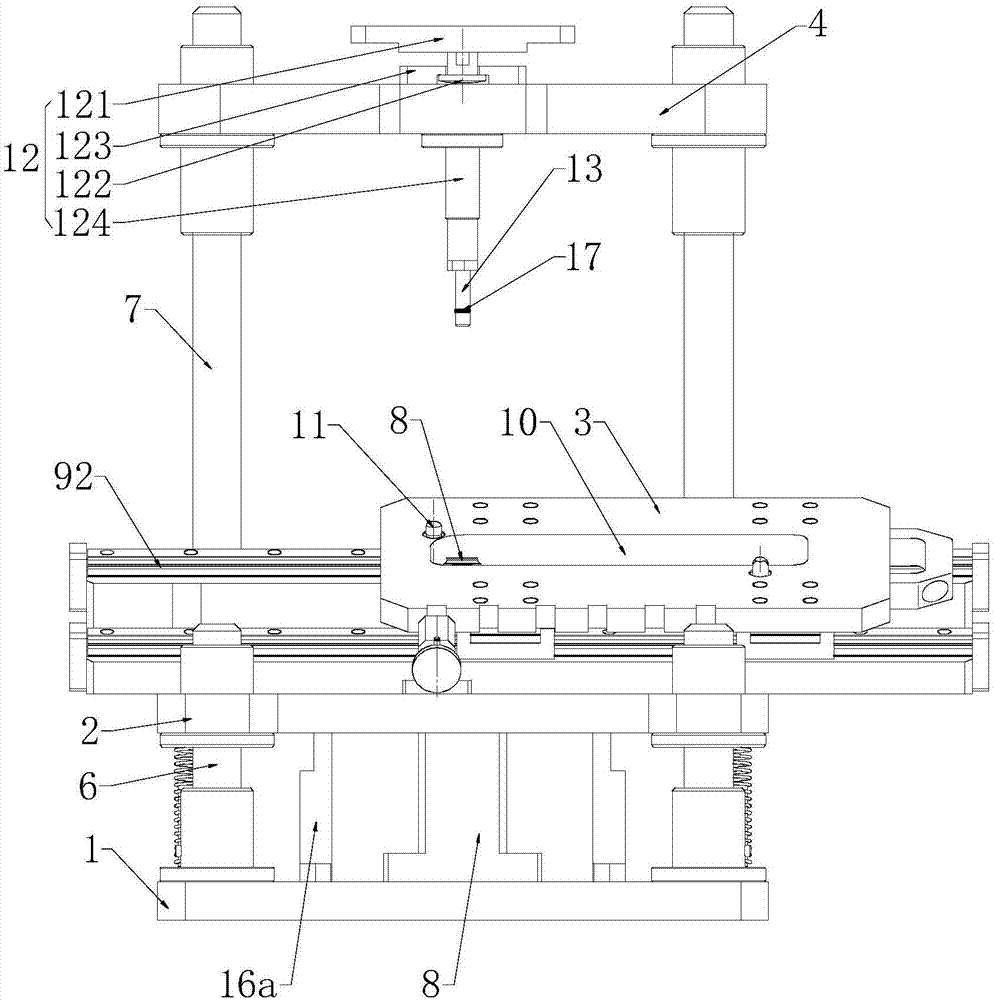

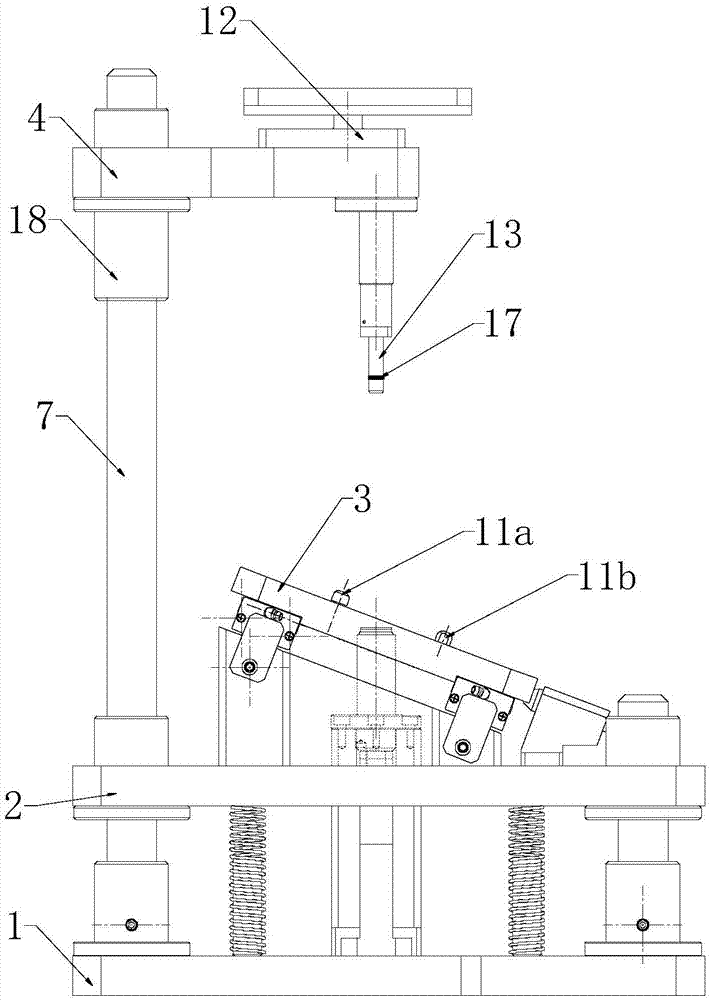

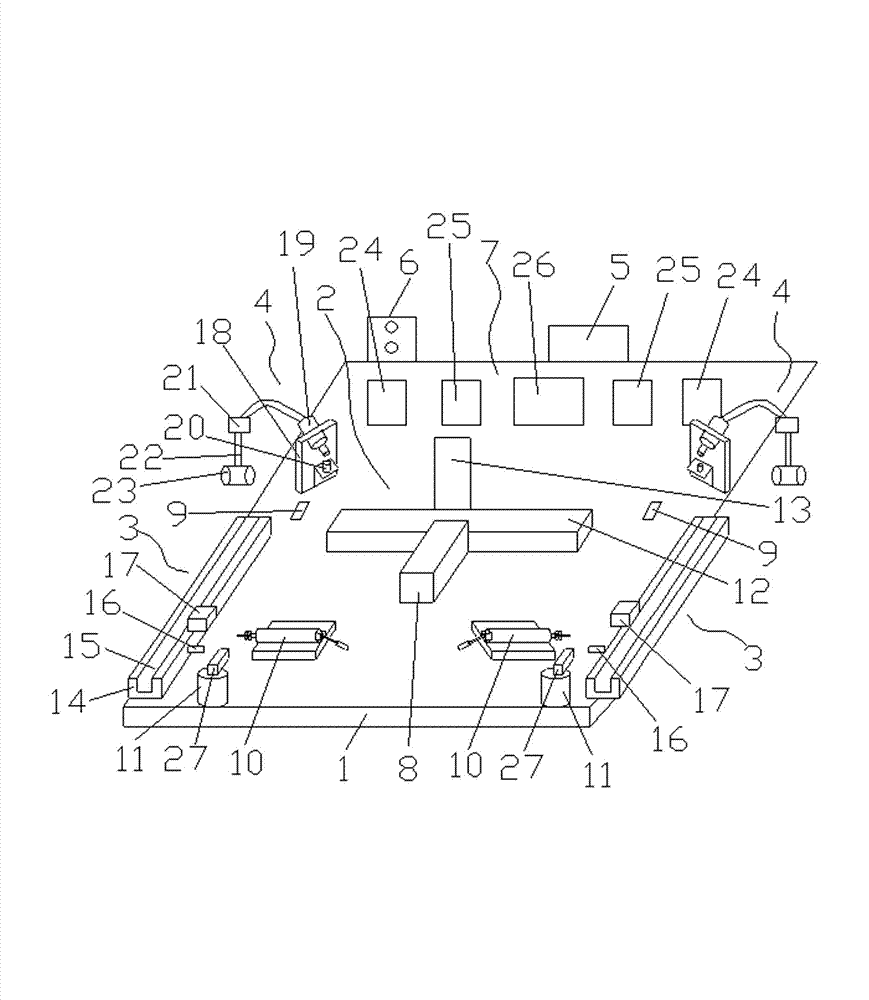

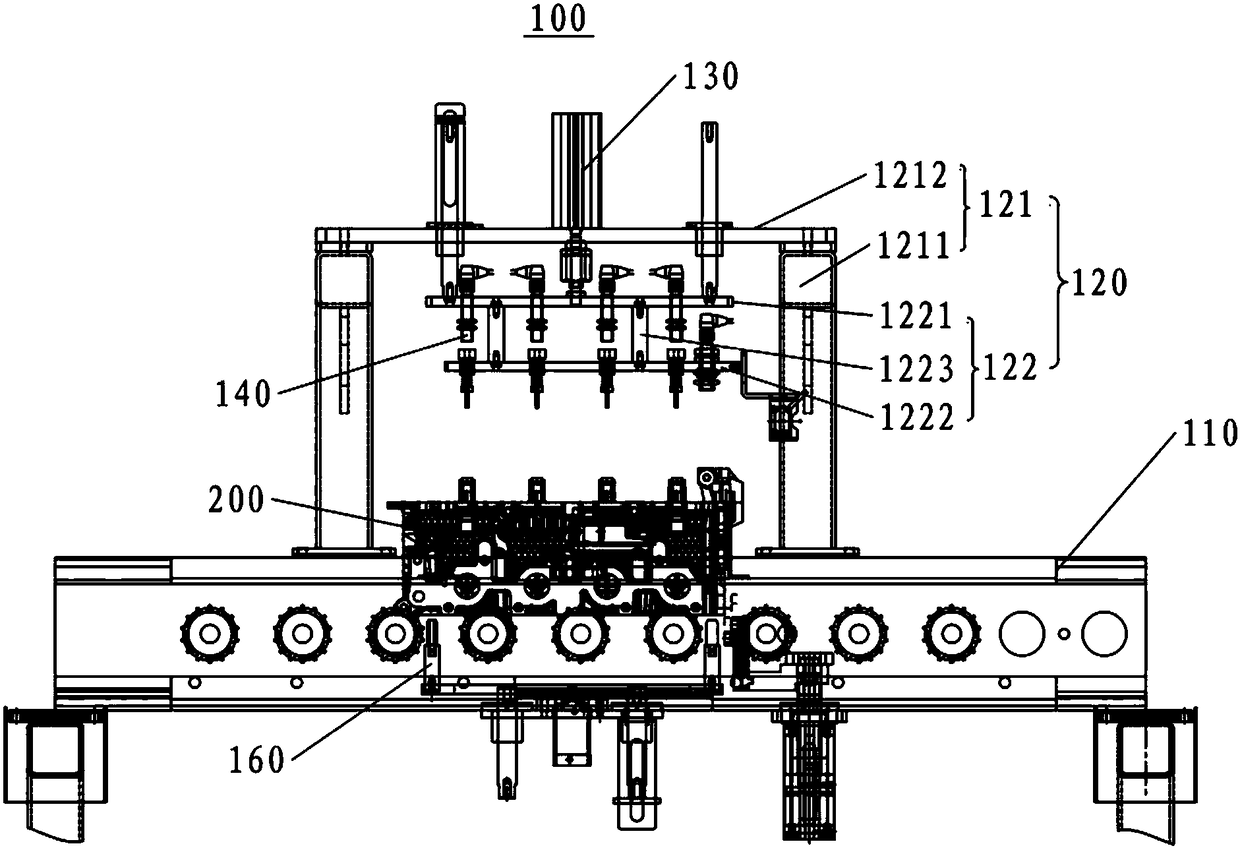

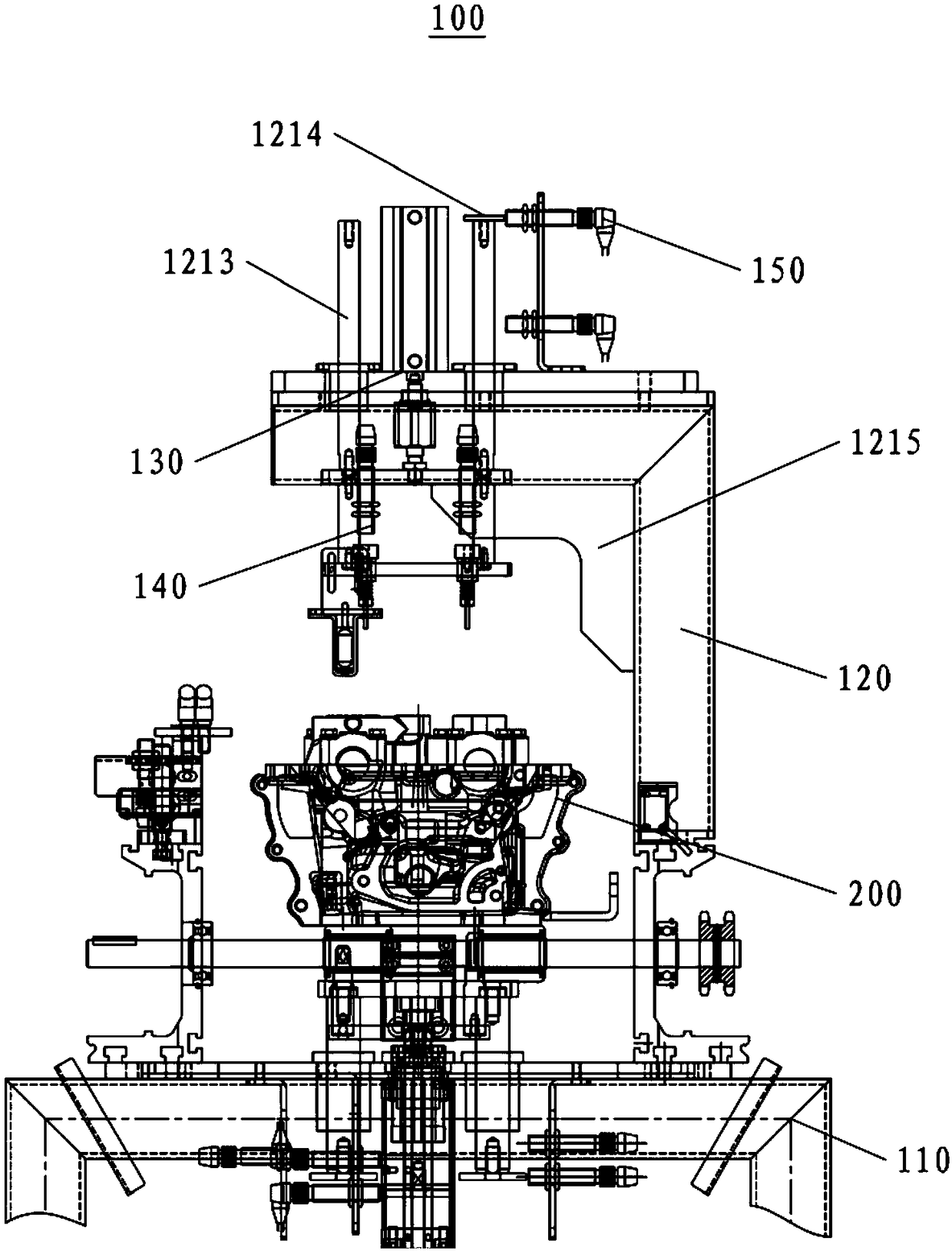

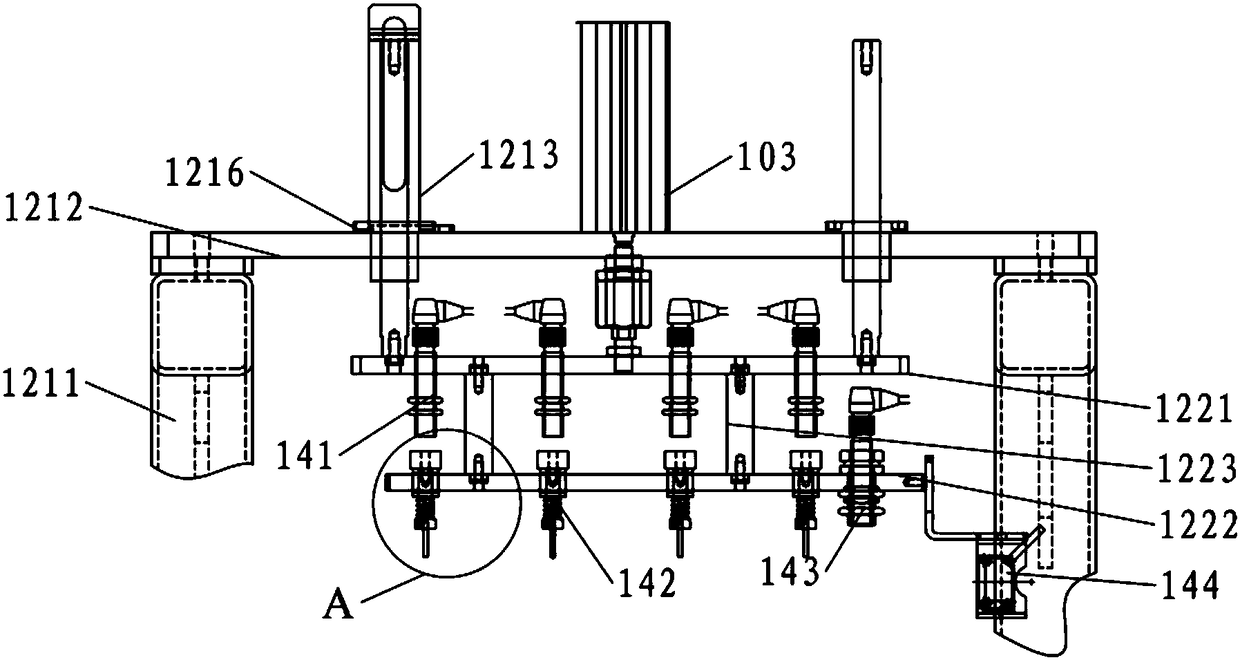

Pressing-mounting equipment for pressing-mounting of cylinder cover guide pipe and seat ring

PendingCN107971729AIncrease productivityPrecise positioningMetal working apparatusOutput deviceEngineering

The invention discloses pressing-mounting equipment for pressing-mounting of a cylinder cover guide pipe and a seat ring. The pressing-mounting equipment comprises a foot plate, a bottom plate, a supporting plate and a top plate; at least two short vertical columns and at least two long vertical columns are fixed to the foot plate through guiding sleeves; the bottom plate is supported on the shortvertical columns and the long vertical columns in sliding and sleeving modes; a positioning shaft is further fixed to the foot plate; the obliquely-arranged supporting plate is mounted above the bottom plate through a sliding supporting mechanism; and a machining groove is formed in the center of the supporting plate, and the upper portion of the positioning shaft extends into the machining groove; a positioning pin assembly is arranged on the supporting plate; the top plate is supported on the upper portions of the long vertical columns in sliding and sleeving modes, and a pressure transferassembly for being connected to a pressure output device is arranged in the middle of the top plate; and the lower end of the pressure transfer assembly is connected with a guide pipe fixing sleeve which corresponds to the positioning shaft in position. The pressing-mounting equipment has the remarkable effects that pressing-mounting work of the cylinder cover guide pipe and the seat ring is completed by the equipment instead of manual work, and the advantages of high pressing-mounting efficiency, low equipment input and good product quality are achieved.

Owner:CHONGQING SCI & TECH CO LTD YINGXI

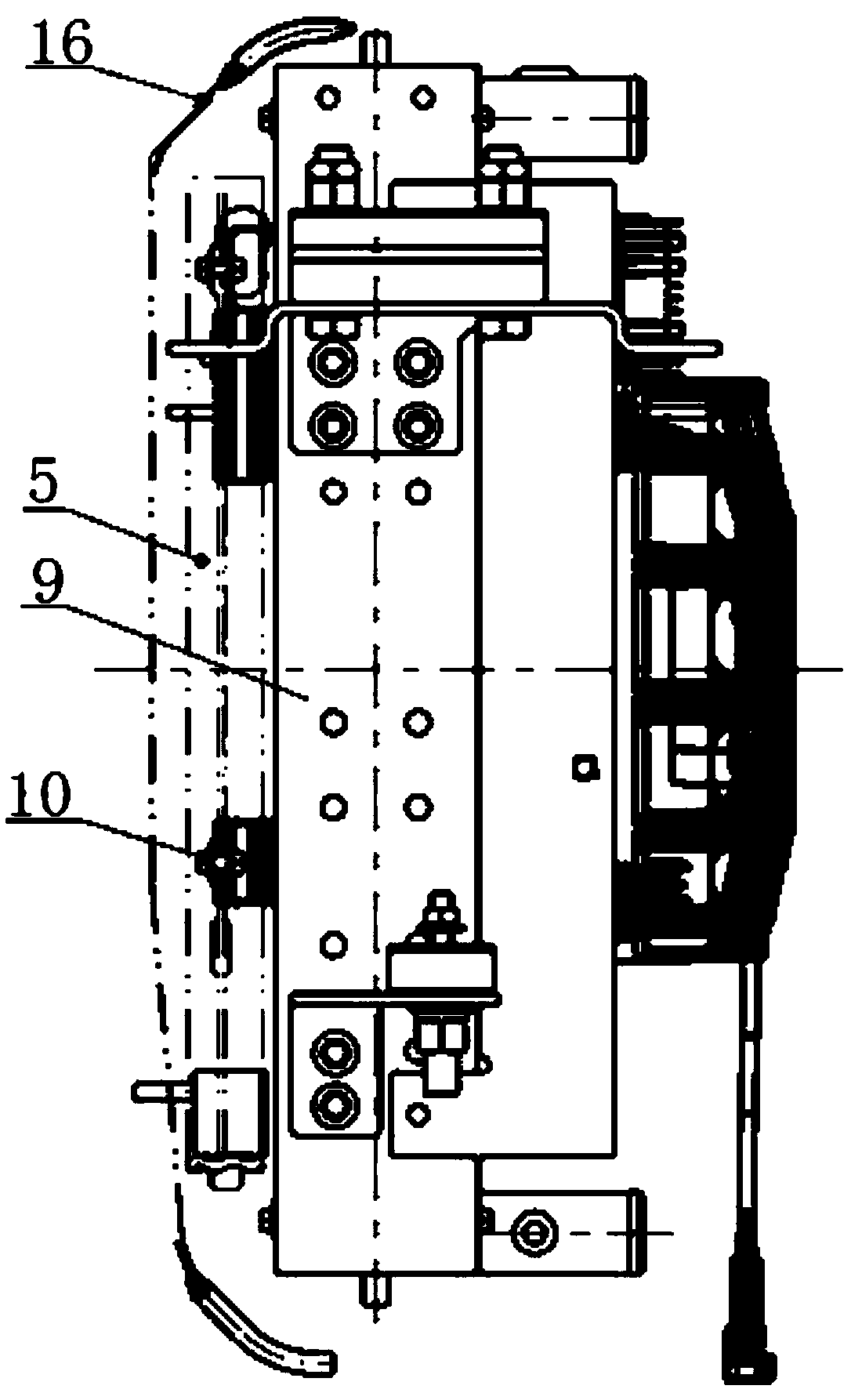

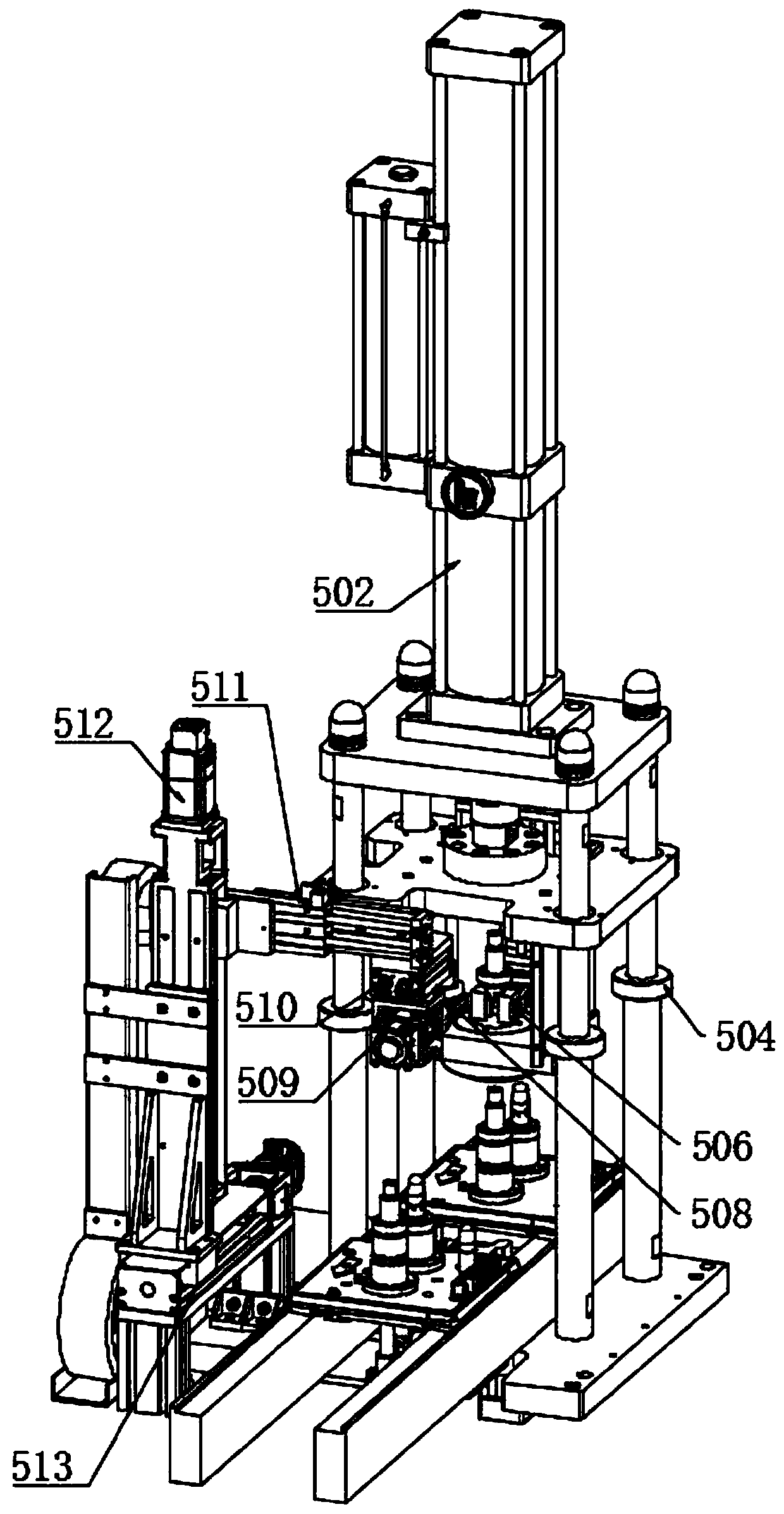

Lean intelligent assembly line for start-stop starter

PendingCN110587267AImprove assembly qualityImprove assembly efficiencyAssembly machinesMetal working apparatusDelivery PerformanceStart stop

The invention relates to a lean intelligent assembly line for a start-stop starter. The lean intelligent assembly line comprises an isolator assembly assembly line, a drive shaft assembly assembly line, a starter assembly assembly line, an electromagnetic switch assembly assembly line and a delivery performance detection line. The isolator assembly assembly line is sequentially provided with a guide cylinder oil spraying line feeding process, a gear shaft feeding process, a gear automatic spinning process, a cap washer assembling process, a cap extruding process, a cap shaping process, a towerspring mounting process, a sliding ring assembly mounting process, a sliding ring assembly pressing process and an isolator line discharging process. By means of the lean intelligent assembly line for the start-stop starter, error prevention is achieved in the whole process; unqualified products are automatically isolated; and the assembly quality and efficiency are greatly improved, and the number of personnel on the whole line is reduced by 80%.

Owner:湖北神电汽车电机有限公司

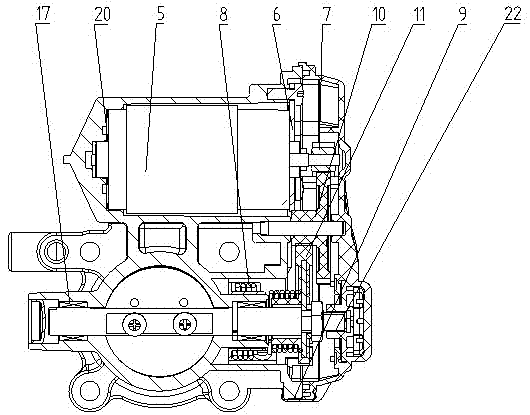

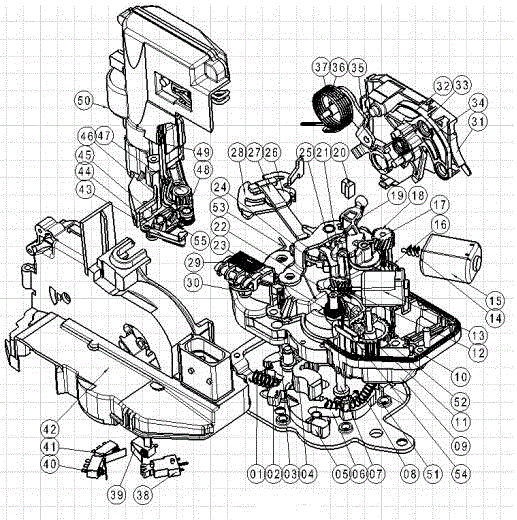

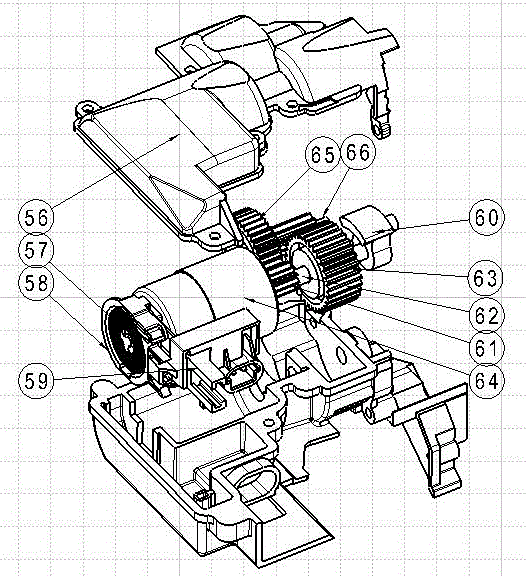

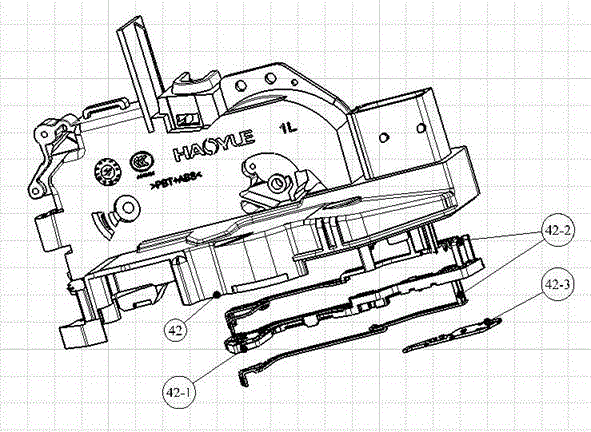

Integral front door lock body assembly

InactiveCN106522698AIncrease the function of electric door openingPrevent escapePower transmission/actuator featuresElectrical locking actuatorsEngineeringTorsion spring

The invention discloses an integral front door lock body assembly. The integral front door lock body assembly comprises a lock body sub assembly, a lock shell sub assembly and an automatic open connecting sub assembly; the lock body sub assembly includes a lock body and a cover plate; the lock shell sub assembly includes a copper piece mounting plate, a copper piece and a shell cover; and the automatic open connecting sub assembly includes an electric door opening torsion spring shell, a gear A and an electric door opening motor. The integral front door lock body assembly adds a vehicle door electric opening function, an inner open double-pull function, a terrified lock function, a super lock function, a super lock mechanical wrong lock preventing function, an outer lock instant signal, a door lock half-open signal, a door lock full-open signal and a lock state signal, is compact in structure, prevents both dust and water, is high in transmission efficiency, and is higher in popularization and application values.

Owner:HAOYUE AUTOMOBILE SAFETY SYSTEM TECHNOLOGY LIMITED BY SHARE LTD

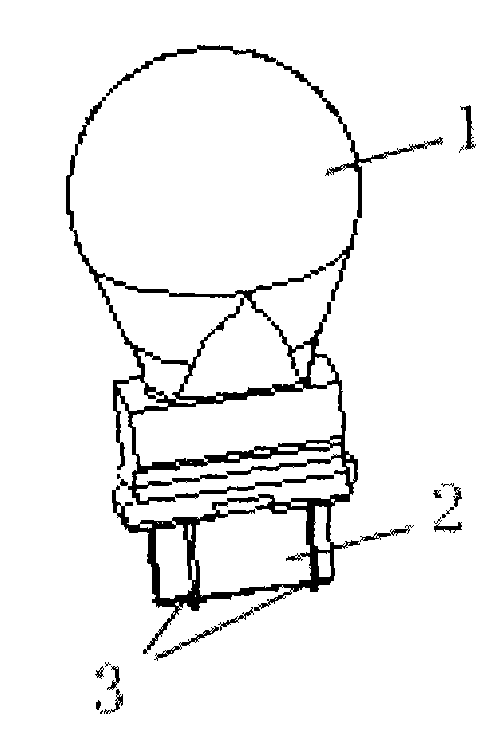

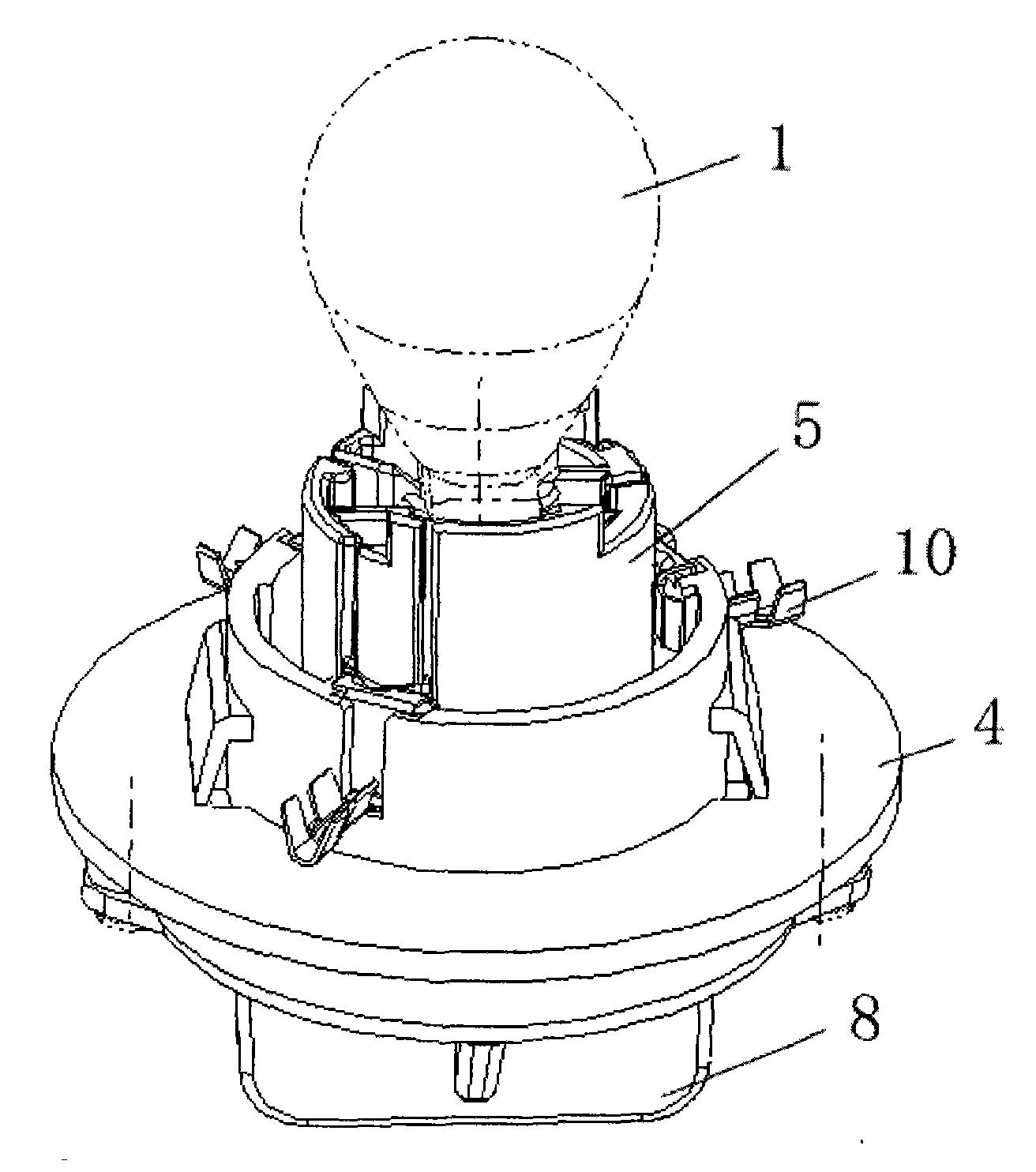

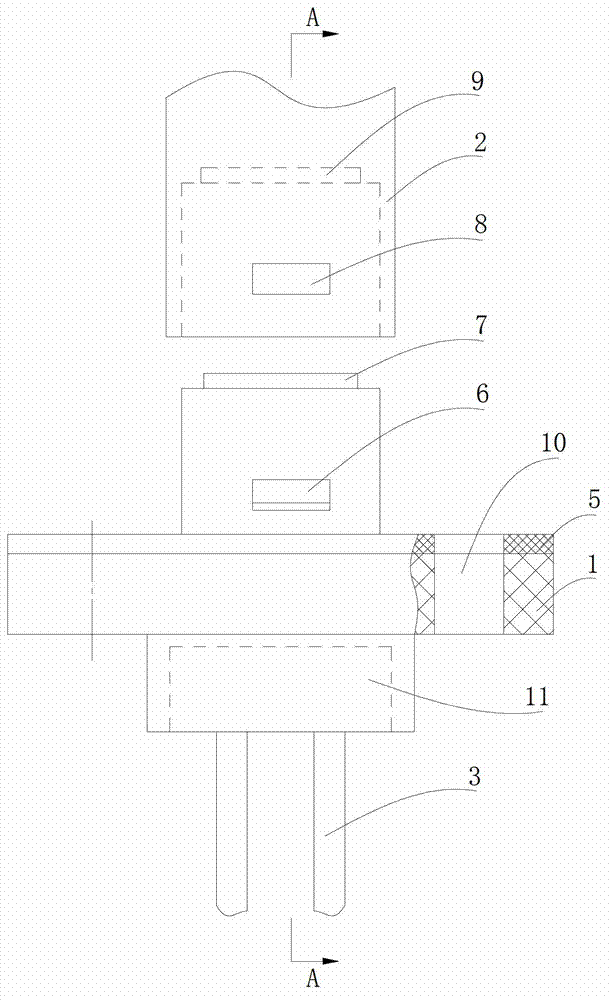

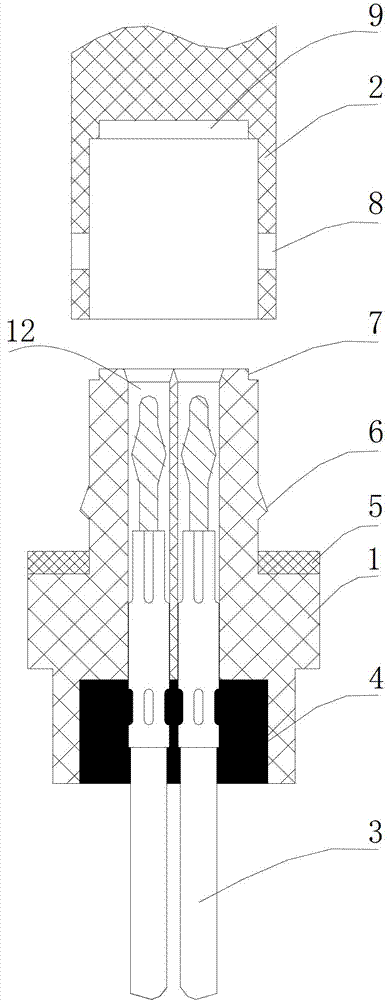

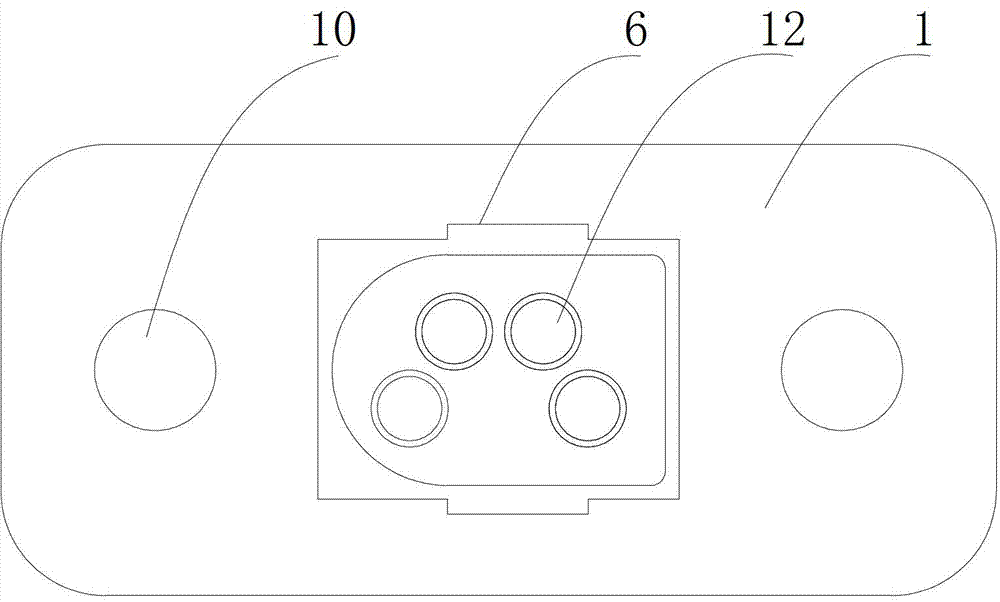

Contact-type lamp holder for wedge-shaped bulb

InactiveCN101615750AEasy to installAvoid wrong loadingCoupling device connectionsElectric discharge tubesEngineeringSignal light

The invention relates to a contact-type lamp holder for a wedge-shaped bulb, which comprises a lamp holder hole closing ring (4) and a cylindrical plug-in piece (5) plugged in the lamp holder hole closing ring (4), wherein the wall of the lamp holder hole closing ring (4) is provided with a cathode electric contact piece (10), the outer wall of the cylindrical plug-in piece (5) is provided with an anode electric contact piece, a slot (12) for receiving a bulb wedged-shaped socket piece is formed in the cylindrical plug-in piece, the inner wall of the slot is provided with an electric contact leaf spring (11A) corresponding to an electric contact point (3) of the bulb wedged-shaped socket piece, and the electric contact leaf spring is electrically connected the anode contact piece (11) protruding out of the outer wall of the cylindrical plug-in piece; and the cathode contact piece is fixedly connected with a power supply. The novel contact-type lamp holder has an integral structure, is adaptive to occasions with narrow mounting spaces, and is particularly suitable for automobile signal lights adopting wedge-shaped bulbs.

Owner:HASCO VISION TECHNOLOGY CO LTD

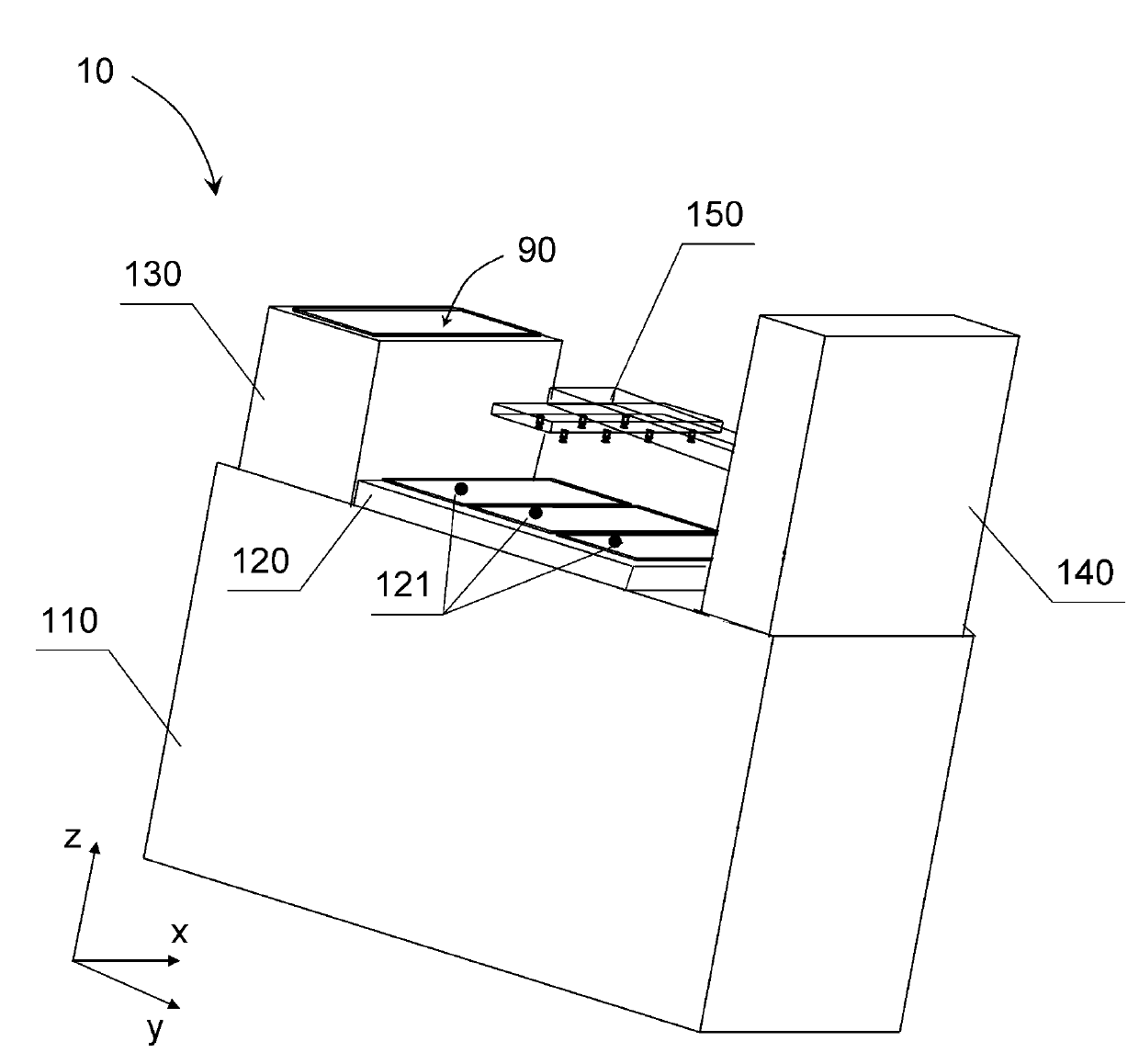

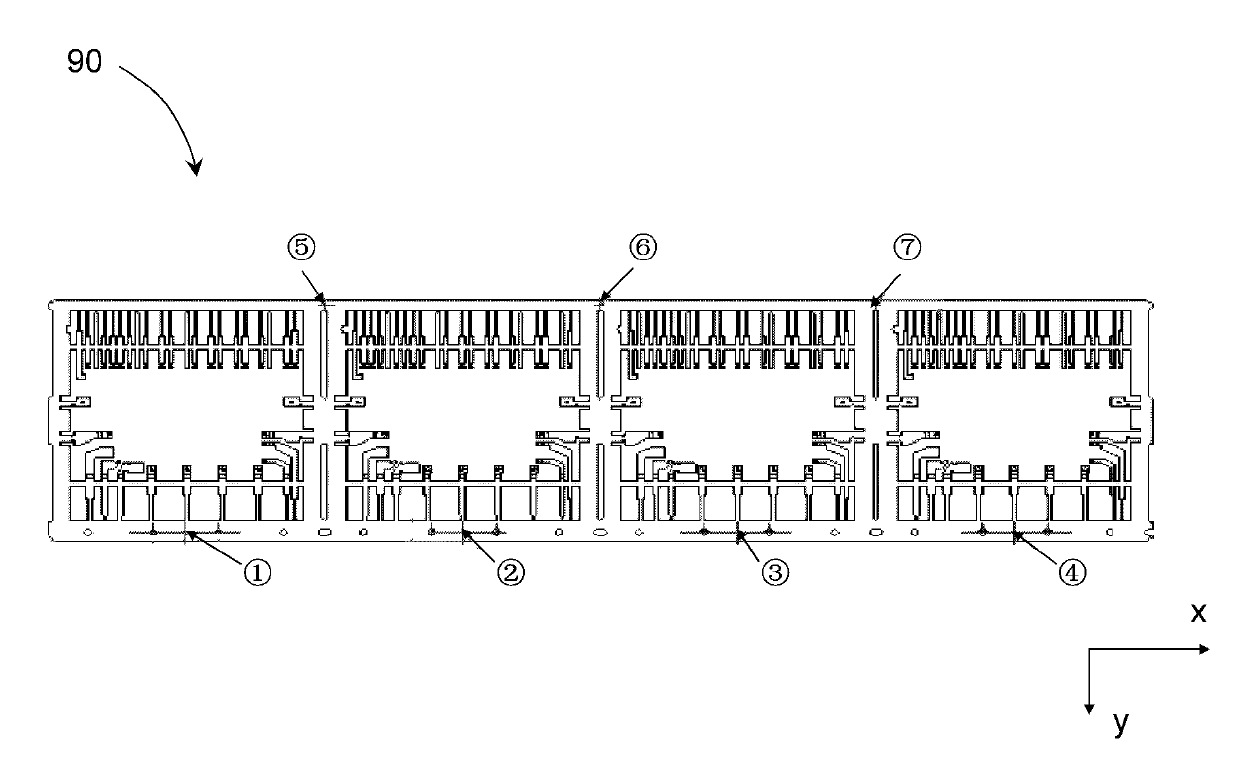

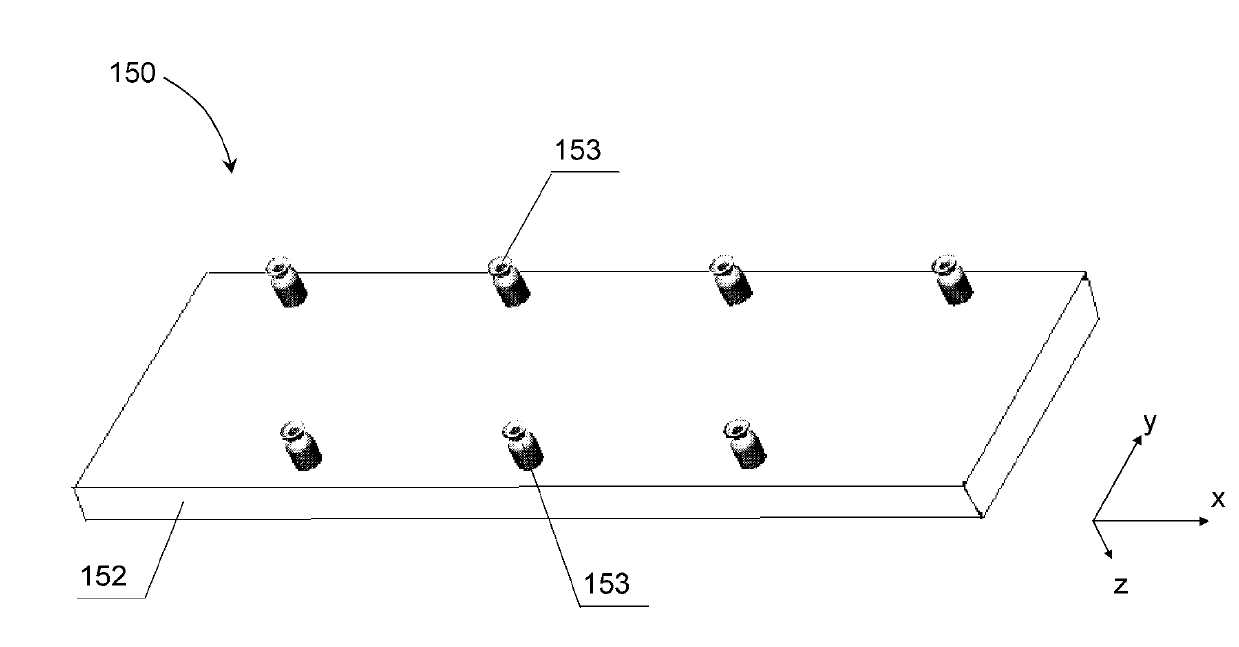

Feeding system of lead frame array

InactiveCN103295942AReduce distortionAvoid deformationSemiconductor/solid-state device manufacturingConveyor partsComputer moduleEngineering

The invention provides a feeding system of a lead frame array and belongs to the technical field of encapsulation. The feeding system of the lead frame array comprises a material pushing device, a sucking module, a detecting module and a transferring module. The material pushing device is used for pushing the lead fame array out of a lead frame array material box. The sucking module is provided with a plurality of suction nozzles used for sucking the lead frame array, and the detecting module is provided with a detection sensor used for detecting the placing direction and the type of the lead frame array. The transferring module is used for transmitting the lead frame array sucked by the sucking module to a reserved part. The feeding system of the lead frame array is high in degree of automation. The lead frame array is little in deformation and high in encapsulation efficiency in the process of feeding. In addition, the accuracy of feeding load is high.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

Automobile skylight weather strip mistake-proof jig

The invention relates to an automobile skylight weather strip mistake-proof jig which comprises a workbench. The workbench is provided with a first positioning device, two second positioning devices, two beef tallow adding devices, a controller, a buzzer and a material box, wherein the first positioning device is mounted at the rear middle end of the workbench; a positioning cylinder is arranged at the front end of the first positioning device; the two second positioning devices and two beef tallow adding devices are mounted at the left and right ends of the workbench respectively; a proximity switch is arranged at each of the rear ends of the two second positioning devices respectively; a quick clamp and a rotary cylinder are arranged close to each of the front inner sides of the two second positioning devices respectively; and the two beef tallow adding devices, the buzzer, the positioning cylinder, the proximity switches and the rotary cylinders are all connected with the controller. The jig provided by the invention prevents wrong assembly and neglected assembly of the parts, realizes easier and quicker assembly, reduces the labor intensity, improves the production efficiency and guarantees the overall assembly quality.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

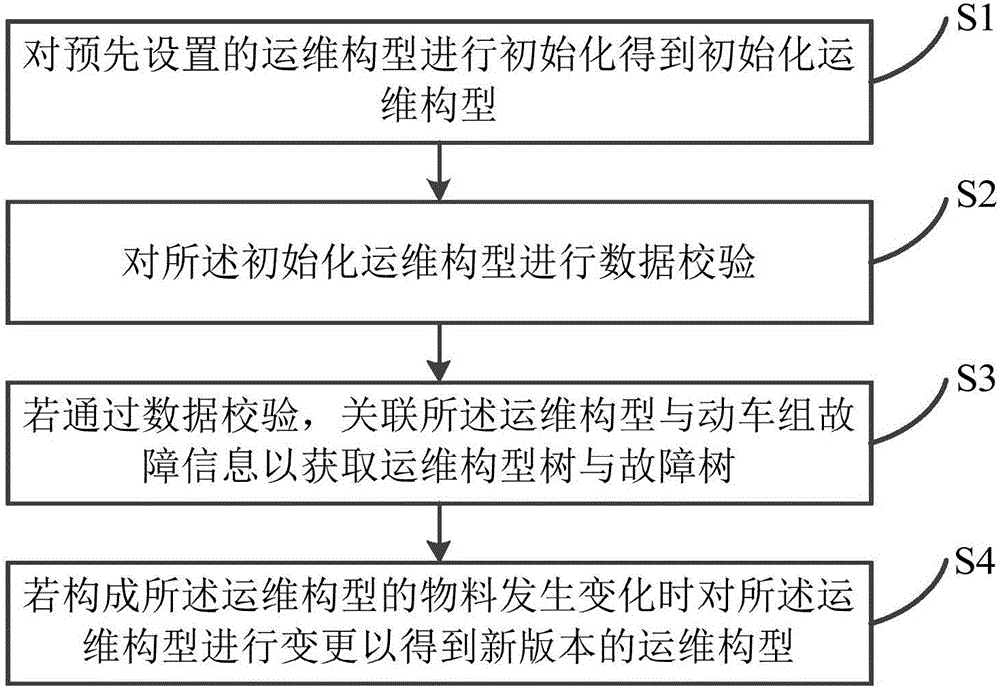

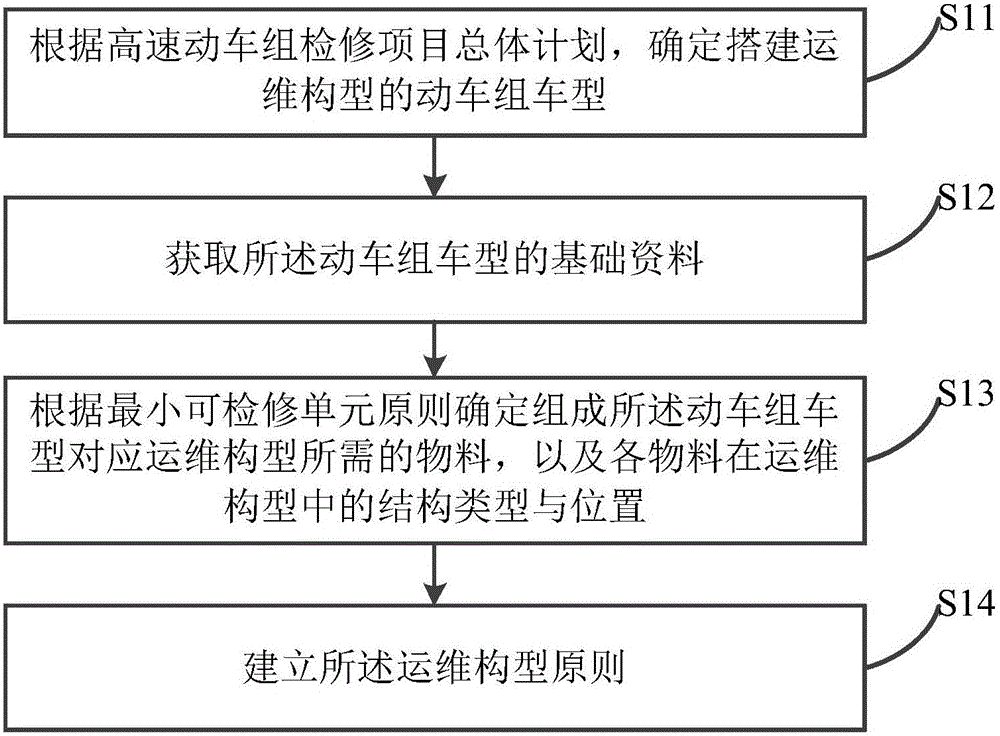

High-speed electric multiple unit-based operation and maintenance configuration management method and device

InactiveCN106203640AAvoid Missing or MispackingEnsure consistencyInstrumentsData verificationAnalysis Reason

The invention relates to a high-speed electric multiple unit-based operation and maintenance configuration management method and device. The method comprises the following steps of: initiating a preset operation and maintenance configuration to obtain an initialized operation and maintenance configuration; carrying out data verification on the initialized operation and maintenance configuration; if the initialized operation and maintenance configuration passes the data verification, associating the operation and maintenance configuration with electric multiple unit fault information to obtain an operation and maintenance configuration tree and a fault tree; and if a material forming the operation and maintenance configuration changes, changing the operation and maintenance configuration to obtain a new version of operation and maintenance configuration. According to the method and device provided by the invention, neglected loading and wrong loading can be avoided so that the consistency and controllability of key parts, files and change data are ensured; and through associating the configuration with the faults, a classification system where the fault are located can be rapidly positioned, so that fault object analysis reasons with finer grit can be positioned under the fault tree and then fault analysis and report are carried out.

Owner:CRRC QINGDAO SIFANG CO LTD

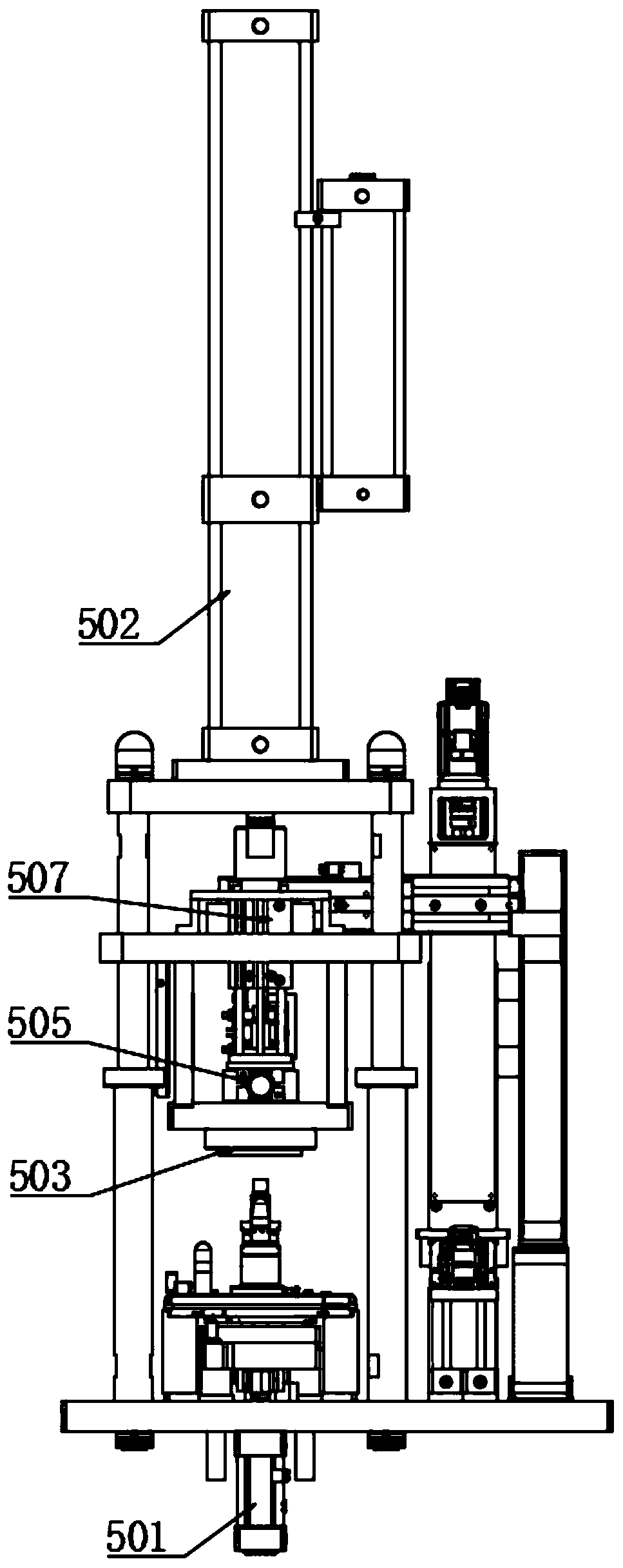

Rotor bearing press fitting device

PendingCN113146191AEasy to pressImprove installation qualityMetal working apparatusFixed bearingEngineering

The invention discloses a rotor bearing press fitting device. The device comprises a workbench, a rotor frame, a bearing press fitting machine and a bearing feeding device, wherein a sliding rail is arranged on the workbench; the rotor frame is used for fixing a rotor, and the rotor frame is fixed on the workbench; the bearing press fitting machine comprises a bearing mounting seat used for fixing a bearing and a press fitting pushing assembly used for pushing the bearing mounting seat, and the bearing mounting seat is arranged on the sliding rail in a sliding mode; and the bearing feeding device comprises a bearing placing assembly, a bearing conveying assembly and a bearing pushing assembly which are arranged in sequence. According to the rotor bearing press fitting device, rotor bearing press fitting is convenient and fast; the mounting quality and the mounting precision are high; the universality is high; and the mounting efficiency is high.

Owner:HANGZHOU DC ENERGY EQUIP

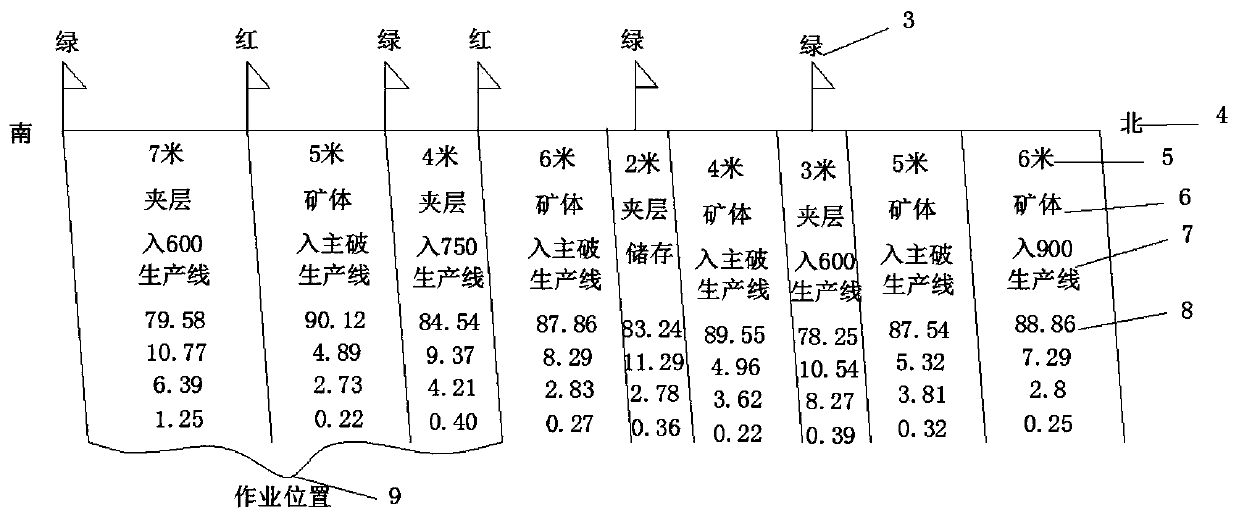

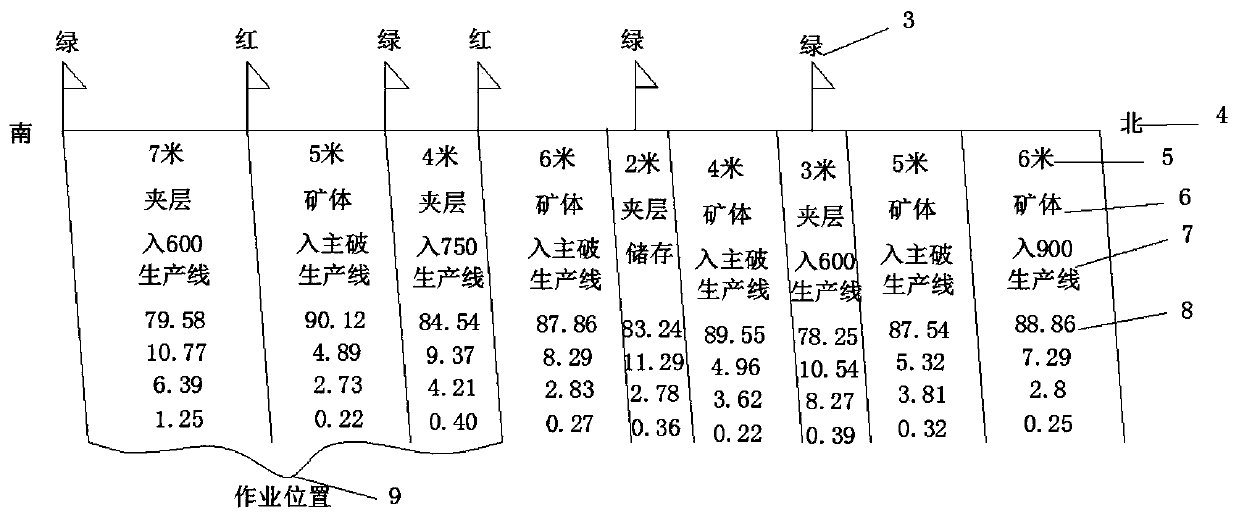

Control method for improving limestone exploitation quality

ActiveCN109989755AImprove mining qualityHigh recovery rateOpen-pit miningProduction lineSurface layer

The invention discloses a control method for improving limestone exploitation quality. The control method comprises the following steps that feed quality indexes of all machining production lines areformulated; according to the physical characteristics of the ore exposed on the surface layer of a new blasting pile, the ore is distinguished, the ore is segmented, the width of the ore segment is recorded, and an ore rock boundary identifier is placed on the blasting pile along the trend of an ore body; blocks are picked and sampled at equal intervals and equal granularity on each segment, the samples are pretreated, the treated samples are placed on a fluorescence analyzer, and the contents of CaCO3, MgCO3, SiO2 and K2O in the samples are detected; according to the detection result and thefeed quality index, a corresponding processing production line is matched on each mineral type segment; and a quality diagram of the blasting pile is compiled. The ore rock boundary identifier is convenient for an operator to find a corresponding operation position; the width of the sample segment is recorded, so that wrong loading of a material source can be prevented; and the quality distribution condition of each segment is detected respectively, so that production management personnel can regulate and control the quality conveniently, and the purposes of accurately controlling the ore quality and improving the resource recovery rate can be achieved.

Owner:唐山三友矿山有限公司

Fast-locking mistaken installation preventive connector

The invention discloses a fast-locking mistaken installation preventive connector. The connector comprises a socket, a connecting matching part casing and a pin component, wherein a pin hole is arranged on the socket, the pin component is arranged in the pin hole, the connecting matching part casing matches with the upper end of the socket, a groove for installing an insulation filler is arranged at the lower end of the socket, a connecting disc protruding outwards is arranged in the middle of the socket, taper bosses are arranged on two opposite sides of the upper end of the socket, rectangular through holes matching with the taper bosses are arranged on two sides of the connecting matching part casing, a door-type boss is arranged at the top of the socket, and a door-type groove matching with the door-type boss is arranged at the top on the inner side of the connecting matching part casing. According to the connector, the locking structure is adopted to replace the existing threaded connection and mechanical deadlock, the operation is convenient and fast, simultaneously, mistaken installation is prevented through matching of the door-type boss on the socket with the door-type boss groove on the connecting matching part casing, and the connection is reliable.

Owner:遵义市飞宇电子有限公司

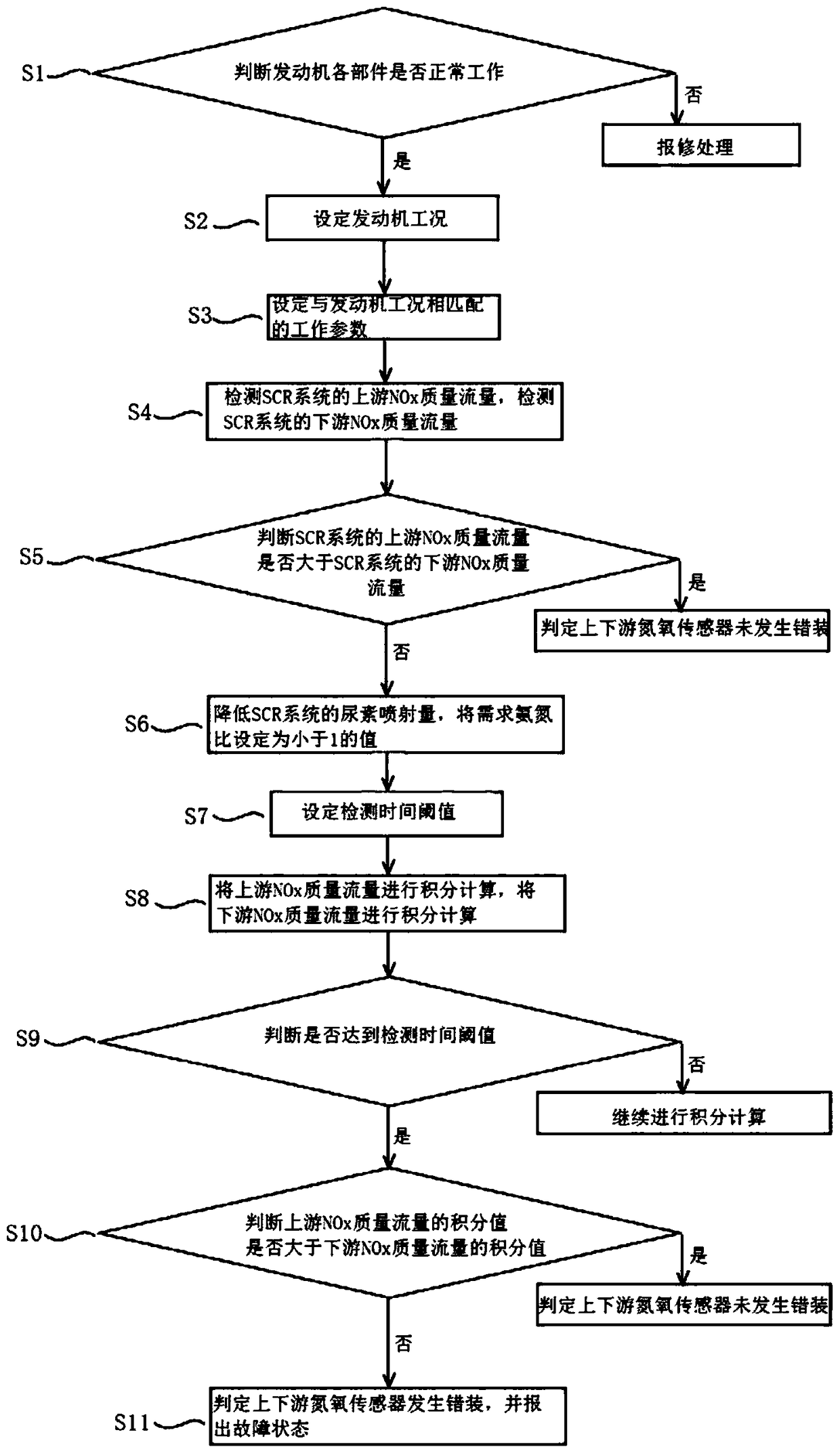

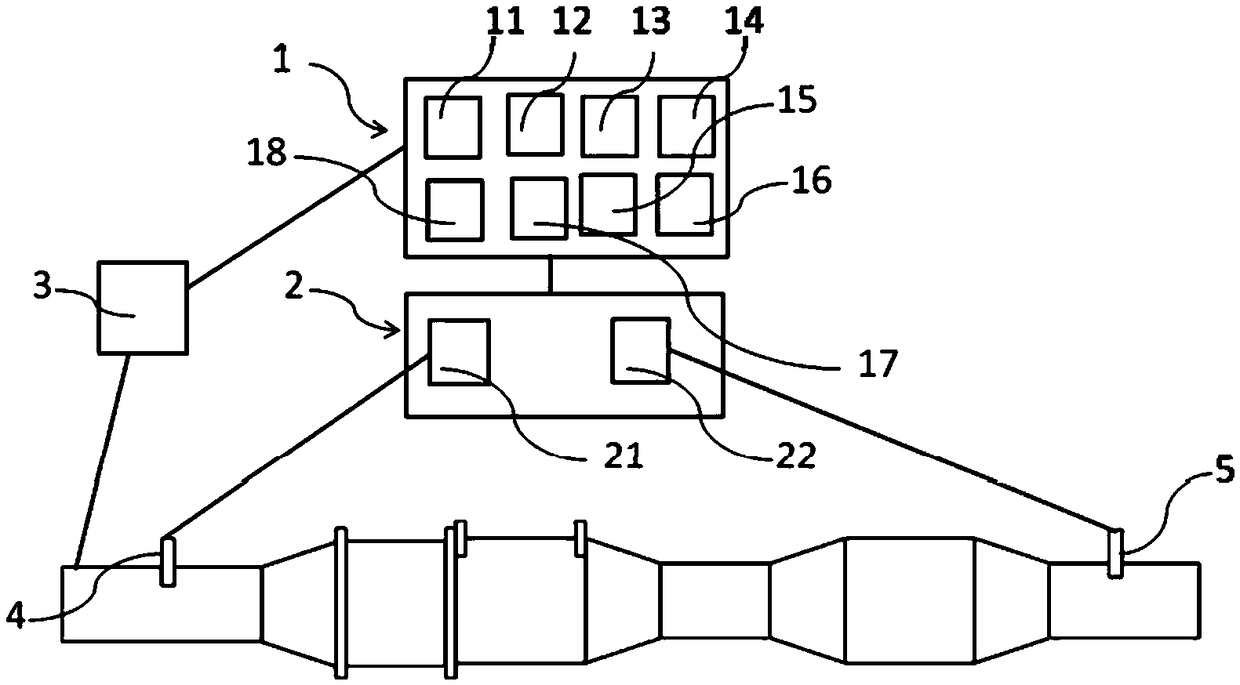

Detection method and detection device capable of preventing wrong installation of nitrogen and oxygen sensors

InactiveCN109141560AAvoid wrong loadingGuaranteed injection controlMass flow measurement devicesOxygen sensorNitrogen

The invention discloses a detection method and a detection device capable of preventing wrong installation of nitrogen and oxygen sensors. The detection method comprises the following steps: detectingupstream and downstream NOx values of an SCR (Selective Catalytic Reduction) system, and comparing the upstream and downstream NOx values to make a rough judgement; and reducing the injection amountof urea, and comparing integral values of the upstream and downstream NOx values within preset time to make a fine judgment. Thus, whether the upstream and downstream NOx sensors are installed wronglyor not can be judged effectively in order to ensure control of urea injection and diagnosis of the SCR efficiency, thereby ensuring the tail gas exhaust standard of a diesel engine.

Owner:WEICHAI POWER CO LTD +1

Cam shaft tile cover type mistake proofing device

The invention discloses a cam shaft tile cover type mistake proofing device. The cam shaft tile cover type mistake proofing device comprises a base, a supporting frame, a drive mechanism and a detecting mechanism. The supporting frame comprises a fixed support and a movable support. The fixed support is fixed to the base, the movable support is connected with the fixed support, and the movable support can ascend and descend in the base direction relative to the fixed support. One end of the drive mechanism is fixedly arranged on the fixed support, the free end of the drive mechanism is connected with the movable support, and the movable support is driven to ascend and descend. The detecting mechanism is arranged on the movable support and moves towards a tile cover along with the movable support so that the type of the tile cover can be detected. According to the technical scheme, when the detecting mechanism arrives at the preset position, a thrust cover and a non-thrust cover cause the detecting mechanism to do different actions, and the type of the tile cover can be judged according to the different response results of the detecting mechanism; and the situation of tile cover type mistaken installing can be effectively prevented, the cam shaft locking risk is reduced, and resource waste caused by cylinder cover repairing is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Automobile navigation system

InactiveCN104296742AReduce scrap rateAvoid wrong loadingNavigation instrumentsLiquid-crystal displayEngineering

The invention discloses an automobile navigation system. The automobile navigation system comprises a liquid crystal display, a volume adjustment knob, an installation groove, a first guide groove, a second guide groove, a first guide post and a second guide post, wherein the liquid crystal display and the volume adjustment knob are arranged on a panel, the installation groove is formed in the panel, function keys are installed on the panel of a navigator in a mistake preventing mode by virtue of the installation groove, the first guide groove and the second guide groove are formed in the panel of the navigator, the first guide groove is positioned on the left upper part of the installation groove, the second guide groove is positioned on the right lower part of the installation groove, the first guide post and the second guide post are arranged on two opposite corners in a rectangular groove of the pressing panel, and the first guide post and the second guide post are respectively in guide fit with the first guide groove and the second guide groove. By using the automobile navigation system, the function keys can be prevented from being mistakenly installed.

Owner:GOLDHONOR MOBILE ELECTRONICS

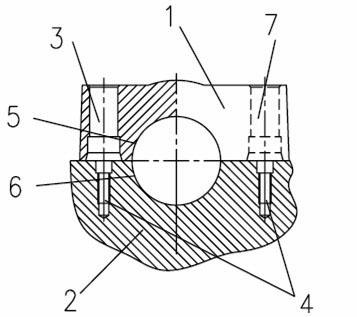

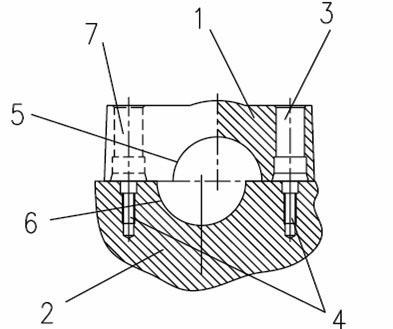

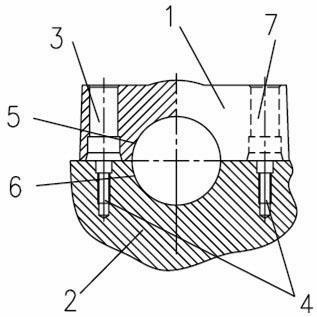

Engine camshaft bearing cover capable of preventing false mounting

InactiveCN102140941APrevent wrong loadingGuaranteed performanceValve arrangementsMachines/enginesAgricultural engineeringCamshaft

The invention discloses an engine camshaft bearing cover capable of preventing false mounting. The camshaft bearing cover is characterized in that a camshaft bearing cover body is provided with a first mounting hole and a second mounting hole; the first mounting hole is positioned at the left side of an upper semi-circular arc of a camshaft mounting hole on the camshaft bearing cover body; the second mounting hole is positioned at the right side of the upper semi-circular arc of the camshaft mounting hole on the camshaft bearing cover body; the distance between a circle center of the first mounting hole and the center of the upper semi-circular arc of the camshaft mounting hole is less than the distance between a circle center of the second mounting hole and the center of the upper semi-circular arc of the camshaft mounting hole; the distance between the circle center of the first mounting hole and the circle center of the second mounting hole is equal to the distance between two circle centers of two threaded holes arranged on a cylinder cover; and the two threaded holes are respectively positioned at the left side and the right side of the lower semi-circular arc of the camshaft mounting hole. The engine camshaft bearing cover provided by the invention has the advantages of simple structure, is easy to manufacture, and the occurrence of false mounting of the camshaft bearing cover can be prevented effectively.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

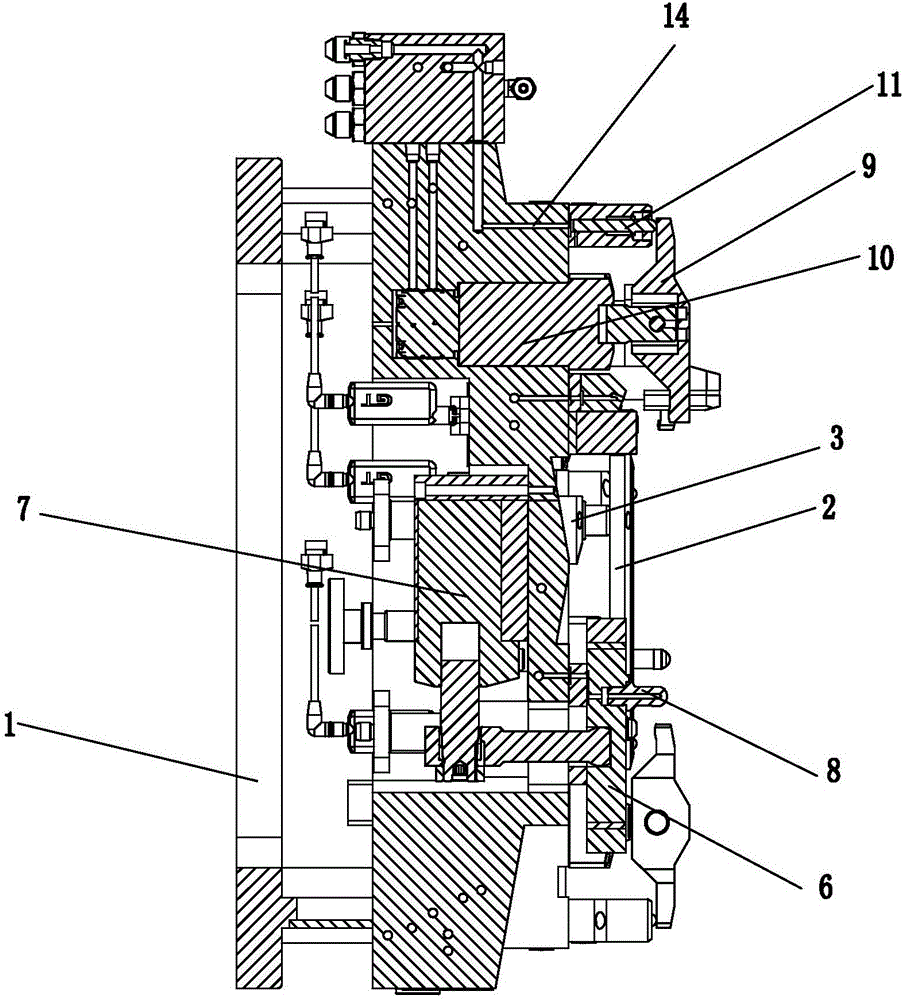

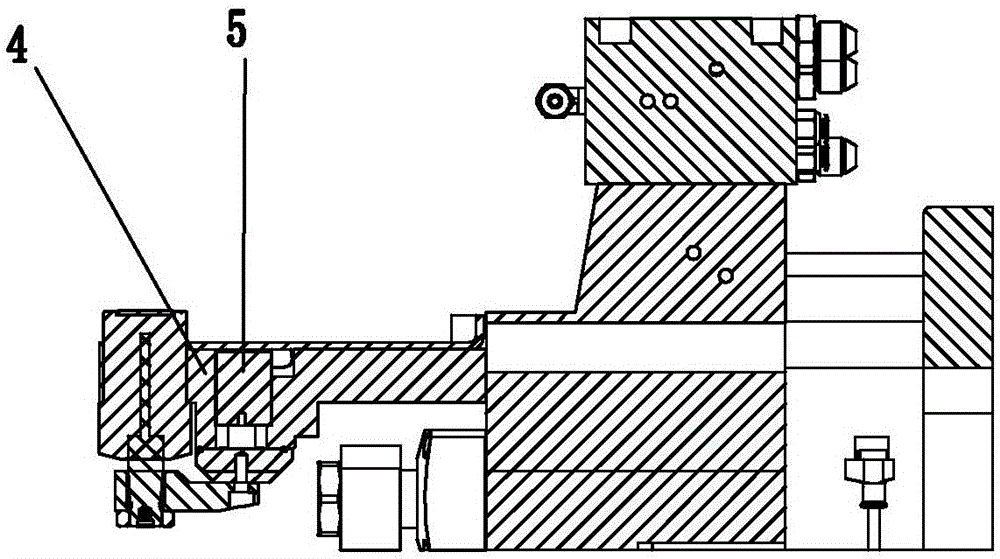

Intelligent fixture

InactiveCN106736751AAchieving Adaptive ControlAutomatic adjustment of clamping forceMeasurement/indication equipmentsPositioning apparatusSelf adaptiveMechanical engineering

Owner:WUXI BEST PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com