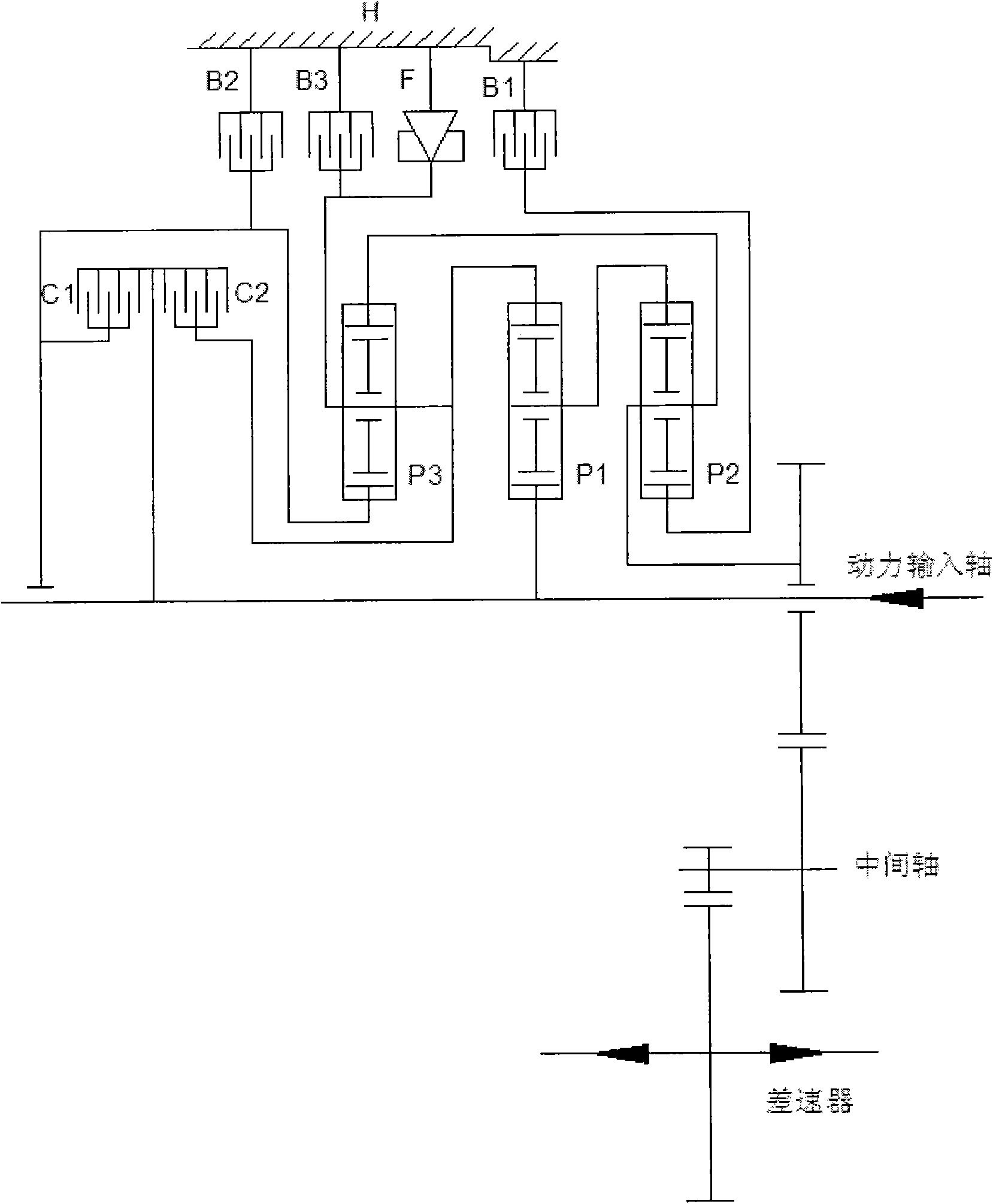

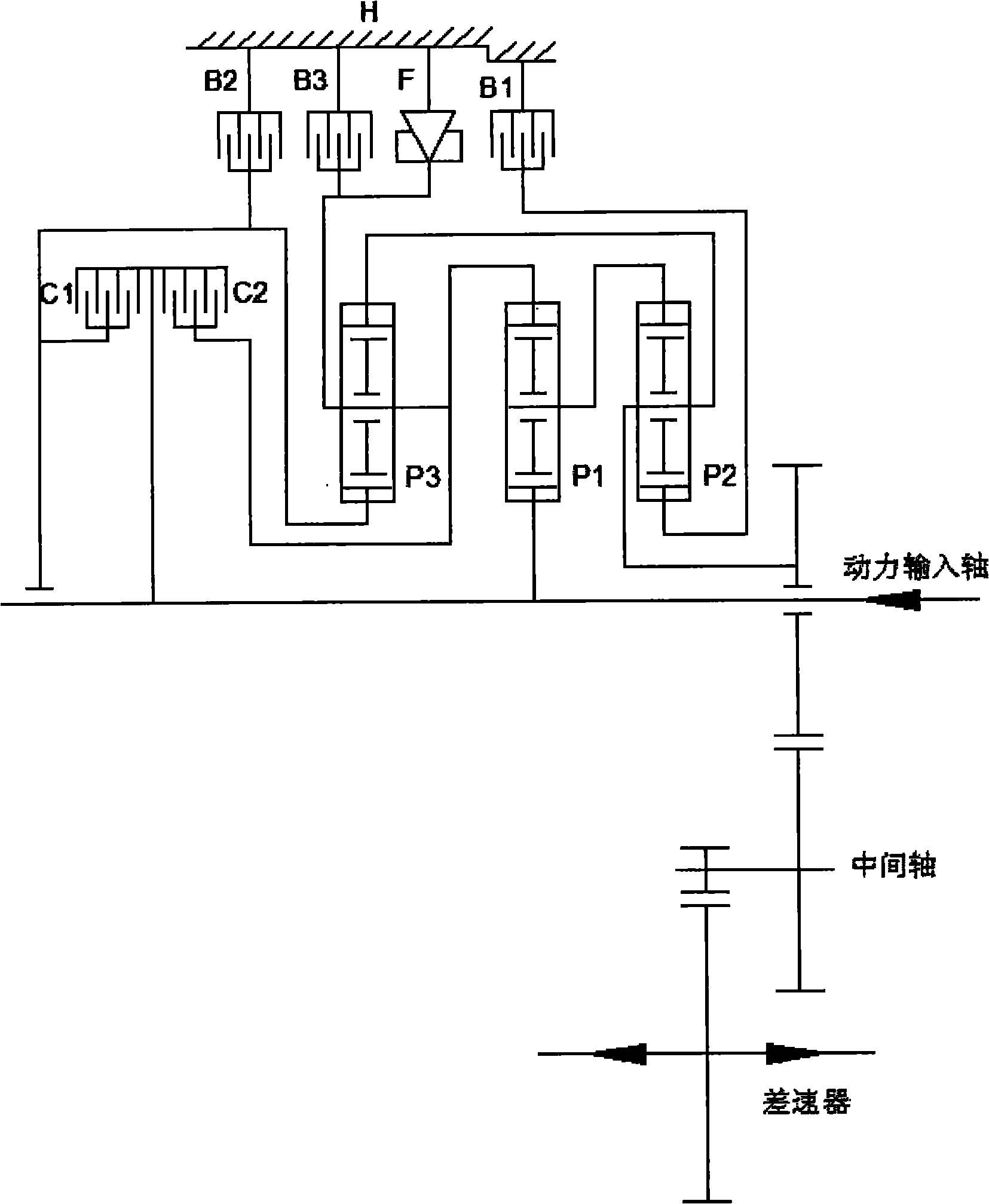

Arrangement of 6AT power drive system

A power transmission system, 6AT technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of reduced efficiency of friction elements, large transmission volume, restrictions on vehicle layout, etc., and achieve short axial distance , compact structure, and the effect of reducing types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

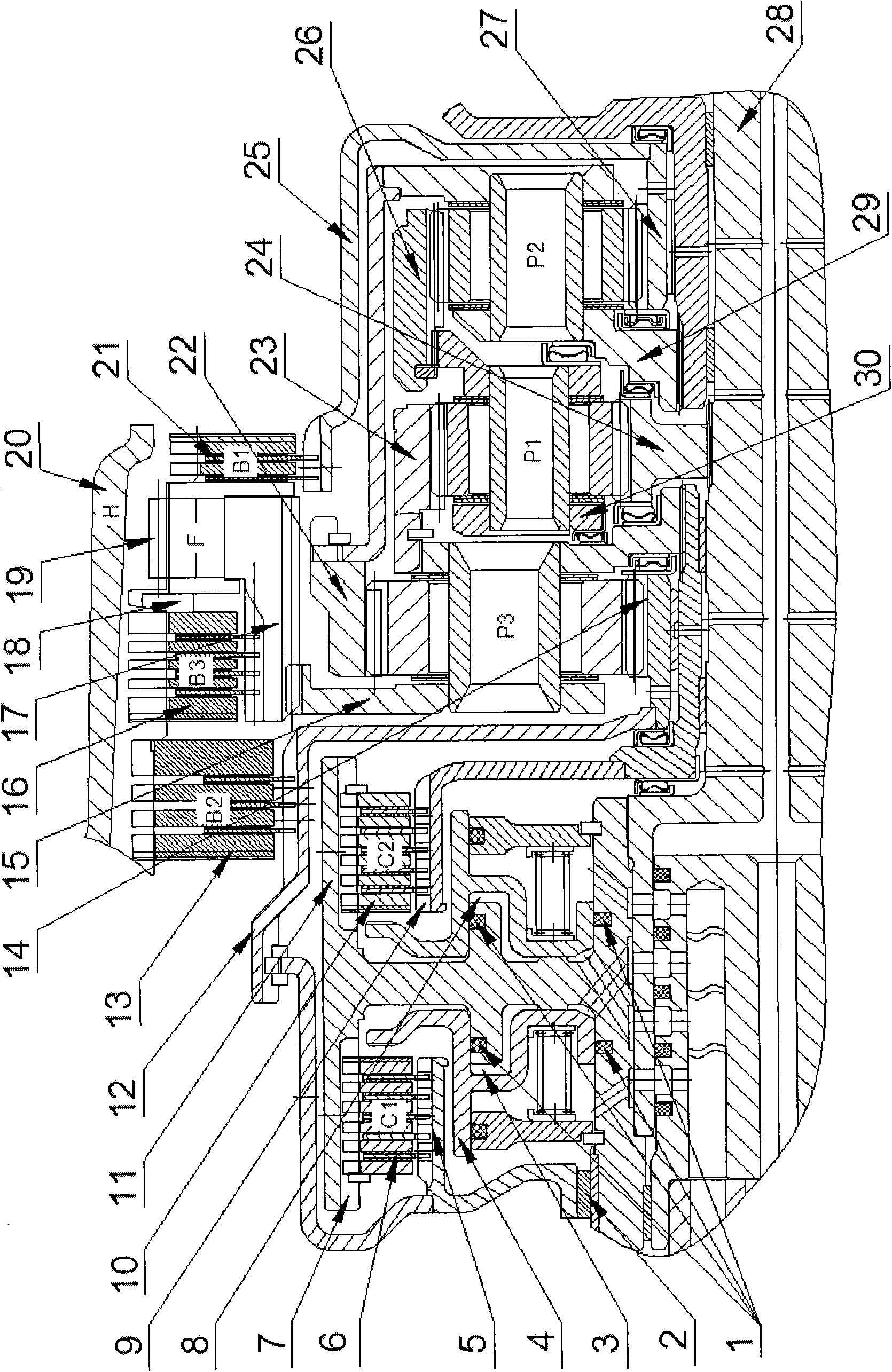

[0040] like figure 1 As shown, it is a schematic diagram of the structure principle of the embodiment of the present invention, including a power input shaft, a transmission mechanism composed of three simple planetary gear sets, a housing H and shifting components, wherein: the three simple planetary gear sets are input The planetary gear set P1, the output planetary gear set P2 and the reaction planetary gear set P3 are arranged in sequence at the front end of the transmission. The sun gear of the input planetary gear set P1 is connected to the power input shaft, and the planet carrier of the input planetary gear set P1 is connected to the output planetary gear The ring gear of the group P2 is connected, and the planet carrier of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com