Fast-locking mistaken installation preventive connector

A technology for preventing wrong installation and connectors, which is applied to the connection, the parts of the connecting device, the coupling device, etc., can solve the problems of low connection implementation efficiency, low efficiency of wrong installation, and burning circuit, etc., and achieves easy implementation and connection. Reliable, effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

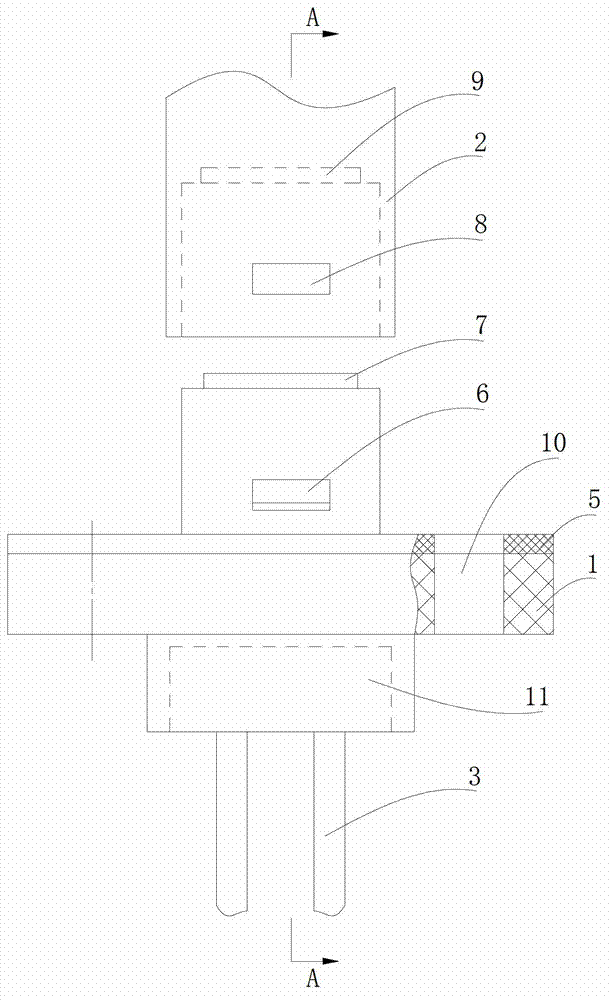

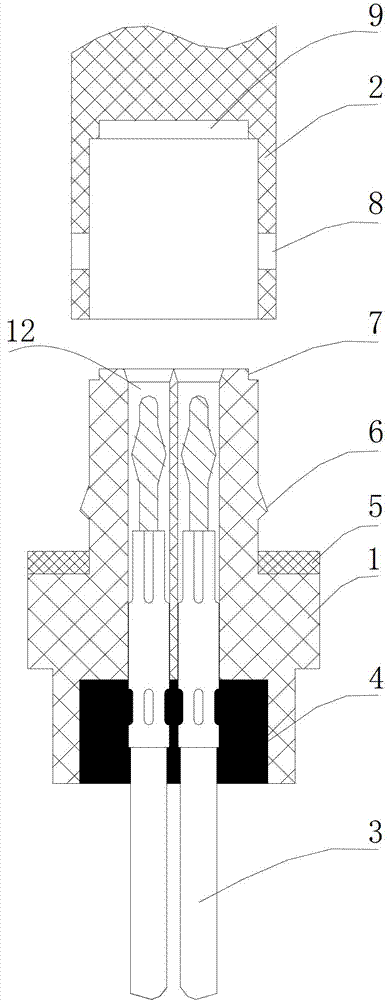

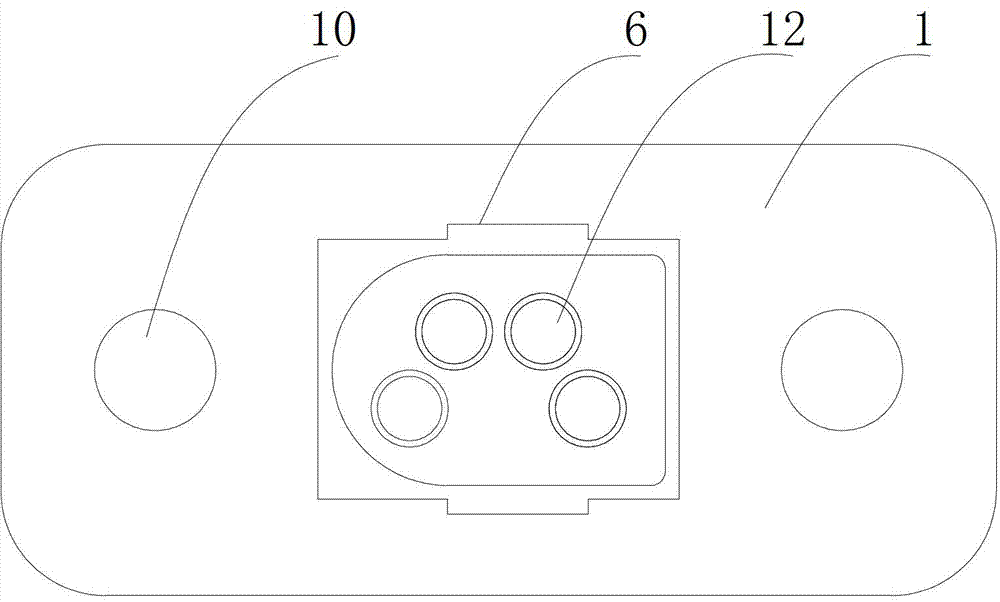

[0024] Such as Figure 1 to Figure 9 As shown, a quick lock anti-wrong installation connector according to the present invention includes a socket 1, a connecting housing 2 and a pin assembly 3, the socket 1 is provided with a pin hole 12, and the pin assembly 3 Installed in the pin hole 12 on the top, the connecting housing 2 matches the upper end of the socket 1, the lower end of the socket 1 is provided with a groove 11 for installing the insulating filler 4, and the middle part of the socket 1 is a connecting plate protruding outward. The opposite sides of the upper end of the socket 1 are provided with tapered bosses 6, the two sides of the connecting coupler housing 2 are provided with rectangular through holes 8 matching the tapered bosses 6, and the top of the socket 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com