Walnut cleaning machine

A washing machine and walnut technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of cumbersome installation and debugging, loose fastening bolts, power consumption, etc., achieve good sewage discharge effect, good cleaning effect, and promote separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

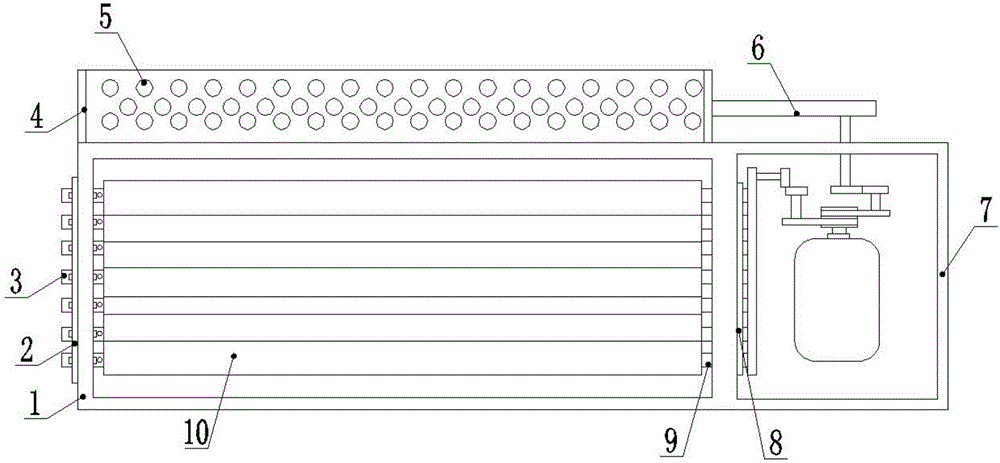

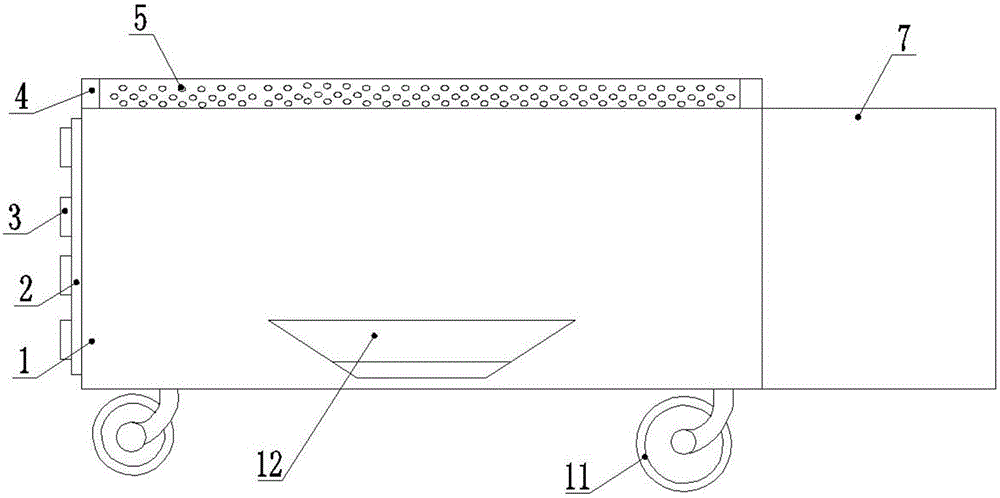

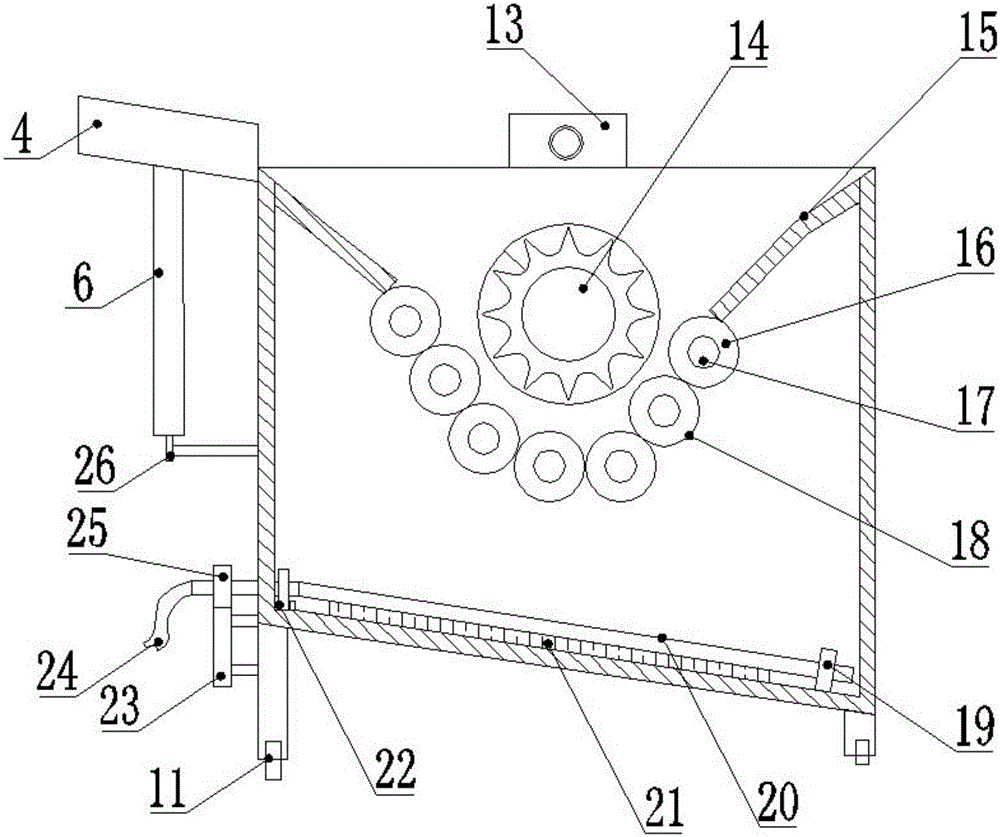

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the walnut cleaning machine includes a cleaning box 1 and a transmission box 7, and two opposite side walls of the cleaning box 1 are provided with fixing devices, and the fixing devices include a plurality of The first bearing seat 2 and a plurality of second bearing seats 8 located on the right side wall of the box body, the first bearing seat 1 is equipped with a first bearing 29, and the inner wall of the first bearing 29 is fixed with a slide The key 28 also includes a first rotating shaft 3 , the first rotating shaft 3 is provided with a key groove 27 along its axial direction, and the sliding key 28 is slidably installed in the key groove 27 . The first rotating shaft 3 can rotate together with the bearing, and can also slide relative to the first bearing along its axial direction. The length of the keyway of the first rotating shaft is related to the sliding distance of the first rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com