Rotor bearing press fitting device

A technology for press-fitting devices and bearing mounting seats, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor press-fit quality, poor stability, and high scrap rate, and achieve high installation quality and versatility Strong, high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

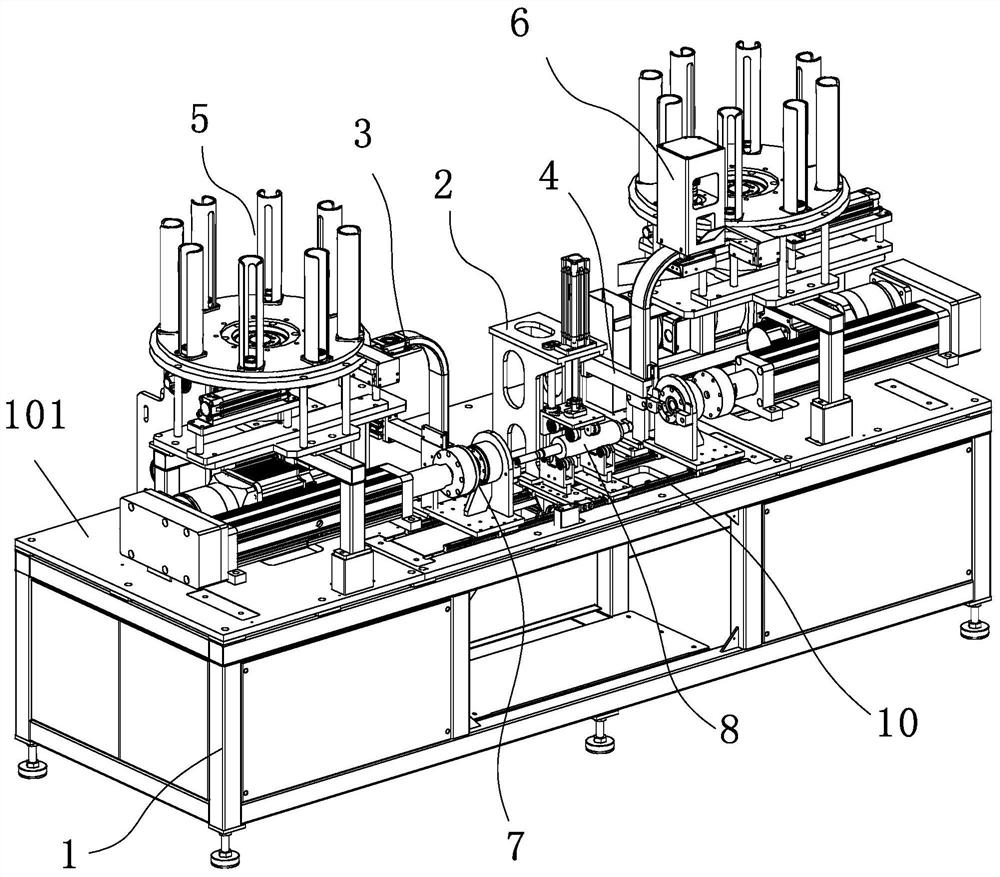

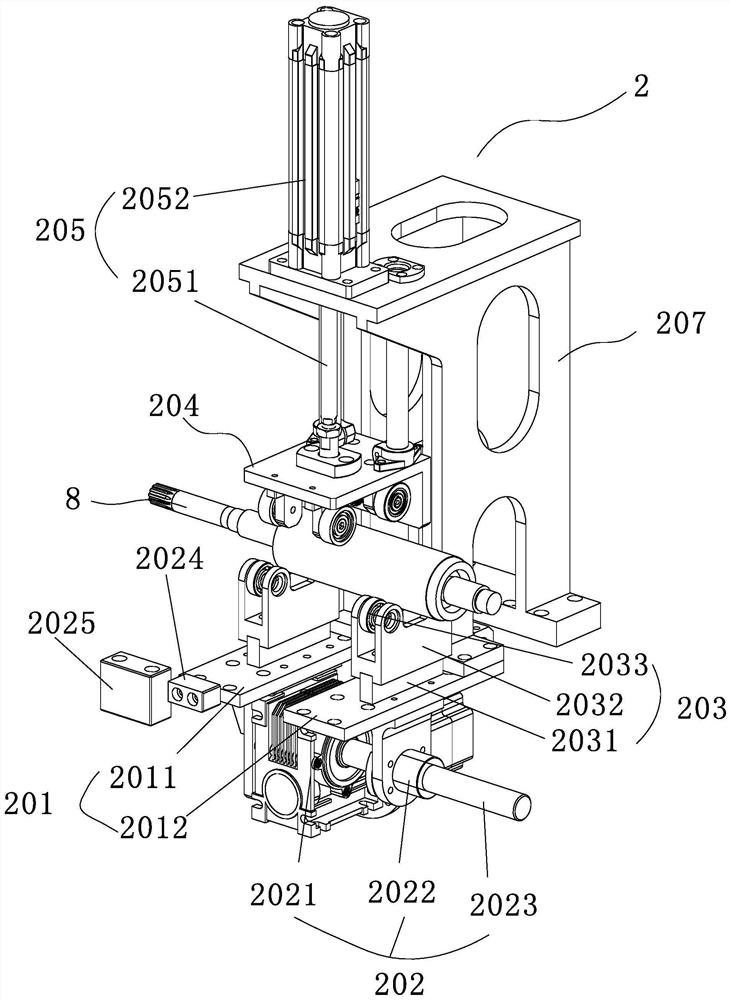

[0031] Such as figure 1 In the shown embodiment 1, a rotor bearing press-fitting device includes a fixed bracket 1, and a worktable 2 is arranged on the fixed bracket 1. The workbench 2 is used to support and install the entire press-fitting device. 1 is arranged horizontally, and paired slide rails 10 are arranged on the workbench 2, and the paired two slide rails 10 are arranged in parallel. The rotor bearing pressing device also includes a bearing feeding device, a bearing pressing machine 7 and a rotor frame 3 , and the bearing feeding device, the bearing pressing machine 7 and the rotor frame 3 are all fixed on the workbench 2 .

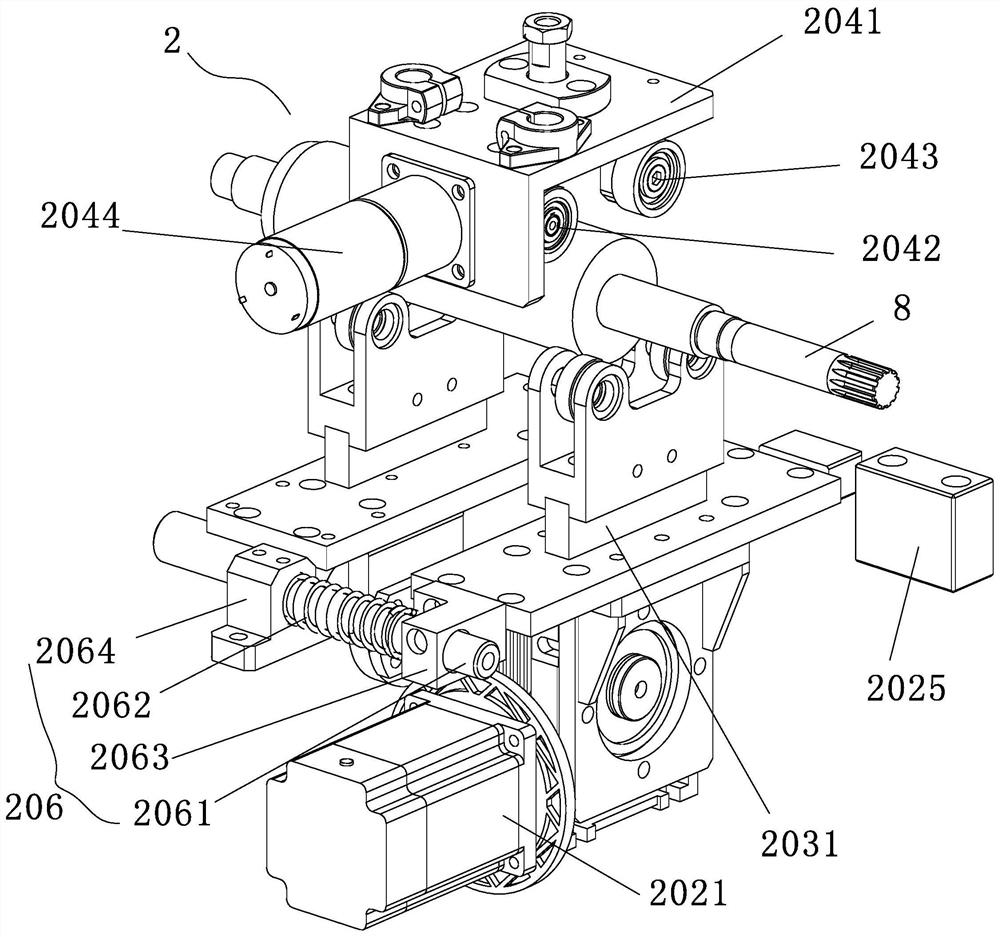

[0032] Such as Figure 7 As shown, the bearing press installation machine 7 includes a bearing mounting seat 701 for fixing the bearing and a press-fit push assembly 702 for pushing the bearing mounting seat 701. The bearing mounting seat 701 is slidably arranged on the slide rail 10, and the bearing mounting seat 701 includes a sliding The be...

Embodiment 2

[0042] Such as Figure 6 , Figure 7 , Figure 8 As shown, the technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, the difference is that: a rotor bearing press-fitting device also includes a visual inspection tool 6 and a material leakage device 9, the material leakage device 9 includes Leakage pipe 901, leakage push plate 902, leakage push cylinder 903 and recovery cylinder 904, the delivery pipe 301 includes a level detection part 3011 arranged at the inlet end, the top of the level detection part 3011 is provided with a detection port 3012, and the bottom is provided with a drain. The material port 3013, the visual detection tool 6 is fixed above the detection port 3012, the inlet of the material leakage pipe 901 is set corresponding to the material leakage port 3013, the outlet of the material leakage pipe 901 groove is set correspondingly to the recovery cylinder 904, and the material leakage push plate 902 slides Set on ...

Embodiment 3

[0044] The technical solution of embodiment 3 is basically the same as the technical solution of embodiment 1 or 2, the difference is that: the bearing feeding device and the bearing pressing machine 7 are arranged in pairs, that is, both sides of the rotor frame 3 are provided with bearing feeding device and bearing press-fitting machine 7, which is convenient for carrying out bearing press-fitting to both sides of the rotor at the same time, improving efficiency, and different bearings can be press-fitted on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com