Integral front door lock body assembly

A front door lock and integrated technology, applied in the field of automobile locks, can solve the problems of high manufacturing precision and high production cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific assembly mode, the present invention will be further described:

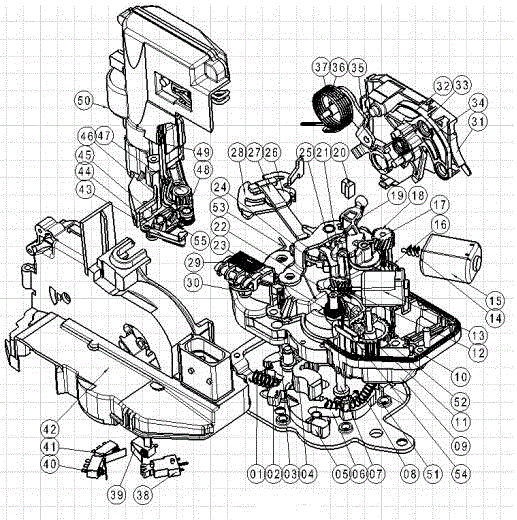

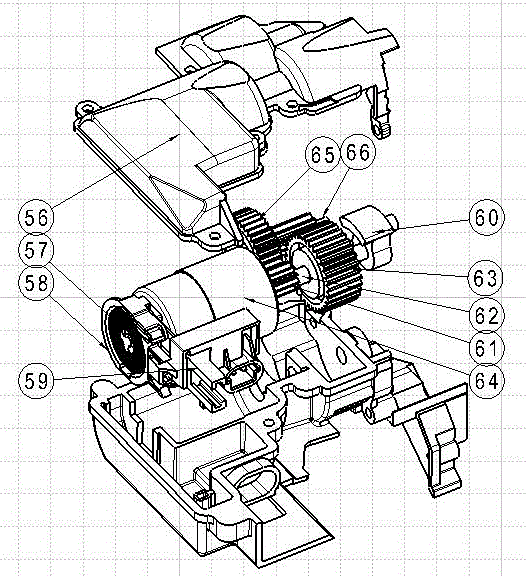

[0025] Assembly of the lock body sub-assembly (see attached figure 1 ):

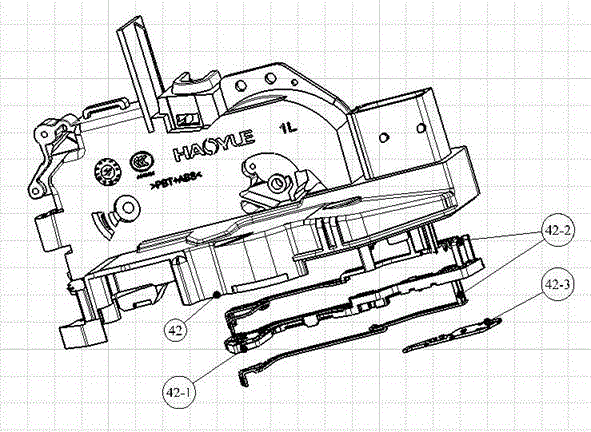

[0026] Fix the lock body 9, place the pawl spring 1 and the ratchet spring 8 on the corresponding positions of the lock body 9 respectively, embed the buffer block A4 and the buffer block B 5 in the corresponding positions on the lock body 9, and place the pawl shaft 3 Insert the ratchet shaft 7 from the back on the lock body 9 and then install the pawl 2 and the ratchet 6, put the cover plate 51 on it and rivet the ratchet shaft 3 and the ratchet shaft 7 to fix;

[0027] Install and open the rocker arm torsion spring 53, the super lock limit spring 54, the ratchet transmission block 22, the outwardly opened rocker arm 30, the locking worm gear 52, the electric door opening pull rod 43, the electric door opening rocking arm 45 on the lock body 9 in sequence, and will open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com