Fully-automatic rivet magnetic circuit assembly machine

An assembly machine and fully automatic technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of increased production costs, large labor investment, wrong assembly, etc., to reduce labor costs, small size, and reduce labor input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

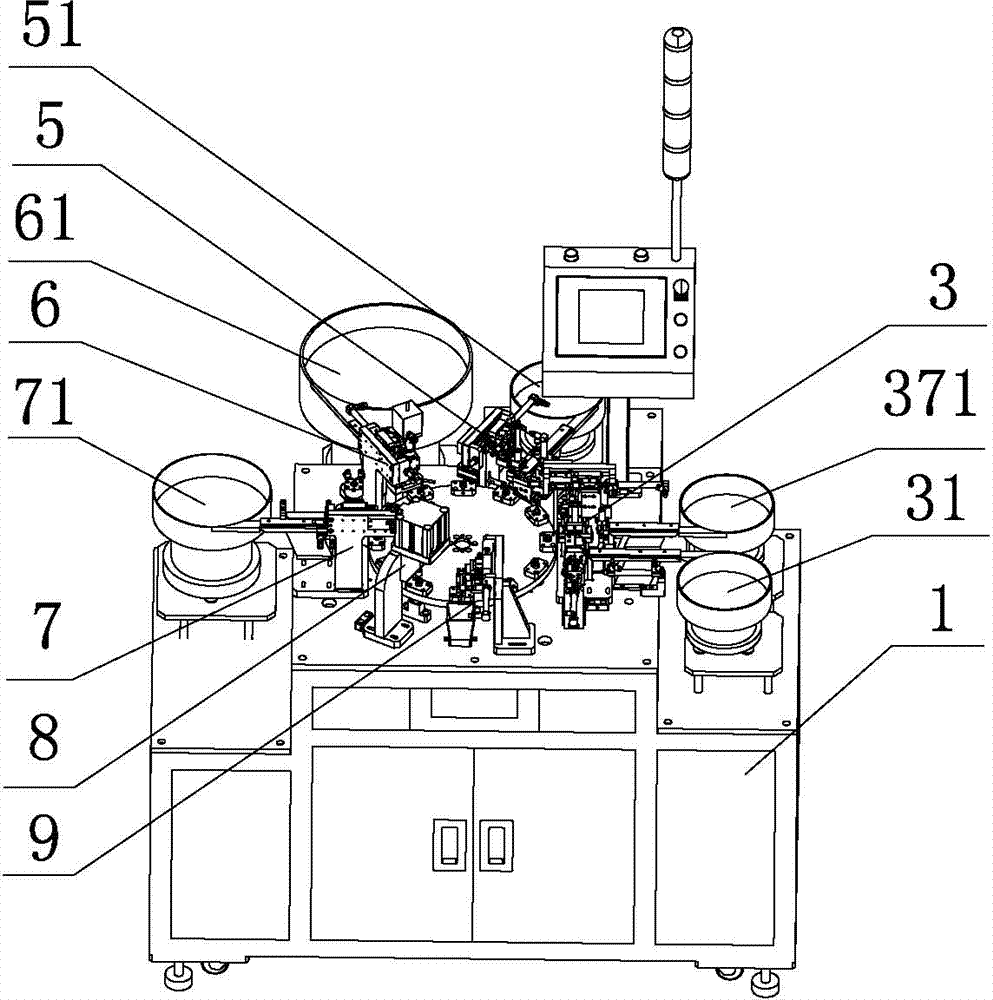

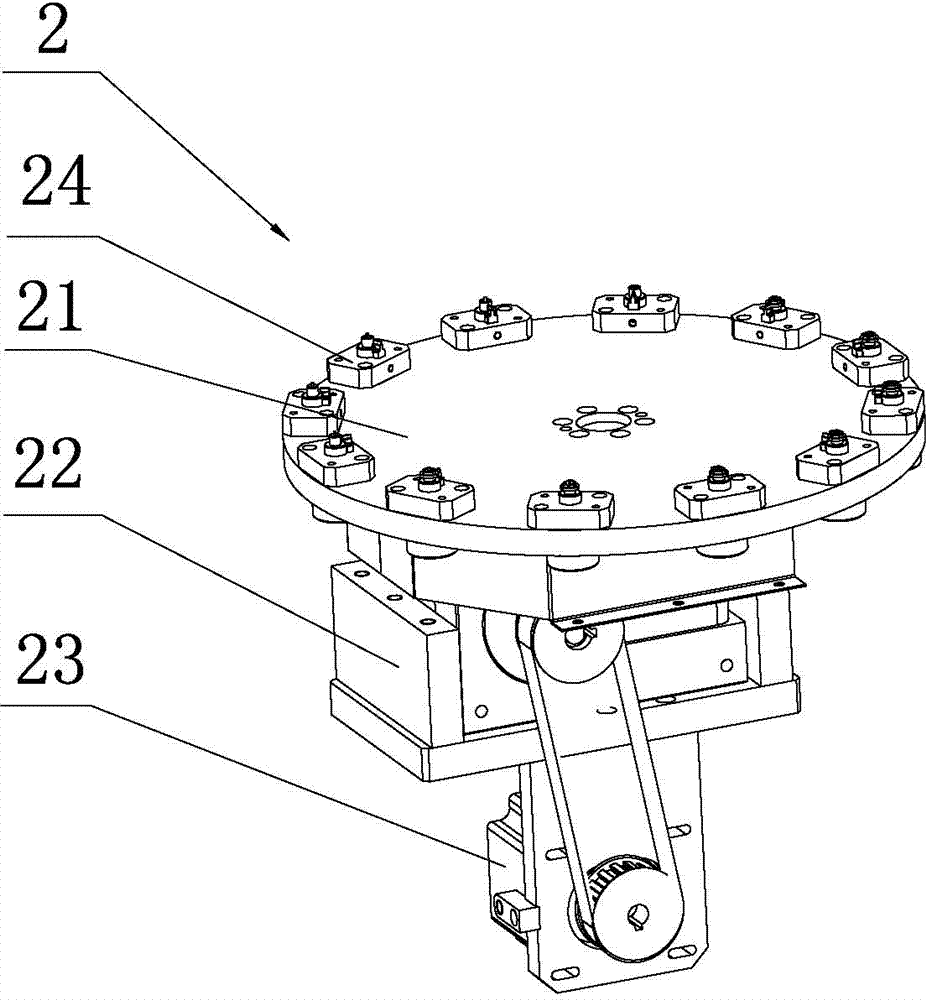

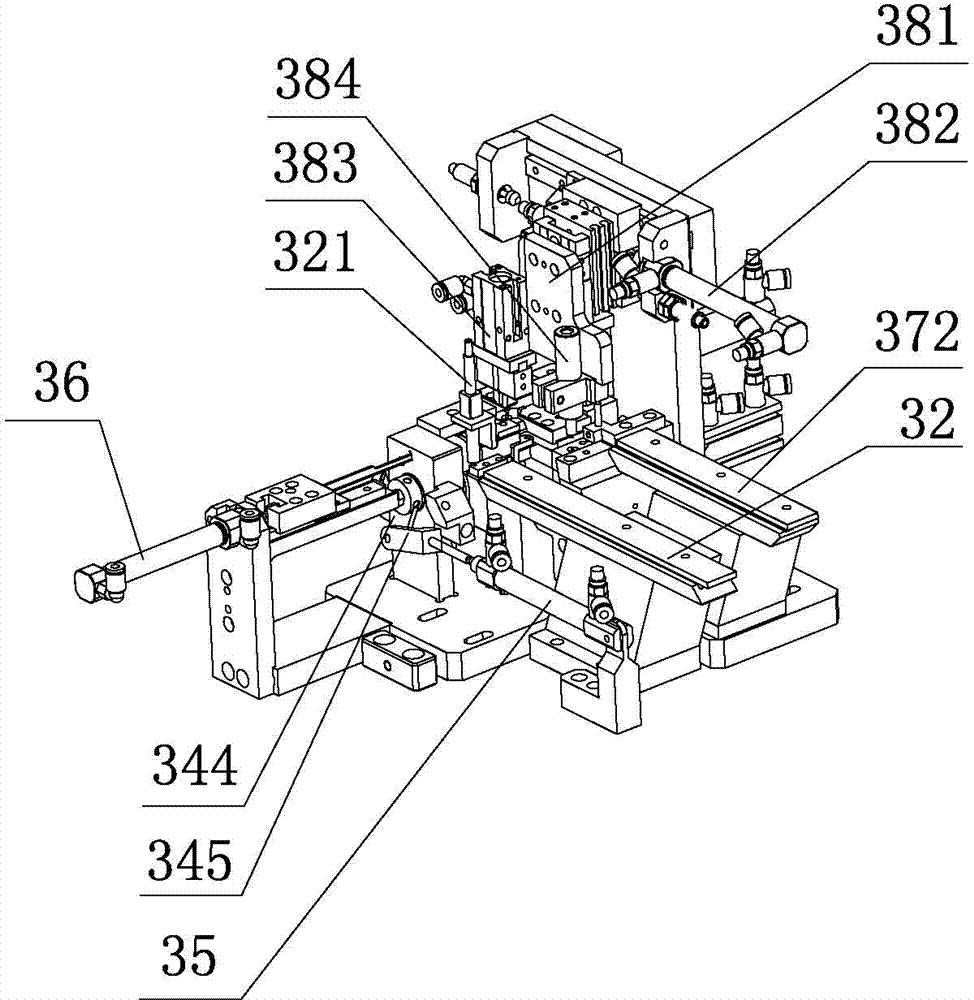

[0036] Such as Figure 1 to Figure 20 As shown, a fully automatic rivet magnetic circuit assembly machine includes a machine 1 and a turntable device 2, the turntable device 2 is arranged on the upper end of the machine 1, and the machine 1 is ring-shaped and successively surrounded by rivet feeding Device 3, rivet correction device 4, magnet assembly device 5, iron box assembly device 6, PCB board assembly device 7, riveting machine 8 and unloading device 9.

[0037] This embodiment adopts fully automated assembly and processing to avoid the phenomenon of wrong installation and missing installation. One worker can be in charge of multiple devices, reducing labor input and labor costs. Moreover, the device of the present invention is small in size, saving space for placement, and easy to use. Restricted by the size of the workshop space.

[0038] Such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com